- Non-contact and simple measurement setup without cables

- Integration of peripheral signals

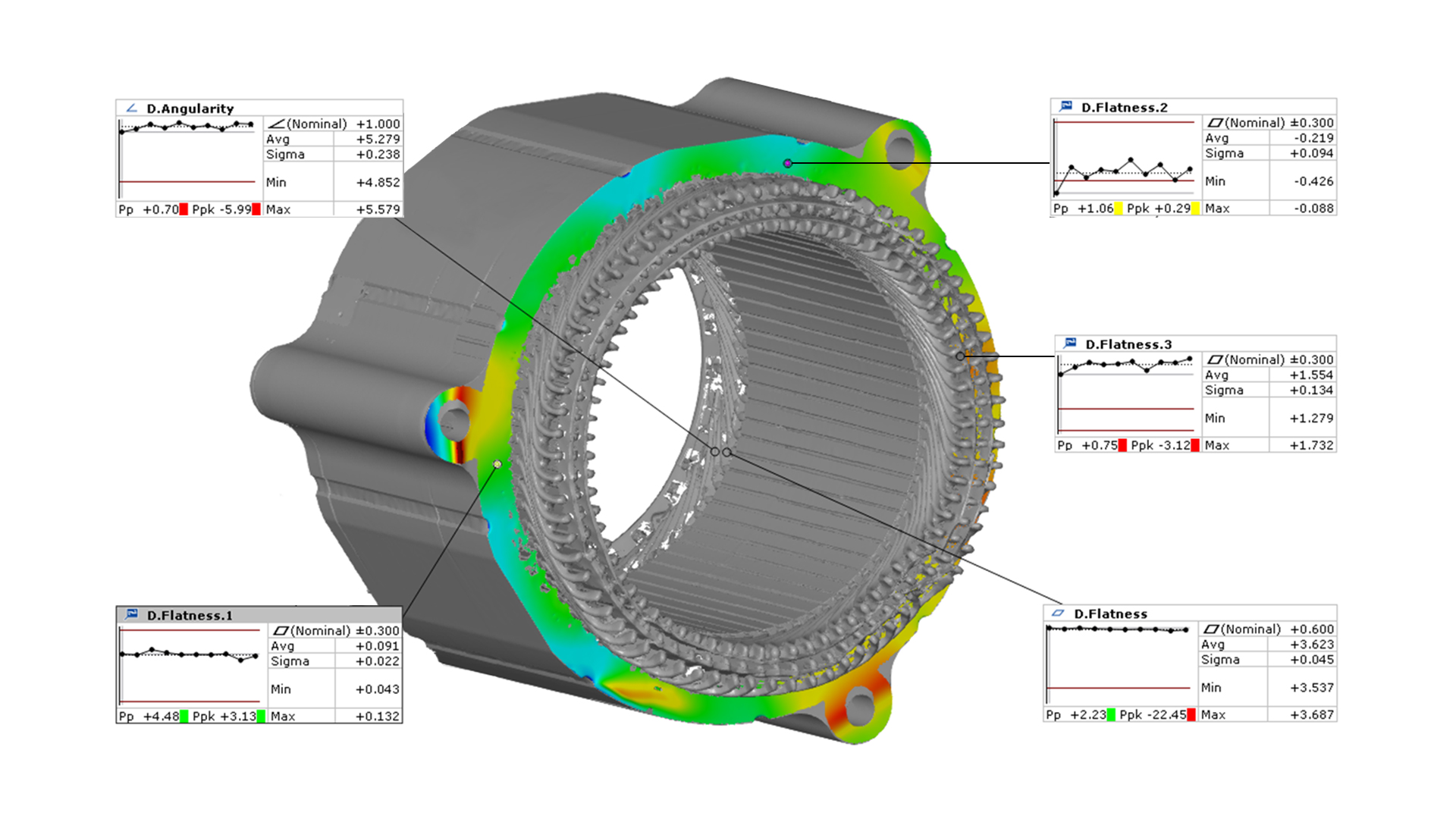

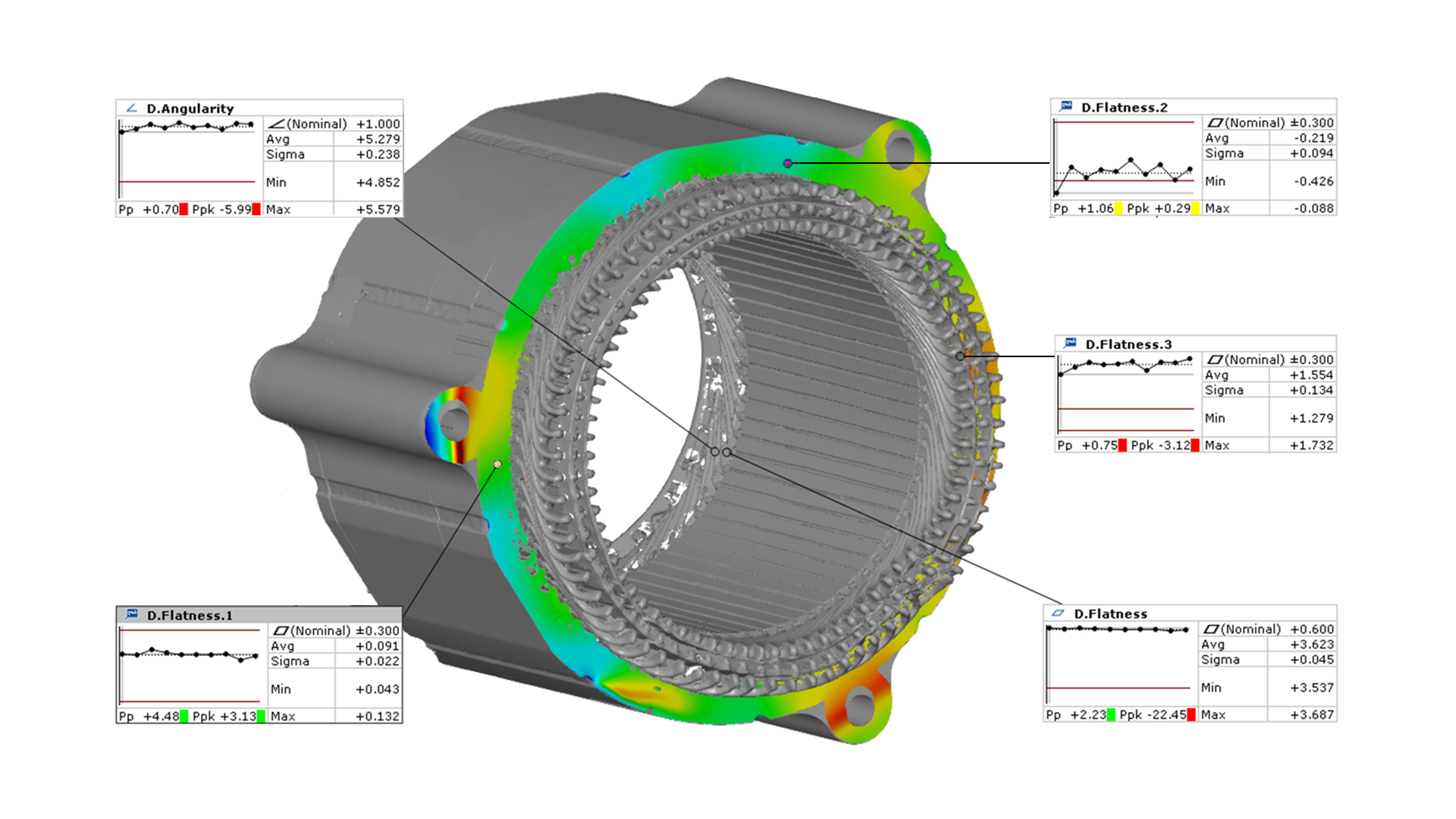

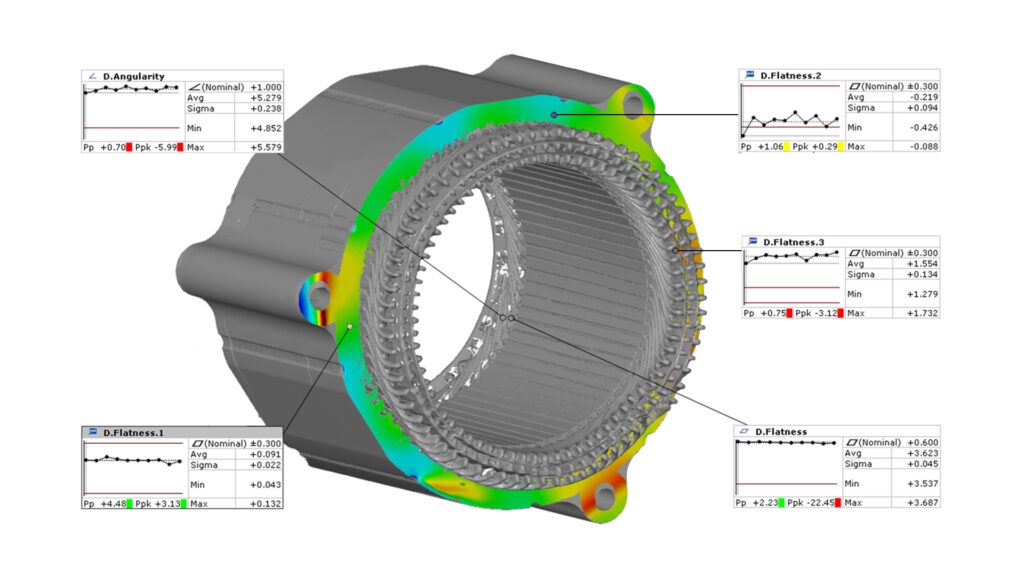

- Graphical representation of the results in 3D

- Subsequent changes to the evaluation possible

- Data export in various exchange formats

- 3D viewer and inspection software

Series measurement

Using our automated ZEISS ScanBoxes, we can easily inspect and evaluate a larger batch of components for you. Using our free inspection and viewer software, we are also able to provide you with the measurement results obtained in a clear form, including trend evaluations.

We are also happy to take care of the logistics and organize the transport of the parts if you are interested.

High detail resolution

Small geometries, such as snap-in hooks or snappers, are often very important for the function of injection molded parts. Our ZEISS ScanBox 4105 typically uses sensors with small measuring fields. This means that even these fine details can be captured with maximum precision.

Components up to 2 meters

The ZEISS ScanBox 5120 is ideal for the precise measurement of components up to 2000 mm in size. It is therefore frequently used for the inspection of larger components such as vehicle interiors. This ZEISS ScanBox has also proven itself for foundry and forging applications, for example when inspecting cast components, sand cores and molds.