High-Performance Turning

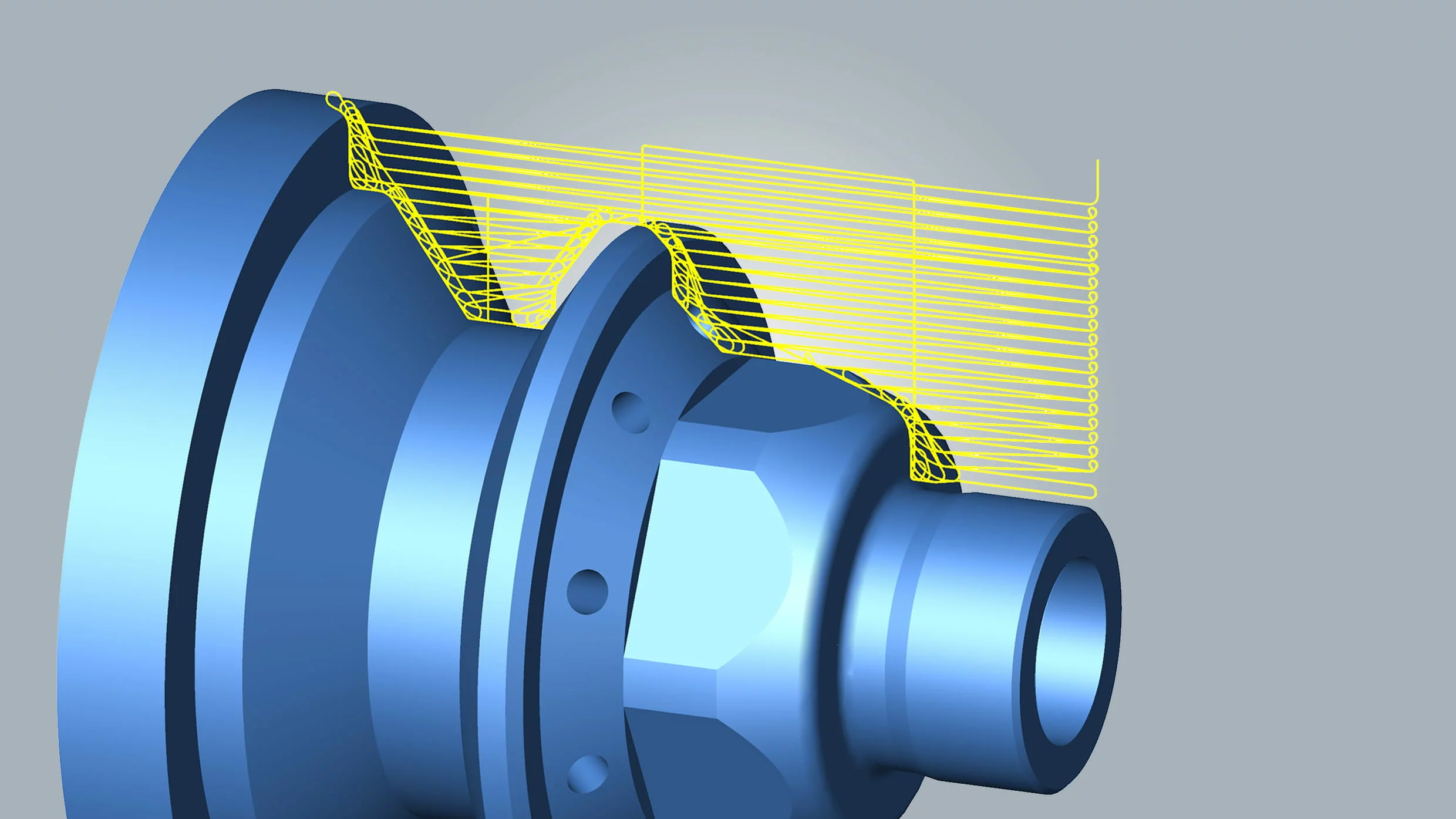

The Maxx Machining module – High-Performance Turning (HPC Turning) from hyperMILL uses trochoidal tool paths to maximize efficiency and process reliability, especially with difficult-to-cut materials.

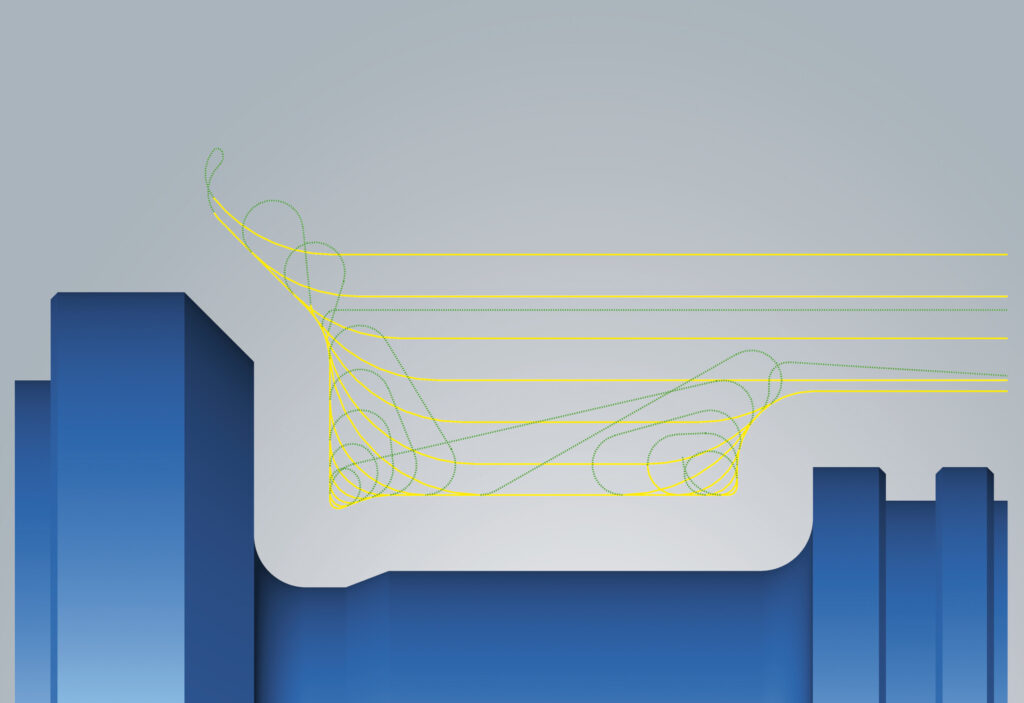

HPC turning is based on the proven concept of trochoidal machining, which has been successfully transferred to turning.

This method enables the use of round inserts, whereby the connecting paths between the individual tool paths and the approach and retraction movements are optimally adapted to the respective machining case. This leads to a significant reduction in machining time and an increase in tool life.

- Trochoidal tool paths for turning operations

- Significantly reduced processing time

- Improved tool life

Machine movements

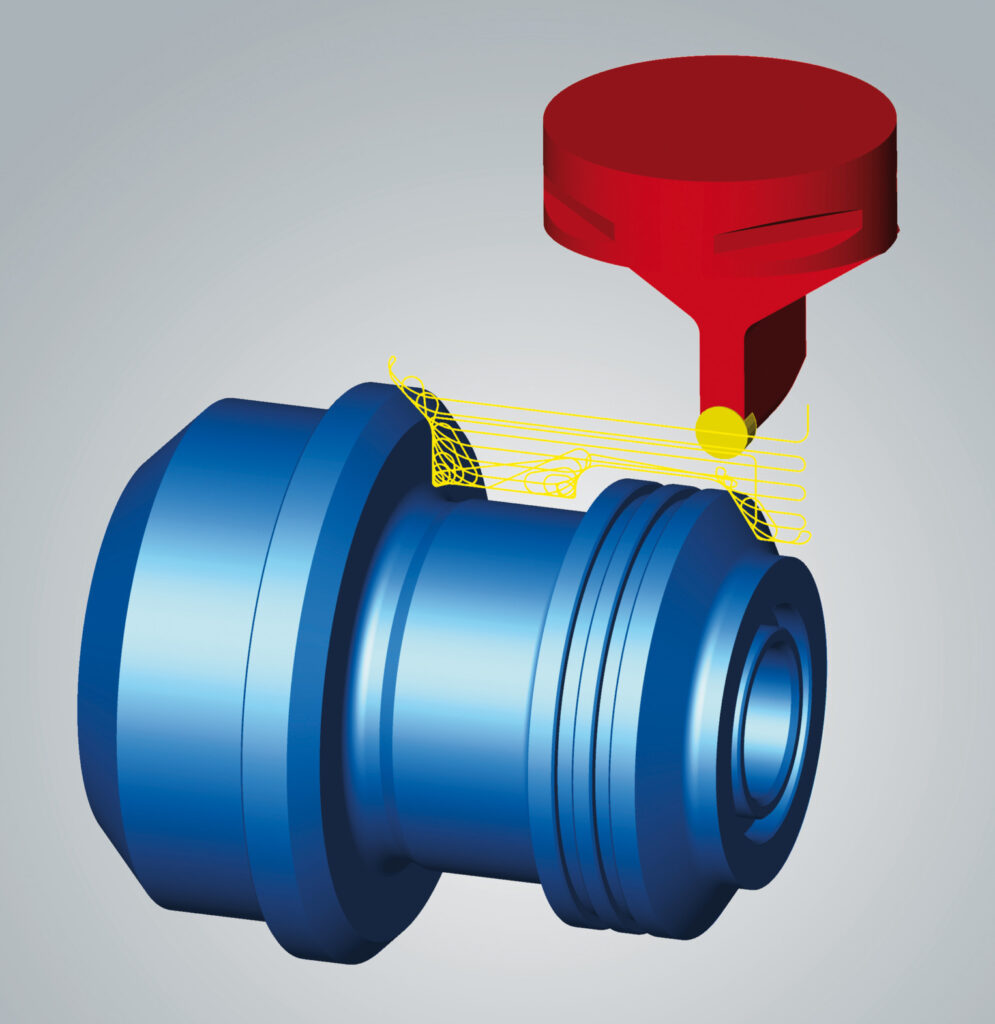

The High-Performance Turning offers increased process reliability thanks to smooth approach and departure movements and even load distribution on the machine axes.

The homogeneous machine movements reduce the mechanical load, which extends the service life of the machine components. In addition, the improved chip breaking behavior ensures stable machining, even with difficult-to-cut materials.

Optimal tool paths

After selecting the contours to be machined, the software automatically creates the optimum tool paths for the required roughing operation.

The tools and holders are of course fully collision-tested, which guarantees the safety and reliability of the process.

Frequently asked questions (FAQs)

What is High-Performance Turning?

High-Performance Turning (HPC turning) is an advanced machining technology that uses trochoidal tool paths to maximize efficiency and process reliability in turning operations.

What are the advantages of HPC turning with hyperMILL?

HPC turning with hyperMILL offers increased productivity, longer tool life and gentle machining. The smooth approach and retraction movements and even load distribution reduce mechanical stress and increase process reliability.

Mechatronics & Robotics

Mechatronics & Robotics