- High-precision, punctual measurement

- Ideally suited for recurring component testing

- Initial sampling

- Shape and position tests

- Tactile scanning

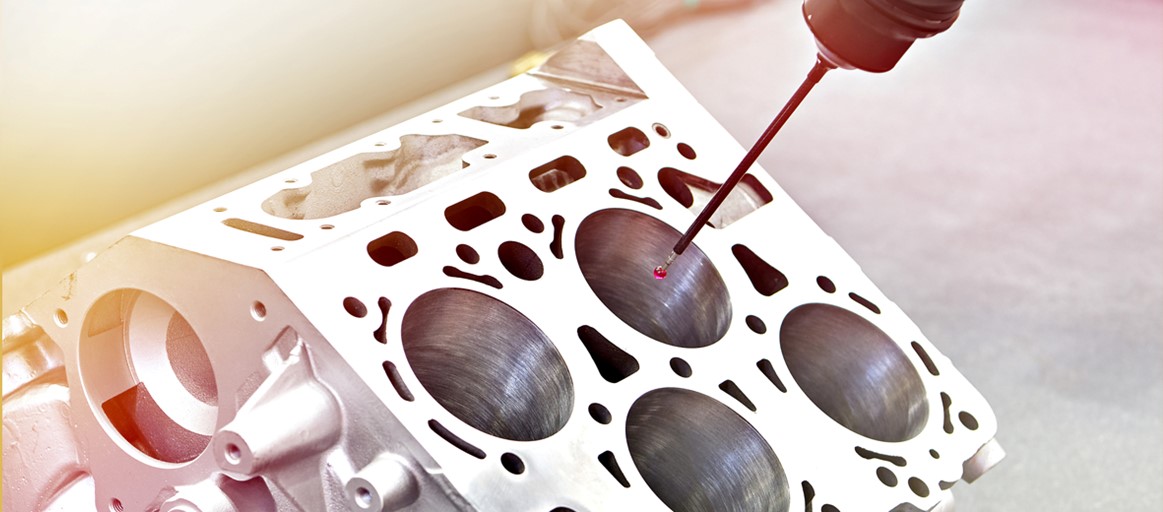

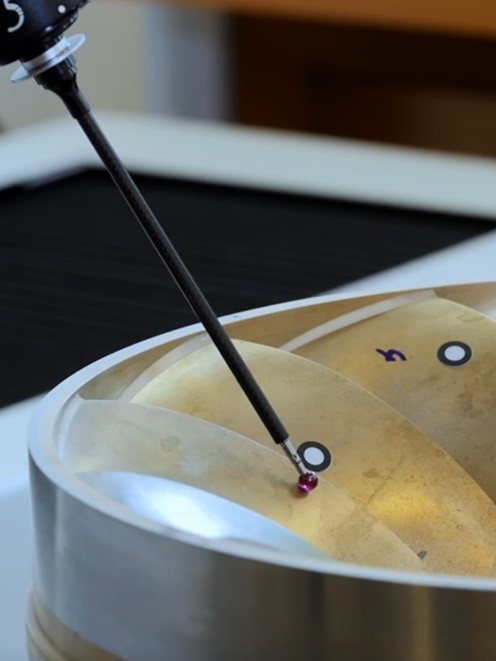

Tactile 3D-Metrology: high-precision measurement

Tactile measurement is a proven technique for high-precision geometry measurement in which the surface of the object is touched with a probe to record measurement data. Precise, computer-controlled coordinate measuring machines – known as CMMs for short – are used.

While non-contact methods such as laser scanning and optical Metrology have gained popularity for certain applications, tactile measurement still offers advantages that make it the preferred choice for many applications.

High accuracy & precision

Ideal for applications that require extremely tight tolerances. Physical contact offers the advantage of direct measurement, regardless of any material reflection or surface irregularities. Enables reliable and repeatable measurements that are important in the aerospace, automotive and precision engineering industries.

Flexibility in measurement

Tactile measurement using our CMMs offers versatility in capturing different types of features, from simple 2D measurements to complex form and position inspections. Difficult geometries and contours that are challenging for non-contact methods are often better measured tactilely.

Frequently asked questions (FAQs)

What are the differences between tactile & optical Metrology

Tactile Metrology: point detection of the object surface by touching it

Optical Metrology: full-surface detection of the object surface without touching it

Tactile and optical Metrology for dimensional inspection: advantages, differences and areas of application of the two measuring methods > To the specialist article

Why do I need tactile Metrology?

For high requirements in terms of measuring accuracy and precision, classic Metrology continues to deliver the most reliable measurement results. Individual parts as well as small and large series can be evaluated efficiently. The ability to automate measurement and inspection is a major added value when evaluating on the coordinate measuring machine (CMM).

The measurement is equally accurate and stable on both shiny and translucent surfaces.

Why is WESTCAM the ideal 3D Metrology partner?

We have been serving customers from a wide range of industries for over 20 years. We can select the ideal equipment for your application from a wide range of different measuring systems. In addition to our tactile coordinate measuring machines, measuring arms and laser trackers, we also have a large selection of optical 3D scanners and photogrammetry systems. Our trained Metrology experts will provide you with competent support for your individual tasks.

Mechatronics & Robotics

Mechatronics & Robotics