ATOS 5

A versatile 3D scanner for precise and fast measurements in industrial environments.

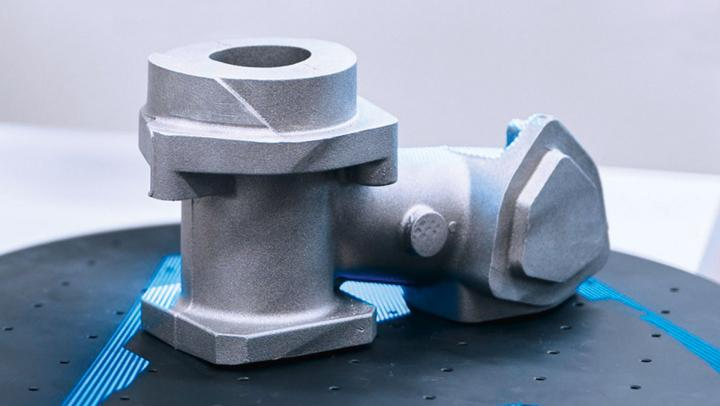

ATOS 5 offers a new level of performance, especially in the measurement of fine structures and edges, shiny and dark surfaces as well as a powerful light source and software.

The technology leads to a reduction in overall measurement time and at the same time enables accurate 3D measurement results.

- For medium to large components

- Can be used manually and automatically

- Powerful Blue Light Technology

Accelerate measurements

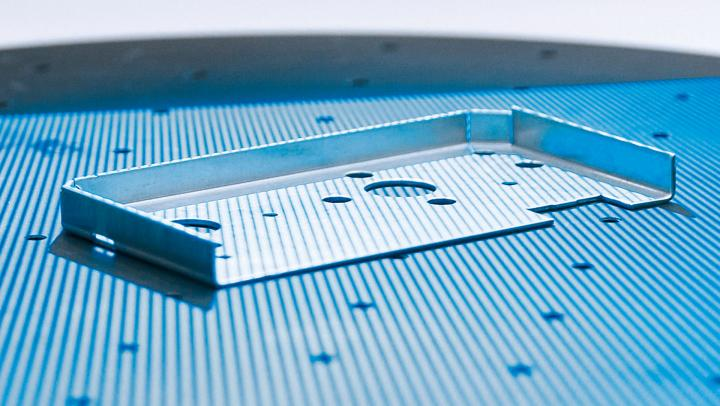

ATOS 5 accelerates inspection procedures by performing full-length 3D scans. The system can achieve short exposure times on both light and dark surfaces.

The extensive measuring field increases the speed of the optical 3D scanner, enabling you to obtain 3D data faster and thus increase your productivity.

Robust precision

ATOS 5 is designed for commercial use and meets the high Metrology requirements of industrial users. The system delivers absolute and repeatable measurement data even in difficult environments.

ATOS 5 has an internal, sensor-controlled monitoring function due to its stereo camera design, which provides feedback on the status of the individual measurement or the calibration status, among other things.

Versatile in use

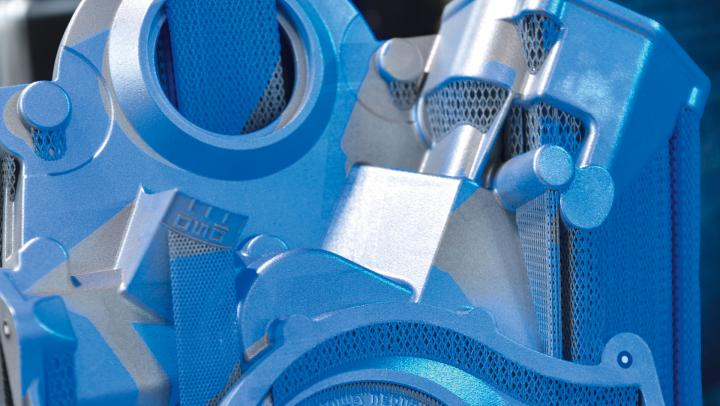

Choose ATOS 5 to combine precision and flexibility. Whether in production or in the measuring room, manual or automated, the system masters demanding measuring tasks.

Depending on the application, the system can be adapted to different requirements. Whether stationary in the measuring room or mobile in production. ATOS 5 also enables automated quality control in standardized ScanBox measuring machines to make series production more efficient.

More power

By using the computing power of the graphics card, the ZEISS INSPECT software accelerates the measurement. Individual scans are processed faster due to the high number of computing cores on the graphics processor.

This leads to a significant reduction in the overall measurement time. This GPU acceleration, together with the powerful light source and camera technology, takes ATOS 5 to a new level of performance.

The ATOS technology

ATOS 5 uses structured blue light to perform non-contact measurements. Up to 12 million independent measuring points are recorded in a single measurement.

You can define the accuracy, resolution and measuring field size according to your requirements. This makes it possible to scan complex components with many details in high resolution as well as to digitize large components very quickly.

Frequently asked questions (FAQs)

Kann das ATOS 5 System auf meine Bauteile angepasst werden?

Yes – different measuring field sizes are available. The measuring field size can be adapted to the component size by simply exchanging the lenses. Measuring fields can also be added to existing systems at any time.

Welche Automatisierungsmöglichkeiten stehen zur Verfügung?

Measurements can be automated using manual or software-controlled rotary tables. For even more efficient measurements during series production, the ATOS 5 system can also be used at any time in a ZEISS ScanBox. Manual ATOS 5 systems can be extended with a ZEISS ScanBox at any time.

Wie kann im laufenden Betrieb die Messperformance sichergestellt werden?

The system is self-monitoring and checks the calibration status of the sensor as well as the ambient conditions. If necessary, the operator can recalibrate the system himself using the calibration plate supplied. To ensure that the measuring equipment is monitored, we recommend an annual inspection and acceptance by certified WESTCAM technicians.

We advise you personally!

Gladly there for you