hyperMILLMAXX Machining

With the MAXX Machining package, you can rough, finish and drill highly efficiently.

More than ever, a focus on efficiency and productivity is essential in CNC manufacturing. The shortest possible production times can only be achieved through perfectly optimized tool paths, sophisticated strategies and machining processes that are designed for modern milling geometries.

For this reason, OPEN MIND developed the MAXX Machining package for optimized roughing, finishing and drilling operations to achieve the highest possible metal removal rate with perfect surfaces.

- MAXXimum roughing – the trochiodal solution

- MAXXimum finishing – finishing in record time!

- MAXXimum drilling

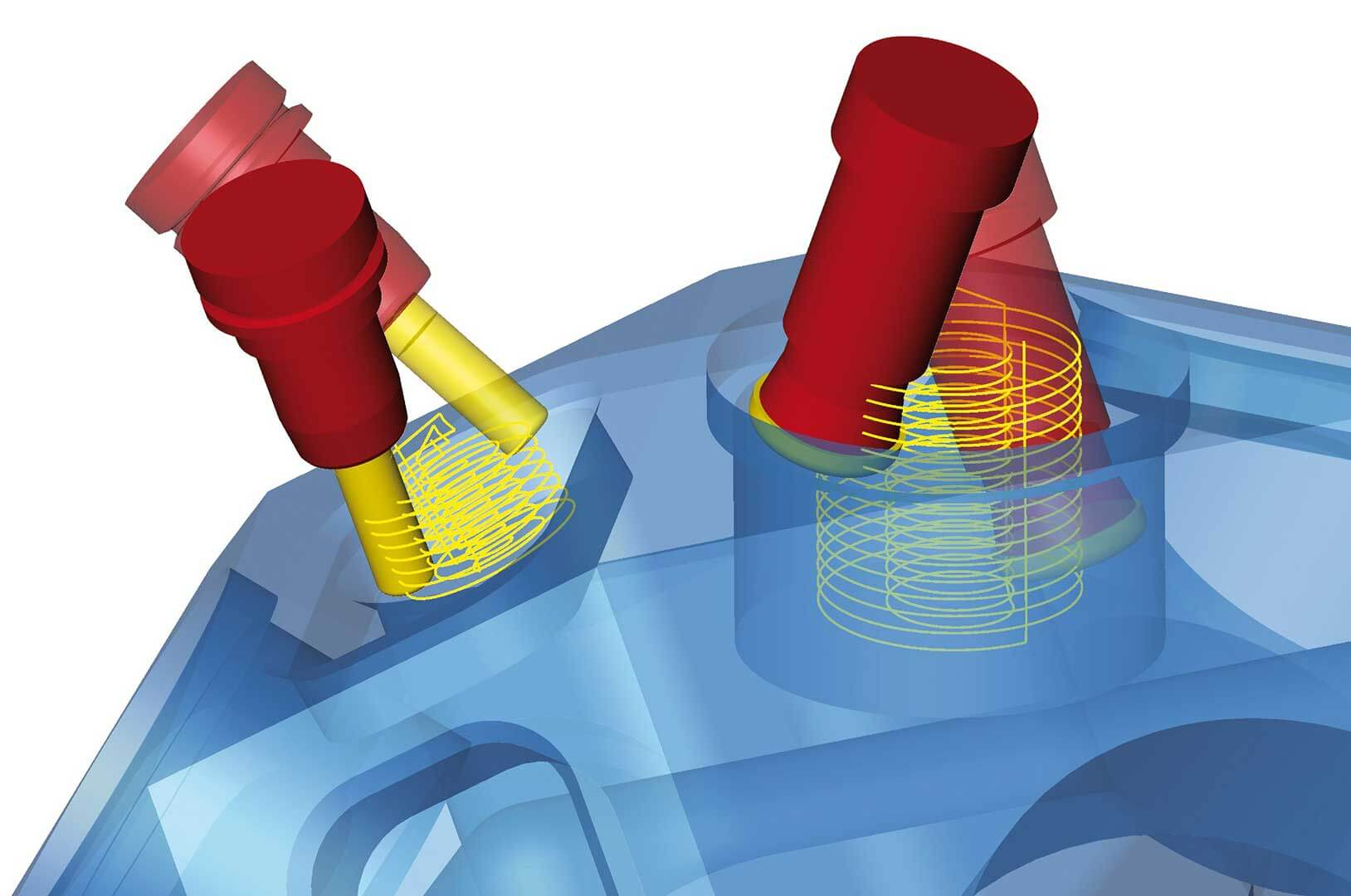

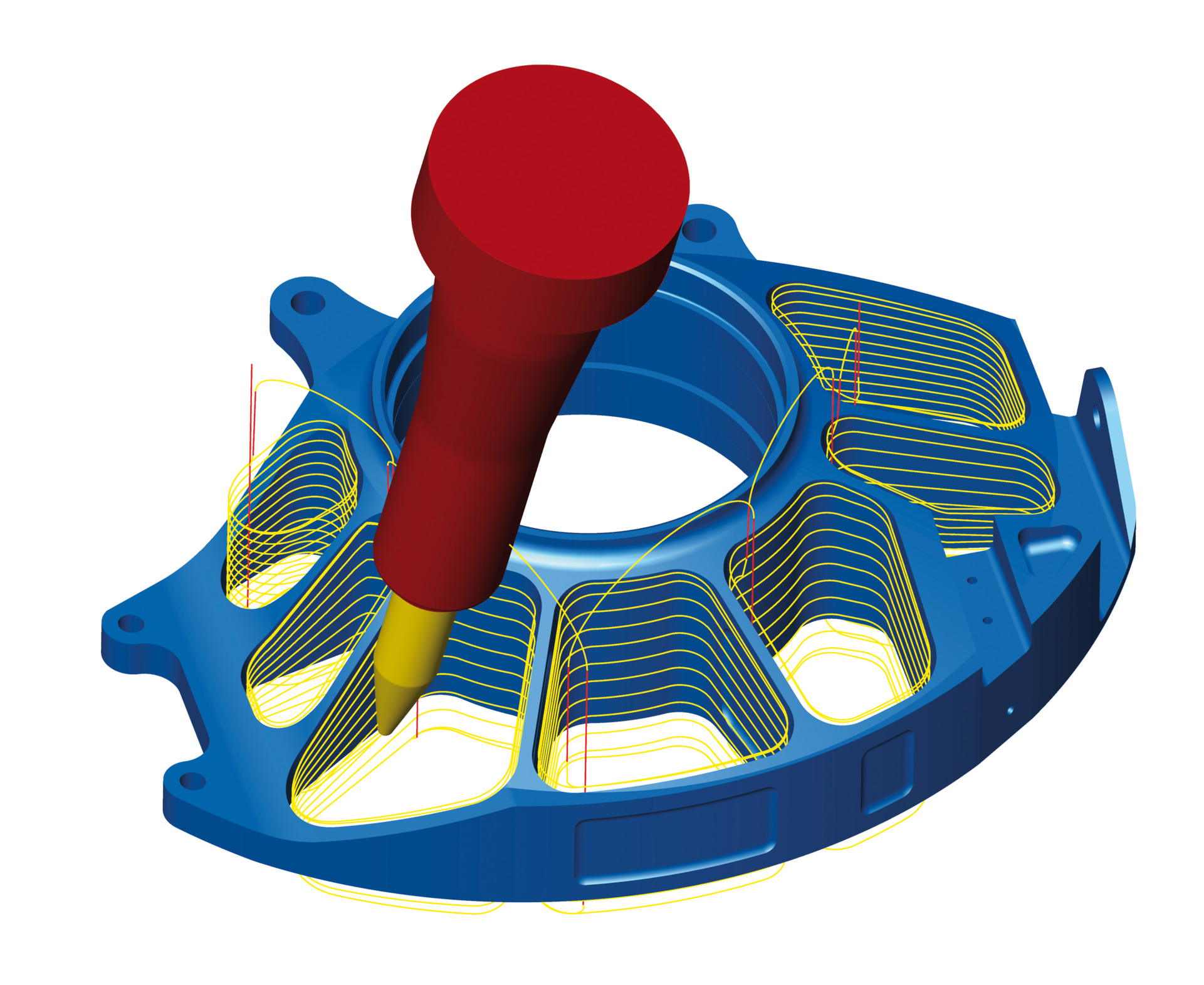

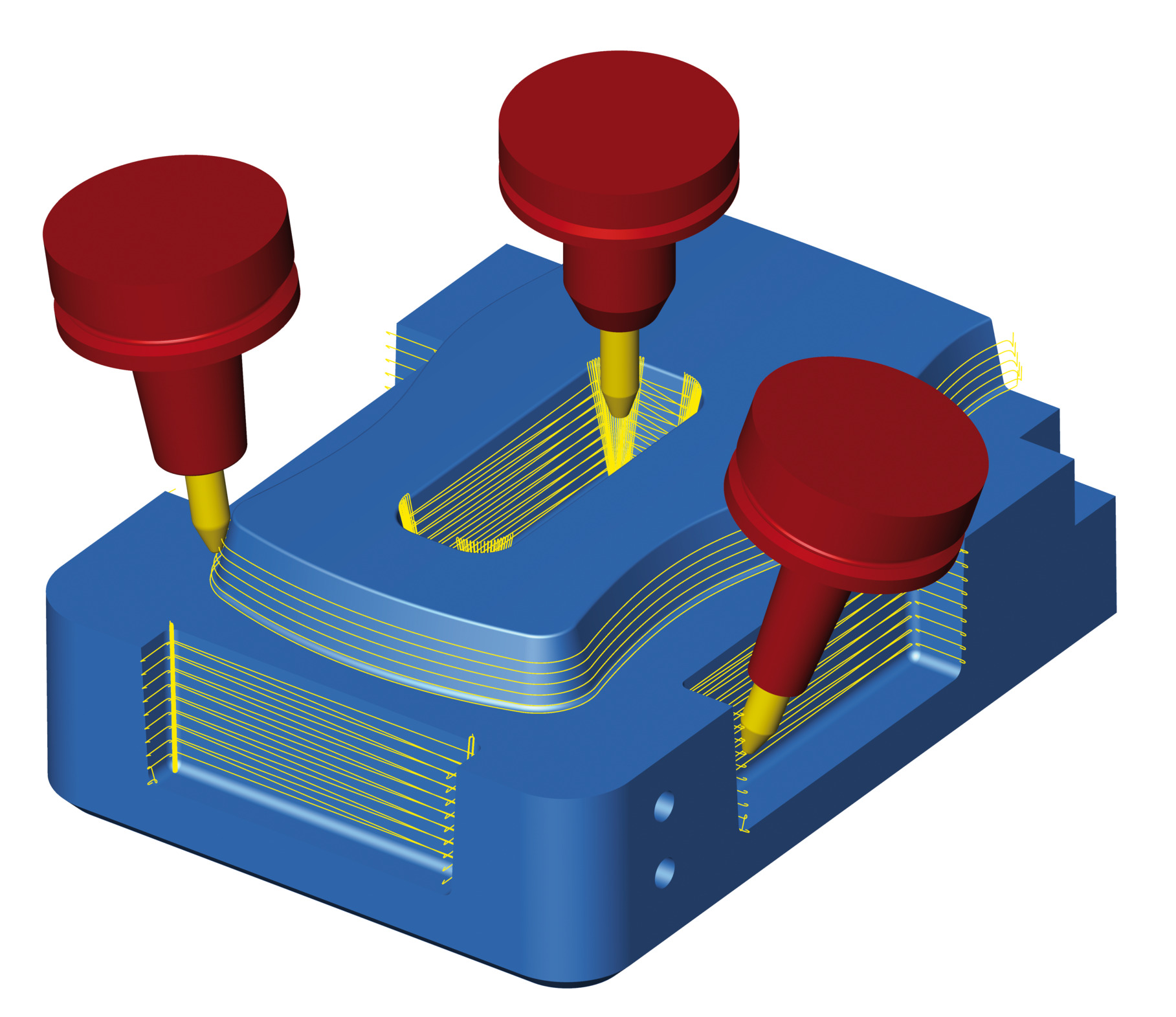

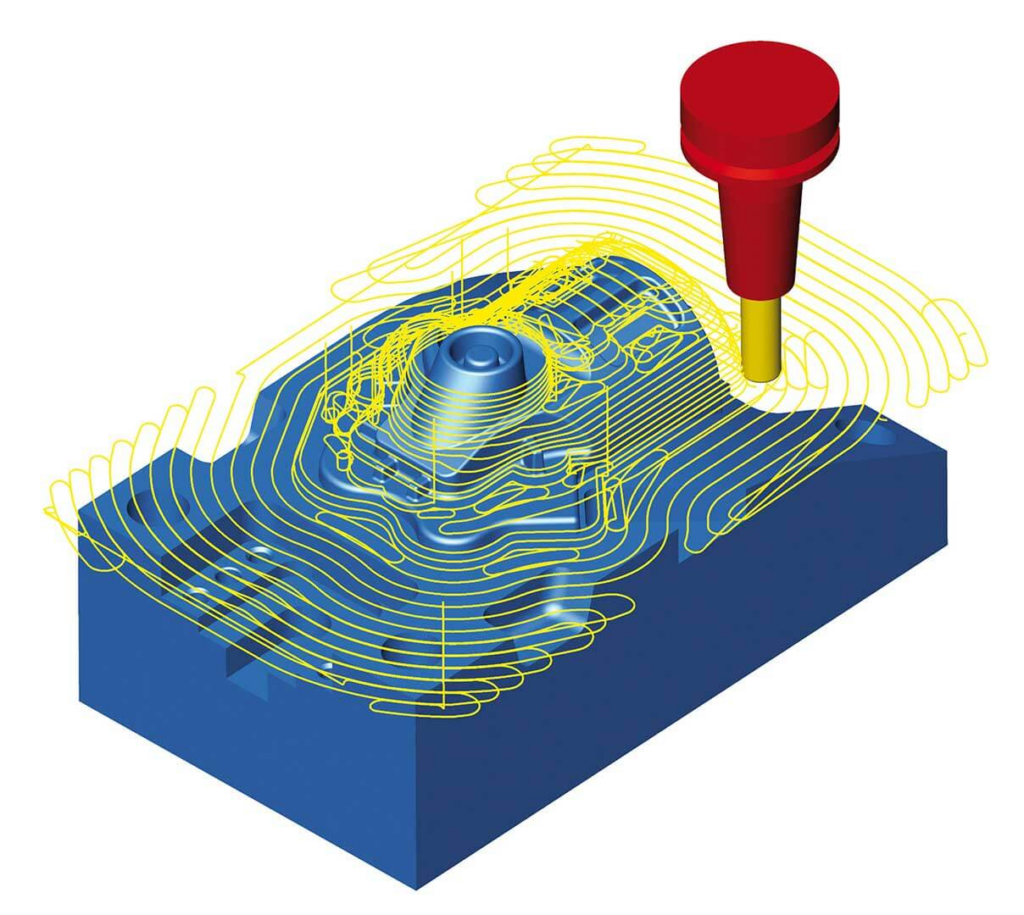

MAXXimum roughing

The roughing module is a particularly powerful and extremely easy-to-use package for creating spiral and trochoidal toolpaths.

Sensationally high chip volumes per time unit ensure extremely fast roughing in 2D, 3D and 5-axis simultaneous strategies! In addition, the avoidance of full cuts and constant loading protects both the tool and the machine.

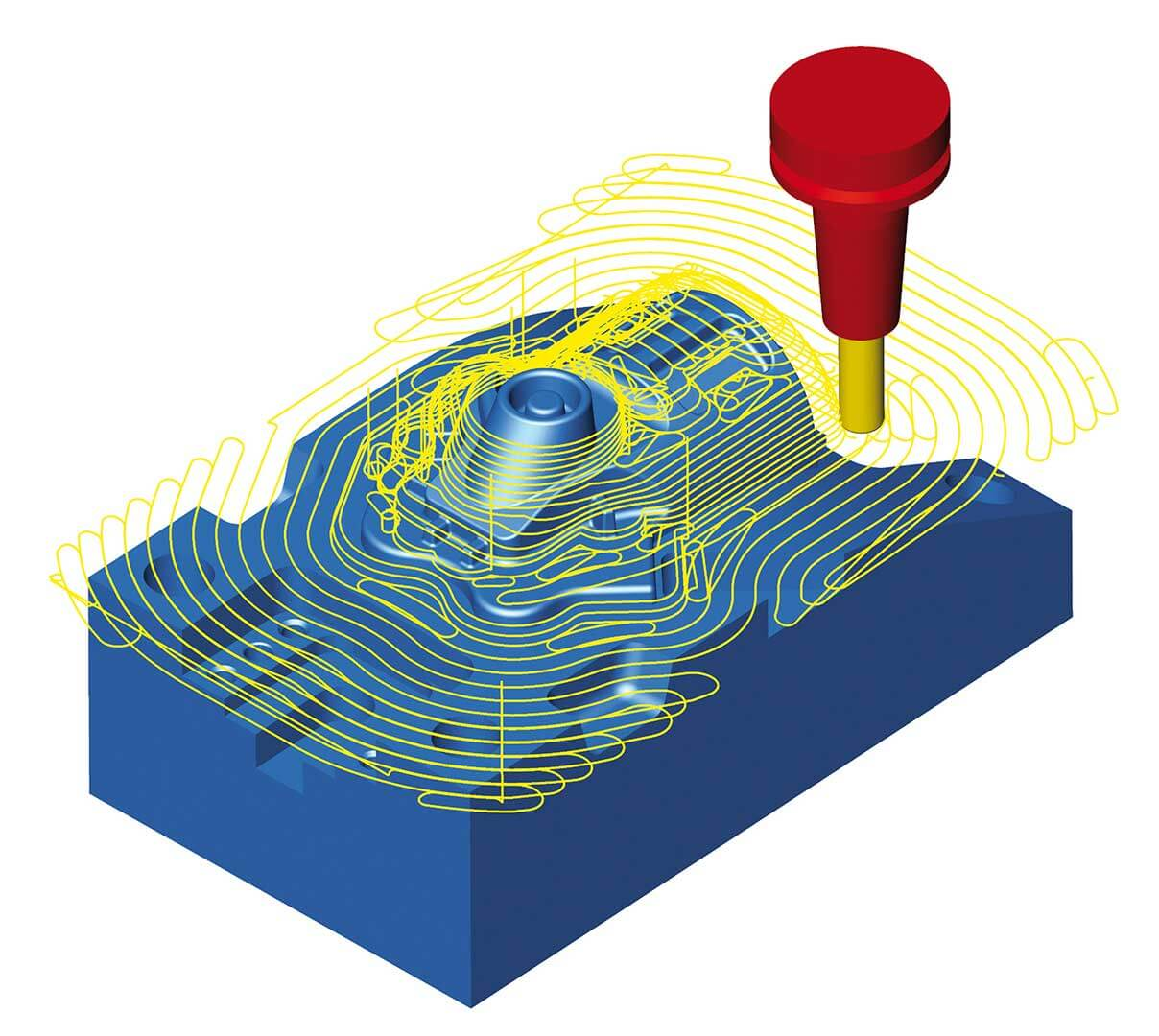

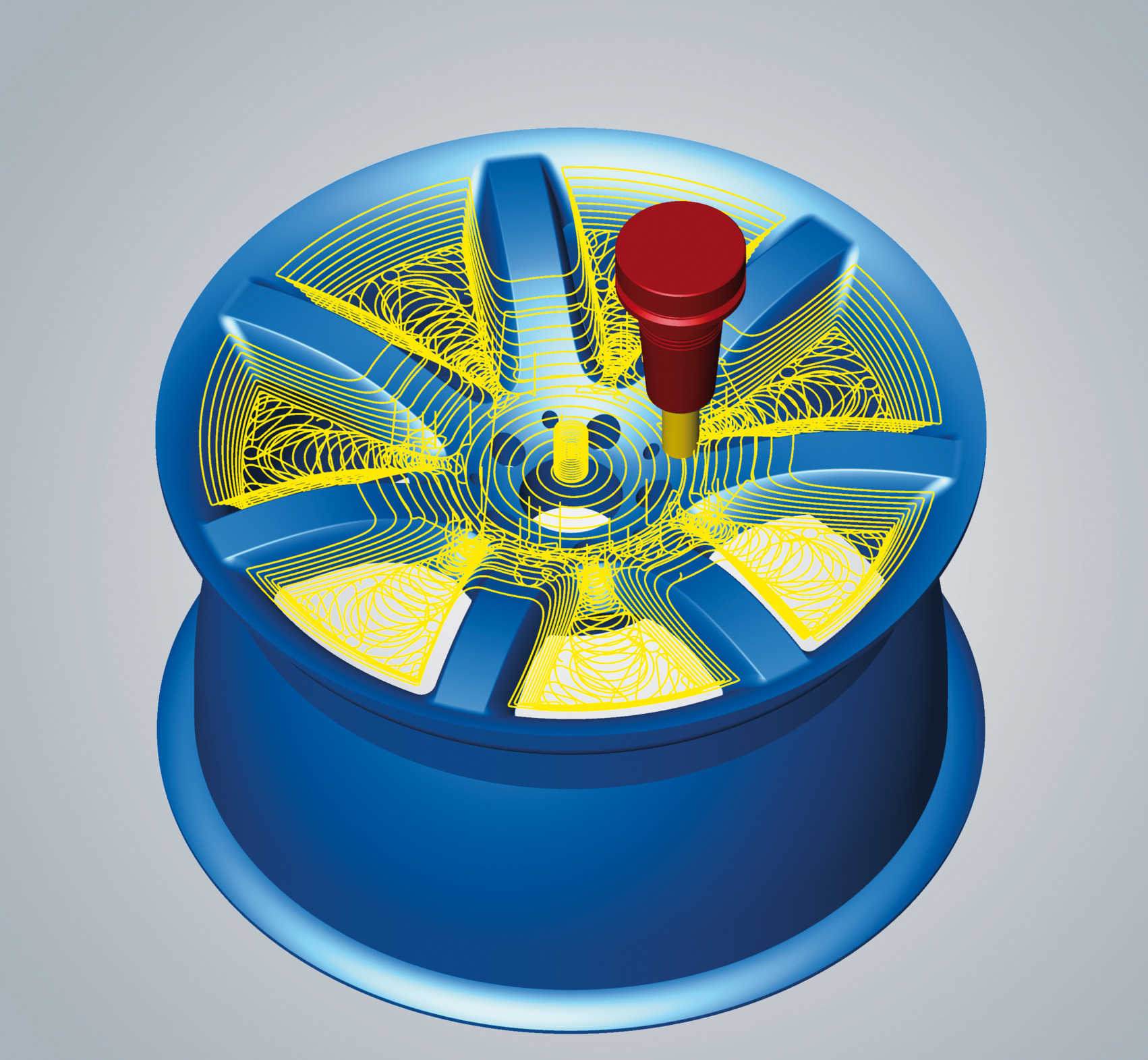

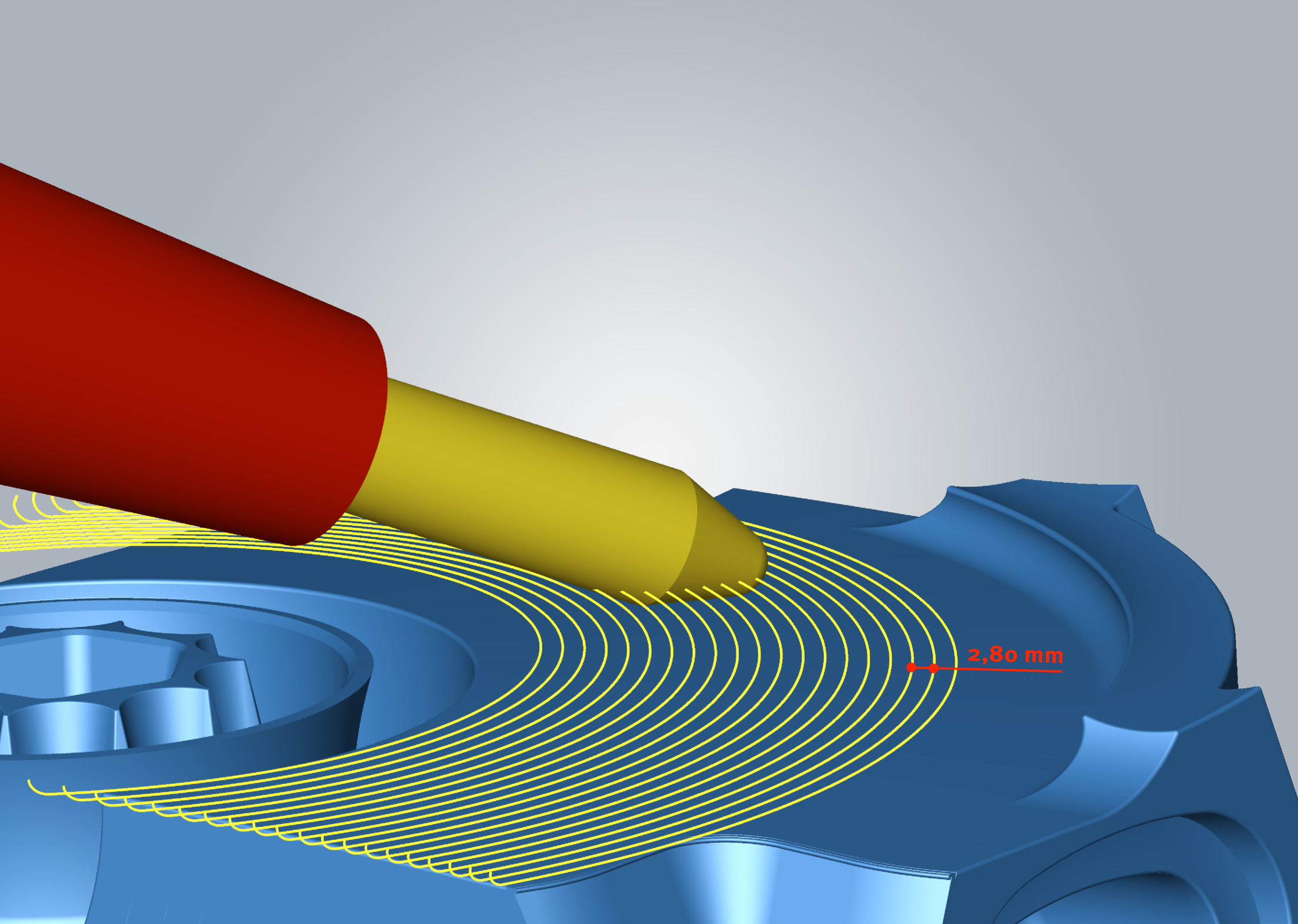

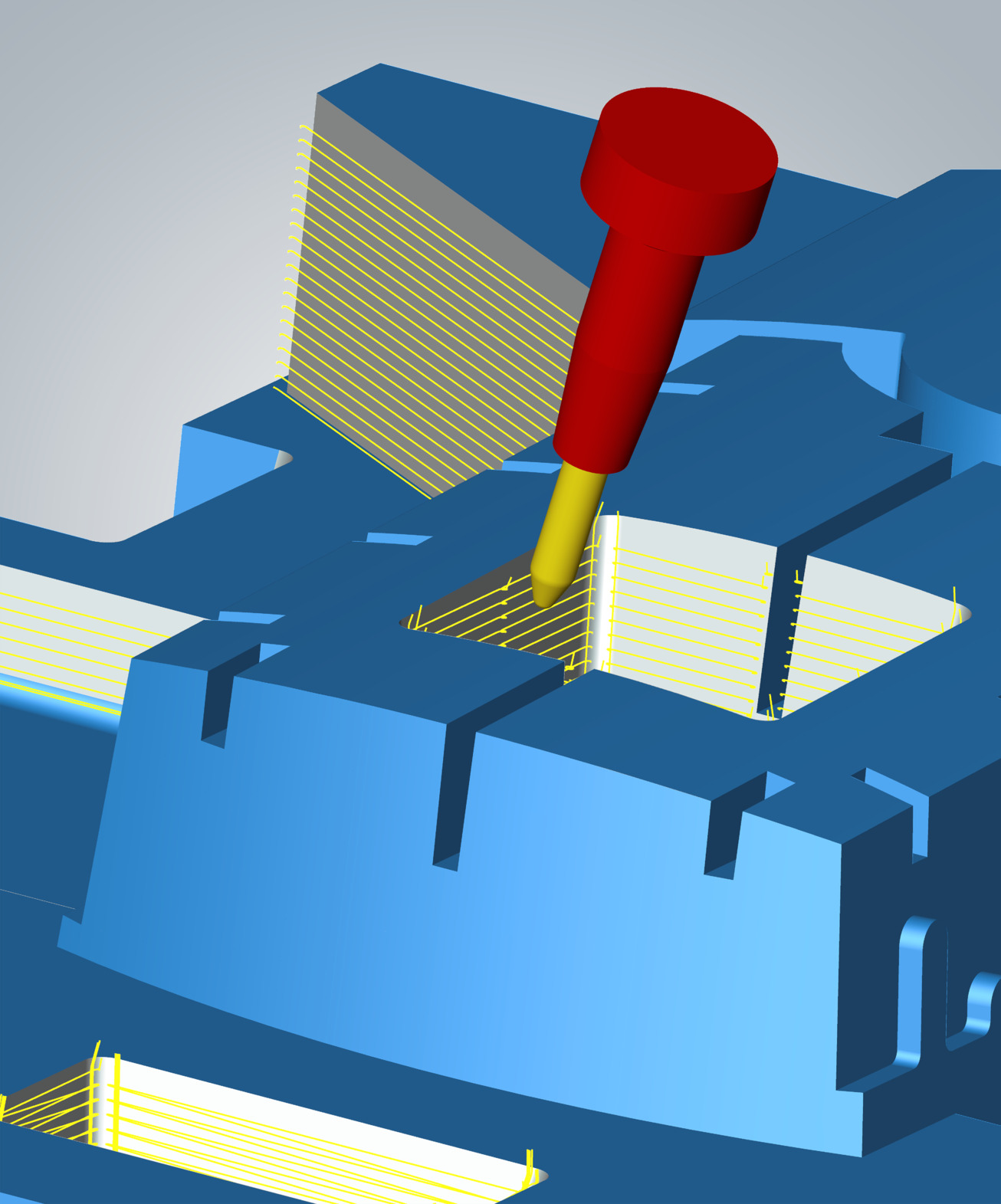

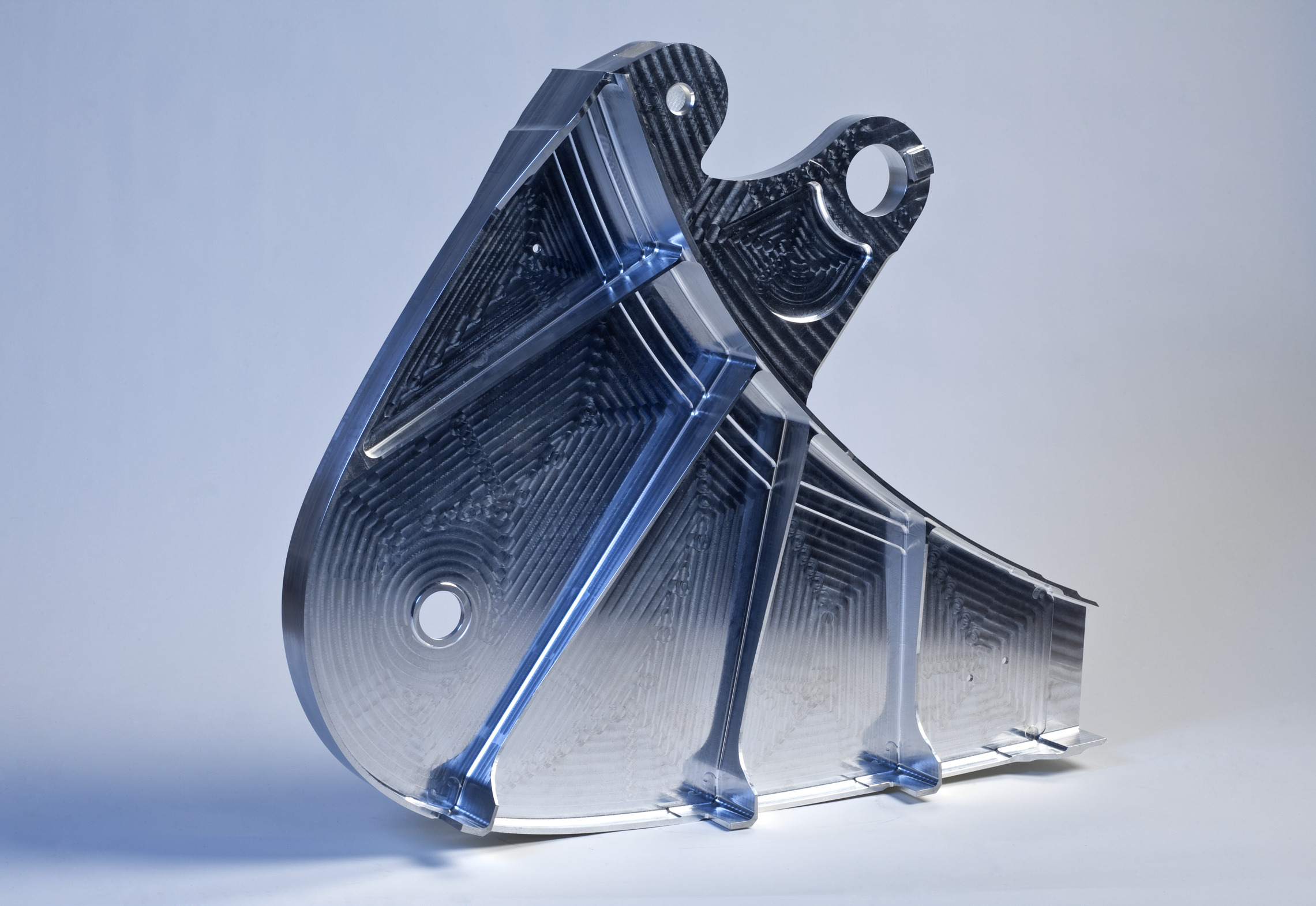

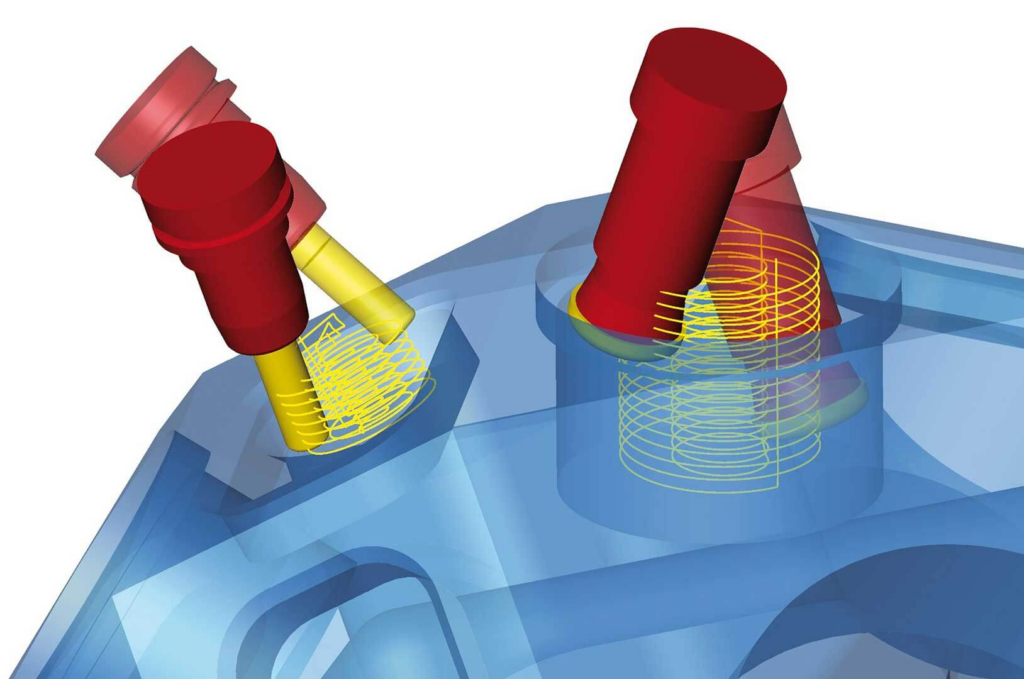

MAXXimum finishing

Pre-finishing and finishing of planes and free-form surfaces with various barrel cutters: Reduce production times through intelligent tool use!

Thanks to OPEN MIND’s many years of expertise in the use of special tools for 5-axis machining, OPEN MIND has been able to develop a very special package for barrel and circular segment milling cutters. With the strategies contained therein, significantly larger path distances can be realized than with conventional methods. The result is immense time savings – and significantly better surface qualities.

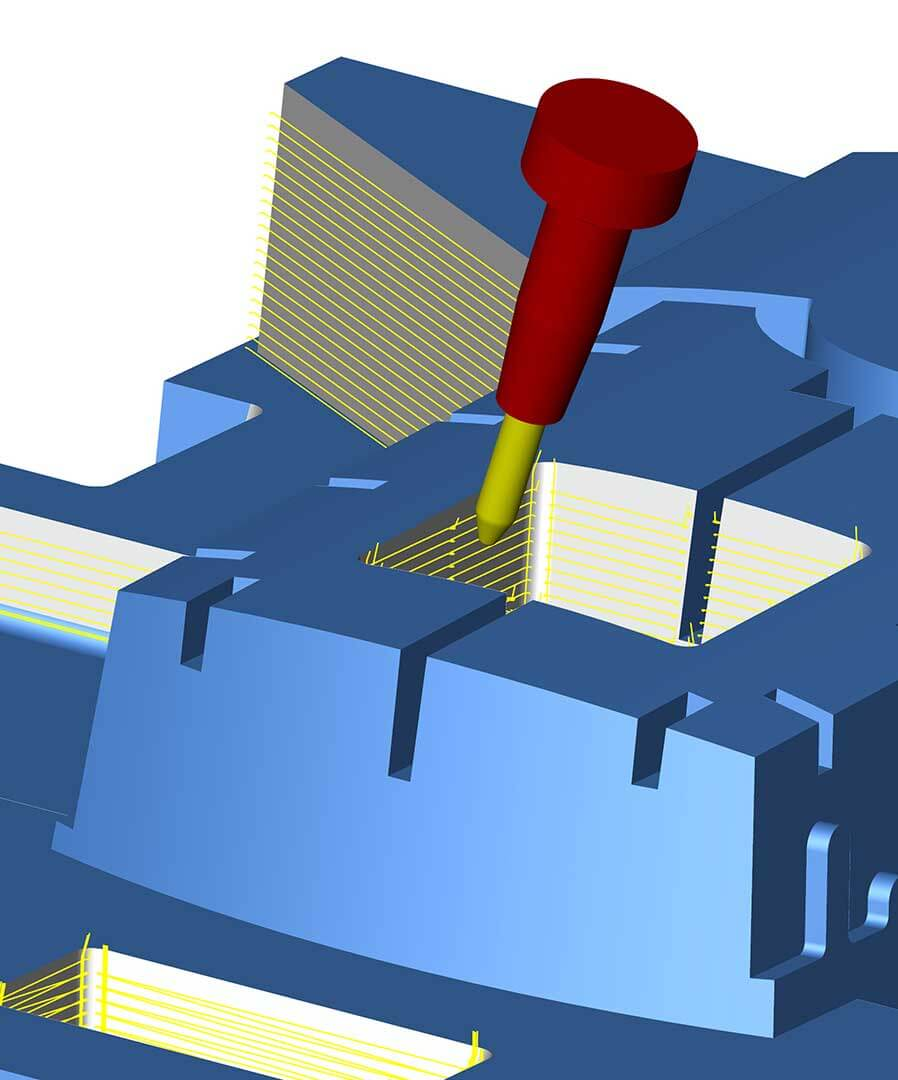

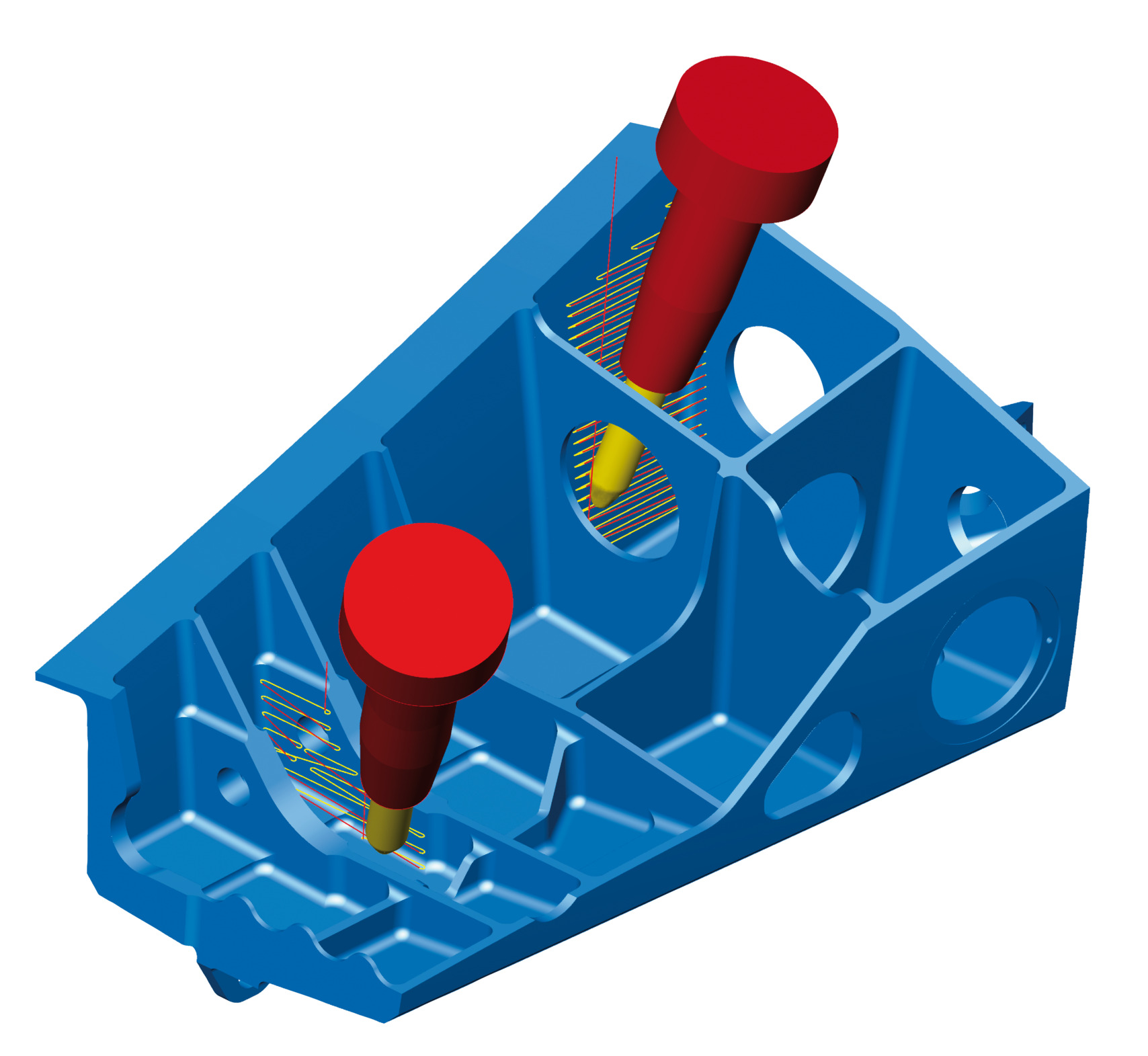

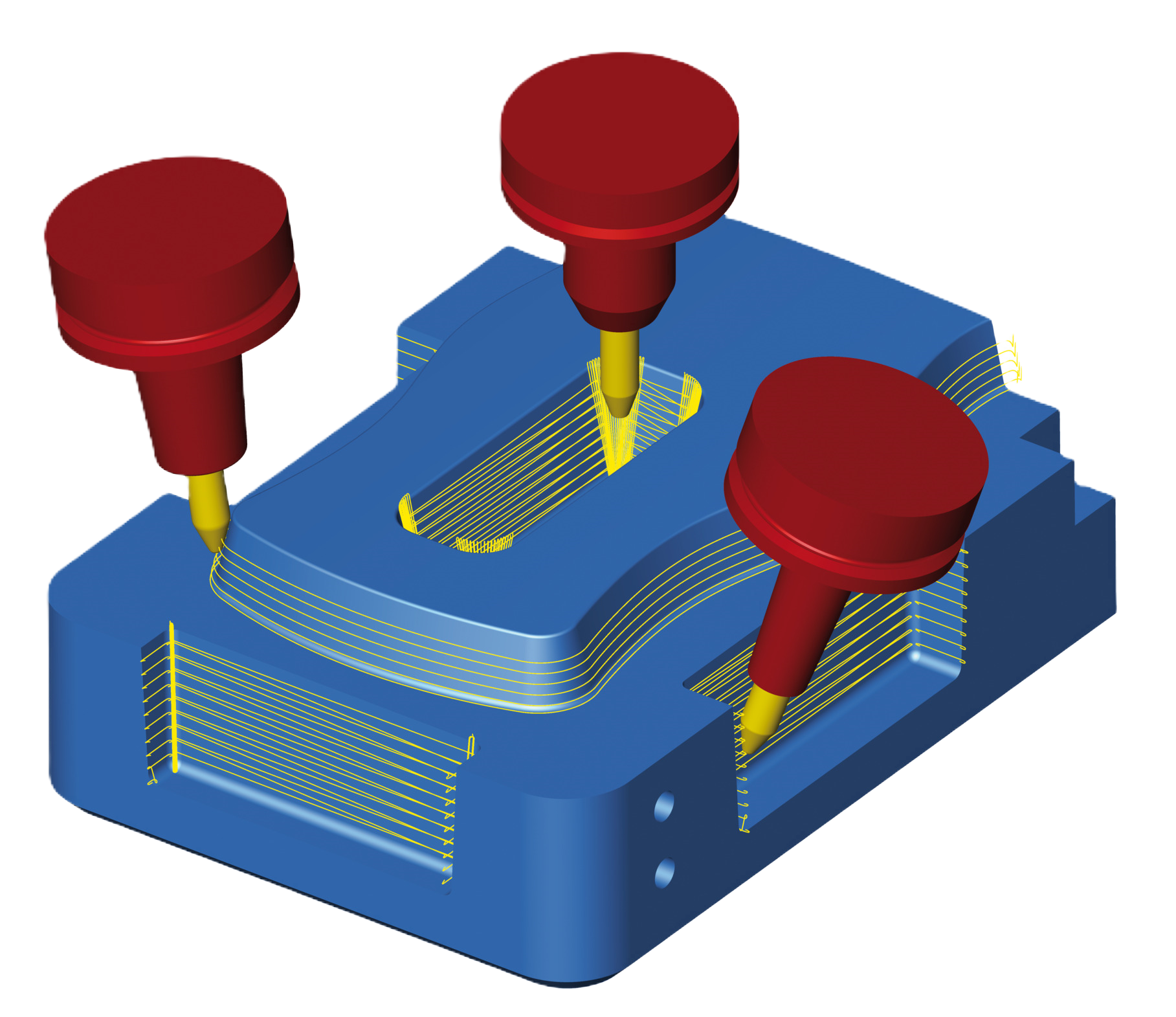

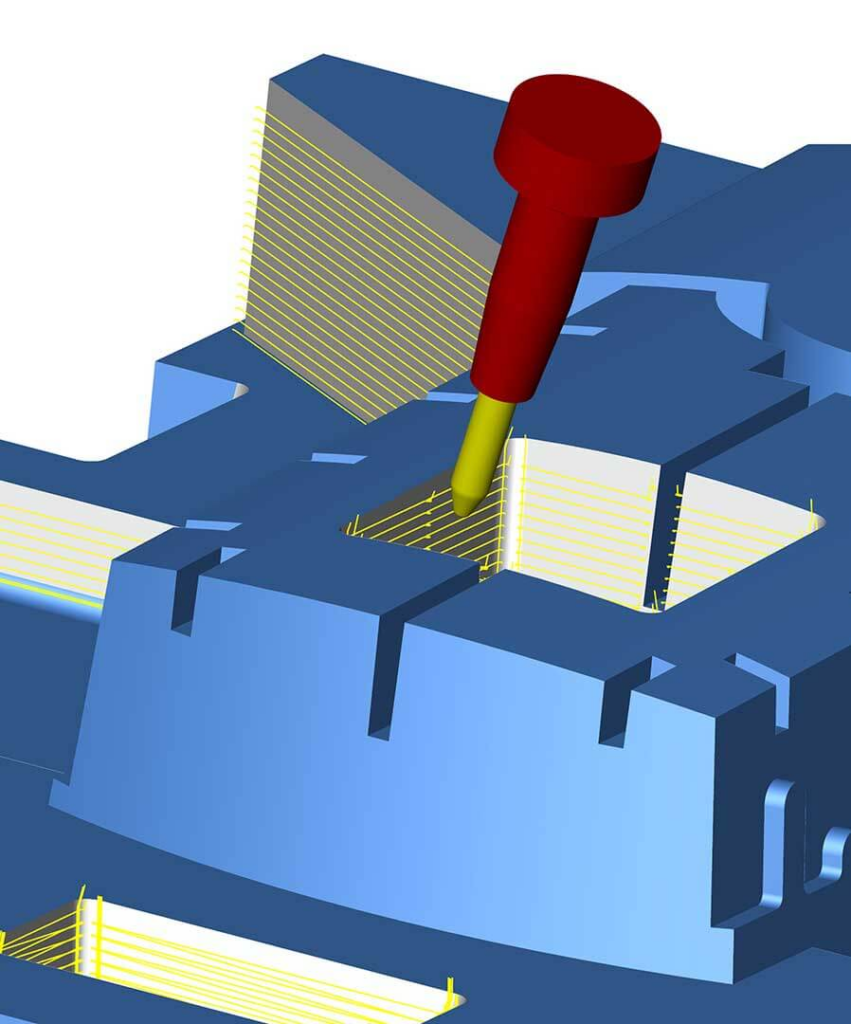

MAXXimum drilling

The task: to extract as much material as possible from a circular pocket efficiently and without damaging the cutter. The solution: 5-axis helical drilling The task: to extract as much material as possible from a circular pocket efficiently and gently.

The solution: 5-axis helical drilling. 5-axis helical drilling is a helical plunge milling process. The milling cutter is tilted forward in the direction of travel. A second approach helps to avoid collisions with the bore wall. This strategy is ideal as an opening cut for roughing deep cavities. The material is removed from circular pockets very efficiently and gently.

Frequently asked questions!

Was ist eine HPC-Bearbeitung?

HPC machining refers to high-performance cuttingduring milling.

With MAXX Machining, hyperMILLoffers three modules: For drilling, roughing and finishing

HPC machining is characterized by a high metal removal rate, high cutting speeds and high feed rates.

Was ist trochiodales Fräsen?

Trochoidal machining, also known as trochoidal milling, refers to milling in trochoidal, circular movements. This technology is programmed in hyperMILLusing MAXX Machining roughing.

Was ist MAXX Machining

MAXX Machining refers to three hyperMILLmodules for highly efficient milling and drilling.

We would be happy to explain the benefits of the hyperMILLCAM solution to you during a free demo or consultation. Just send a short e-mail to cam@westcam.at and we will contact you immediately.