- 3D measurement methods for every application

- Mobile devices and robot cell for series testing

- Standardized evaluation according to ISO 8015 in the VDA standard

- Meaningful measurement reports

- Advice and support from specialists before and after surveying

- Free 3D viewer and inspection software

Quality assurance & initial sampling

At our 4 locations in Austria and Switzerland, we are happy to support you with your inspection and analysis tasks. Our range of services extends from full-surface analyses to ISO 8015-compliant initial sample inspection reports in accordance with the VDA standard, high-precision tactile Metrology and full-surface roughness evaluations.

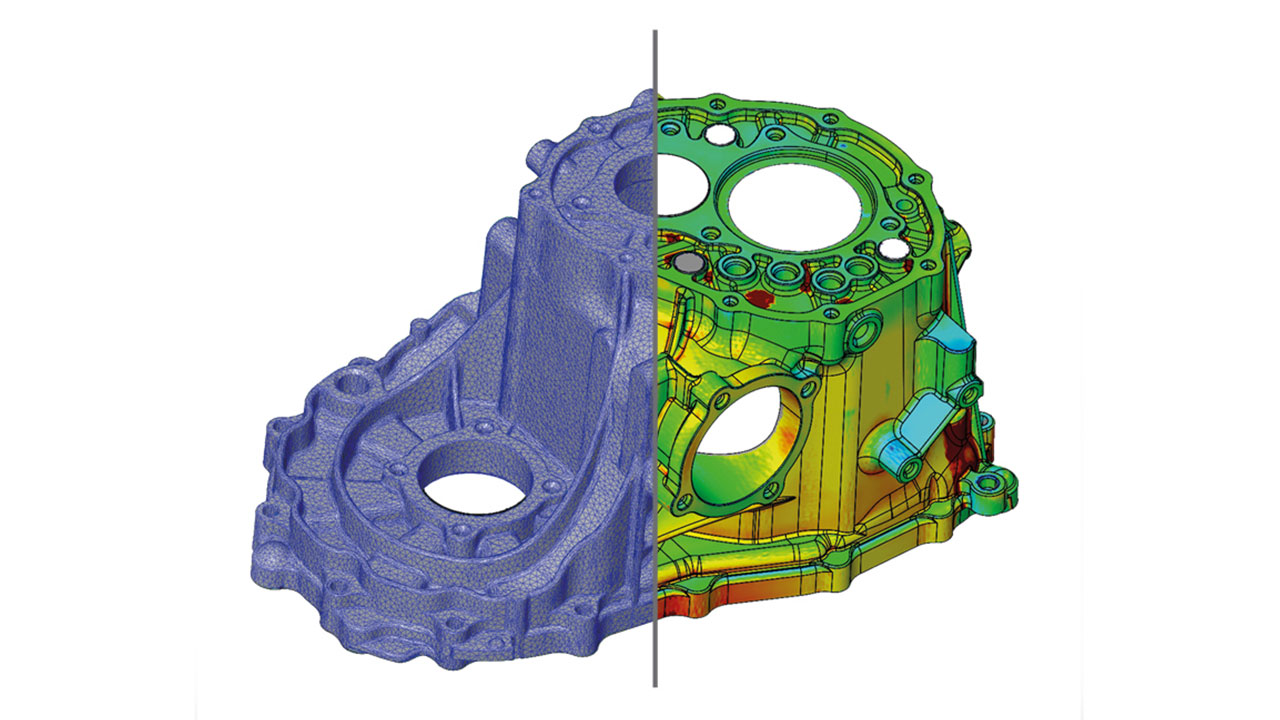

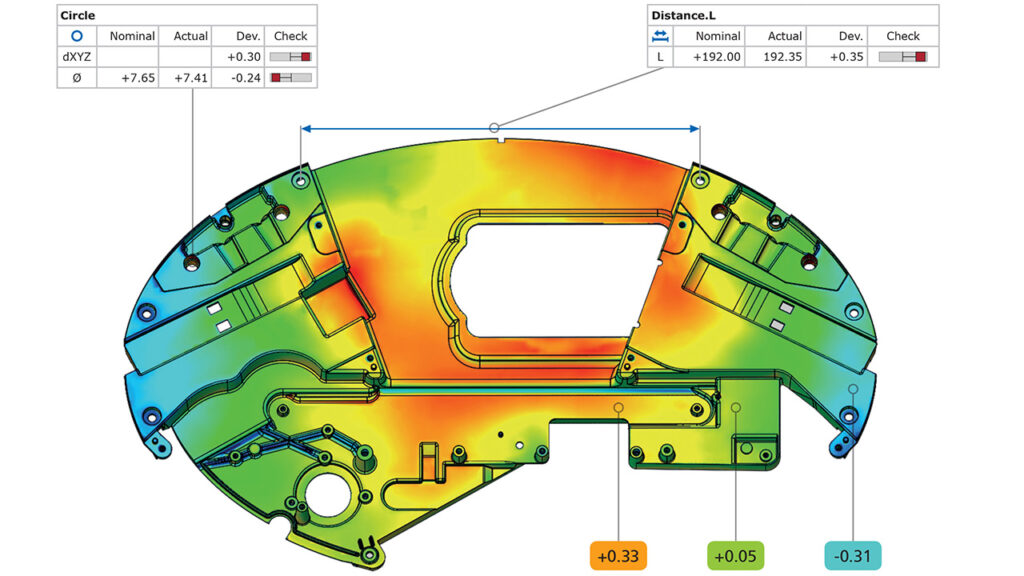

Two-dimensional deviation images

A picture says more than 1000 points. Full-surface measurements are used to create meaningful reports using color comparison images. Easy to understand: RED component areas are oversize, BLUE means undersize, GREEN areas are within tolerance. Even the first glance tells you the quality of the component and helps you to better assess shrinkage, warpage or recession. This makes it easier to deduce necessary corrections than by studying multi-page measurement reports

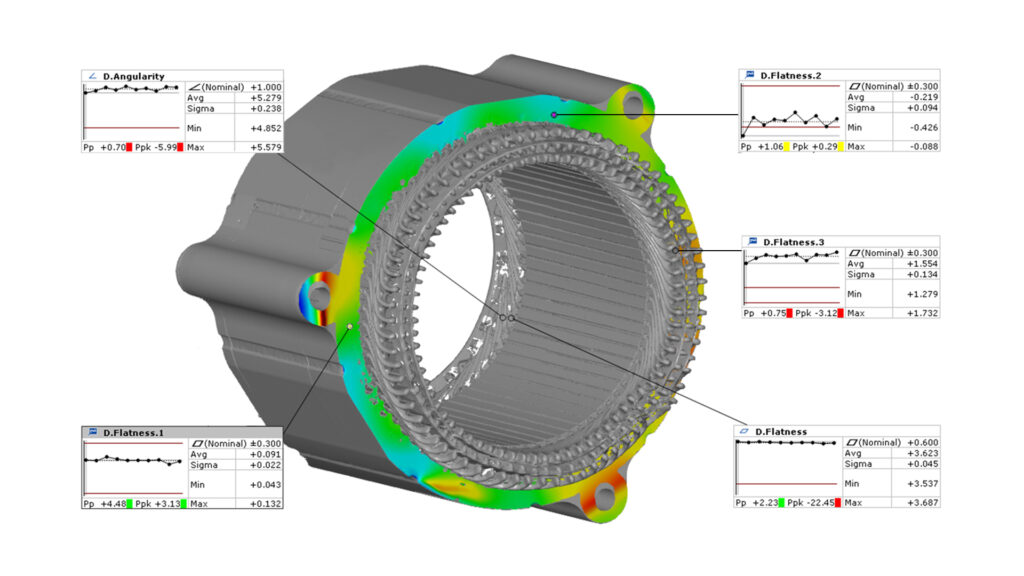

Initial sample test reports

and evaluations of specific characteristics are, of course, still an integral part of Metrology. Standard-compliant component evaluation in the VDA standard in accordance with ISO 8015 is therefore part of our standard repertoire.

Free viewer and evaluation software

In addition to our measurement reports, you also receive our free viewer and inspection software! This allows you and your customers to edit and supplement evaluations at any time.