GRIPPLANNING System

AWARD-WINNING software package for automated position calculation and calculation of grip points for manipulation tasks using robots. (Handling Award 2016)

The problem solver and its areas of application:

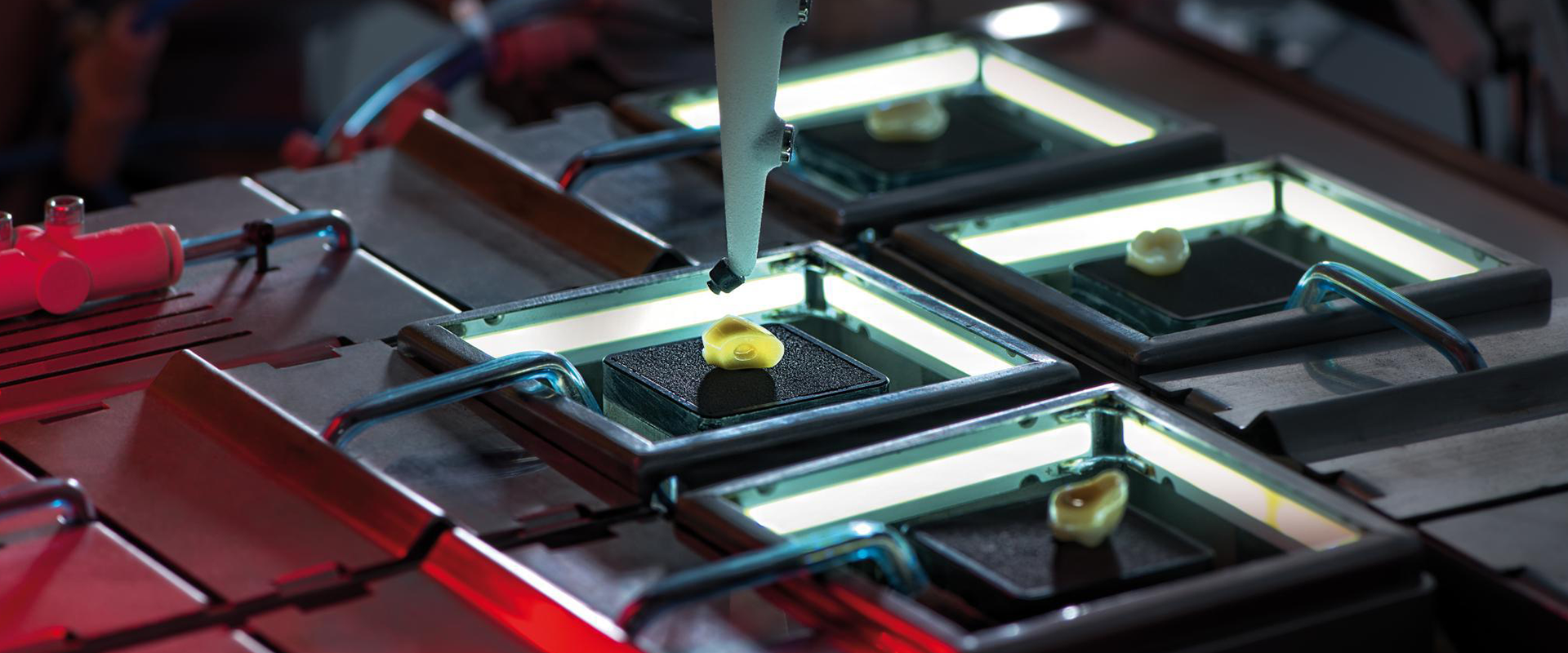

Teach-in of freely positioned, complex or organically shaped components with a large variety of objects for automated pick & place applications. Can also be used for simple parts with a high variety of types.

This might also interest you:

- No manual pre-orientation and alignment of the components necessary

- Automatic teach-in process massively reduces the time required and manual errors

- “Teaching” of any 3D data sets for a wide range of applications

- Robot-calibratable gripper tool for small components (offset suction cup)

- Can be flexibly adapted to customer-specific gripper geometries

Features

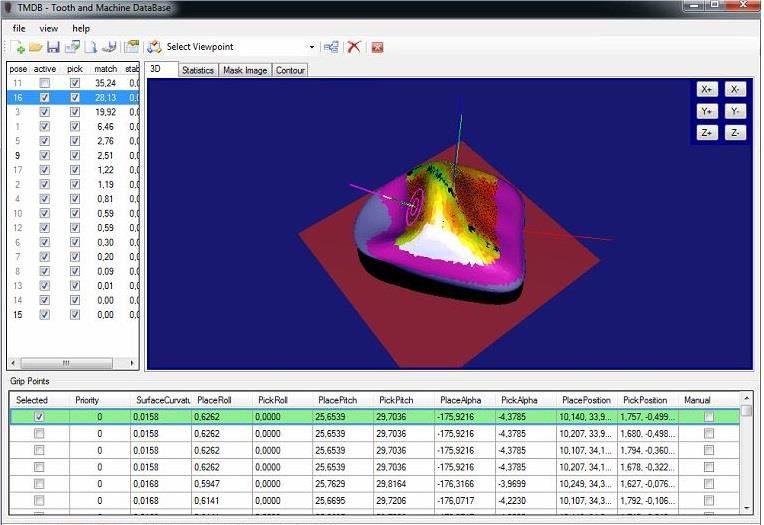

Fully automatic pre-calculation of possible stable positions with handle positions based on CAD geometry

Manual optimization possible if required by selecting alternative handle positions

Statistics on position, probability of occurrence and pick & place quality returned from the Pick & place systems

REFERENCE PROJECT

TMM© – Tooth Mounting Machine

(European patent No 2925254 and Brazilian patent NoBR 11 2015 012500 0)

Manipulation of denture teeth

Hundreds of differently shaped tooth models with a large number of stable layers are placed in the correct position in a counter mold with a cycle time of up to less than 2 seconds.

We are ready for your project!

Even if you don’t produce any teeth!

Which complex challenge can we realize for you with the software license for Gripplanning ?

Contact Harald Unterrainer right away.

This might also interest you:

Frequently asked questions (FAQs)

Gripplanning – was ist das und wie wird es eingesetzt?

Systems for detecting the position of parts in robot systems are essential for automating processes.

Gripplanning is a system for automated position calculation and calculation of grip points for manipulation tasks using robots. No manual pre-orientation and alignment of the components is necessary. An automatic teach-in process massively reduces the time required and manual errors.

Funktioniert Gripplanning bei großer Teilevielfalt mit komplex-/organisch-/frei-geformten Teilen?

Yes, if there is a very high component variety of complex/organic/free-formed parts in your production, “manual teaching” is often not efficient. We have the right automation solution in the Pick & Place area for you, with which you can automatically teach-in parts, sort them and move them with Pick & Place. The WESTCAMGripplanning© software supports these processes.

Ihr Unternehmen hat bereits Greifroboter im Einsatz – Sie möchten sich über die Vorteile von Gripplanning informieren?

Anytime with pleasure! We are at your disposal for a free consultation. Contact us right away. We look forward to seeing you!