- Customized postprocessors

- Safe and executable NC programs

- Creation of machine models

of postprocessors and creation of machine models

Machine simulation & postprocessor optimizations

The precise adaptation of postprocessors is crucial to ensure a seamless transition from the CAM to the NC program. We offer professional customization and configuration of postprocessors for hyperMILL, Peps and OPTICAM.

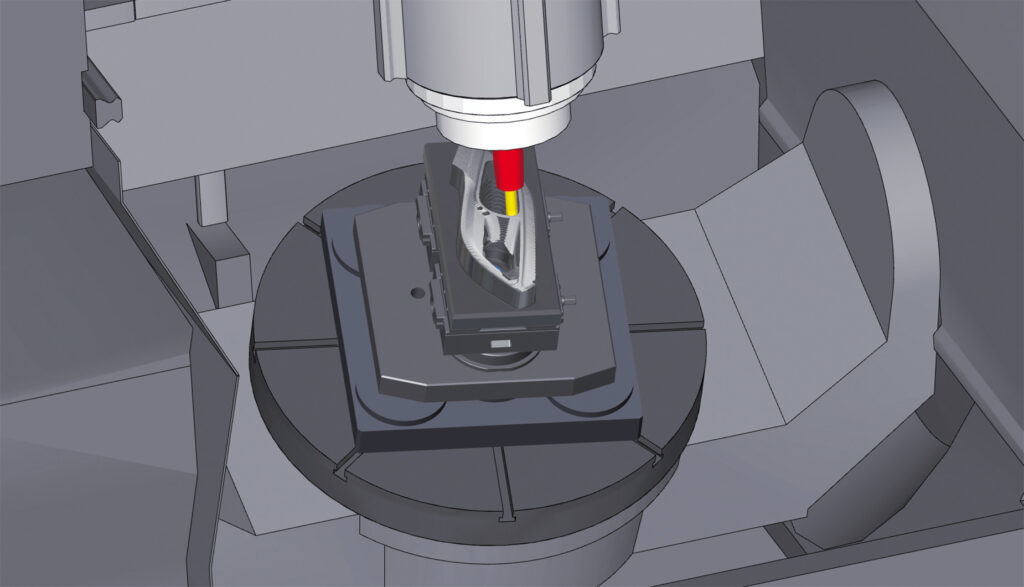

Whether standard applications or customized solutions – we ensure that your NC programs are optimally adapted to the specific requirements of your machines and control systems. We also offer the creation of precise machine models that enable realistic simulation and therefore greater process reliability.

Our experts adapt post-processors to the specific requirements of your production task, machine and control system. This makes optimum use of the control intelligence, ensuring smooth and reliable production.

Thanks to the close integration of NC code generation and simulation, your NC programs run precisely and error-free with no room for interpretation.

This significantly increases the safety and efficiency of your production processes. We create machine models based on the CAD data provided by the machine manufacturers. This enables a realistic simulation of the machine environment and optimization of the manufacturing processes in advance. In this way, errors can be avoided, set-up times reduced and the quality of your products sustainably increased.

Frequently asked questions (FAQs)

Why is the customization of postprocessors important?

The adaptation of post-processors ensures that the NC programs are optimally adapted to the specific requirements of your machines and control systems.

How can we ensure that the postprocessor also meets future requirements?

We develop our postprocessors to be flexible and expandable in order to be prepared for future requirements. In addition, we offer updates to ensure that your postprocessors remain compatible.

How do we benefit from machine models?

By using machine models, you can carry out realistic simulations. This makes it possible to identify potential problems at an early stage, reduce set-up times and achieve greater process reliability.

Mechatronics & Robotics

Mechatronics & Robotics