hyperMILLBEST FIT

Are you familiar with the problem that, despite meticulous alignment of the blanks or components on the machine, the end result does not fit?

hyperMILL BEST FIT solves this problem and makes your work easier. Our innovative technology ensures that alignment is automatic and precise – at the touch of a button.

- Simplified component alignment through virtual correction

- Reduced set-up times on the machine

- Safe, collision-tested process

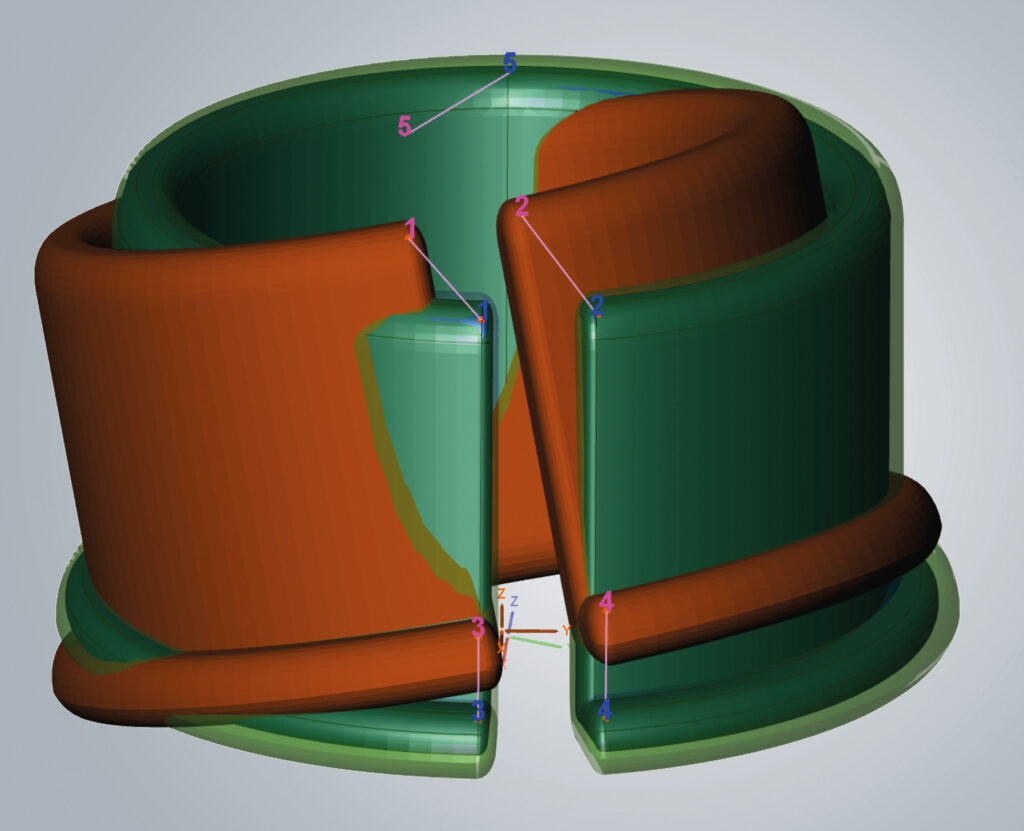

- Greater precision

Real-time alignment in CAM

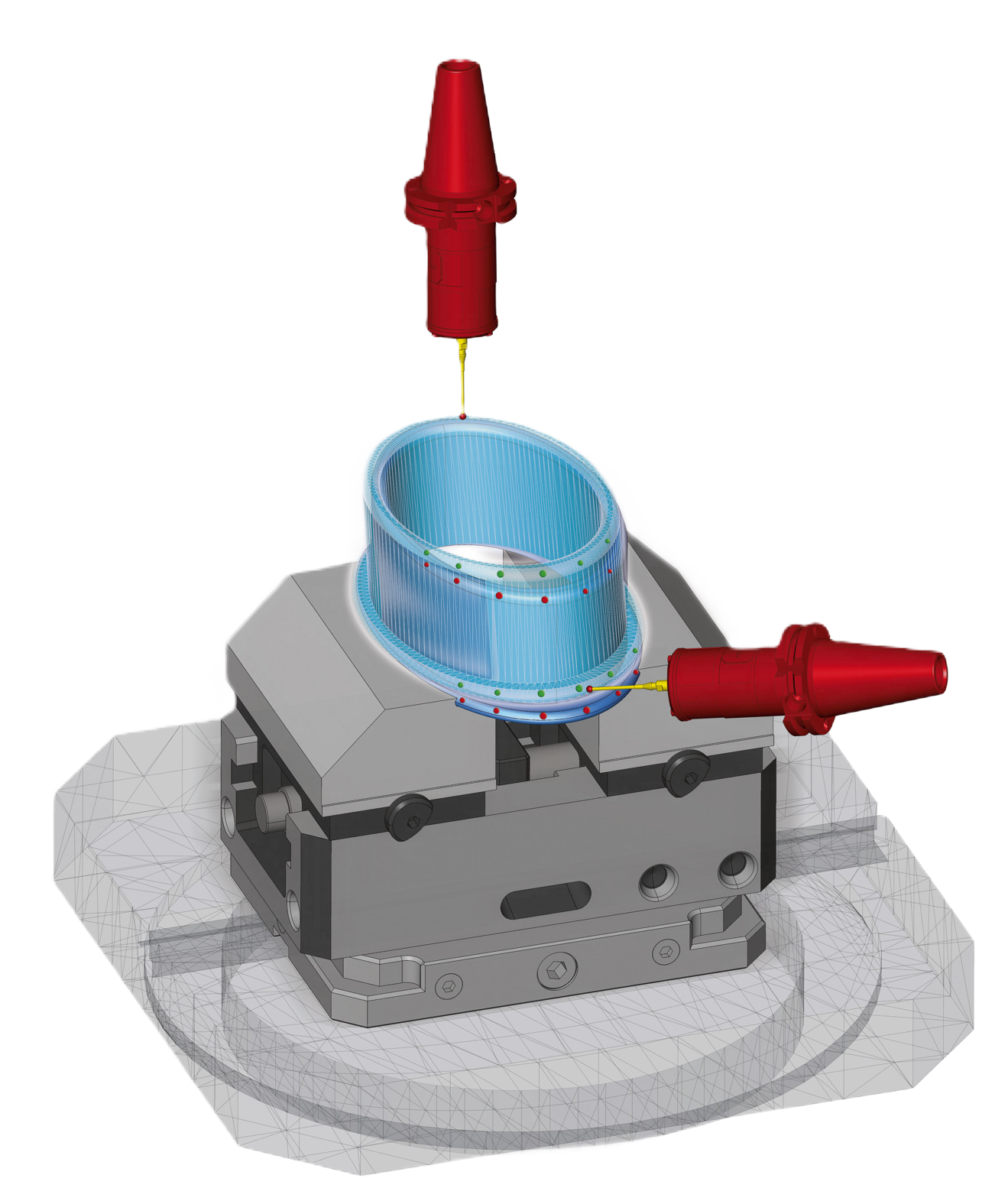

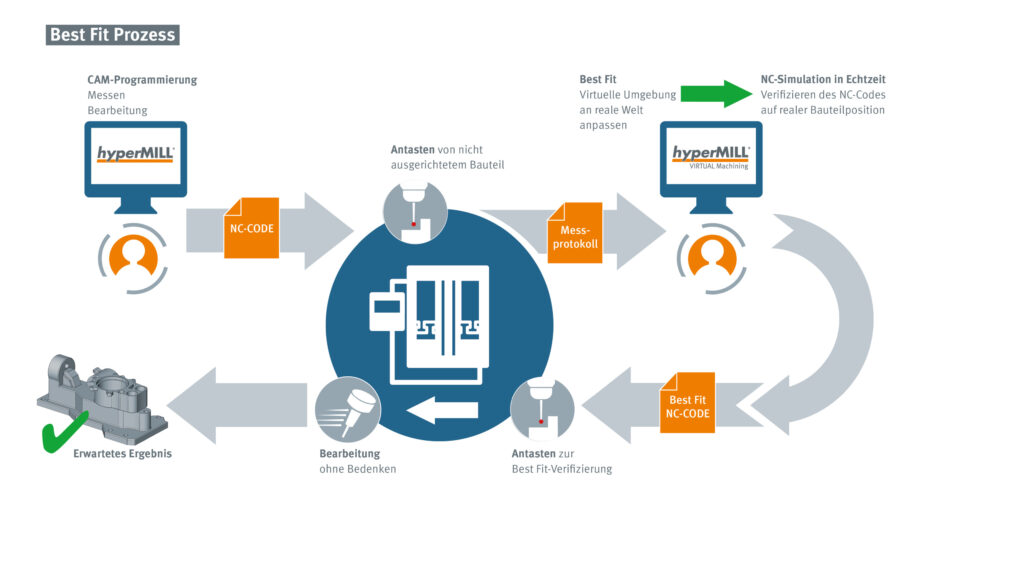

Instead of manually aligning the component, our solution enables real-time alignment in CAM.

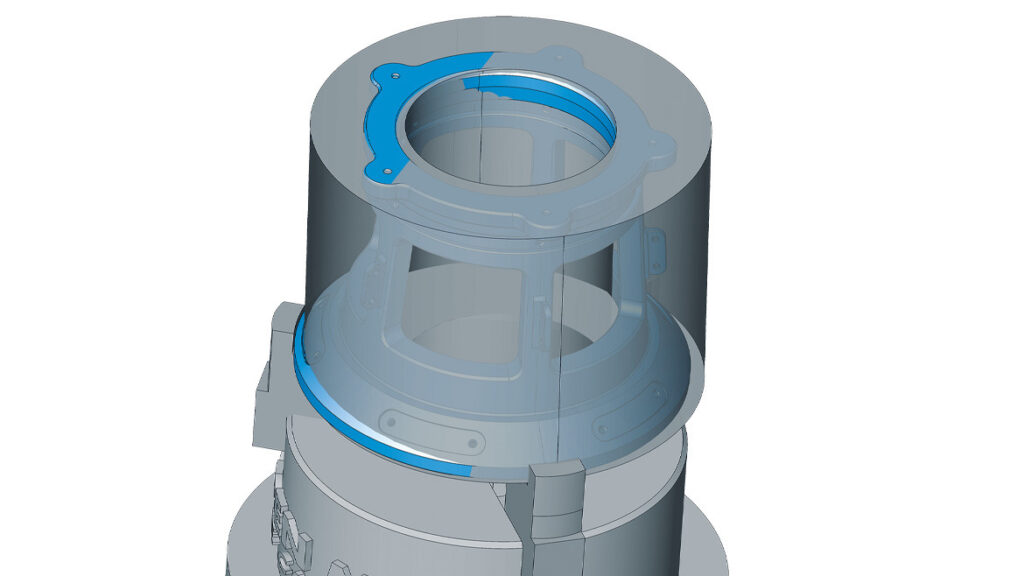

A 3D measurement records the position of the unaligned component on the machine.

The recorded measuring points are sent directly to hyperMILL, processed and the programming is adapted to the real conditions on the machine.

Safer, more precise and easier to plan

With hyperMILL BEST FIT, the challenge of component alignment is mastered effortlessly.

Rely on a solution that makes your production processes safer, more precise and easier to plan.

Virtual & without manual intervention

hyperMILL BEST FIT automatically adapts the NC code to the actual component position. This adjustment takes place completely virtually, without manual intervention by the operator.

Improvements in your process with hyperMILLBEST FIT

Reduced effort for clamping & measuring equipment

Automated alignment eliminates the need for expensive and time-consuming manual adjustments.

Plannable and efficient processes

Automation reduces set-up times.

Easier operation for less experienced employees

Thanks to automation, special clamping skills are no longer required, which makes training easier.

Less effort in construction

Dispensing with additional auxiliary geometries saves time and resources in the design phase.

Simple machine changes

Machine-independent programming enables flexible and fast changes between different machines without interrupting the process.

Features of hyperMILL BEST FIT

Component alignment is carried out efficiently and reliably directly in the CAM system.

The virtual machine precisely simulates and optimizes the component position.

The NC code is adapted exactly to the actual component position.

Potential collisions and machine limitations are automatically detected and compensated for.

Frequently asked questions (FAQs)

Was ist hyperMILL BEST FIT?

hyperMILL Best Fit is a technology for the automatic and precise alignment of parts directly in the CAM system to reduce set-up times on the machine.

Wie funktioniert die Echtzeitausrichtung mit hyperMILL BEST FIT?

A 3D measurement records the position of the component and the CAM system automatically adapts the NC code to the actual component position.