ZEISS ScanCobot

Perfect combination for simple and automated inspection tasks.

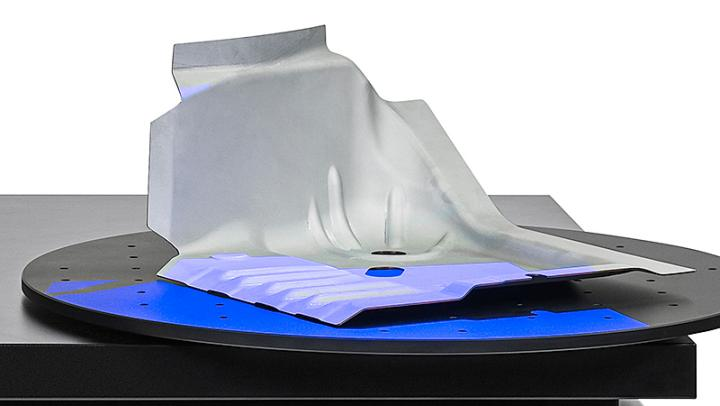

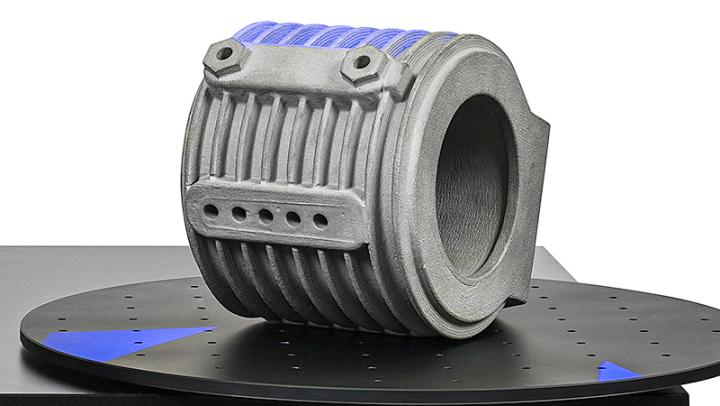

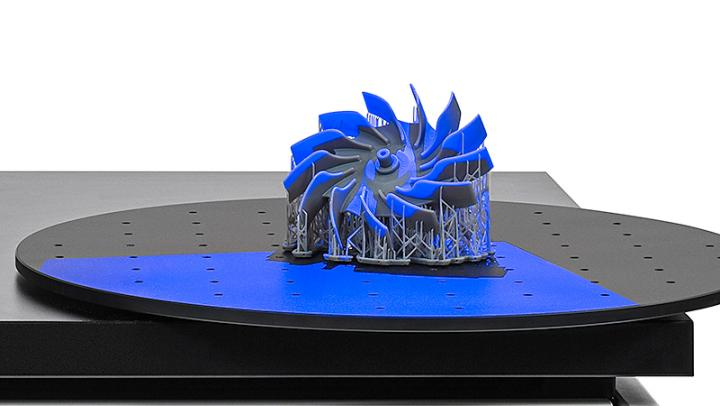

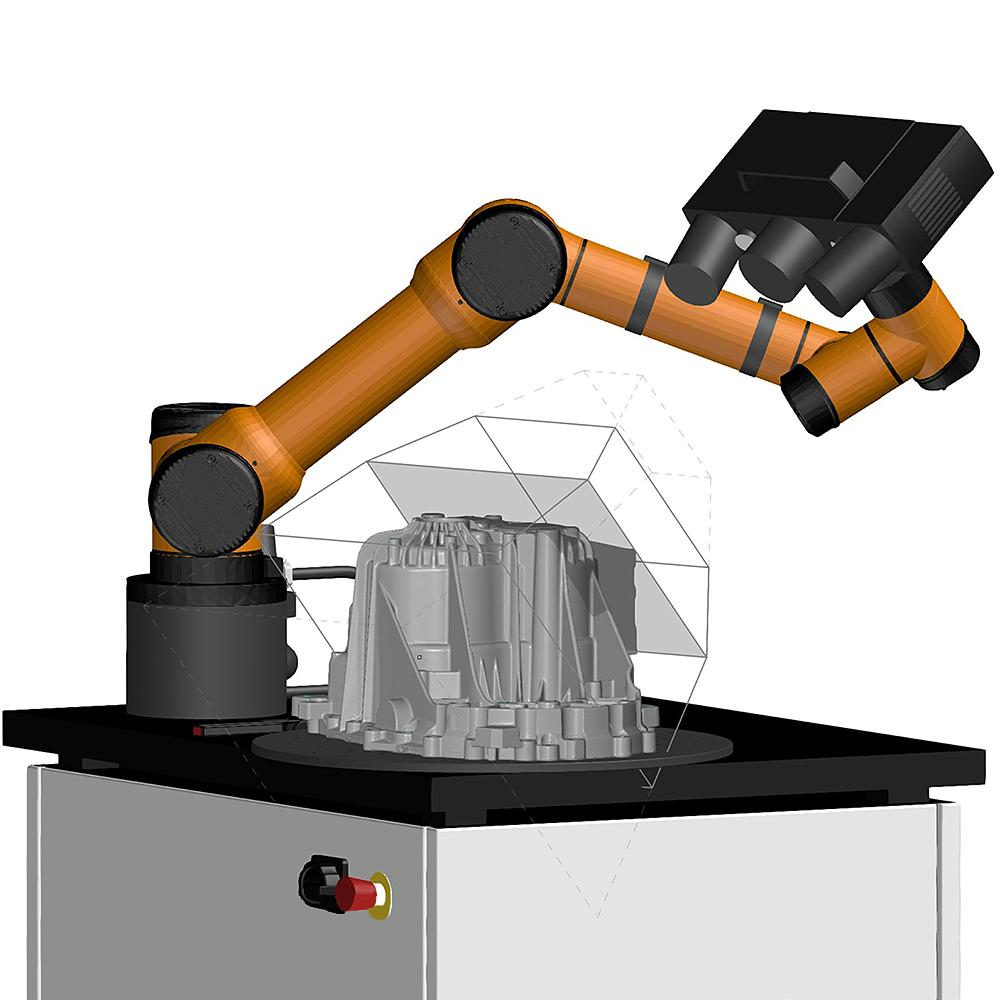

ZEISS ScanCobot is a mobile measuring station with a collaborative robot, motorized turntable and powerful software. The system is particularly suitable for the efficient quality control of small and medium-sized components made of plastic, metal or cast iron. It can be used in pre-production phases such as design and prototyping as well as for market launches.

The optical 3D scanner ATOS Q captures the component geometry in a short time and with a high level of detail, creating a reliable basis for easy interpretation of the measurement data. Efficient scanning and subsequent automatic inspection can significantly speed up quality control processes.

- Simple robot programming in the Virual Measuring Room

- ATOS Q – High-speed 3D scanner with the highest data quality

- Powerful software incl. “Virual Measuring Room”

- “Offline” programming possible

Simple robot programming in the Virual Measuring Room

The ZEISS ScanCobot is programmed via the Virual Measuring Room (VMR). The VMR is the central control and measurement planning software for mapping the entire measurement process.

The CAD data set of the component to be tested is imported into the software together with the associated measurement plan. The software calculates the necessary sensor positions and robot paths fully automatically at the touch of a button.

ATOS Q – High-speed 3D scanner with the highest data quality

ATOS Q impresses with its outstanding performance thanks to the Blue Light Equalizer and fast data processing. Industrial connections with fiber optic cables and robust plug connections ensure high data throughput. The interchangeable lenses enable precise measurements of small and medium-sized components in various industries.

Technical information and safety

ZEISS ScanCobot is a mobile measuring station that can be moved quickly and easily from one location to another. Only a standard socket is required for commissioning. In order to comply with market-specific safety regulations, the system can be equipped with a standardized safety housing.

975 x 775

1000

Standard, 100 – 240 V (1-phase, 16A)

500

50

ATOS Q

Frequently asked questions (FAQs)

When is the ZEISS ScanCobot used?

The system is often used for changing measurement tasks and different operating personnel. The automated and therefore user-independent data acquisition ensures maximum reproducibility of the measurement results.

What prior knowledge is required for operation?

No special prior knowledge is required. All the necessary knowledge is imparted during the product training. The system is controlled exclusively from the pre-installed system software. The classic robot programming via teach pendant is therefore completely eliminated.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics