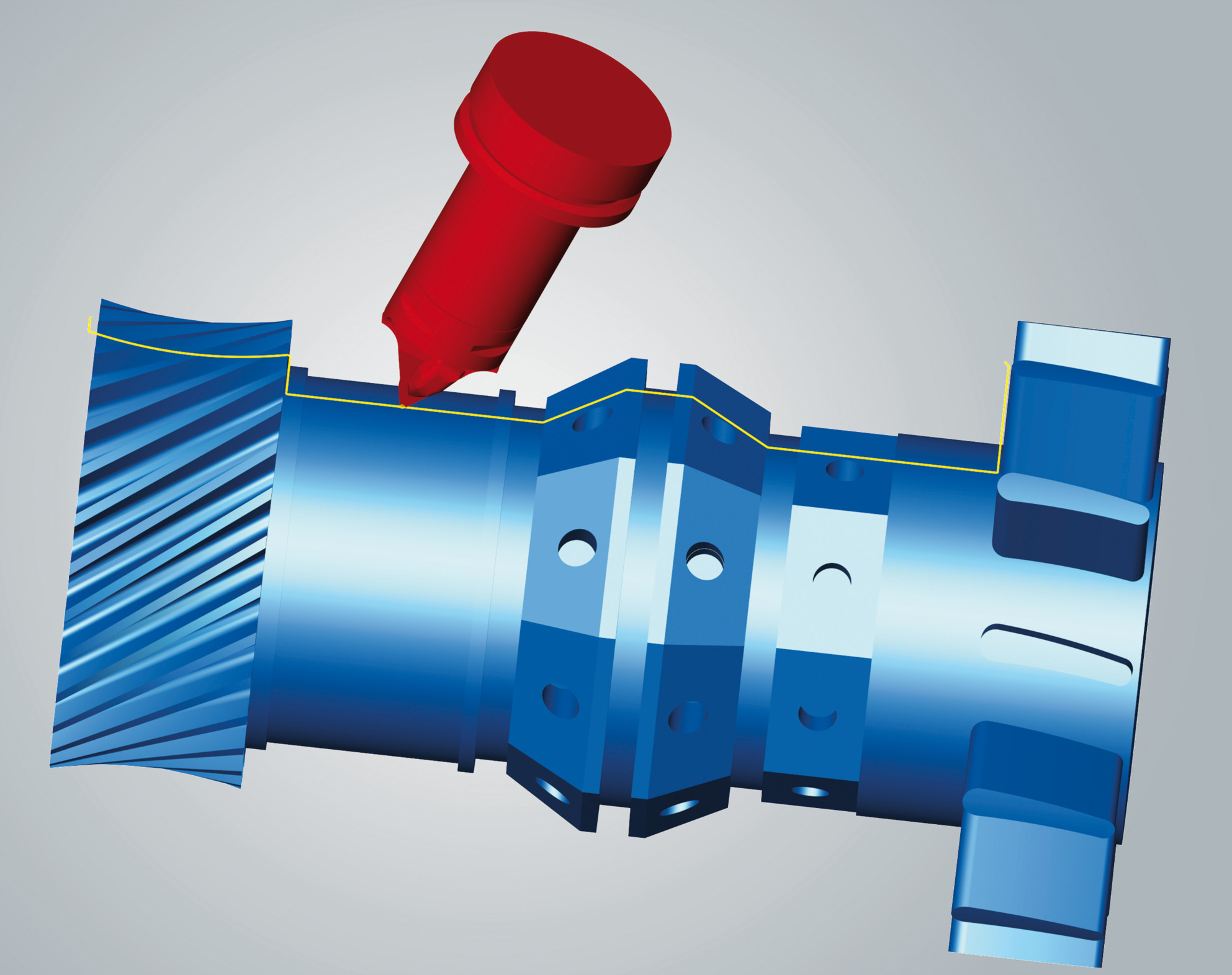

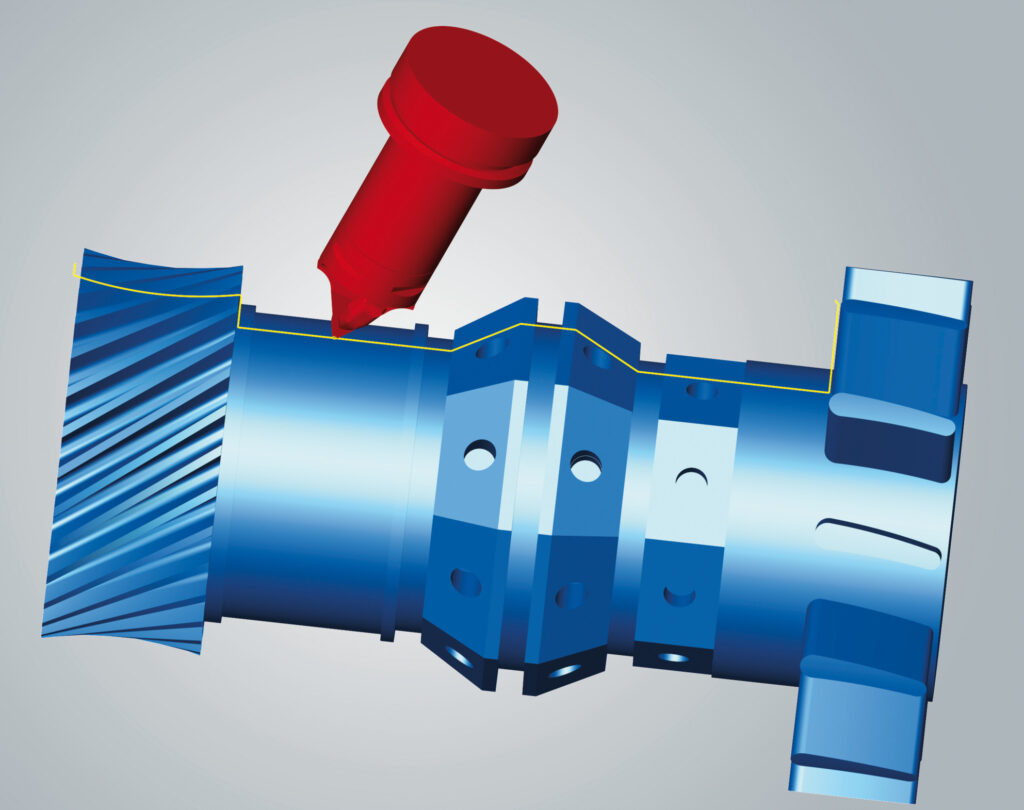

3 axis Simultaneous Turning

Maximum precision: simultaneous turning with hyperMILL.

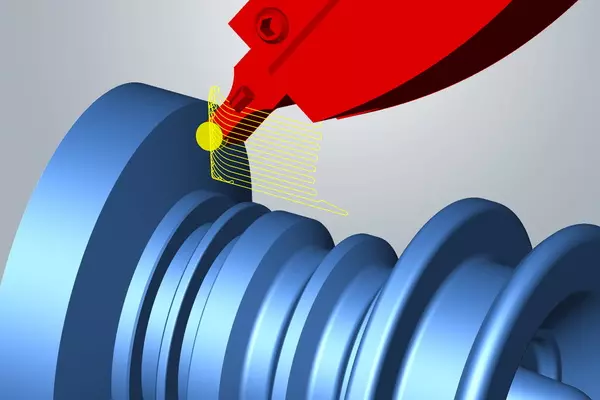

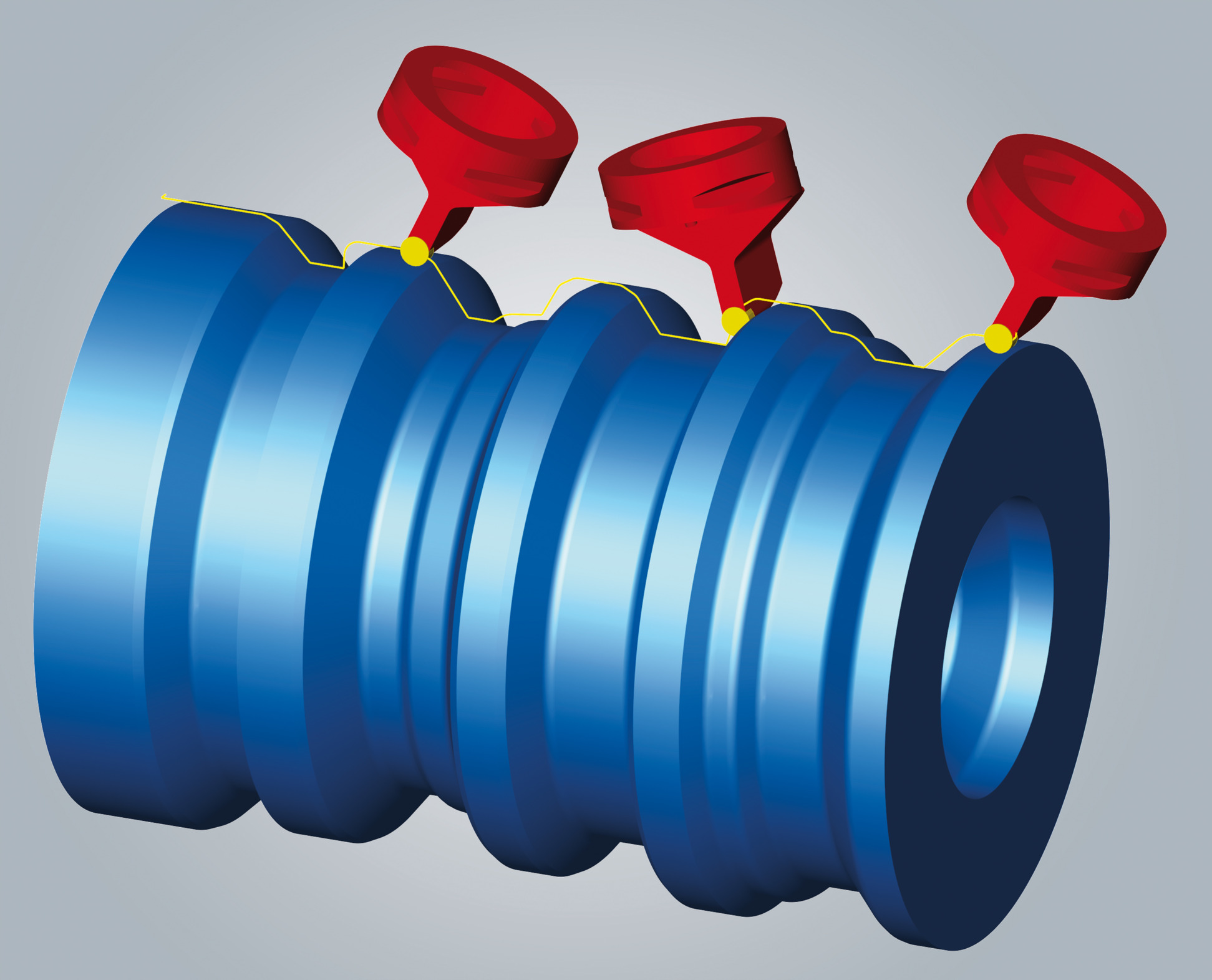

Simultaneous turning with hyperMILL enables highly efficient and precise machining of workpieces. This technology uses the simultaneous adjustment of the setting angle during turning to produce complex geometries and undercuts in a single step.

This reduces the number of tool changes required and thus significantly increases efficiency and accuracy.

- Simple and safe programming

- Complex contours can be produced

- Reduced number of tool changes

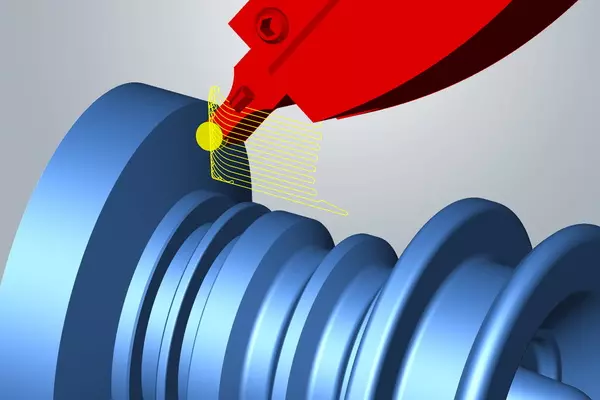

Simple and safe programming

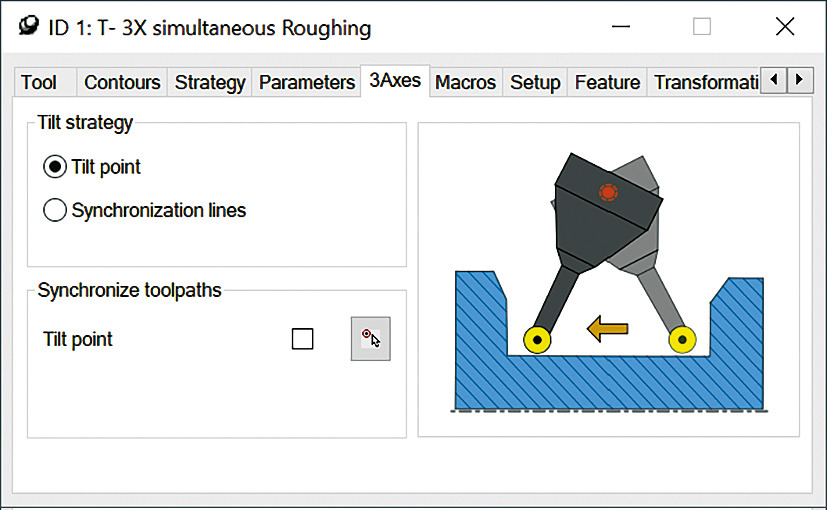

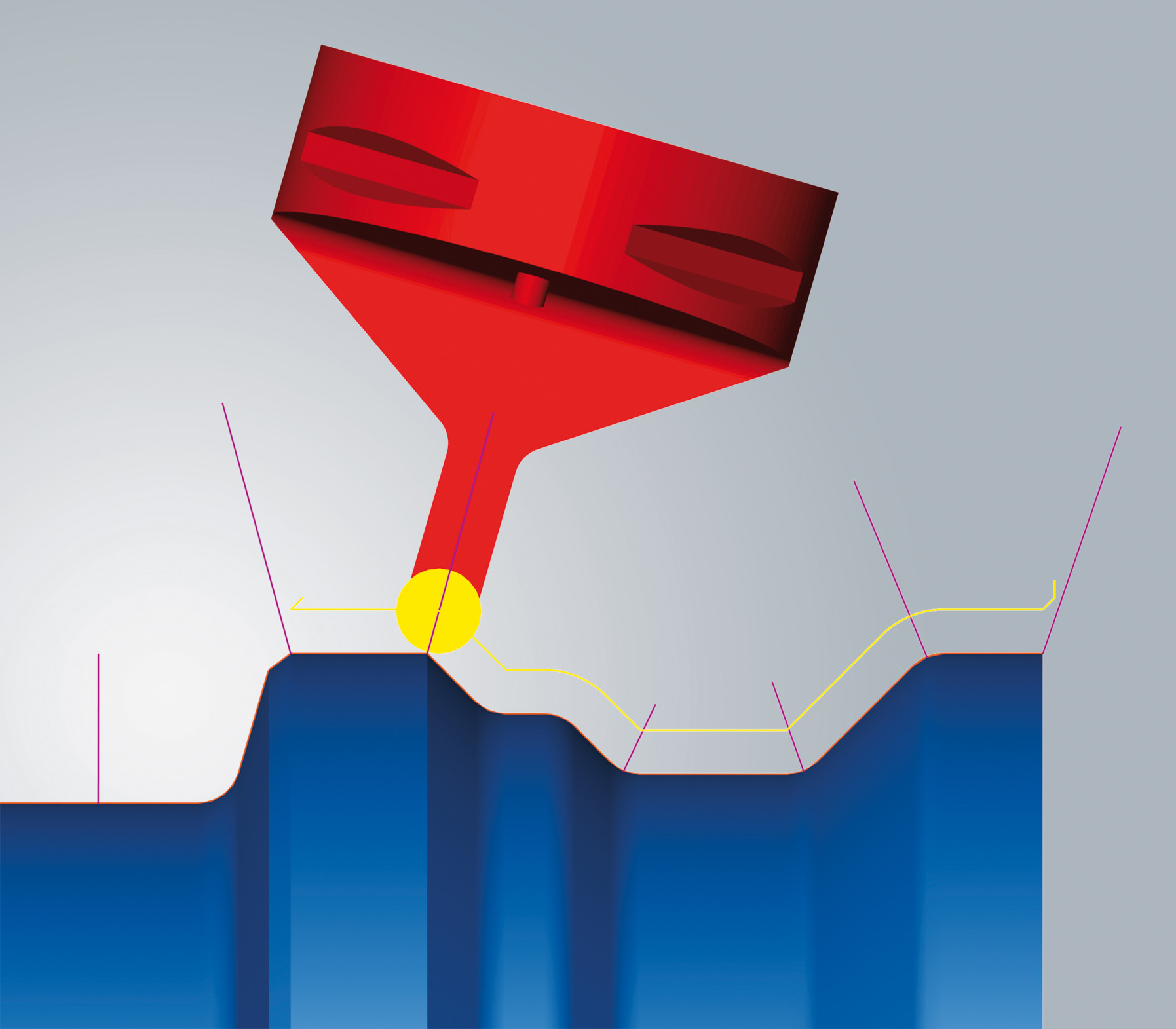

hyperMILL offers special strategies for simultaneous roughing and finishing. The movement sequence of the B-axis is defined by pivot points or synchronization lines.

The simultaneous movement is calculated automatically, making programming simple and safe. The full collision check of the tools and holders ensures the safety of the process.

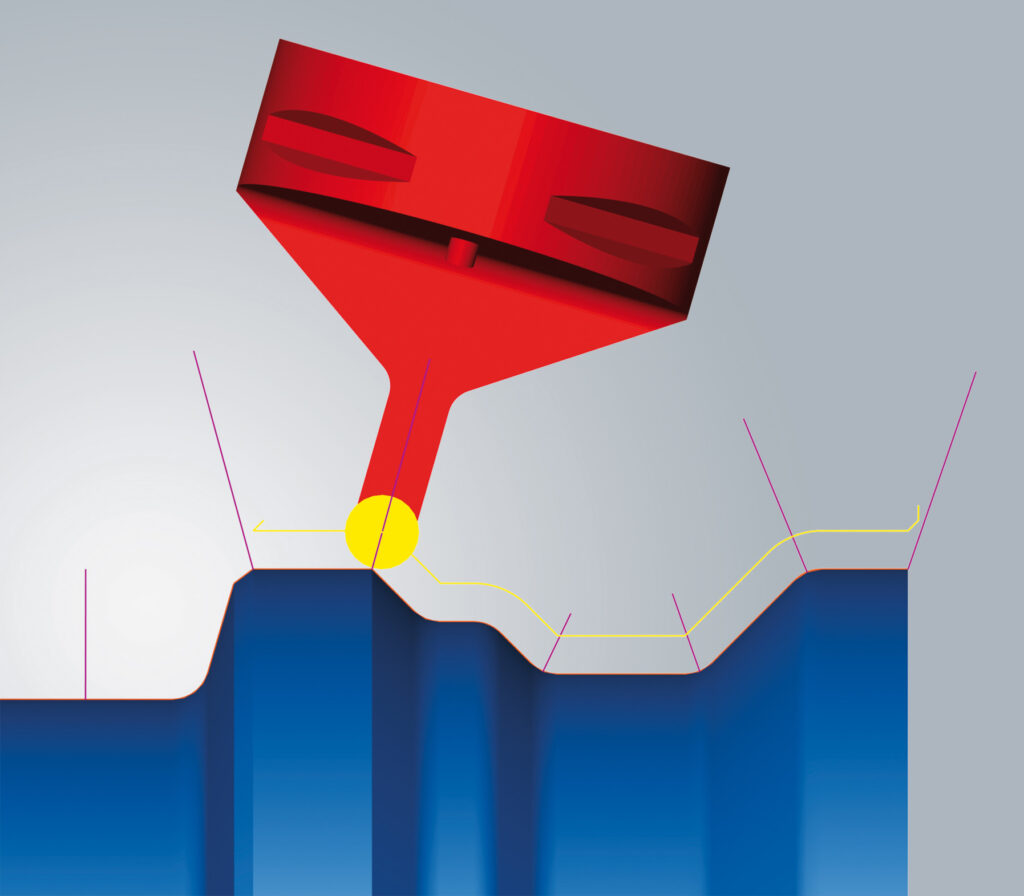

Complex contours

Thanks to the simultaneous adjustment of the tool position, the cutting insert can also be optimally utilized. This leads to increased tool life and reduces the need for tool changes.

Complex contours can be machined in a single step, which increases the efficiency and precision of production.

Frequently asked questions (FAQs)

Was ist Simultandrehen?

Simultaneous turning is a machining technology in which the setting angle of the tool is adjusted simultaneously during the turning process.

Welche Vorteile bietet Simultandrehen?

Simultaneous turning enables the machining of complex contours and undercuts in a single step.

Please add pictures if possible