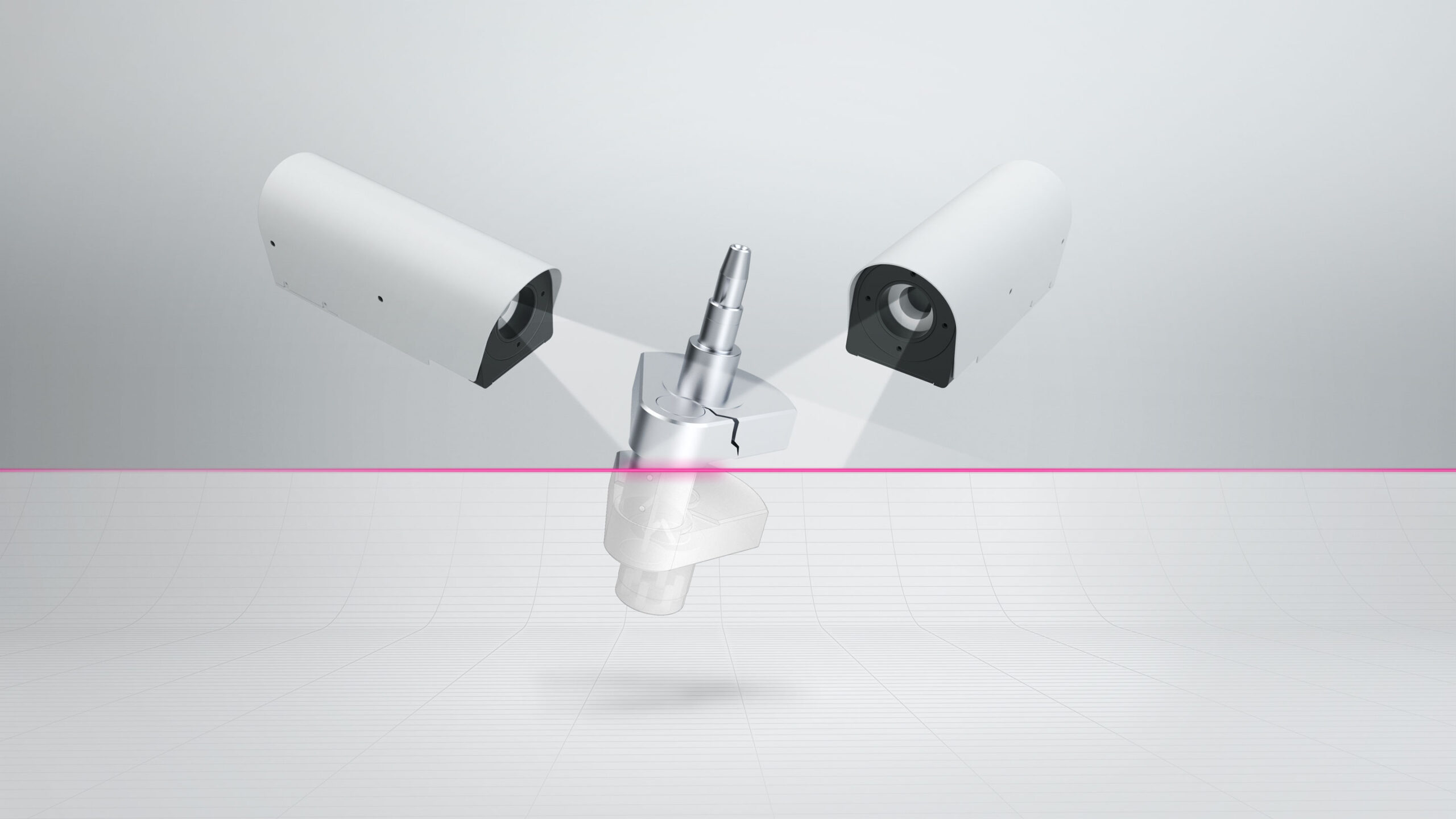

BVS-R system

Crack detection using Image processing – versatile! Discover the

future of quality control with our crack detection system.

With the BVS-R product family for Crack detection, you have the following options:

- Automated image processing

- Automated crack detection

- Automated measurement

- Increased efficiency through Multi Test Bench

Reliably detect cracks – thanks to BVS-R. With our standard BVS-R system, data from 1 to 6 cameras can be recorded simultaneously.

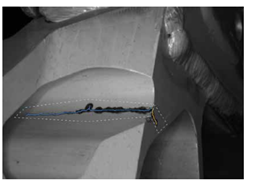

Automatic Crack detection and monitoring of the crack progress is displayed. In addition, valuable information such as time, load changes and image number stamps are integrated for each image.

This might also interest you:

- Easy-to-use software

- Simultaneous monitoring with up to 6 cameras

- Output of the crack length

- High quality documentation

- 24/7 availability

- Shorter test cycles

- Customized solutions

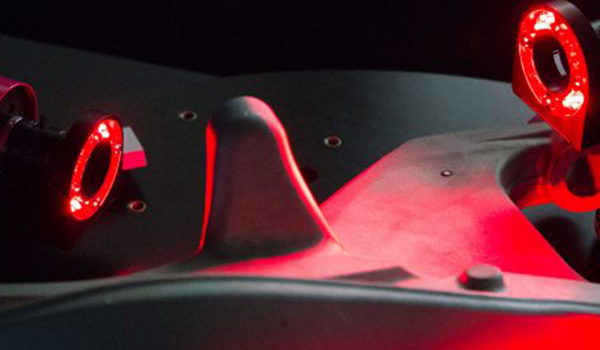

Practical example: Automotive component on the fatigue strength test bench for test life cycles. Shown here: Crack formation and crack progression during the test procedure.

How to optimize your quality control

- Continuous progress monitoring without personnel

- 24/7 monitoring of the test benches incl. crack pattern data recording

- Percentage-accurate postscript evaluation of the test progress and crack formation

- High quality documentation and evaluation

Crack detection on the test bench

- Test run is completely automated without pauses →15 % time saving on average

- Reduction in inspection time → approx. 4 hours saved per inspection (on average)

- Crack initiation time and crack progress is determined to the exact percentage

- Automatic stop of the test run when a predefined crack length is reached

- Crack formation and crack progress are clearly documented

- Crack formation video from the individual shots

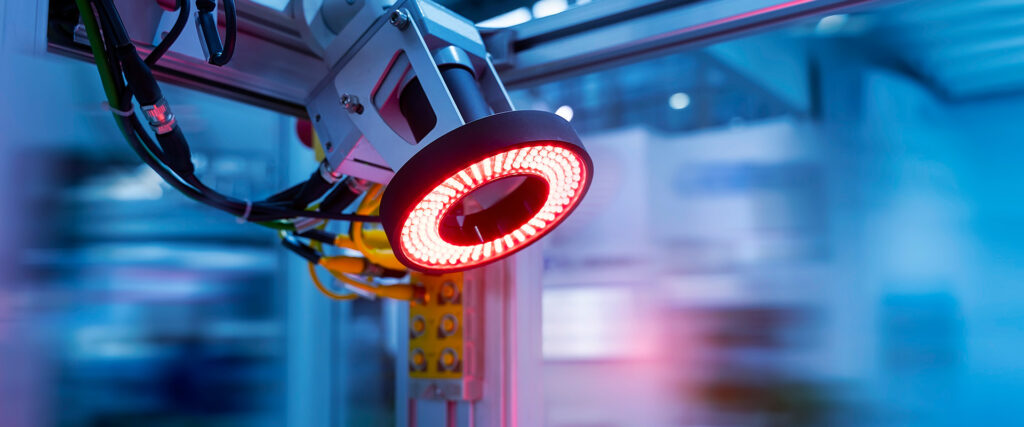

Crack detection during inline quality inspection in production

Time-consuming manual quality inspection steps are replaced.

The efficiency of your inspections is increased thanks to the image processing system.

Do you have very specific requirements?

Our 4 models of the BVS-R system for Crack detection generally cover all relevant test requirements.

BVS-R/F/S/C image processing system

If this does not apply or does not apply sufficiently to your practice, no problem!

Our development engineers in the fields of mechatronics, Image processing and software will be happy to work out a customized solution for you.

Frequently asked questions (FAQs)

Welche Branchen sollten unser BVS-R Bildverarbeitungssystem zur Risserkennung verwenden?

Our BVS-R system is ideal for companies in various industries such as the automotive industry, metal processing, electronics, aerospace and many more. Wherever high quality standards are placed on products and defects, such as cracks on the surface, need to be detected and documented in good time.

Warum Qualitätskontrolle mittels Risserkennungssystem?

Powerful camera systems for the identification of production defects such as cracks surpass human capabilities in terms of measurement accuracy and speed. Detect and track reproducible and objectively detected defects Contact us and benefit from our many years of WESTCAM expertise.

Welche Branchen sollten unser BVS-R Bildverarbeitungssystem zur Risserkennung verwenden?

All those who carry out fatigue strength tests, material tests and fatigue tests using dynamic test runs and want to increase the quality of observation.

Our BVS-R system is ideal for companies in various industries such as the automotive industry, metal processing, electronics, aerospace and many more. Wherever high quality standards are placed on products and defects such as cracks on the surface need to be detected and documented in good time.