ZEISS T-SCAN hawk 2

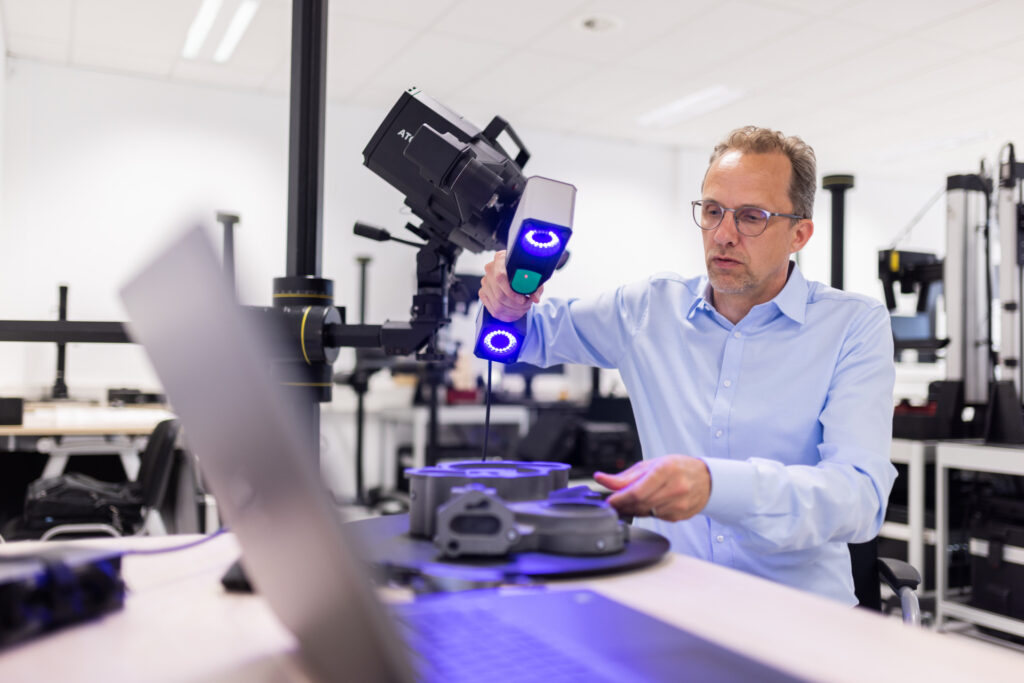

ZEISS T-SCAN hawk 2 – Hand-guided precision, developed and produced by ZEISS.

The portable T-SCAN hawk 2, the next generation lightweight 3D laser scanner, is characterized by Metrology precision and remarkable ease of use. No matter the task or location, it’s a powerful tool that fits right in the palm of your hand.

- Flexible measuring fields

- Satellite Mode

- One software for data acquisition & inspection

- Outdoor measurements possible

- Flexible depth of field

A solution that adapts to your workflow

T-SCAN hawk 2 is intuitive to use and adapts easily to the movements of your hand.

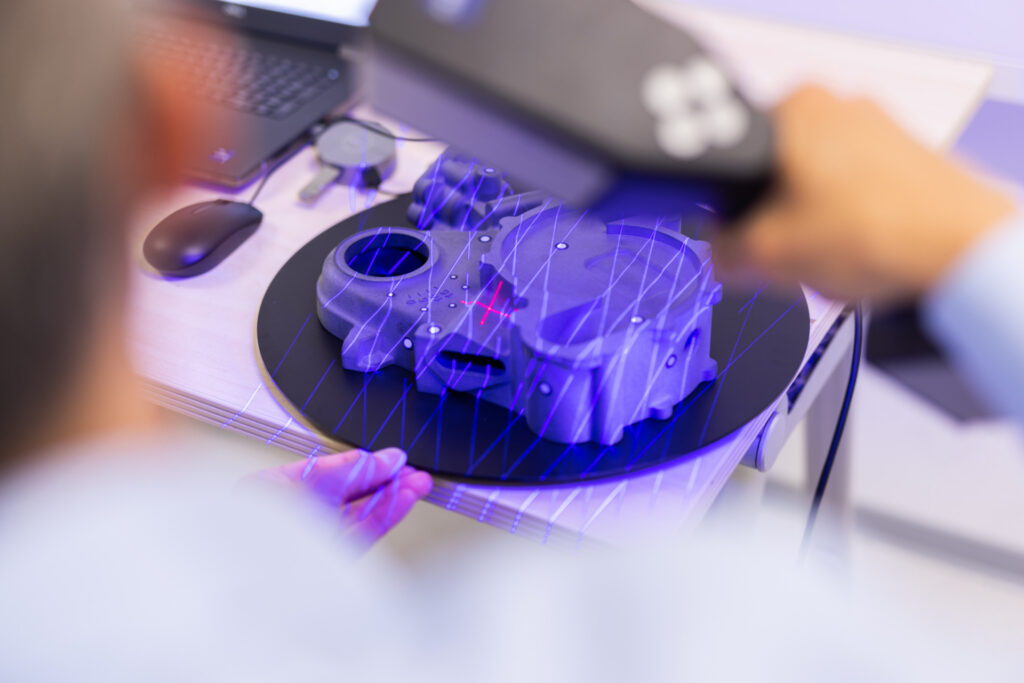

Achieving great things with the new Satellite Mode

T-SCAN hawk 2 is the first portable laser scanner with the new Satellite Mode for scanning objects up to several meters. The classic built-in photogrammetry with coded markers is no longer required, without compromising on accuracy.

The all-rounder software for 3D inspection

T-SCAN hawk 2 works with ZEISS INSPECT, the proven standard in 3DMetrology and part of ZEISS Quality Suite. Use the free trial version of ZEISS INSPECT Optical 3D Pro for 14 days.

Features

The all-rounder software for 3D inspection

T-SCAN hawk 2 works with ZEISS INSPECT, the proven standard in 3DMetrology and part of ZEISS Quality Suite. Use the free trial version of ZEISS INSPECT Optical 3D Pro for 14 days.

Operation at the touch of a button

T-SCAN hawk 2 has four buttons that you can use to start and navigate your workflow directly. You do not need to operate the software separately on your laptop.

Strong performance on dark and glossy surfaces

T-SCAN hawk 2 supports scanning on a wide range of materials and surfaces and provides 3D measurement data with the highest precision.

Technical data

- High-speed scanning: Included (several blue laser crosses)

- Scan of deep pockets: Included (single blue laser line)

- Flexible depth of field: Included (on-object distance radar)

- Scan of fine details: Included

- Recalibration of the sensor in a single operation: Included (Hyperscale)

- Large parts: Included (Satellite Mode, no coded markers required)

- Carbon fiber length standards: Certified (DAkks / ILAC) (1)

- Volumetric accuracy: 0.02 mm + 0.015 mm/m (2)

- Laser class (IEC 60825-1:2014): Class 2 (eye-safe)

- Weight: < 1kg

- Cable: 10m (ultra-light)

- Software: ZEISS Quality Suite / ZEISS INSPECT

- Complete remote workflow: Supports

Frequently asked questions (FAQs)

Wann sollte ich den T-SCAN hawk 2 verwenden?

With high requirements in terms of mobility and flexibility, the new T-SCAN hawk 2 offers the ideal combination of simple operation and sophisticated Metrology technology with a minimum of necessary equipment.

You can switch between high-resolution measurement and large-area data acquisition with just one click without any conversion work. The integrated photogrammetry function maximizes measurement accuracy for large objects.

Welche typischen Anwendungsfelder bedient der T-SCAN hawk 2?

The T-SCAN hawk 2 is the ideal companion for reverse engineering applications, such as CAD model creation for revision work, archiving tools and molds, or sculptures from the field of art and culture. From small to large, the T-SCAN hawk 2 covers a wide range of components.

Maintenance and repair tasks require rapid measurement in areas that are often difficult to access: with the T-SCAN hawk 2, measurements can be carried out both in the assembly hall and outdoors.

3D Metrology comes to the measurement object and not the other way around: Comparison of measurement data with the existing 3D CAD model or evaluation of measurement data using classic dimensions – with the ZEISS INSPECT software you have a wide range of evaluation options at your disposal.

Warum T-SCAN hawk 2 bei WESTCAM?

Buying a system is a matter of trust!

Trust WESTCAM as an official & certified quality partner!

As the exclusive ZEISS Certified Metrology Partner for Austria, Switzerland & Liechtenstein, we are the first choice for:

- Measurement system inspection in accordance with VDI/VDE 2634 Sheet 3 (inspections as part of the

- recurring measuring equipment monitoring)

- Regular hardware maintenance and, if necessary, repair for your ZEISS optical system

- Software maintenance (SMA) for your measurement system and inspection software licenses

- Robot-supported automation via ZEISS ScanBox or ZEISS ScanCobot for your ATOS system

- Training for new employees

- Consumables and accessories such as reference marks, spray and calculators for your ZEISS measuring equipment

We take care of the right system selection and provide you with comprehensive advice. We have access to the complete GOM/ZEISS Metrology portfolio and can offer you the right solution from a wide range of systems – whether manual, semi-automatic or automated with our ATOS ScanBox solutions.

We also take care of the installation and implementation of the purchased trade fair equipment at your site and provide both training and ongoing support.

We are your first point of contact for product and application questions of all kinds and offer on-site hardware service, repairs and measuring system acceptance for all Metrology systems.

Just send a short e-mail to 3d-scan@westcam.at or 3d-scan@westcam.ch and we will be happy to show you how the T-SCAN hawk 2 can help you.

We advise you personally!

Gladly there for you