ScanBox Series 4

Inspect small components up to 500 mm quickly, precisely and flexibly – anywhere and at any time thanks to the plug & play concept!

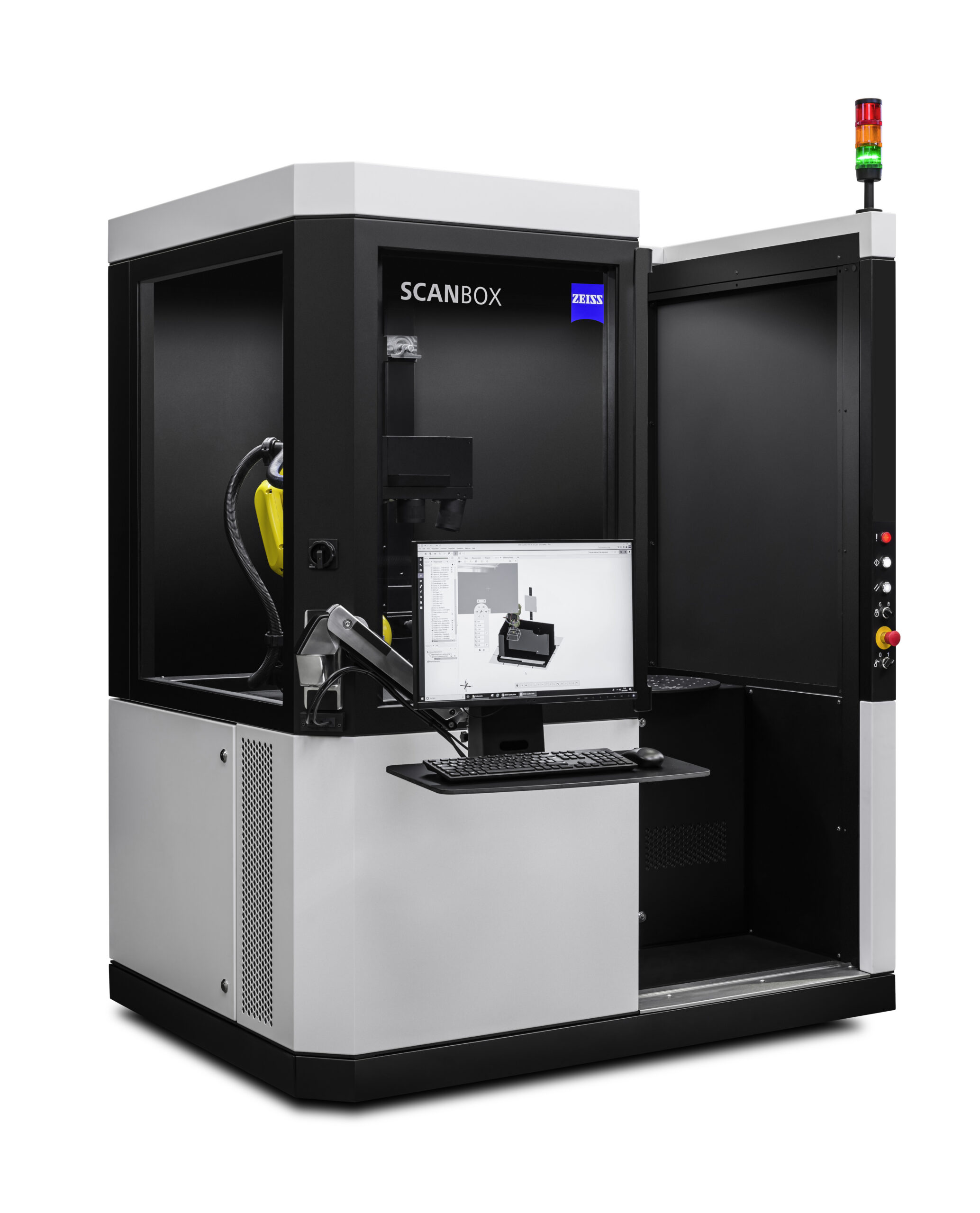

The ZEISS ScanBox 4105 enables fast and efficient inspections of small and complex components up to 500 mm. The mobile system is immediately ready for use and can be flexibly positioned in the production environment.

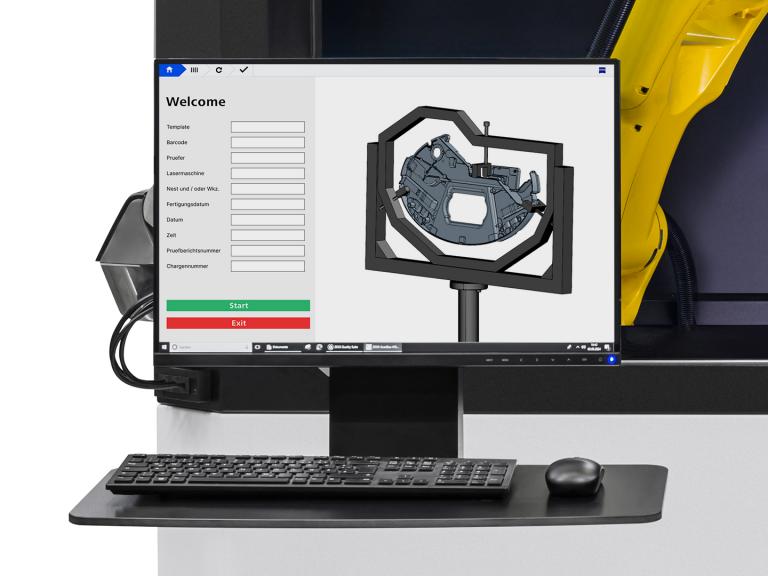

Simply start your measurement processes via the Kiosk interface and the Virual Measuring Room (VMR) in the ZEISS INSPECT software.

- Plug & Play

- Simple operation

- Precise & fast

- Virual Measuring Room

- Production-related automation

Plug & Play

The ZEISS ScanBox 4105 works with 230 V and can be configured quickly and easily. In addition, the device can be flexibly converted and reconnected according to the “plug & play” principle.

Simply connect, switch on and get started!

Simple operation

Automated process control made easy The ZEISS ScanBox 4105 is easy to operate via the user-friendly kiosk interface.

Your employees in the factory do not need any special knowledge: Simply insert the component, select the desired measuring program and press the start button – done!

Precise & fast

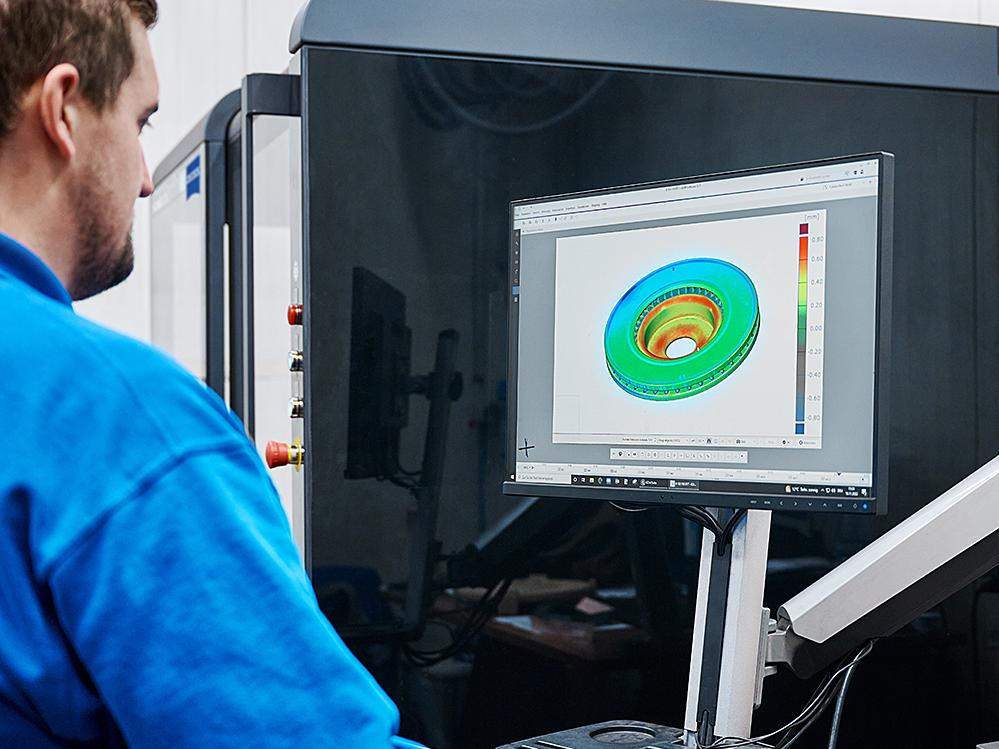

ATOS Q for the highest Metrology requirements. With the integrated ATOS Q sensor, you can quickly obtain detailed quality information for precise analyses.

By using the multi-part fixture, you can measure several components in one run, even in 24/7 operation. Increase your throughput, minimize rejects and standardize your quality assurance effectively.

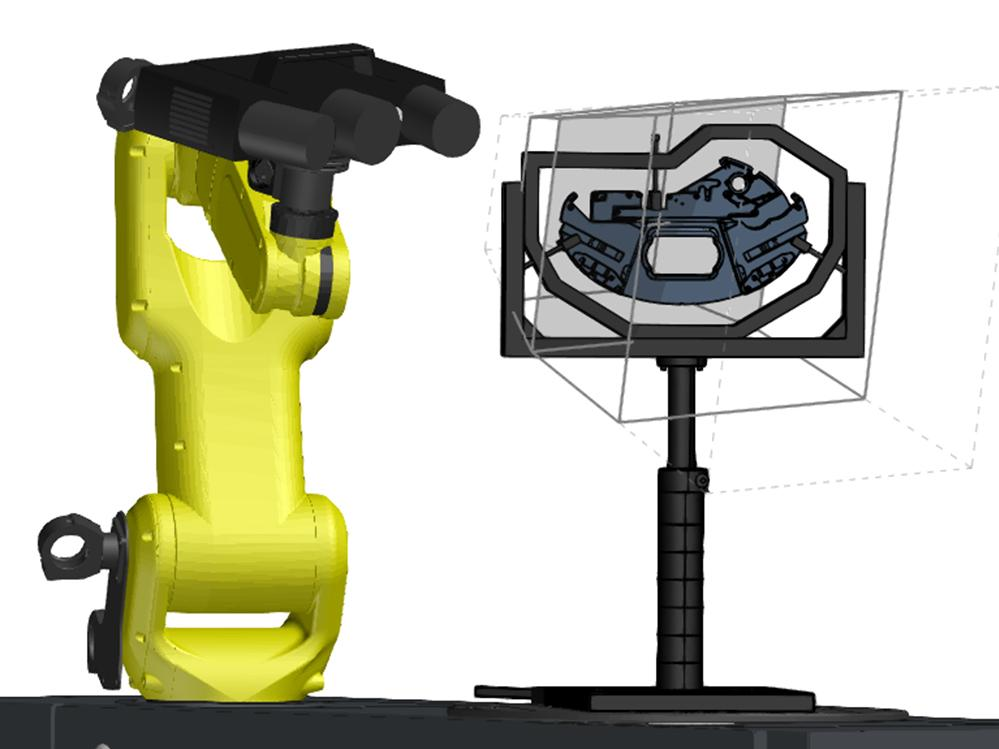

Virual Measuring Room

The Virual Measuring Room (VMR) is the central control and planning software for the optical 3D measuring machine. This is where the real environment is mapped in a precise virtual simulation.

The VMR includes a robot with sensor, the programming of the robot paths and the creation and execution of the measurement plan. Thanks to the VMR, no special robot knowledge is required: all movements are simulated in advance and checked for safety before execution.

Analysis tool included

WESTCAM offers everything from a single source: scanning, checking and reporting for detailed target/actual comparisons as well as shape and position tolerances. The easy-to-understand results enable you to implement any necessary corrections directly.

Carry out comprehensive analyses, create detailed reports and integrate the measurement results seamlessly into your existing processes.

Frequently asked questions (FAQs)

Welche automatisierten Lösungen werden mit der ZEISS ScanBox Serie 4 für die optische 3D-Messtechnik angeboten?

The ZEISS ScanBox Series 4 offers automated solutions for precise optical 3D measurements in industry. It integrates the advanced ATOS Q sensor for fast and accurate measurement of small to medium sized components and complex geometries up to 500mm.

Was sind die Hauptmerkmale der ZEISS ScanBox Serie 4 im Vergleich zu den Vorgängermodellen?

The main features of the ATOS ScanBox Series 4 are improved speed and accuracy in 3D measurement, increased flexibility for a wide range of component sizes and intuitive operation thanks to automated processes.

Wie unterstützt die ZEISS ScanBox Serie 4 die industrielle Fertigung und Qualitätssicherung?

The main application is the quality control of complex parts and components during series production in single or multi-shift operation. Operation in series production can easily be carried out by semi-skilled workers – trained application personnel are only required for the initial program template creation.

We advise you personally!

Gladly there for you