ARAMIS 3D Camera

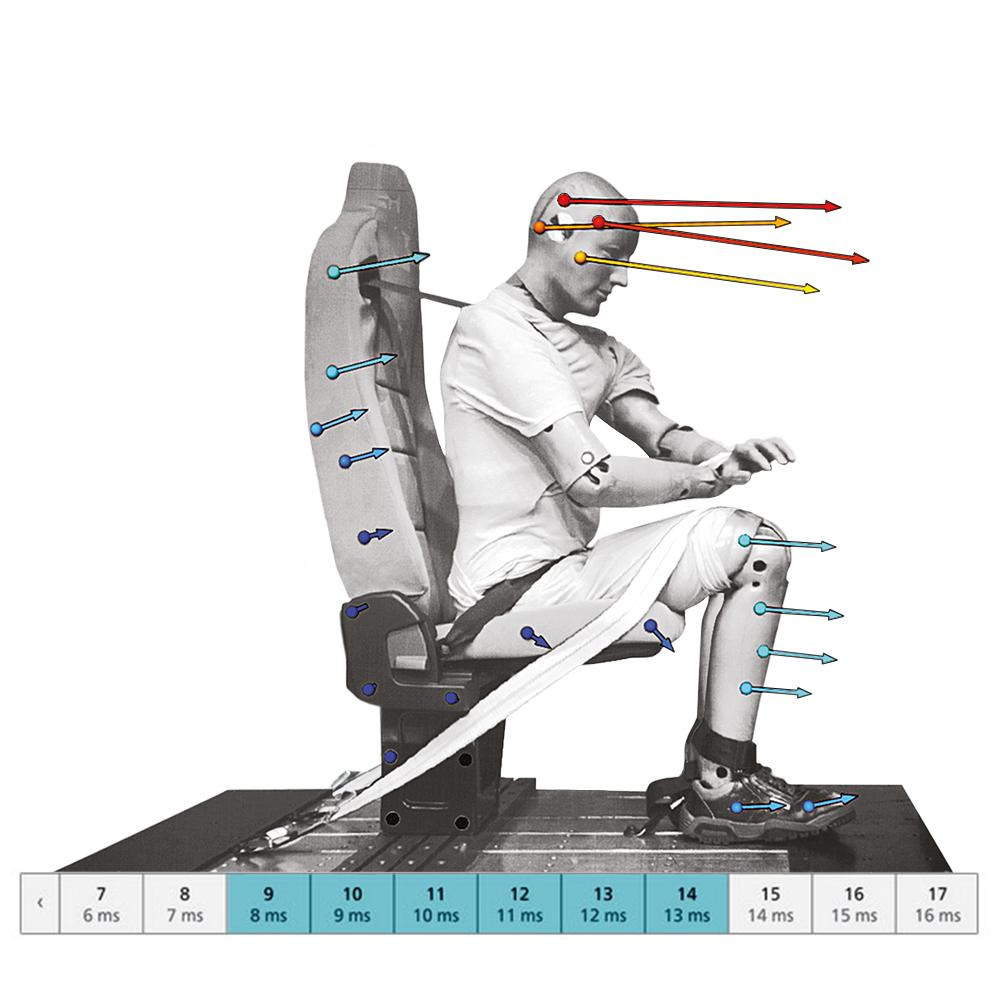

Dynamic 3D-Metrology for full-surface and point analyses.

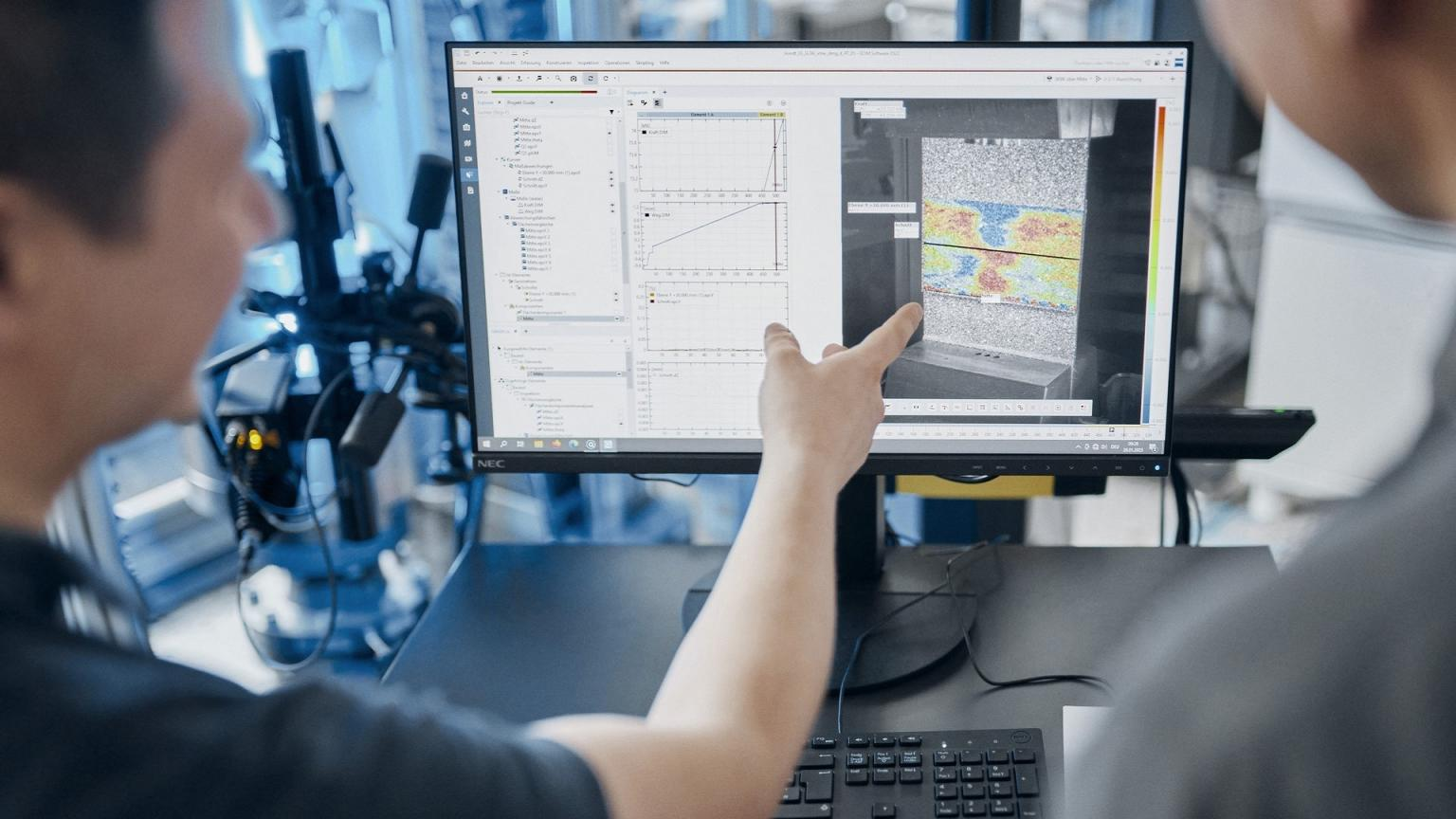

The ZEISS ARAMIS 3D Camera is the high-resolution optical 3D measuring system for full-surface and point-based measurements.

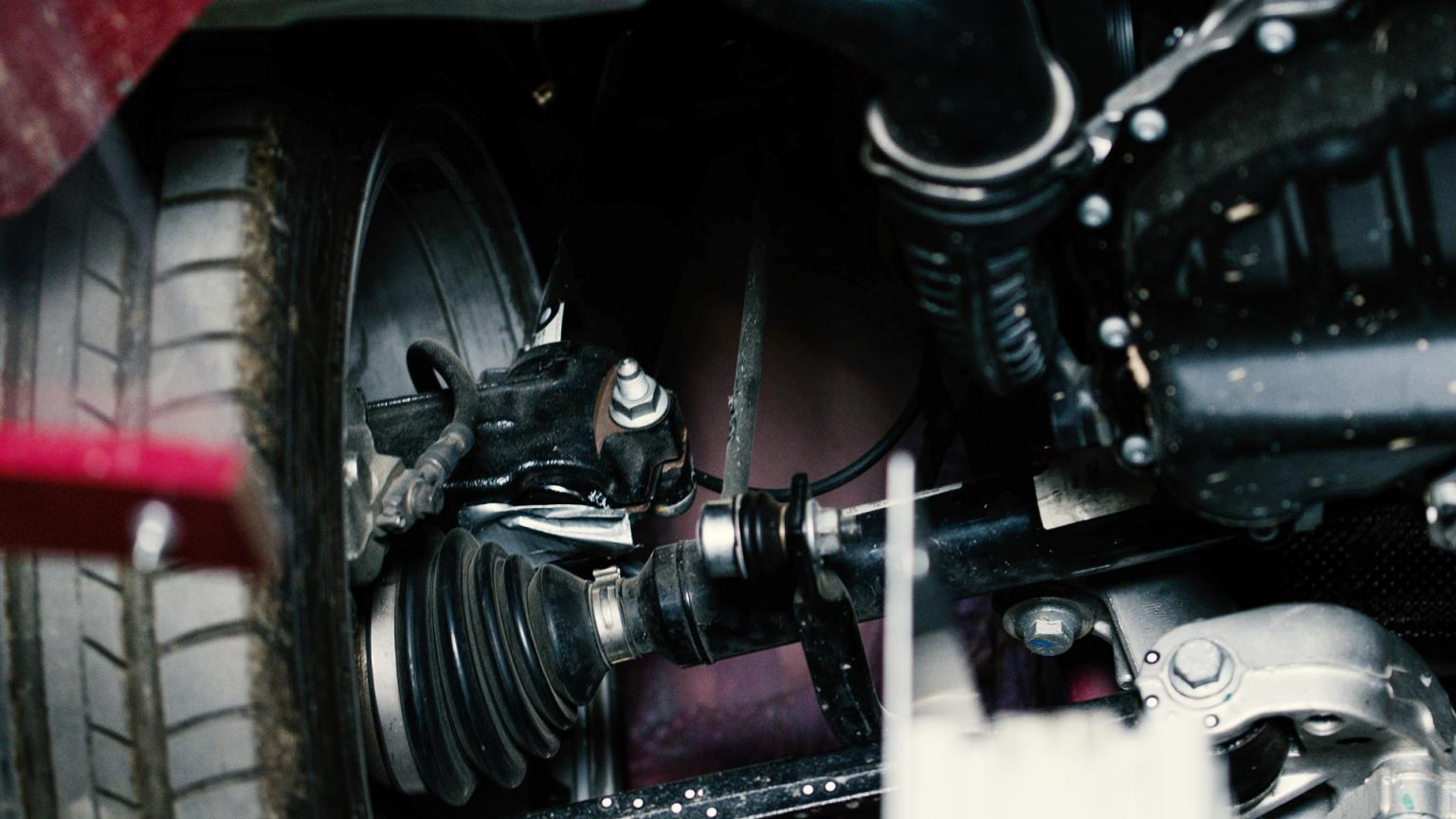

With high system stability, process reliability and user-friendliness, the system is the first choice for high-end applications in industrial environments and offers the perfect configurations for a wide range of testing tasks.

- Ready for use out-of-the-box

- Fast and high-resolution

- Simple integration

Ready for use out-of-the-box

The robust design of the housing ensures the stability of the sensor and reduces the need for calibration in industrial applications.

Quick adjustment of the measurement volume is made possible by an interchangeable camera profile and preset and certified lenses, which minimizes the time required for the measurement setup.

Fast and high-resolution

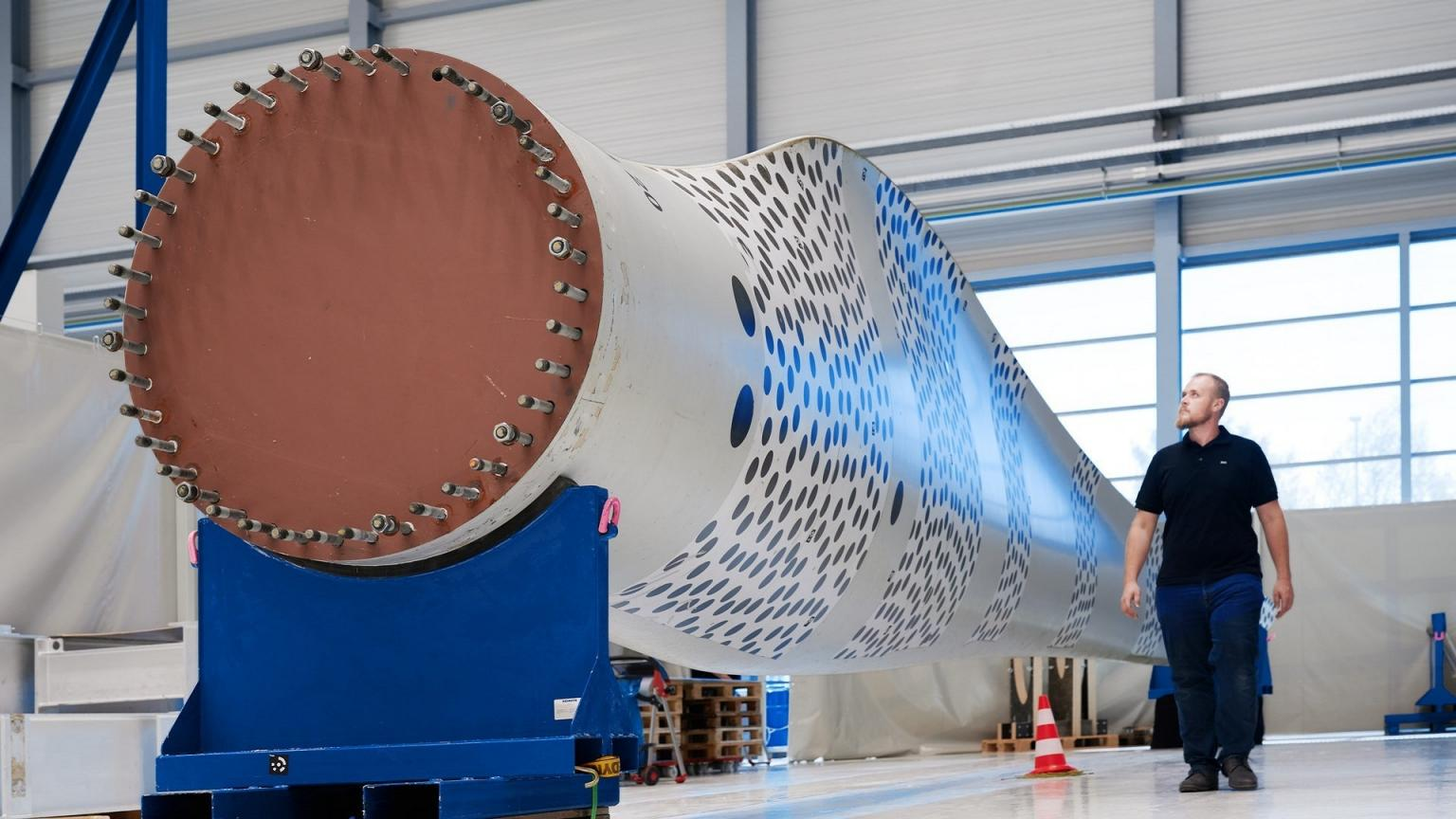

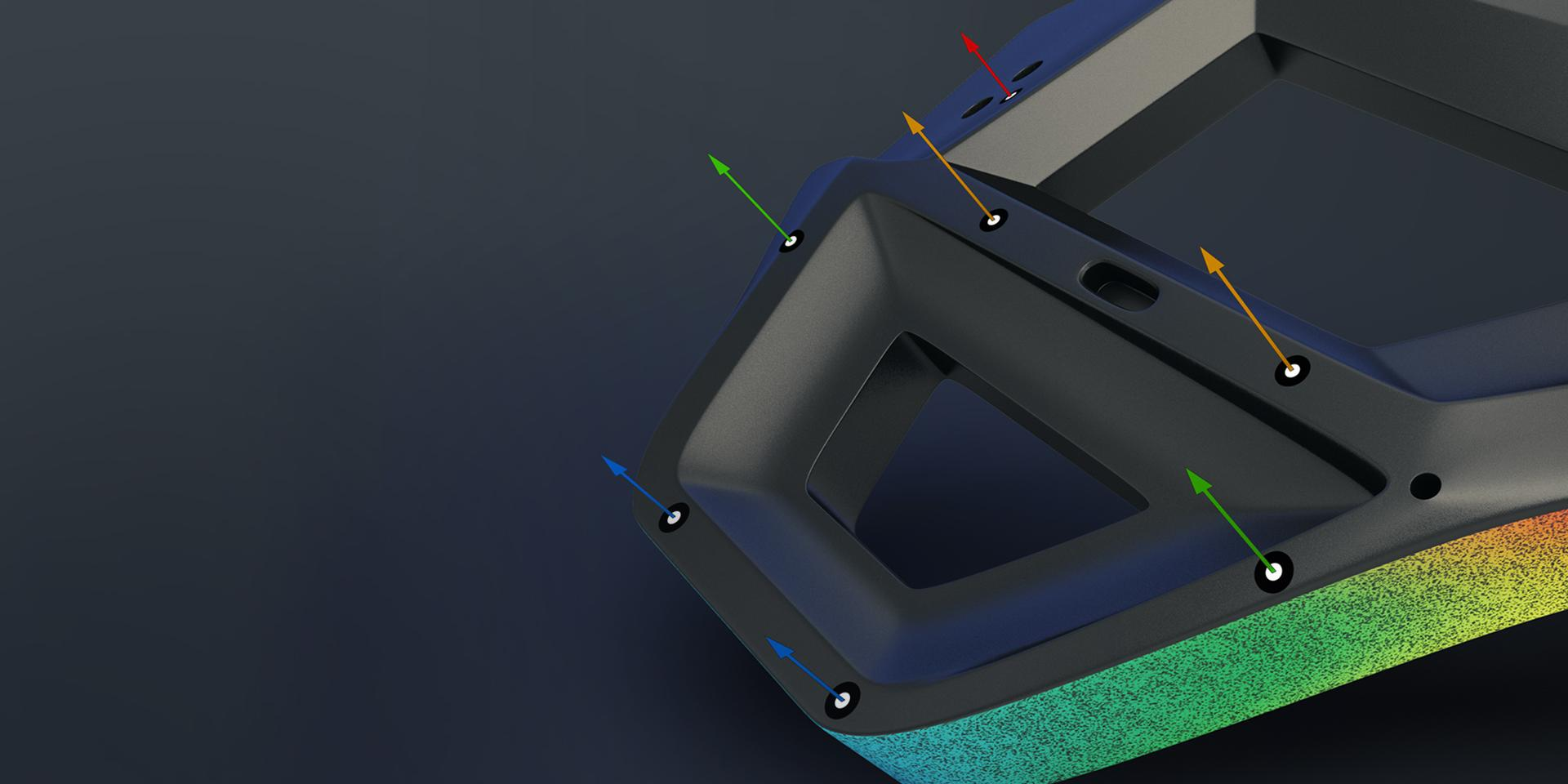

A dense network of measurement data (high spatial resolution) is created using modern camera technology with high-resolution image sensors. This makes it possible not only to record the smallest strains, but also to guarantee the evaluation of local strain effects.

Even dynamic processes at full resolution can be recorded with the ARAMIS 3D Camera SRX, which has an image capture rate of 335 images per second. This means that the system delivers reliable measurement results with an excellent level of detail.

Simple integration

The ARAMIS controller ensures that communication between software and hardware remains reliable. This allows external signals to be integrated into the ARAMIS measurement project.

The precise PTPv2 network protocol ensures that the devices involved in the experiment are synchronized in time. This ensures that reliable measurement results are available even for demanding material and component tests.

Frequently asked questions (FAQs)

What advantages does ARAMIS 3D Camera offer for industrial applications?

The ARAMIS 3D Camera has many advantages for use in industry, such as high system stability, process reliability and user-friendliness. Its robust design reduces the need for sensor calibrations. The system can be quickly adjusted to different measuring volumes thanks to interchangeable camera profiles and preset, certified lenses. This reduces the time required for the DIC measurement setup.

How does ARAMIS 3D Camera support the recording of dynamic processes?

At full resolution, the ARAMIS 3D Camera SRX can capture dynamic processes at 335 frames per second. A dense network of measurement data is generated by modern camera technology and high-resolution image sensors. This makes it possible to measure the smallest strains and analyze local strain effects in large measurement volumes. This leads to reliable and detailed measurement results.

What role does the ARAMIS controller play in the function of ARAMIS 3D Camera?

The ARAMIS controller plays a central role in controlling the ARAMIS 3D Camera. It ensures stable communication between software and hardware and enables the integration of external signals into the ARAMIS measurement project. With the help of the highly accurate PTPv2 network protocol, the time synchronization of the devices involved in the experiment is realized, which ensures reliable measurement results even for complex material and component tests.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics