MDE machine data acquisition

Machine data acquisition (MDA) with Hummingbird MES

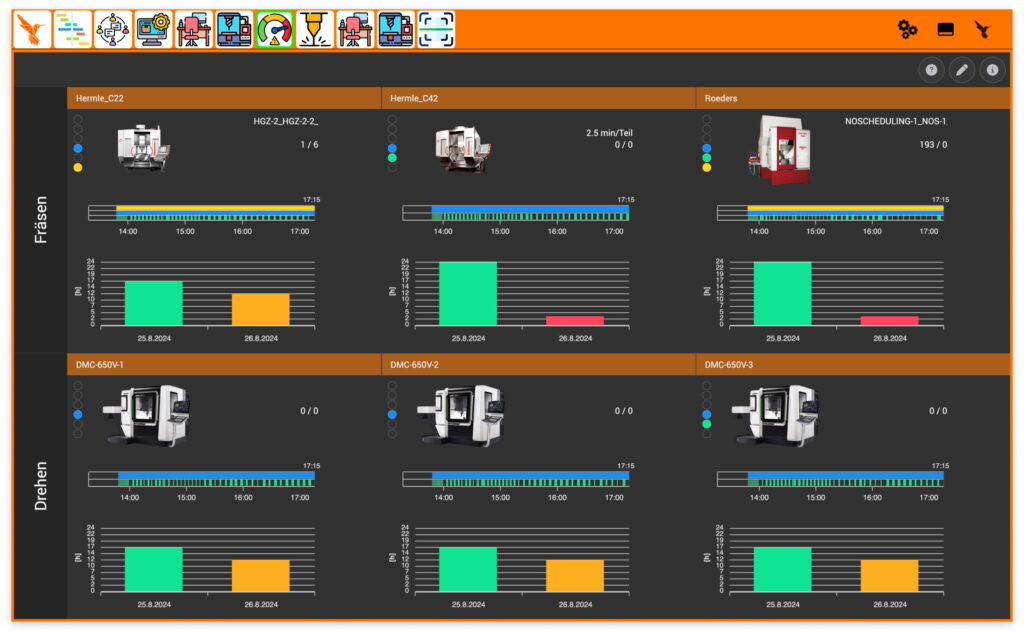

Machine data acquisition (MDA) is a crucial part of modern manufacturing processes. With Hummingbird MDE, you can capture and analyze all machine data in real time to maximize the efficiency of your production processes.

With Hummingbird MES, machine data is automatically recorded and stored centrally. This includes information such as operating times, downtimes, production quantities and machine faults. The data is collected continuously and is available in real time.

You too can benefit from the possibilities of real-time monitoring and process optimization for maximum efficiency and productivity – we would be happy to present our solution to you!

- Automatic recording of machine data

- Recording and analysis in real time

- Full transparency in your production

MDE explained

An MDC involves the automatic collection and analysis of data directly from the machines on the shop floor. This data provides valuable insights into machine status, production output and current capacity utilization.

With Hummingbird MES, you can monitor this data centrally and use it to optimize your production processes.

Advantages of MDE with Hummingbird

Real-time monitoring: Gain access to all relevant machine data. This enables a quick response to faults and helps to increase productivity.

Process optimization: Use the collected data to continuously improve your production processes. From planning to execution, all steps can be analyzed and optimized.

Transparency: Create full transparency in your production process. All machine data is centrally available and can be easily analyzed.

Frequently asked questions (FAQs)

Was ist eine Maschinendatenerfassung (MDE)?

Machine data acquisition, or MDA, is the automatic collection and analysis of machine data that provides insights into machine status and production.

Welche Vorteile bietet die MDE mit Hummingbird MES?

Real-time monitoring, increased efficiency, process optimization and full transparency in production processes.