ZEISS INSPECT X-RAY

GOM Volume Inspect is now called ZEISS INSPECT X-Ray

With the 2023 release, the GOM software products were united under a common name and umbrella: ZEISS INSPECT.

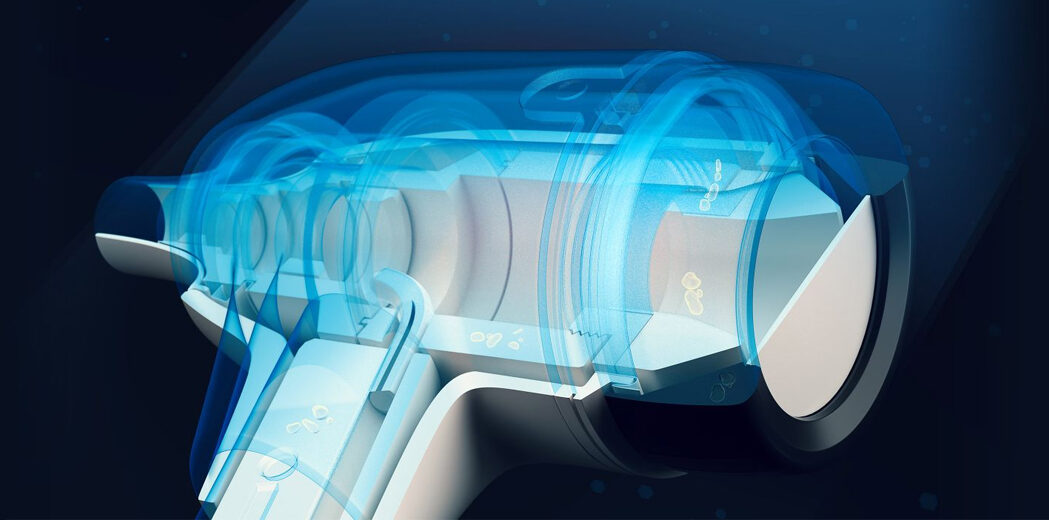

However, one thing remains the same: ZEISS INSPECT X-Ray is still the software with which you can analyze your components down to the last detail. Regardless of which computer tomograph you use, the software supports all common file formats so that you can quickly identify internal defects and efficiently decide how to proceed with the component.

And to work even more efficiently, simply scan several parts of a series at the same time. The software then separates them automatically.

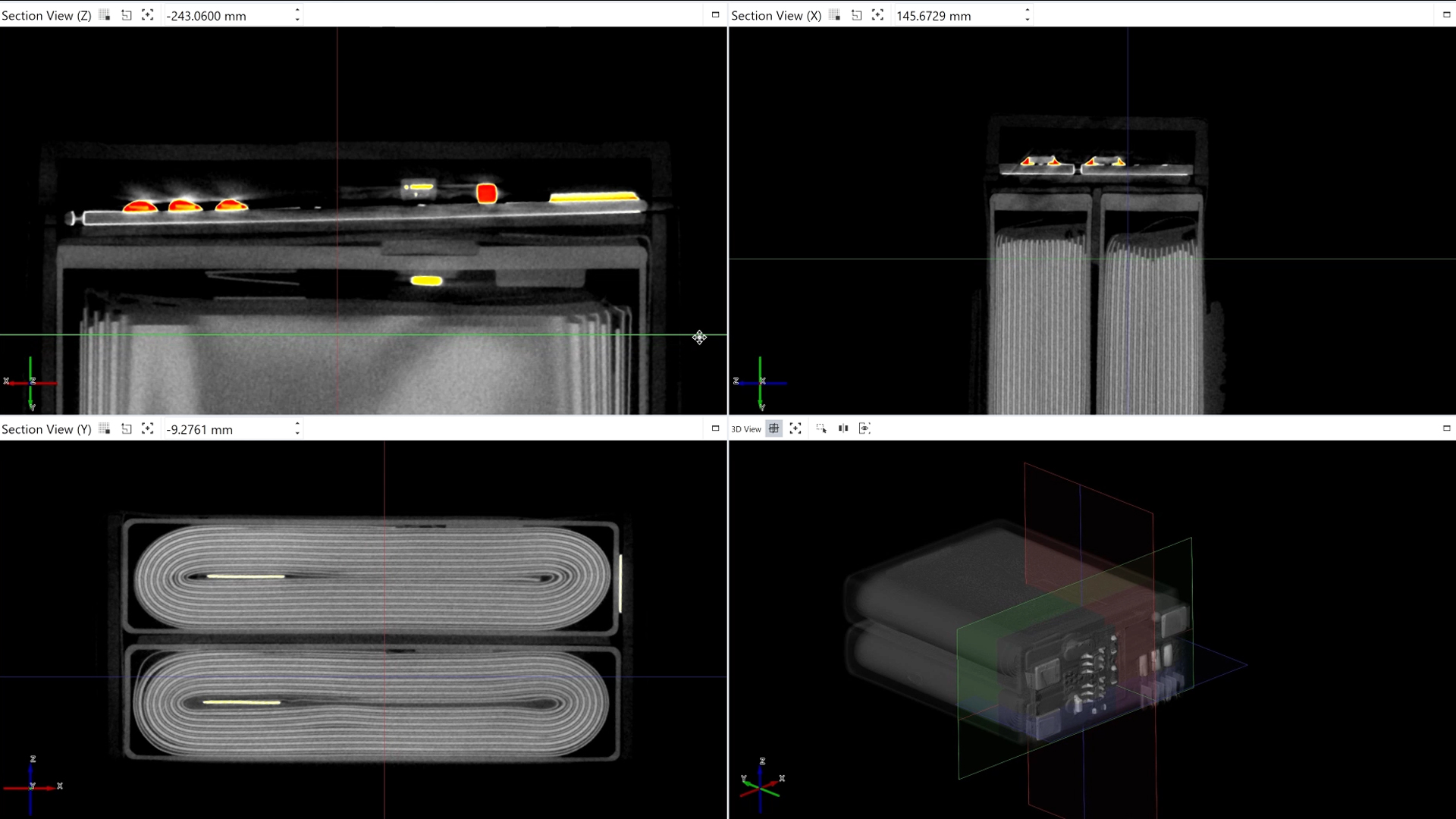

- Better orientation thanks to Multiview

- Detect defects in 2D and 3D

- Batch scan for increased efficiency

- Treat different component areas individually

ZEISS INSPECT X-Ray at a glance

Intuitive operation and high performance: CT data analysis has never been so easy. ZEISS INSPECT X-Ray guides you through the entire workflow from data import to report generation. Clever functions make it easier for you to analyze your CT data.

Whether 2D or 3D: choose the display you like.

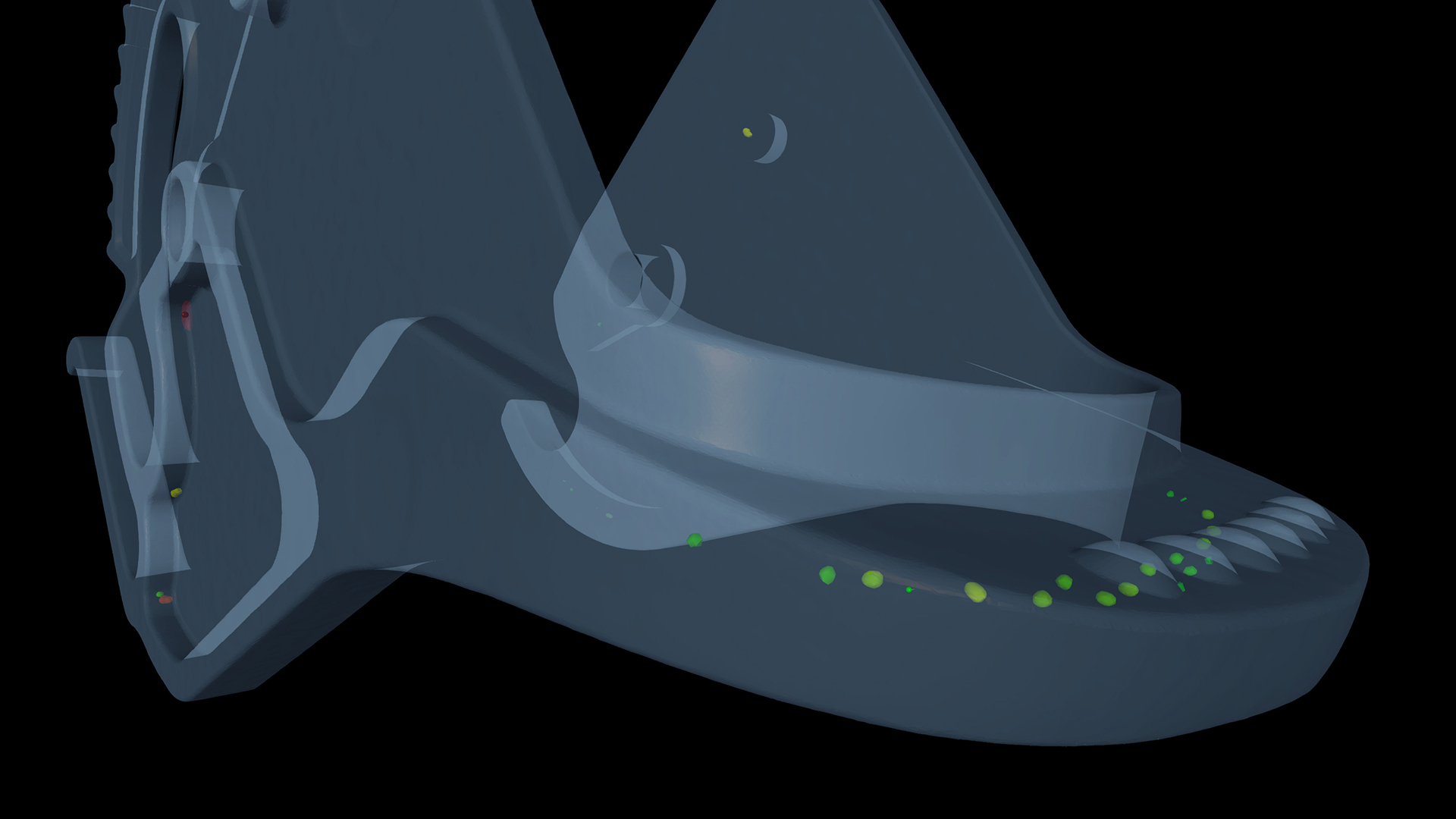

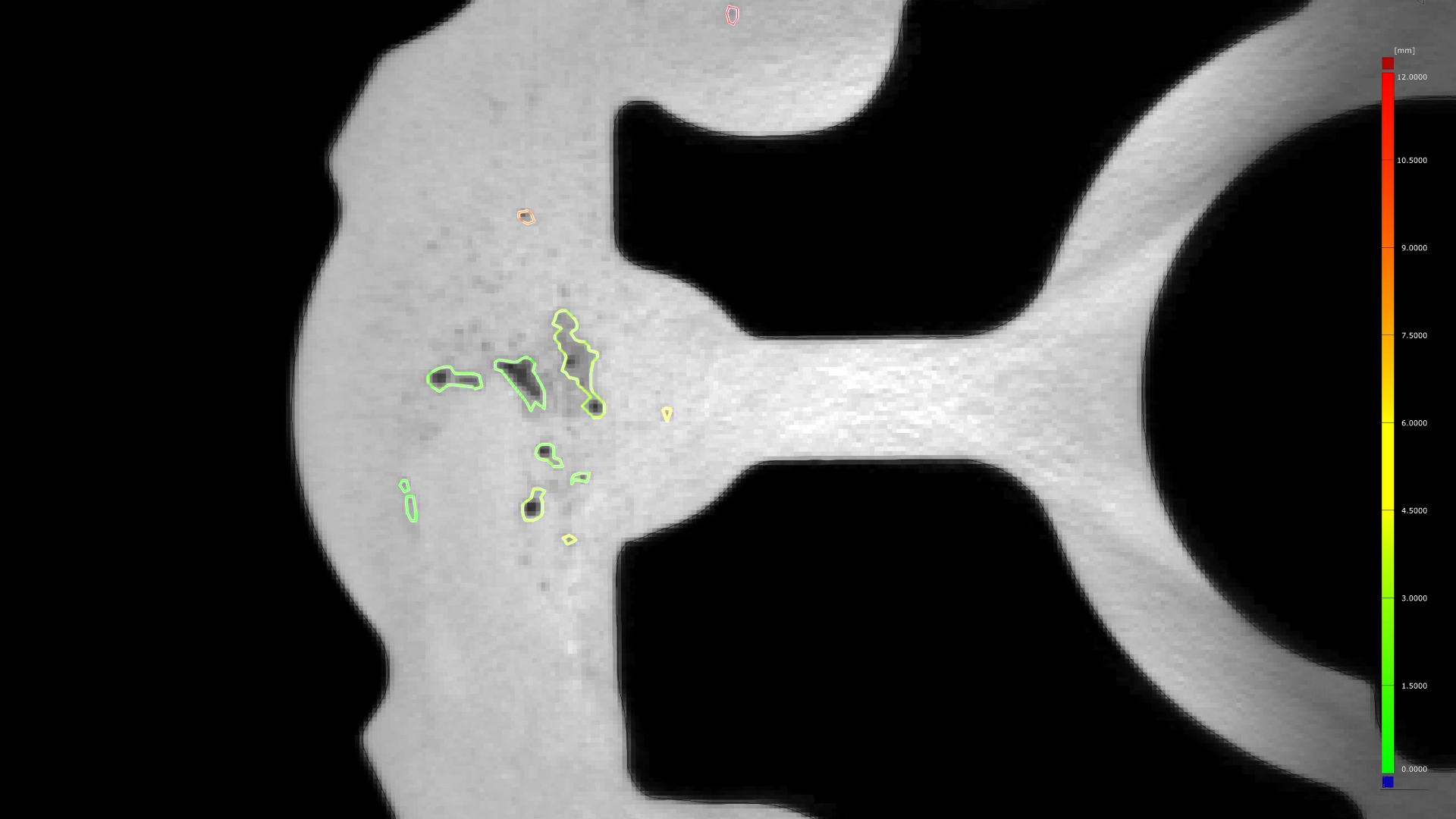

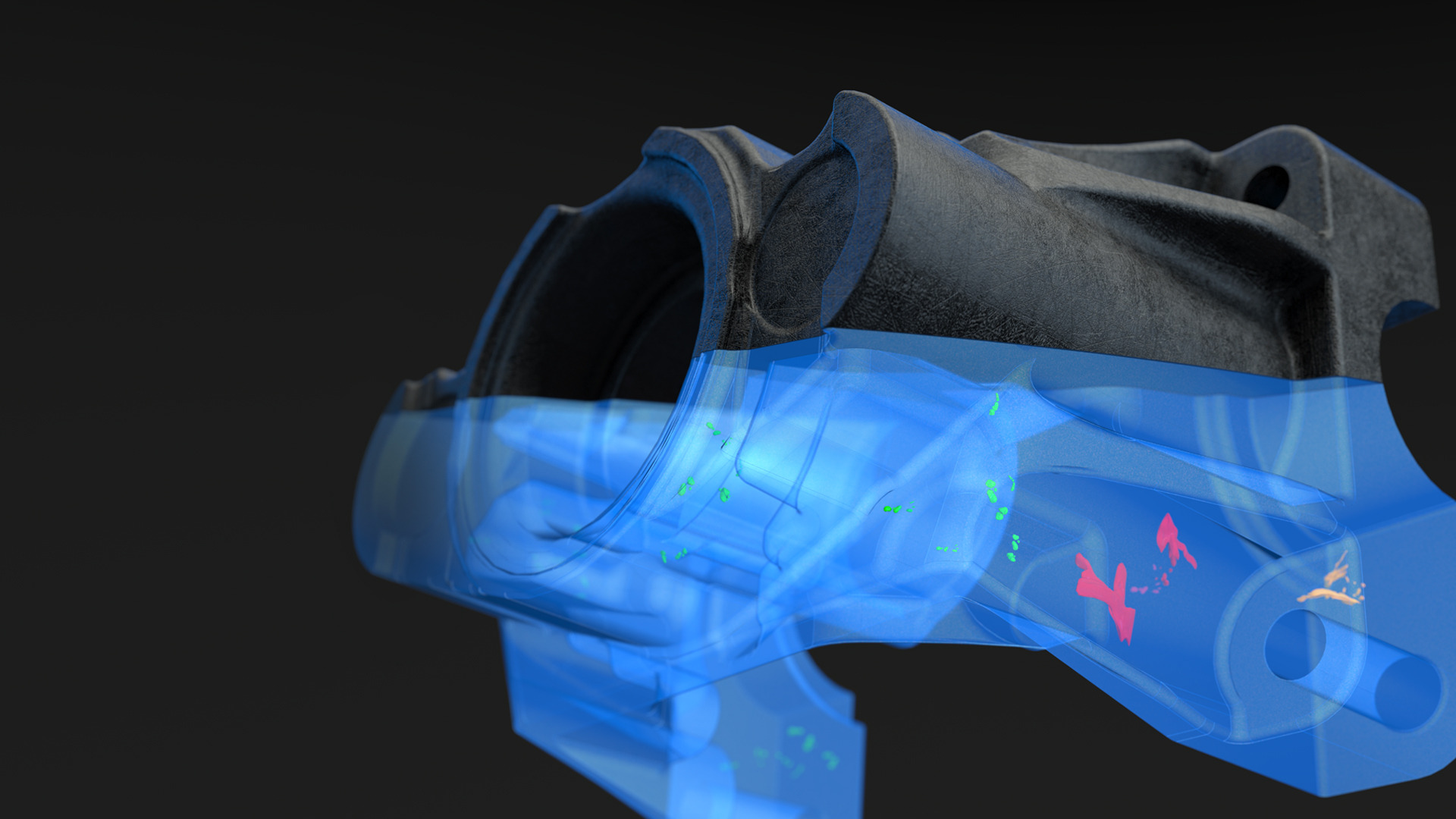

Detect blowholes, cracks, inclusions, porosity and other defects – even automatically.

Evaluate several components in a project automatically, set one as a reference and analyze the differences.

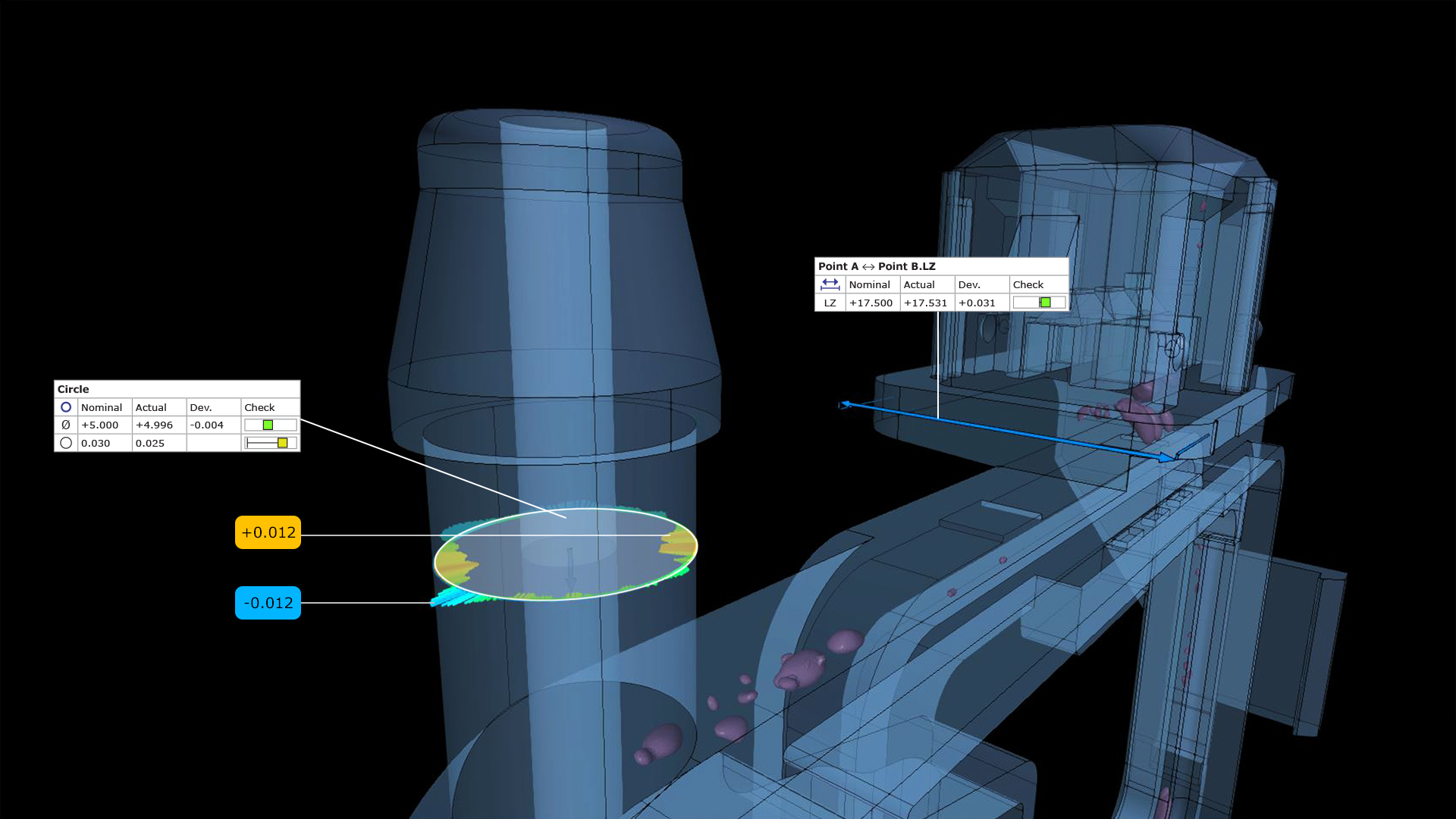

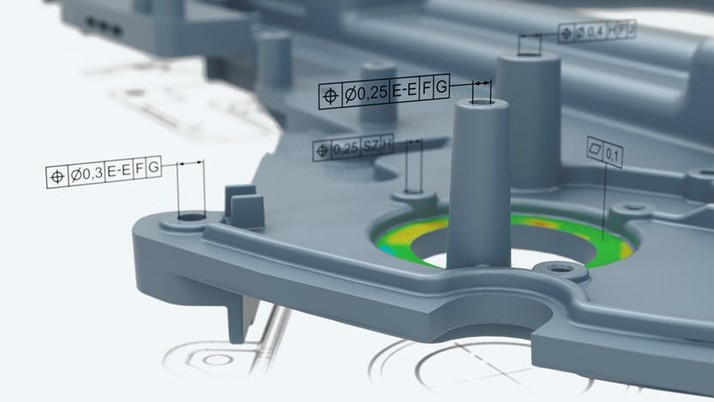

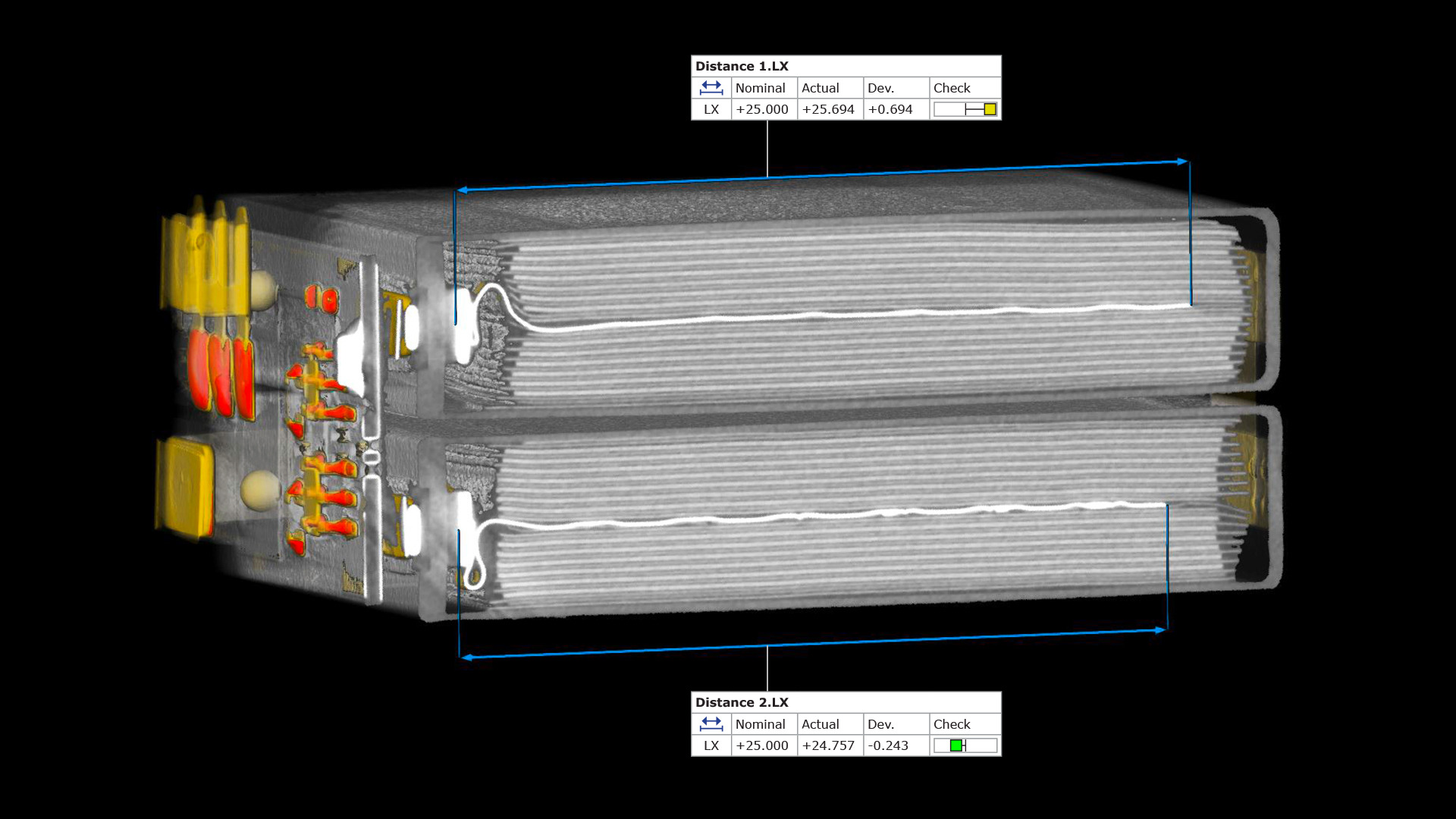

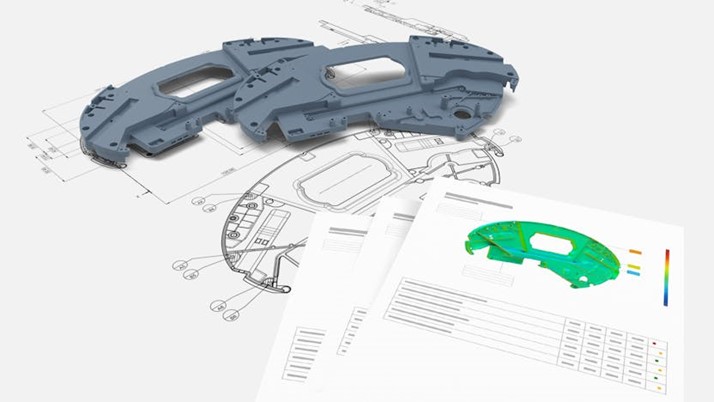

Check your components three-dimensionally, for example for shape and position tolerances.

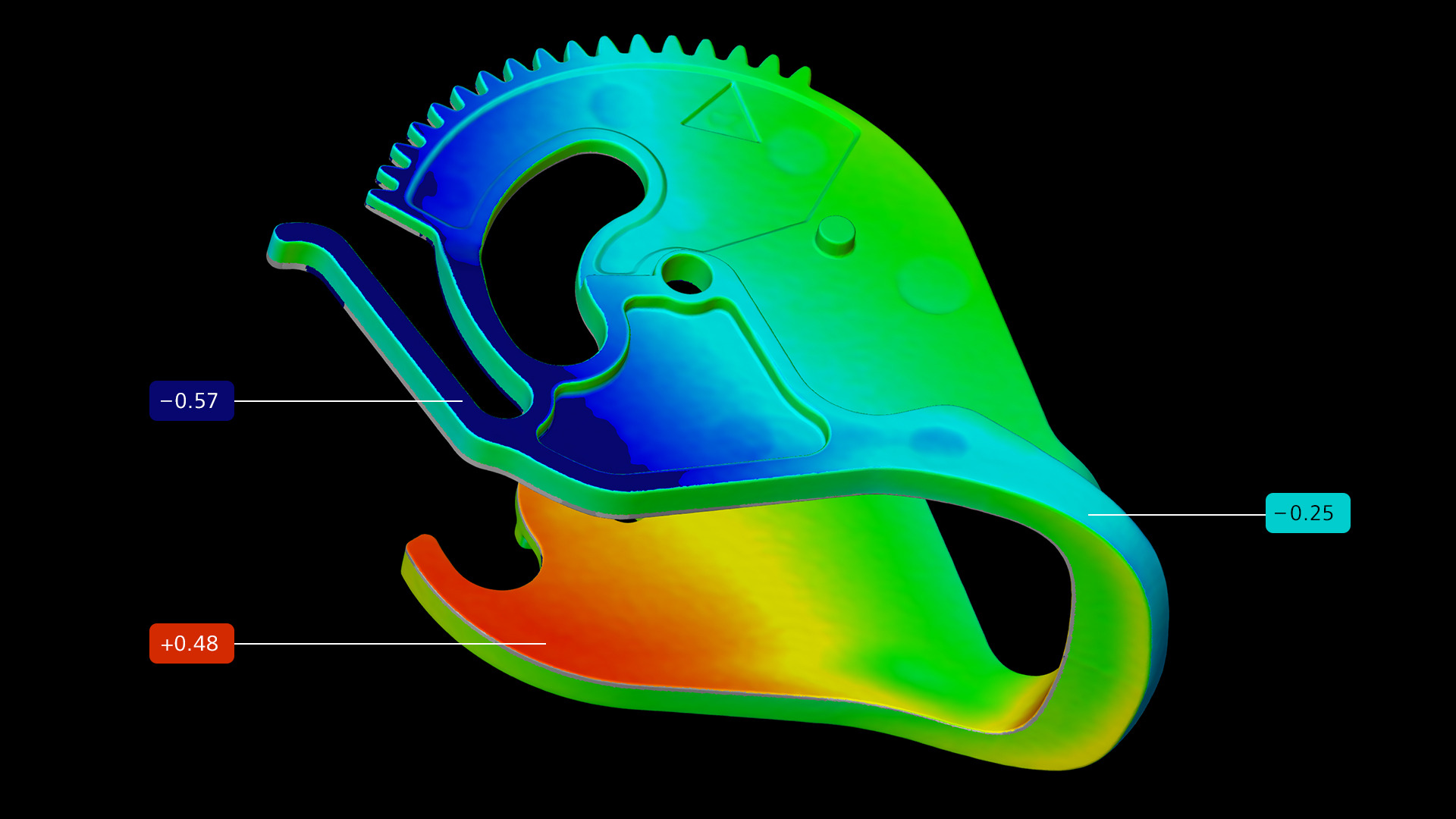

Identify deviations using a color scale that is easy to understand.

Record your operations and run them as Python scripts or use additional apps for process automation.

Intuitive geometric inspection with ZEISS INSPECT X-Ray

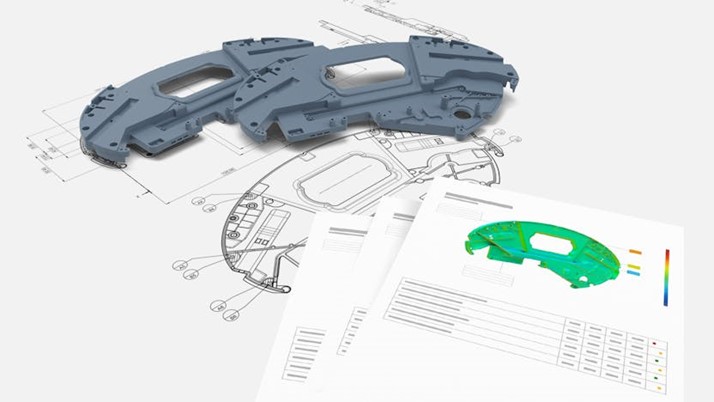

In addition to the extensive functions for volume and defect analysis, ZEISS INSPECT X-Ray offers a wide range of options for ensuring the geometric dimensional accuracy of the measured components. Automatic multiple evaluations of cavities and intuitive report generation are just two keywords in this area.

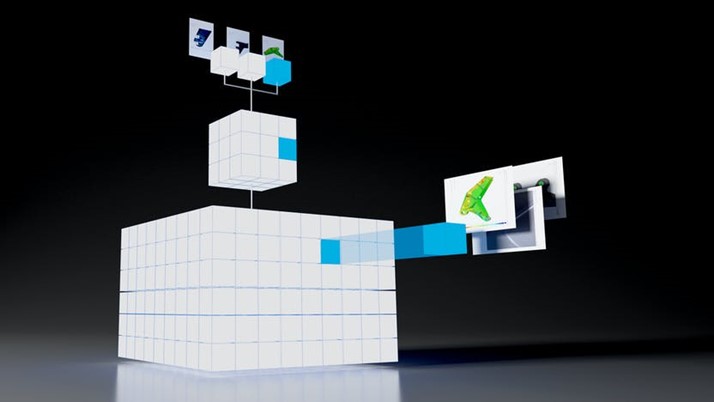

Efficient evaluation of multiple parts

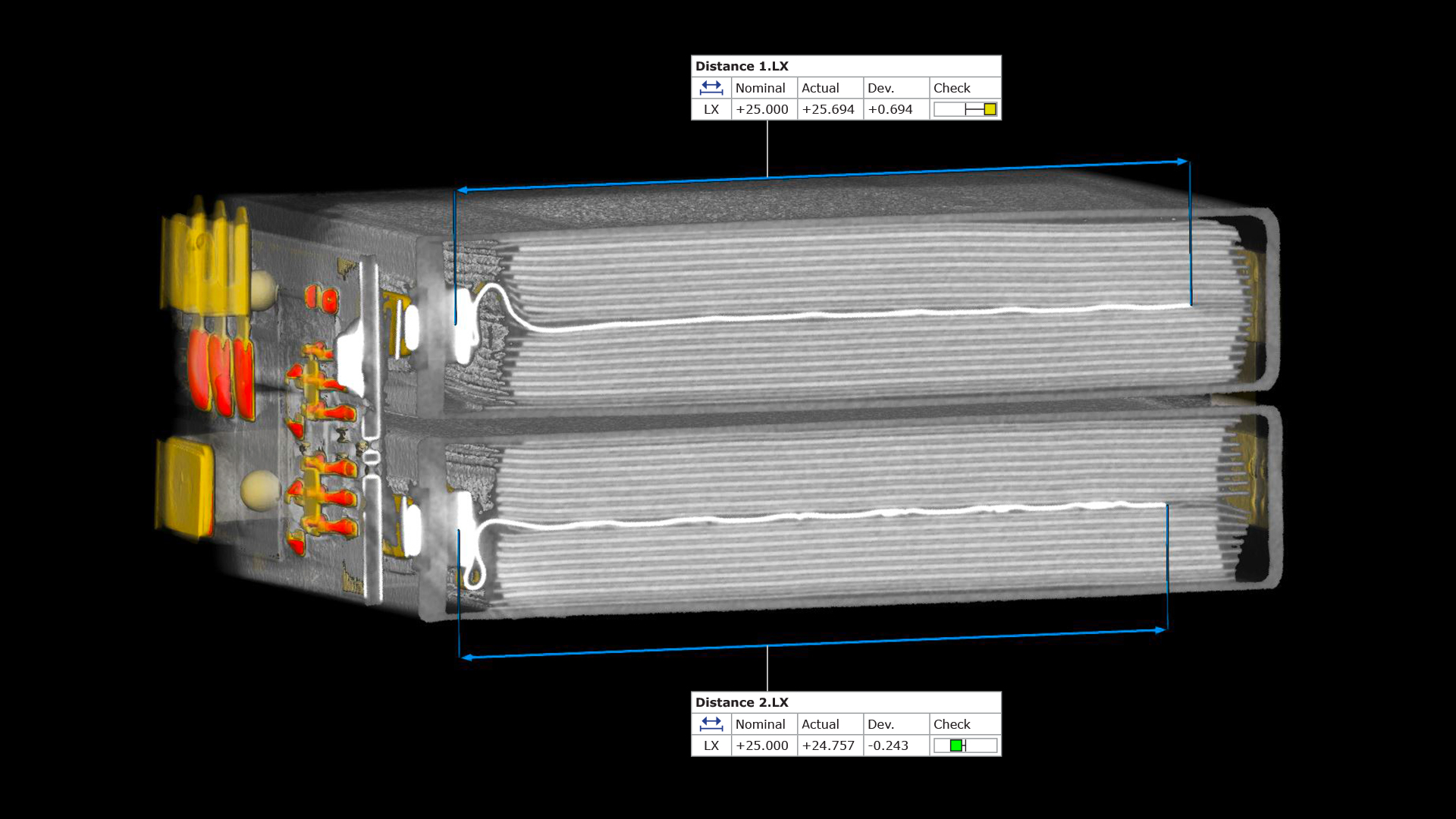

The simultaneous capture of several components in a series enables efficient working methods, as the data can then be separated and automatically evaluated by the software. The comparison of different scans of the same object type using trend projects also allows optimized control for recurring tasks. Complete traceability is a major advantage here.

Simple analysis of multi-component parts

Sometimes it is not so easy to analyze complex parts that consist of several elements. In ZEISS INSPECT X-Ray, the specifications of all parts in a multi-component data set are shared. This makes the inspection process much easier.

With a new, user-friendly concept, regions of interest can be created interactively. The assembly can be taken apart digitally and the various areas can be analyzed with individual tolerances. This saves a lot of time.

Reporting

With the ZEISS INSPECT reporting module, you can export your analysis results as print-ready documentation or as a fully animated PDF. To better understand and share the results, share the complete project file.

Even the smallest defects become visible through individual cross-sectional images and can be automatically evaluated using a wide range of criteria.

Frequently asked questions (FAQs)

How can I install ZEISS INSPECT X-Ray?

Simply download here ZEISS Quality Suite and install ZEISS INSPECT 2023. You can test all versions of ZEISS INSPECT directly from ZEISS Quality Suite for 14 days.

How do I access the free version of the new ZEISS INSPECT free software?

After downloading the ZEISS Quality Suite (here) and receiving your ZEISS ID (after successful registration), the free version of the ZEISS INSPECT X-Ray software is available to you. At the end of the 14-day trial period, you can continue to use the basic version of ZEISS INSPECT free of charge or purchase the full version.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics