ZEISS Weld Check

Simple and digital visual inspection of weld seams

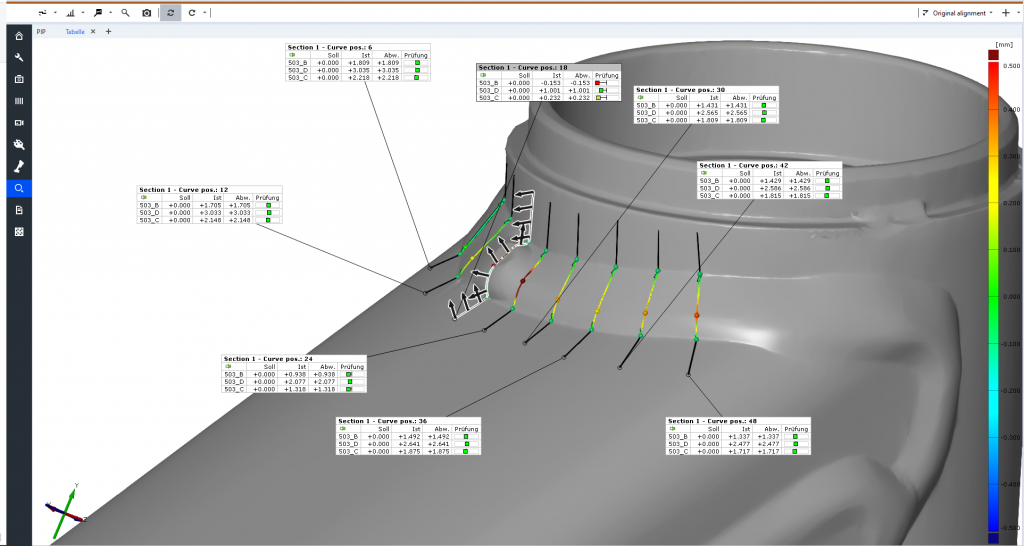

The Weld Check app enables the automated visual inspection of weld seams. Weld seams can be inspected in a 3D scan according to all DIN EN ISO 5817 characteristics with a click of the mouse.

The function allows the weld seam inspector to create a report of all characteristics. The visual inspection is thus digitized and can be checked at a later date.

- Automated visual inspection of weld seams

- Weld Check App

- Testing according to DIN EN ISO 5817

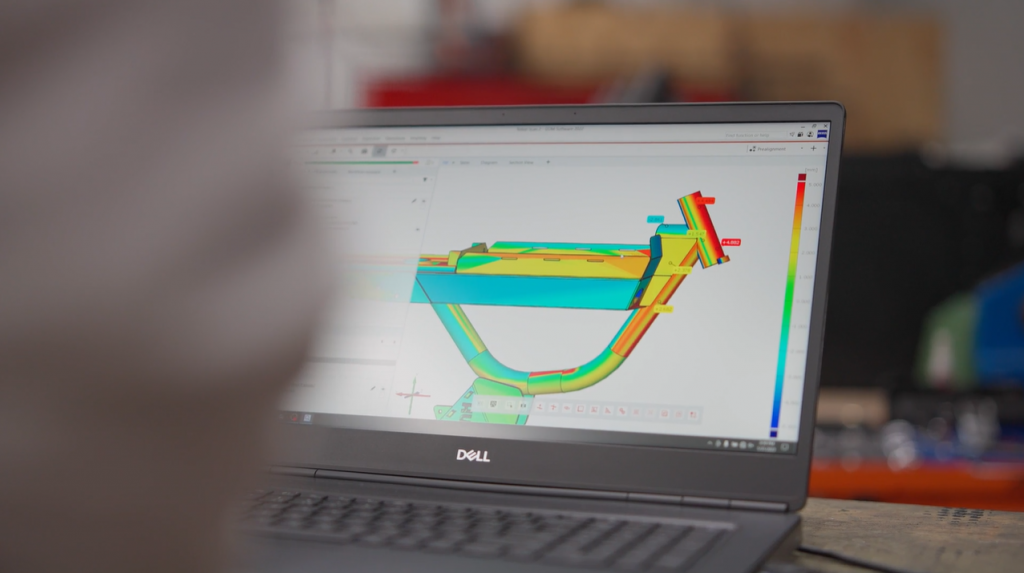

PRACTICAL EXAMPLE: HUCK CYCLES

Huck Cycles: Weld seam inspection electric motorcycles

The basic structure of a motorcycle is the welded frame. Weld inspection is therefore not only necessary to maintain the quality of the installed parts, but also for the safety of the riders. See here how weld seams are easily scanned, classified and inspected with ZEISS T-SCAN hawk 2 and the Weld Check app.

The ZEISS Weld Check app offers you more

Flexibility

A reference can be saved with which the position and completeness of the weld seams can be checked. This reference can also be used as a template for series inspections.

Functionality

You expect less manual effort and fast results. With the Weld Check function in the full version of ZEISS INSPECT, you can check every component and its weld seams.

Optimized processes

The Weld Check app not only saves a lot of time, but also digitizes the visual inspection process.

This makes it traceable and standardizable.

The advantages make the difference

Less manual effort

No more manual measuring required: the weld seam to be inspected is captured with a 3D scanner and evaluated in the full version of ZEISS INSPECT with the Weld Check app.

Detailed and simple inspection of weld seams

At the click of a mouse, all DIN EN ISO 5817 characteristics are not only checked, but also assigned directly to the corresponding evaluation groups.

With the help of a simple traffic light system, you can see at a glance whether the characteristics are fulfilled.

Evaluation

Tracking and digitization of visual inspections made easy: Both overall reports and individual reports can be created.

Frequently asked questions (FAQs)

What is ZEISS INSPECT?

With ZEISS INSPECT, surface inspections can be visualized easily, intuitively and across the entire workflow. A wide range of GD&T analyses and reporting functions are also available. The software is used in quality inspection, product development and production and inspects 3D measurement data captured with structured light scanners, laser scanners, coordinate measuring machines or other measuring devices.

What is ZEISS Weld Check?

ZEISS Weld Check enables the automated visual inspection of weld seams. At the click of a mouse, weld seams can be inspected on the basis of a 3D scan according to all DIN EN ISO 5817 characteristics. The function allows the weld seam inspector to create a report of all characteristics. The visual inspection is thus digitized and can be checked at a later date.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics