ZEISS INSPECT Airfoil

Revolutionize turbine analysis: Precise 2D/3D evaluation, system-independent & powerful.

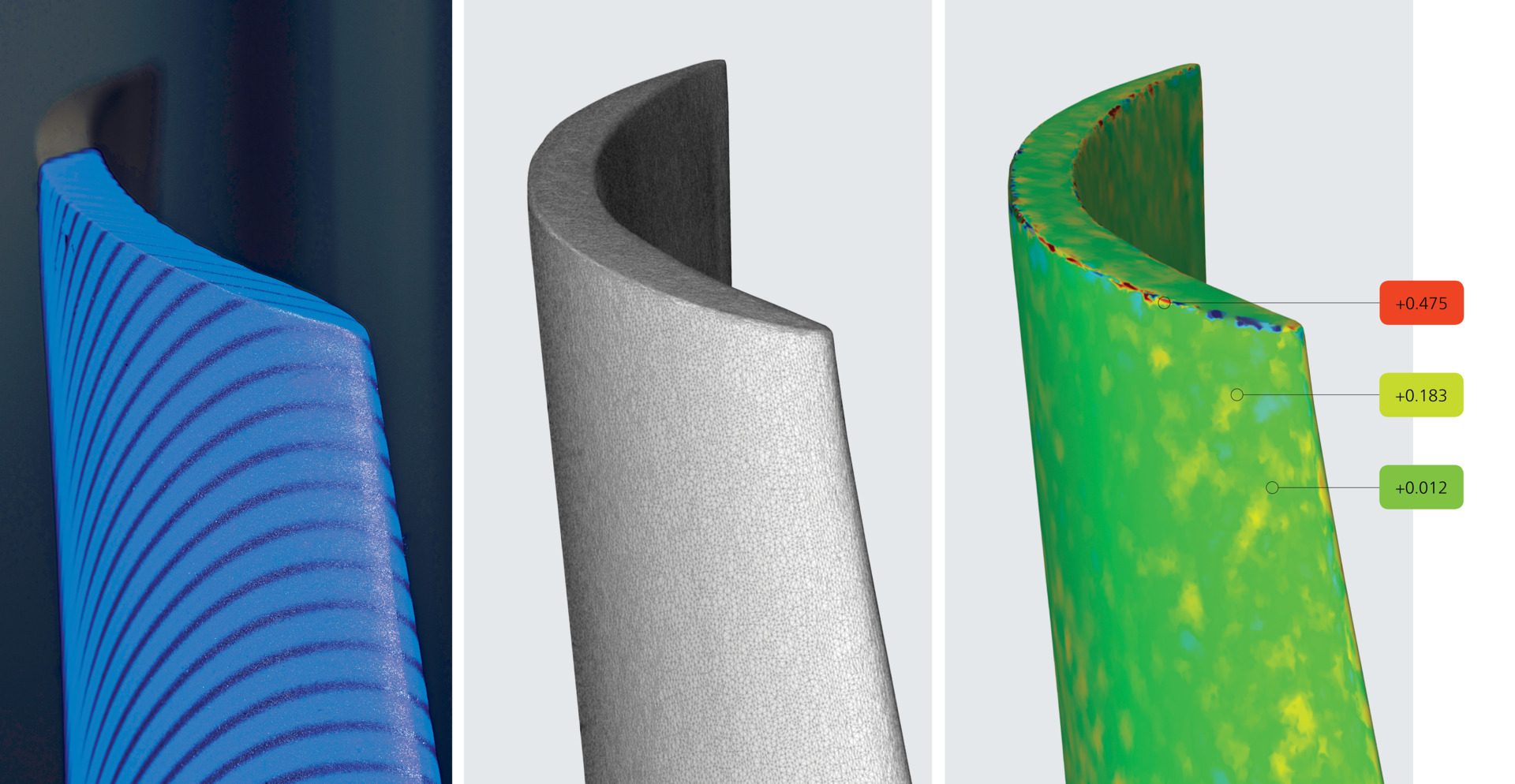

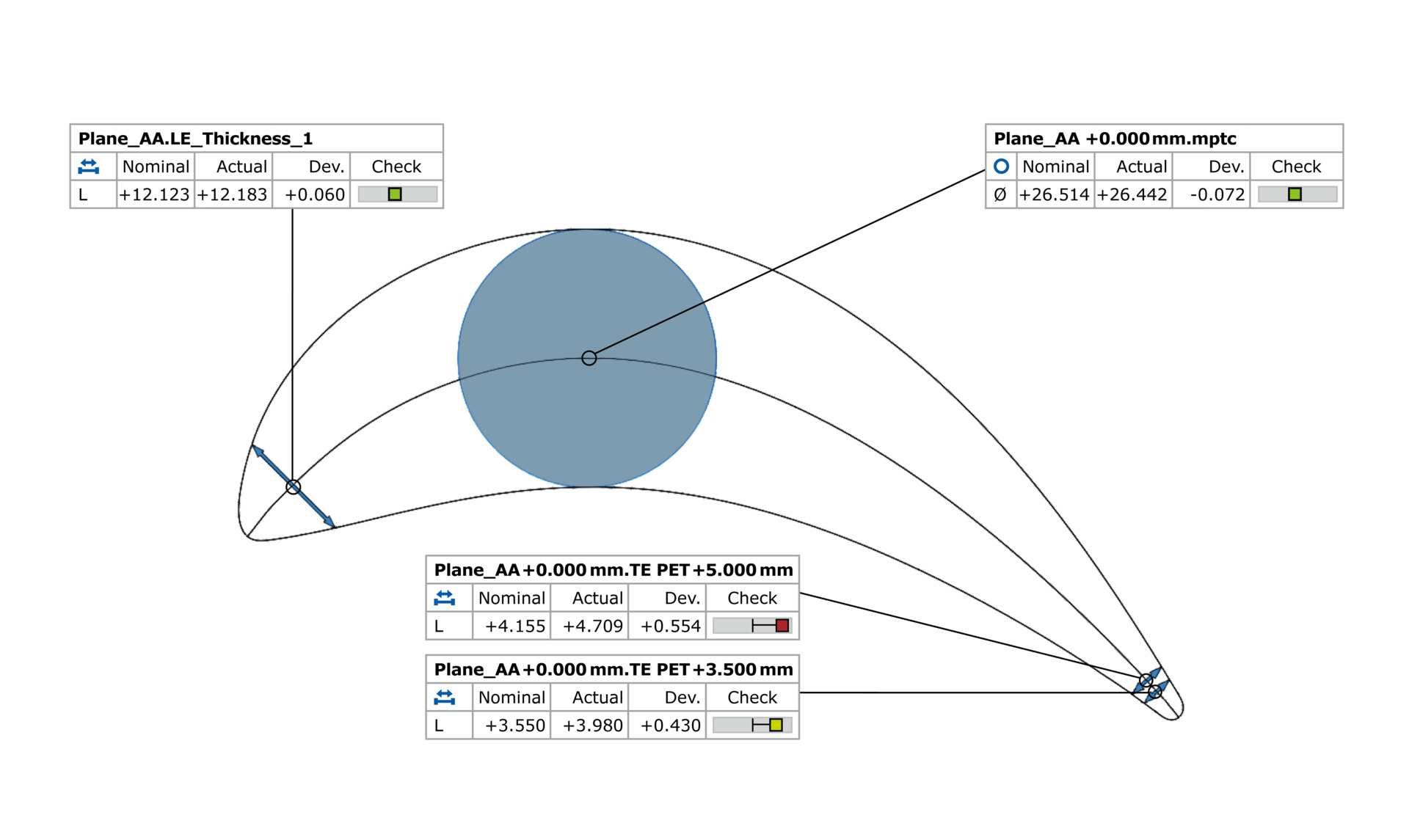

ZEISS INSPECT Airfoil ensures that everything runs smoothly when it comes to blade geometry. The software evaluates both optical and tactile measurement data from coordinate measuring machines (CMMs) – from energy supply to aircraft and shipbuilding to the electrical appliance and automotive industries.

It is also compatible with all common data formats. The software supports you in the efficient evaluation of your measurement data from design to quality control. You can also benefit from customized analysis tools for blades and airfoils.

- 3D Throat Area

- Virtual Balancing

- Create your own functions

- Save time and costs

- Suitable apps

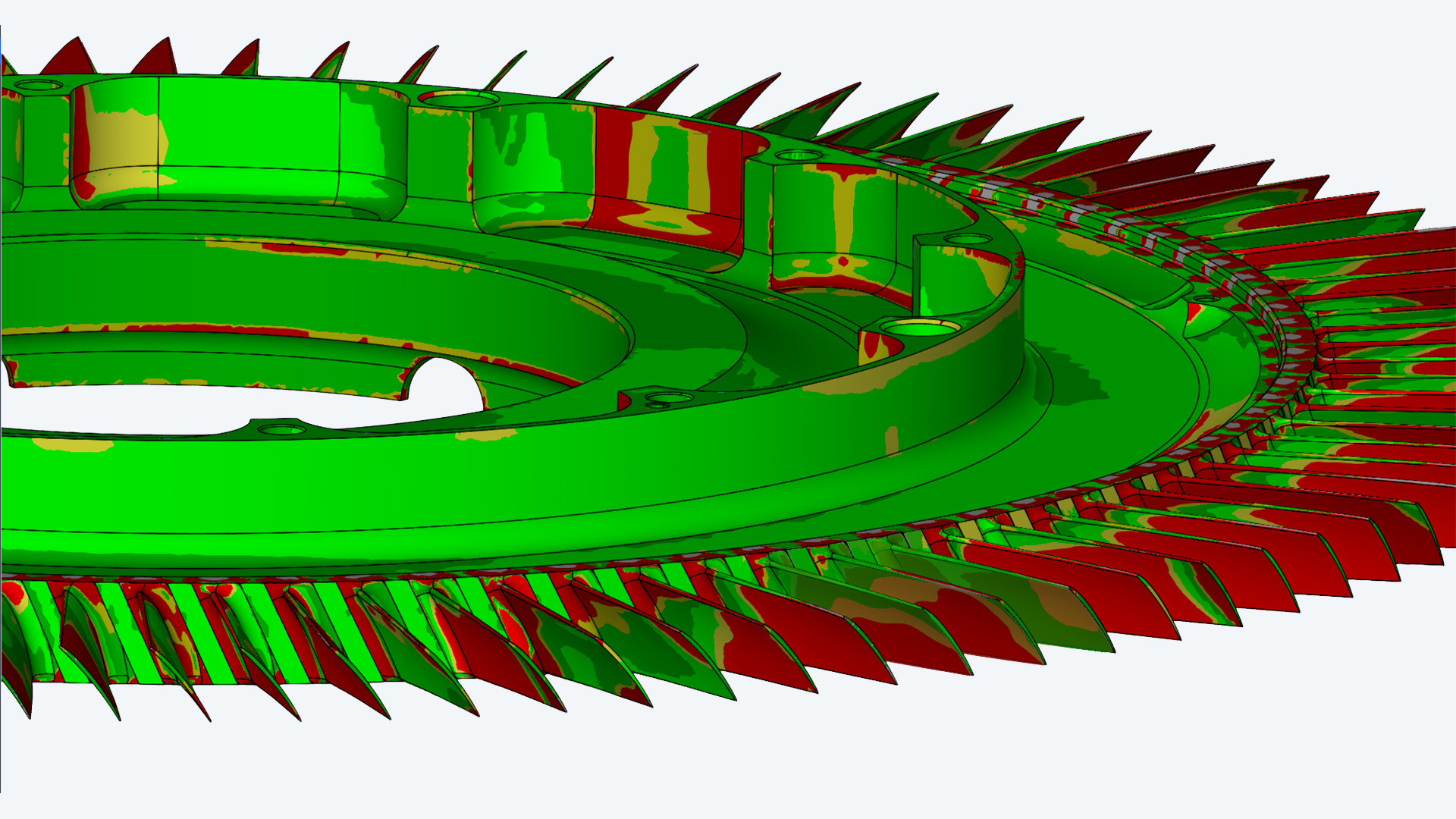

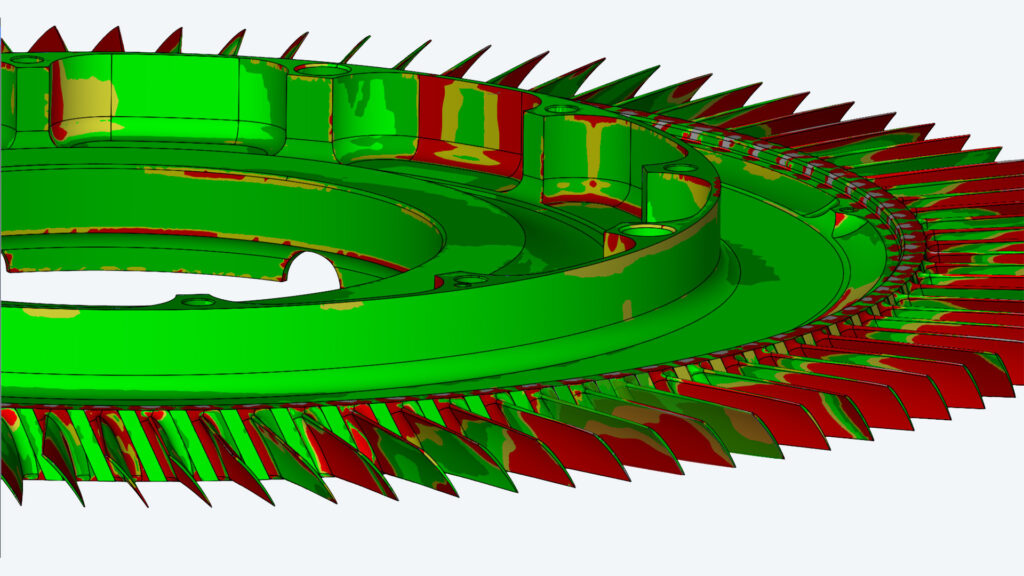

3D Throat Area

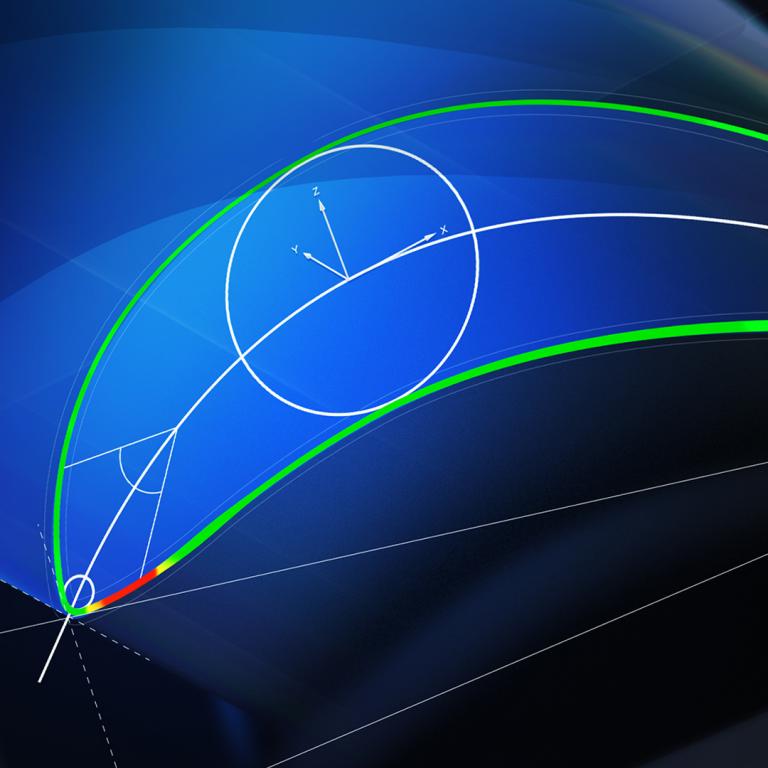

The digital analysis of the blade surface is unique on the market. ZEISS INSPECT determines the smallest three-dimensional area between two blades.

Regardless of whether it is a partial area or a closed channel, you get the geometrically narrowest cross-section.

Virtual Balancing

A digital twin saves you valuable assembly time. To avoid imbalances, use the digital 3D model to determine the ideal blade sequence before assembly.

ZEISS INSPECT will support you step by step.

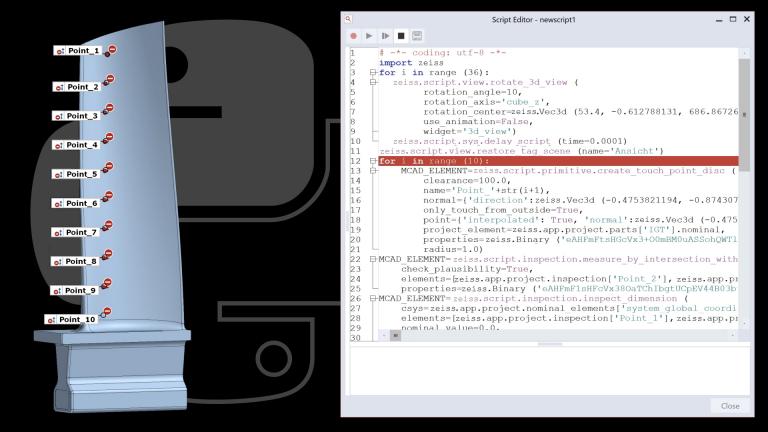

Create your own functions

Using the Python interface and the command recorder, you can record all operations performed in the software and save them in the form of a script. This code can be edited and adapted and is extended with functions that make your work easier.

Or simply take a look at one of the available apps: We have already implemented many functions here to increase efficiency and reduce process fluctuations.

Save time and costs

The same series, a new part? The parametric kernel from ZEISS INSPECT Airfoil allows you to dispense with a new inspection plan.

All inspection steps are saved in the background so that you can reuse them at any time, adapt them to new conditions and create your measurement reports. Experience a new dimension of efficiency.

Suitable apps for your tasks

With the right apps, you can expand the range of functions of ZEISS INSPECT Airfoil. There are also numerous other applications available to make your work even easier.

This also includes an app for efficient blisk measurements. All apps are available at ZEISS Quality Suite.

Frequently asked questions (FAQs)

How can ZEISS INSPECT Airfoil improve the efficiency of blade geometry analysis?

ZEISS INSPECT Airfoil improves efficiency in the analysis of blade geometries through customized 2D and 3D evaluation functions that evaluate both optical and tactile measurement data from coordinate measuring machines (CMMs). The software saves all inspection steps in the background so that they can be reused at any time and adapted to new conditions. This significantly reduces time and costs and increases productivity in the quality control of blade geometries.

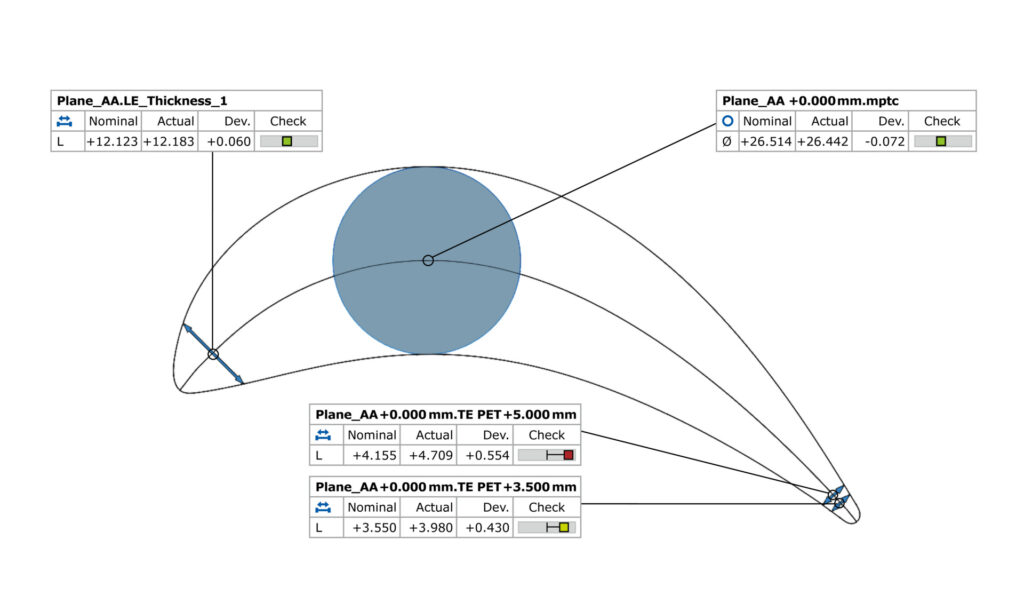

What unique analysis functions does ZEISS INSPECT Airfoil offer for turbine analysis?

ZEISS INSPECT Airfoil offers several unique analysis functions, including the 3D Throat Area and Virtual Balancing. The 3D Throat Area enables the determination of the smallest three-dimensional area between two blades, which is crucial for precise geometry analysis. Virtual Balancing helps to save assembly time by allowing the ideal sequence of blades to be determined based on a digital 3D model before assembly, thus avoiding imbalances.

What are the advantages of the Python interface in ZEISS INSPECT Airfoil?

The Python interface in ZEISS INSPECT Airfoil allows users to record all operations performed in the software and save them in the form of scripts. These scripts can be edited and customized to extend specific functions and make work easier. In addition, ZEISS INSPECT Airfoil offers a variety of available apps that increase efficiency and reduce process variations, making the software flexible and customizable to individual needs.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics