ScanBox Series 6

Efficient 3D measurement solutions for maximum production output.

The ZEISS ScanBox Series 6 offers an optimal solution for quality assurance in industrial production. Designed for large and heavy components, it enables the fully automatic inspection of surface deviations between 3D actual coordinates and CAD data in two versions.

Simultaneous loading and measurement significantly increases throughput and guarantees fast, precise measurements and flexible component changes for efficient production control.

- Two separate work areas

- Fast loading and unloading

- ATOS 5 & ATOS 5X Integration

- Virual Measuring Room

- Use in shift operation

REFERENCE: Coko (plastic injection molding)

The company Coko-Werk GmbH & Co KG has a long tradition in plastic injection molding. The ATOS ScanBox 6235 optical 3D measuring machine is used at the development & innovation site in Bad Salzuflen for efficient quality control in the production process.

Two separate work areas

The optical 3D measuring machine optimizes your production cycles with two separate work areas. Components such as doors, tailgates or battery modules with dimensions of up to 3500 mm and a weight of up to 5000 kg can be positioned on the rotary tables.

The integrated automatic gates ensure safe and efficient operation of the two work areas, supporting a smooth and productive measuring environment.

Fast loading and unloading

The generously dimensioned entry areas of the ZEISS ScanBox 6135 and 6235 considerably facilitate the use of various loading devices such as cranes, forklift trucks or pallet trucks. With the multi-part fixture, attachments can be measured more quickly as there is no need to change the measuring fixture.

The multi-part fixture can be easily positioned via the Human Machine Interface (HMI) so that the attachments can be conveniently changed from the front.

ATOS 5 & ATOS 5X Integration

Full-surface detection of complex geometries: ATOS 5 sets new standards with advanced camera technology, a powerful light source and efficient software. Especially for shiny and dark surfaces as well as fine structures and edges, this technology achieves an outstanding level of performance by shortening the overall measurement time while delivering precise 3D measurement data.

ATOS 5X also uses the integrated Laser Light Compressor to generate ultra-bright light, which enables measuring fields of up to 1000 mm with very short exposure times.

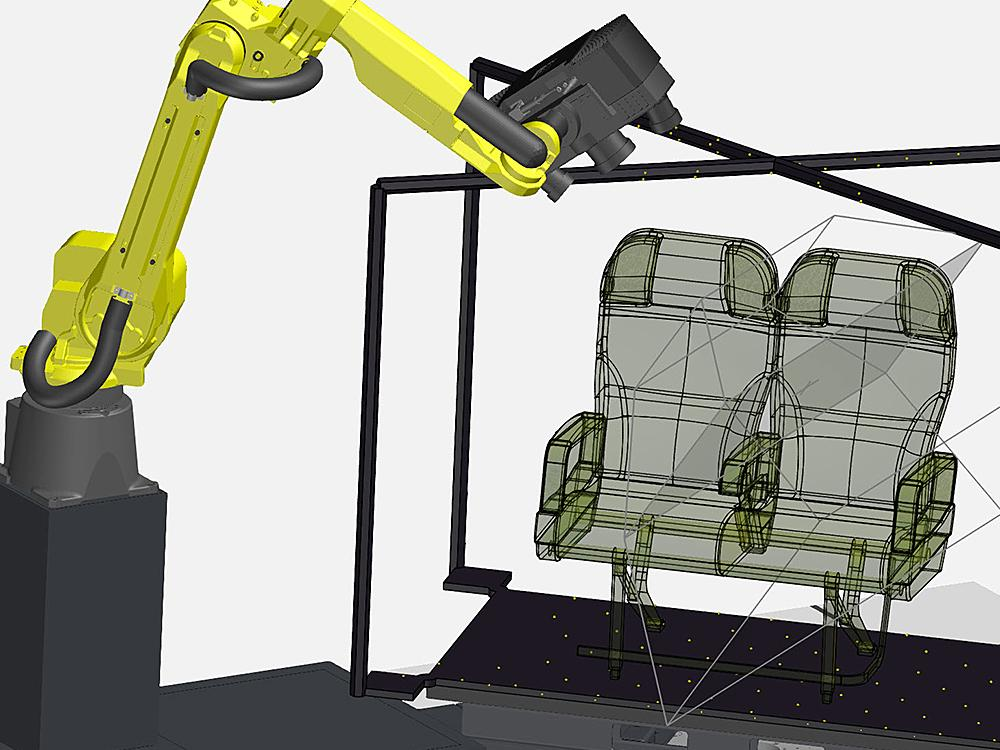

Virual Measuring Room

The virtual measuring room (VMR) is the central control and planning tool for ZEISS ScanBox. Here, the real environment is depicted in a precise virtual simulation.

The VMR contains a robot with sensor, enables the programming of the robot paths and the creation and execution of the measurement plan. Thanks to the VMR, no special robot knowledge is required.

Frequently asked questions (FAQs)

Welche Vorteile bietet die ZEISS ScanBox Serie 6 für die automatisierte 3D-Messtechnik?

The ZEISS ScanBox Series 6 offers a state-of-the-art solution for automated 3DMetrology applications in industrial production. It enables the precise measurement of large components and optimizes production throughput by simultaneous loading and measuring.

Wie unterscheidet sich die ZEISS ScanBox Series 6 von den Vorgängermodellen in Bezug auf Flexibilität und Skalierbarkeit?

Compared to its predecessor models, the ZEISS ScanBox Series 6 is characterized by its extended modularity, which makes it possible to efficiently measure different component sizes and weights. It offers flexible configuration options and supports integration into a wide range of production environments.

Welche Rolle spielt die ZEISS ScanBox Serie 6 bei der Qualitätssicherung und Prozessoptimierung?

The ZEISS ScanBox Series 6 plays a decisive role in industrial quality assurance by enabling fast and efficient 3D measurements on complex components. It can be easily operated in series production by semi-skilled workers – trained application personnel are only required for the initial program template creation. The optimized loading concept is specially designed for high throughput and maximizes the output of the system.

We advise you personally!

Gladly there for you