top measuring accuracy

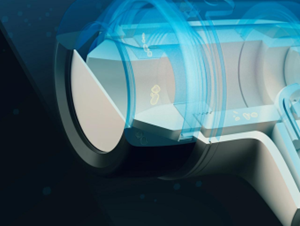

ZEISS METROTOM 6 scout

Precise measurements for the inspection and measurement of small plastic parts.

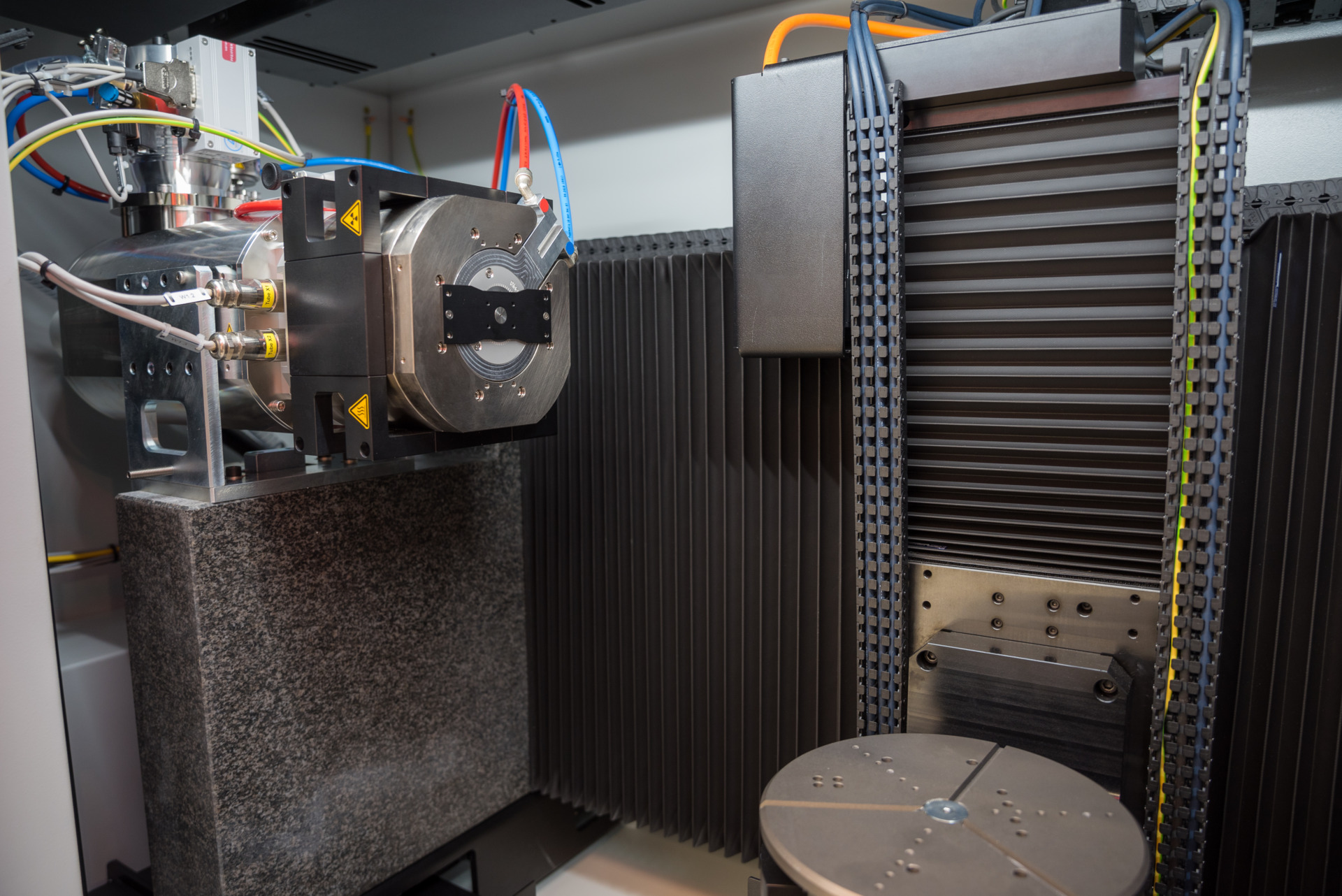

ZEISS METrotom 6 scout (GOM CT) – your ultimate solution for high-resolution CT inspection and geometry evaluation of complex components.

This advanced system not only digitizes external structures, but also reveals the finest internal details to provide you with a precise digital twin for comprehensive analysis and comparison.

- Maximum resolution

- Highest measuring accuracy

- 5-axis kinematics

- Software for data acquisition and inspection

Maximum resolution

ZEISS METrotom 6 scout (GOM CT) delivers impressive accuracy when digitizing components.

This is partly due to the fact that a high-resolution X-ray detector is used for data acquisition and partly due to the fact that each component is always measured in the optimum measuring position.

Highest measuring accuracy

The METROTOM 6 scout uses advanced ZEISS technology to generate its precise 3D measurement data. The system ensures maximum accuracy by intelligently linking algorithms along the measurement chain and digitally modeling the measurement space.

The mechanical optimization of all relevant components also provides a basis for reliable measurement results. This makes it possible for the METROTOM 6 scout to provide reliable information about the quality of the components and simplify further analyses.

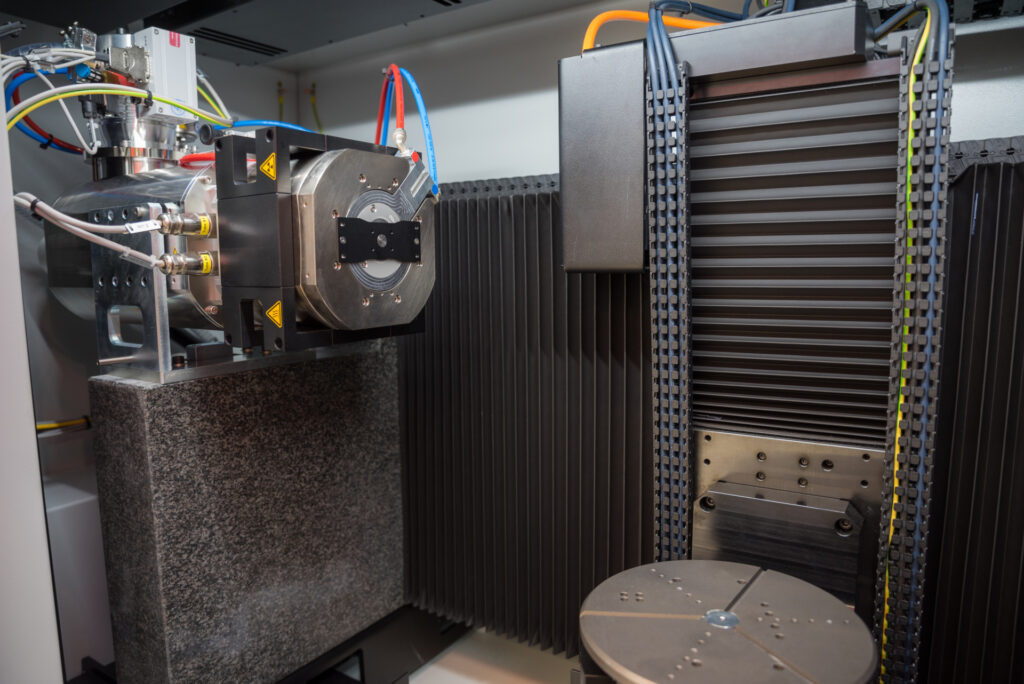

Centers parts automatically

A 5-axis kinematic system with integrated centering table positions the part optimally in the measuring volume. The component is simply placed on the rotary table – the rest is done automatically by the software.

One software

The device is controlled and the data analyzed using a single software package. As a result, additional software packages or intermediate steps are avoided.

This leads to a considerable simplification of the entire process chain, from data acquisition and inspection to the creation of the measurement report.

ZEISS INSPECT X-Ray

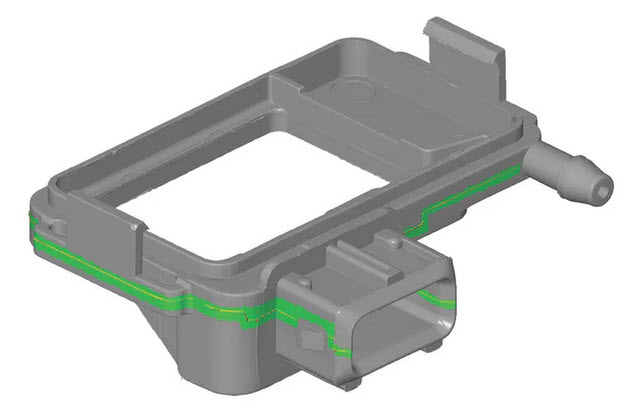

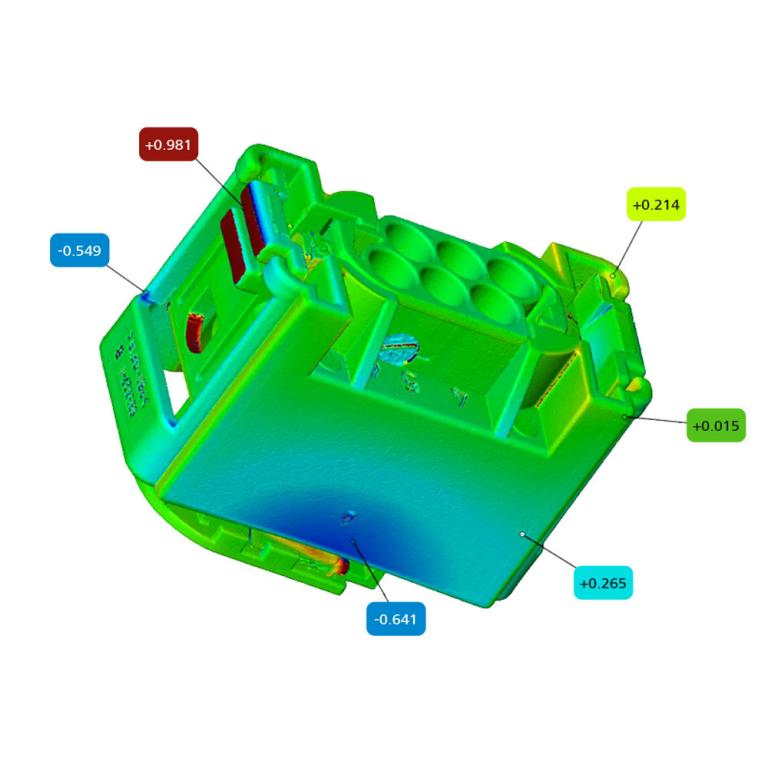

ZEISS INSPECT X-Ray enables comprehensive 3D analysis of CT data to evaluate components and optimize the manufacturing process.

It offers sectional images for detailed inspection, automatic defect analysis, comparison of volume data with CAD and clear report generation. User-friendly and powerful – CT data analysis made easy.

Frequently asked questions!

What distinguishes the METROTOM 6 scout system from ZEISS?

The ZEISS METrotom 6 scout is a very powerful and user-friendly 3D CT system for very precise and high-resolution inspection and analysis applications of small to medium-sized parts and assemblies. The focus is on the measurement of plastic parts and castings. (Aluminum/Magnesium)

How is the measuring accuracy of the system ensured?

The ZEISS METrotom 6 scout uses modern algorithms across the entire measurement chain as well as digital measurement room modelling for optimized internal calibration. Active temperature management and DAkkS-certified calibration for tracing the measurement results round off the overall concept for ensuring system precision.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics