- Exact copy

- Digital twin

- Scan to CAD

- Parametric reconstruction

- Hybrid reconstruction

- Over 20 years of experience

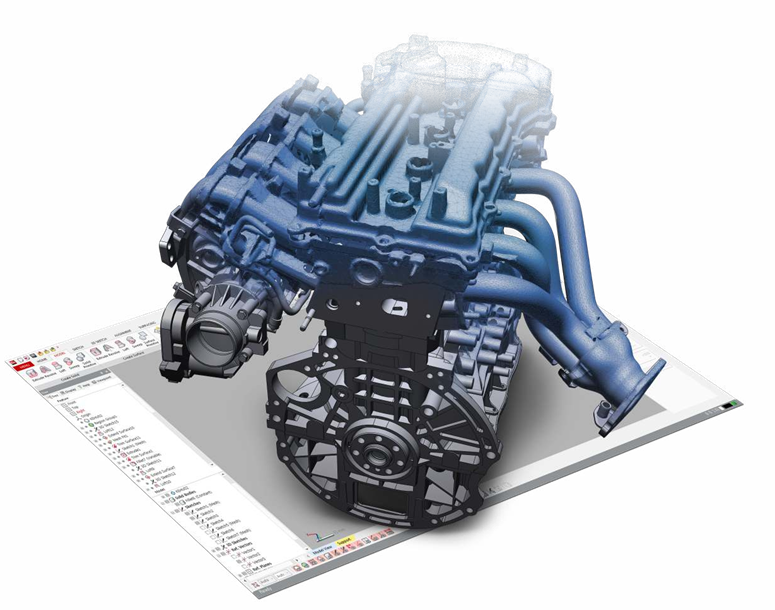

Reverse engineering (reverse engineering)

We combine modern technologies such as 3D scanners, computer tomography and reverse engineering software with the most important thing: specialist process knowledge. You have the idea – we have the powerful solution. From the exact digital copy to the fully parametric data set.

There are different approaches to the reconstruction strategy depending on the application and intended use. We will be happy to advise you and suggest the right reverse engineering approach.

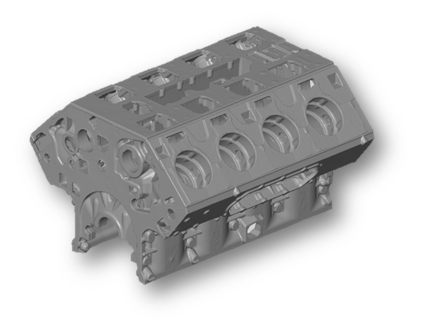

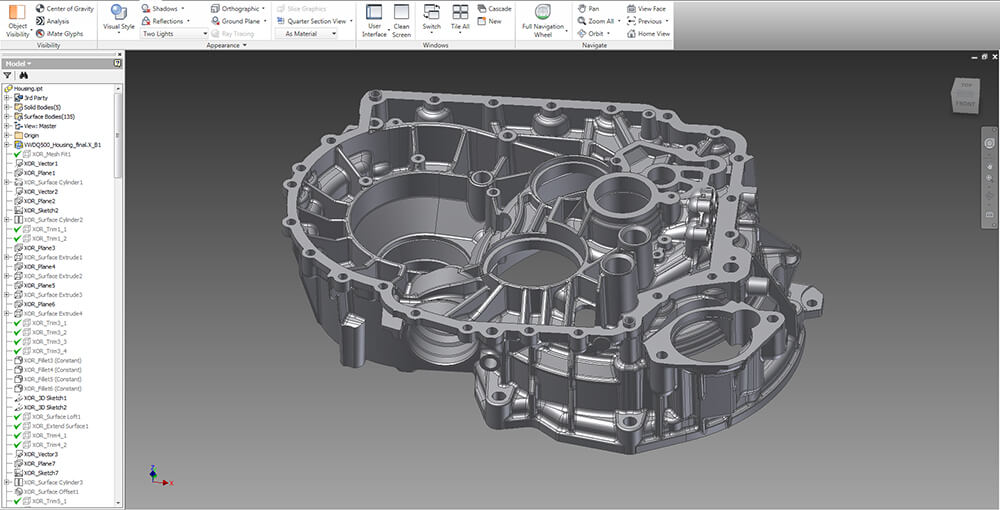

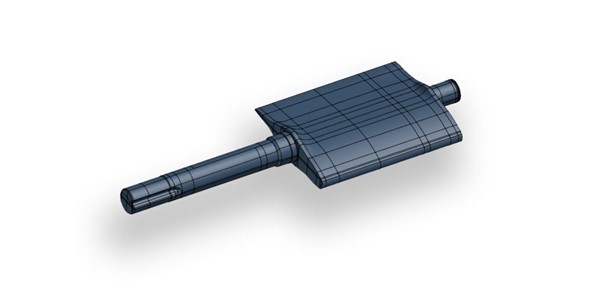

Exact copy

You need an exact 1-to-1 replica of your component – no problem for us!

Based on a highly accurate and detailed 3D scan, we create an exact, three-dimensional model using free-form surfaces. In this case, the model is not available parametrically – however, this type of reverse engineering is the most dimensionally accurate method of converting a real component into the digital world. The result can be output in STEP, IGES or Parasolid format.

Typical fields of application for exact reverse engineering:

- Surface model as a design aid

- 1to1 copy of the component

- Simulation models

- Strongly free-formed components

- Surface models for production

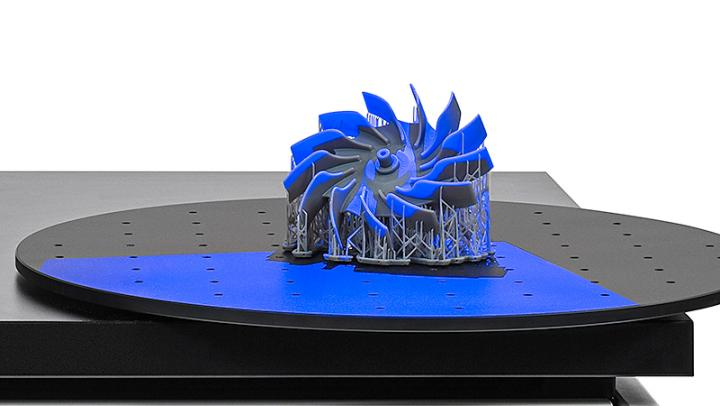

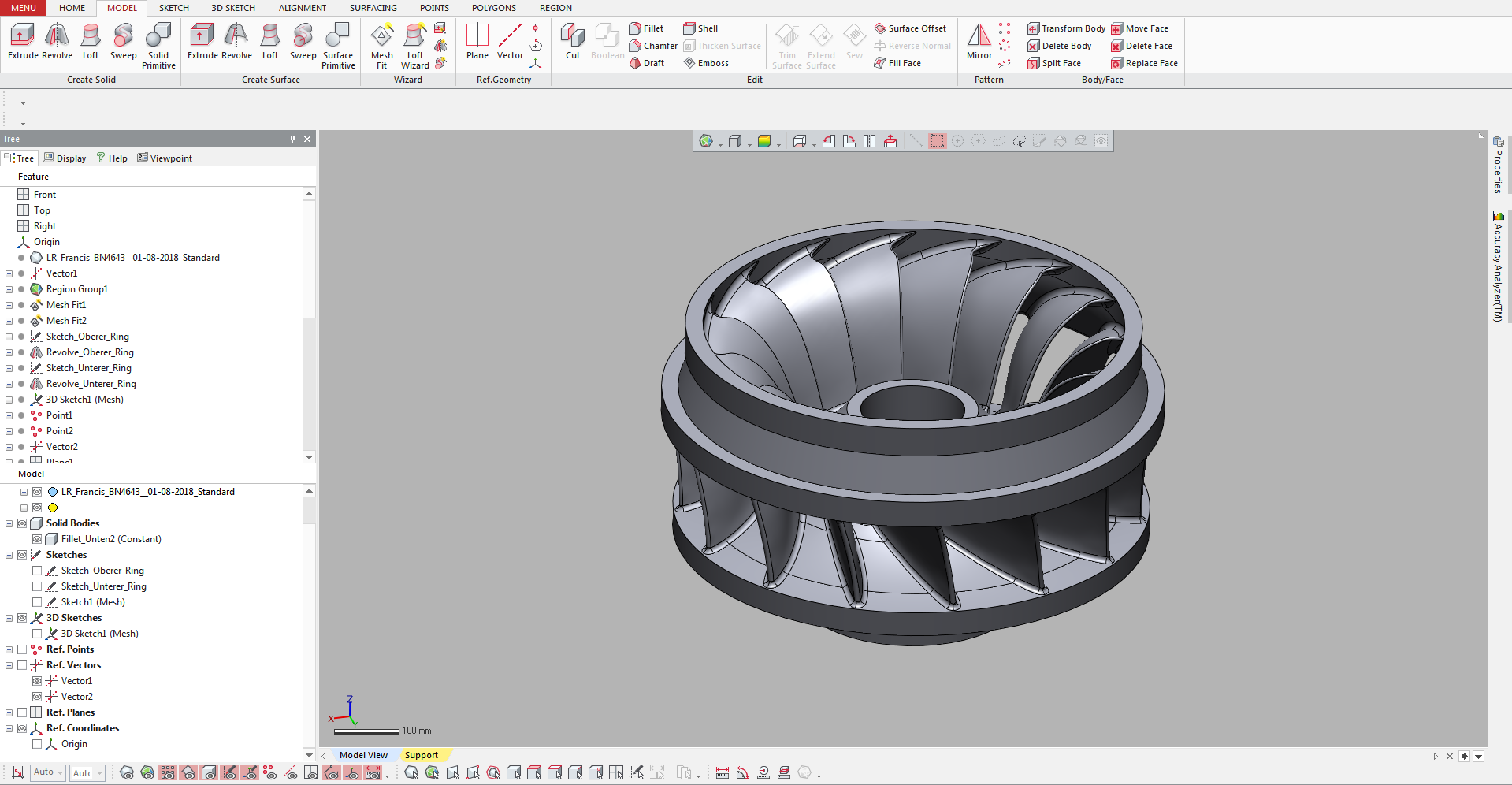

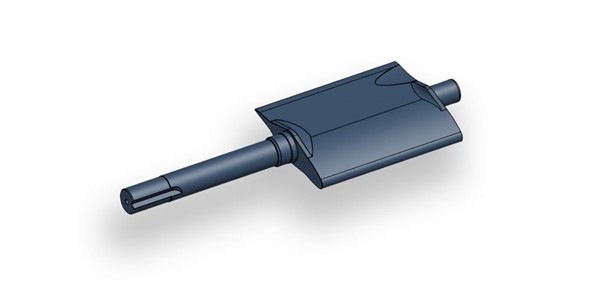

Parametric reconstruction

In the second variant of reverse engineering, a parametric CAD model is created on the basis of a high-precision 3D scan. Similar to designing in CAD software, an attempt is made here to reconstruct the scan data set using standard geometries (planes, cylinders, radii, LOFT surfaces, etc.). This variant deliberately accepts greater deviations from the real model in order to obtain a CAD model that is as “clean” as possible. In addition, the parametric structure gives us the opportunity to incorporate your wishes. You receive the parametric CAD model in STEP, IGES, Parasolid or in native data formats.

Typical fields of application of parametric reconstruction:

- Applications where clean CAD surfaces are required

- Models for further processing in the engineering and manufacturing process chain

- All applications where a parametric model is required

- Applications where accuracy (to the original component) is not the top priority

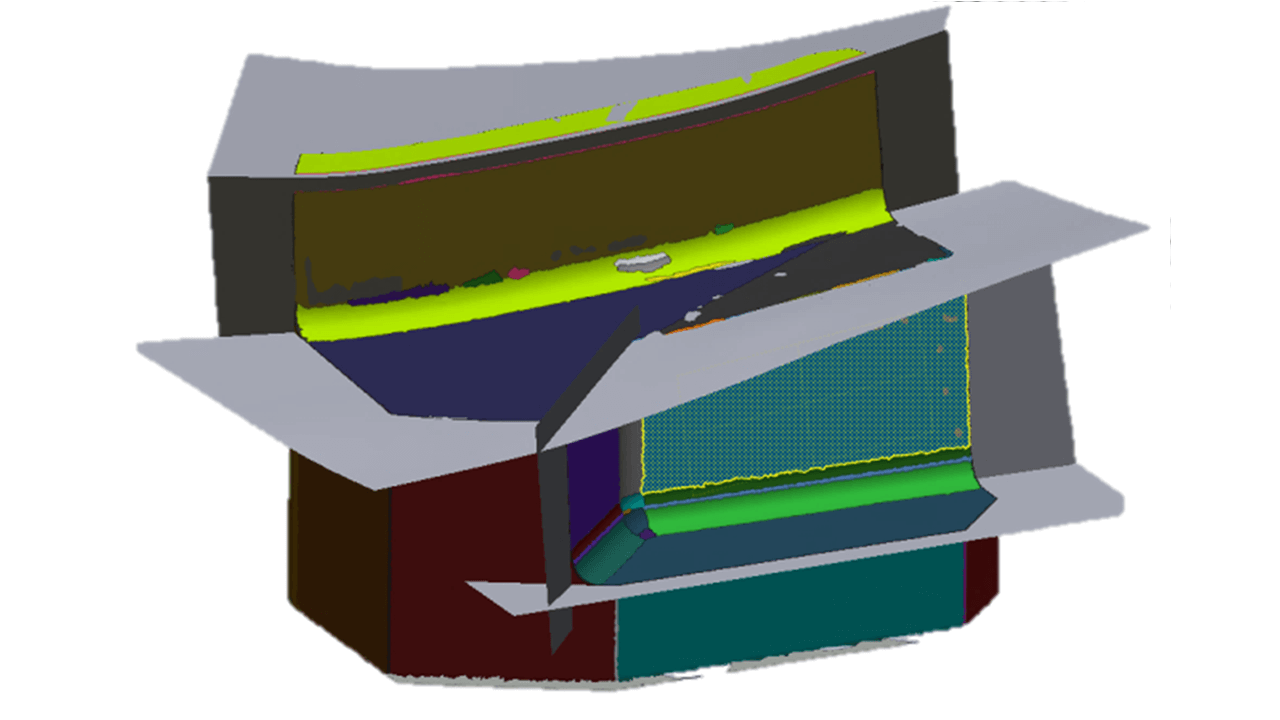

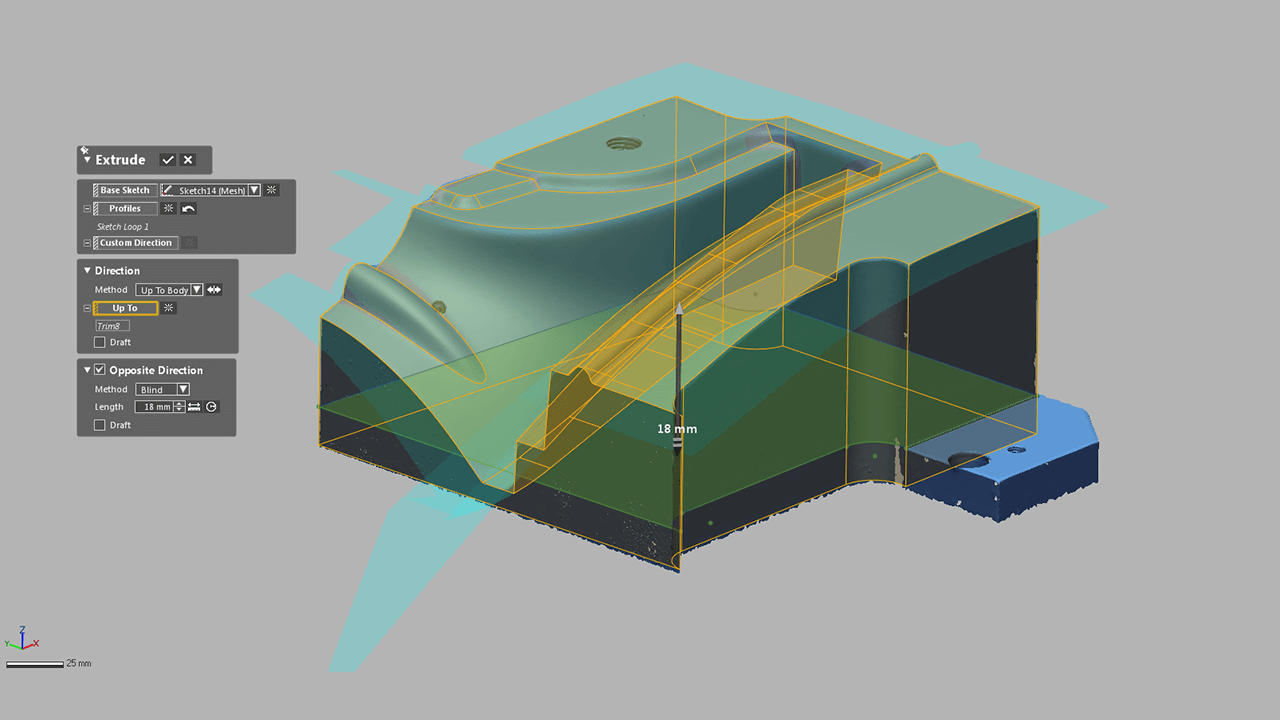

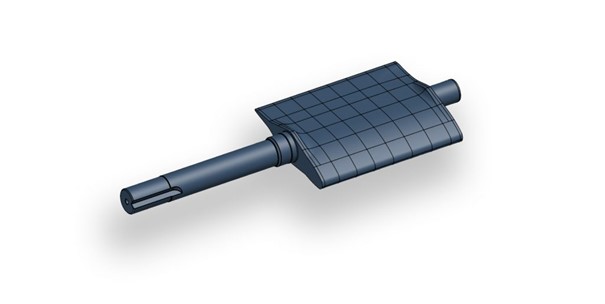

Hybrid modeling

Hybrid modeling combines exact and parametric data feedback. This allows the respective strengths to be perfectly utilized. The data output is again in STEP, IGES or Parasolid format.

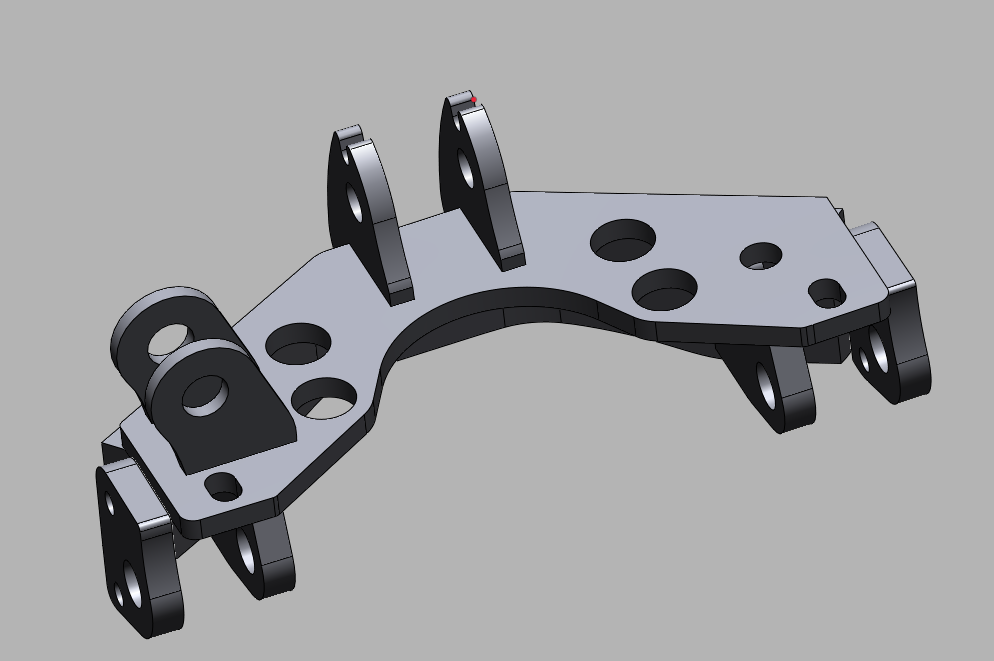

Design aid and add-on constructions

Load point clouds, IGES sections and connection geometries into your design program and use them yourself for subsequent design.