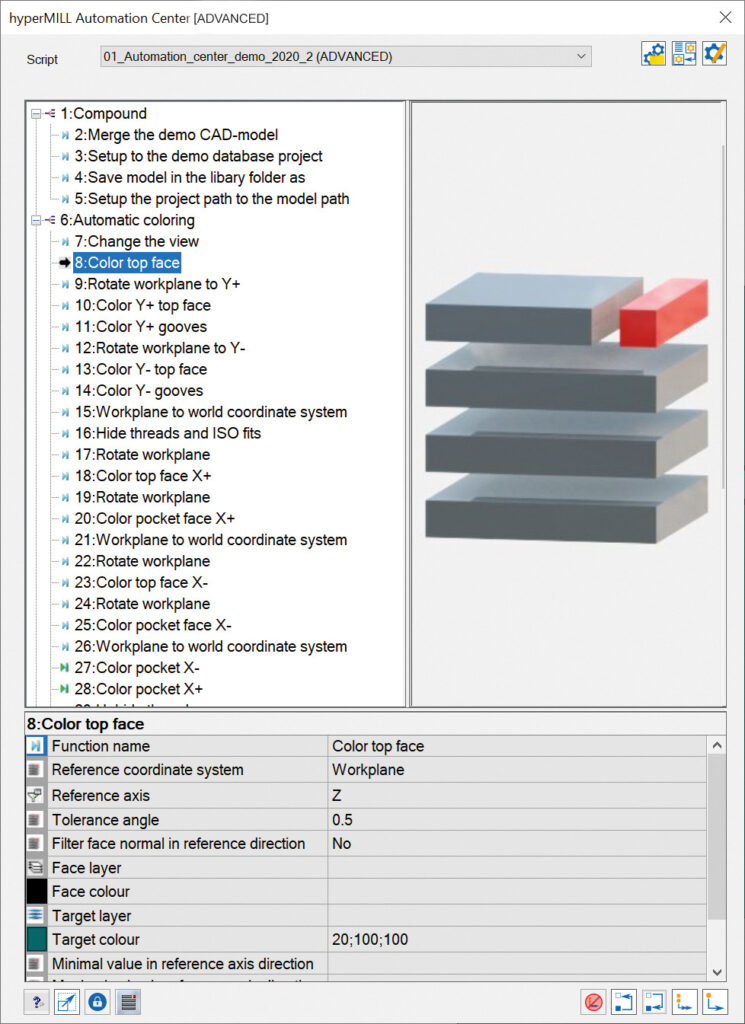

Automation Center Advanced

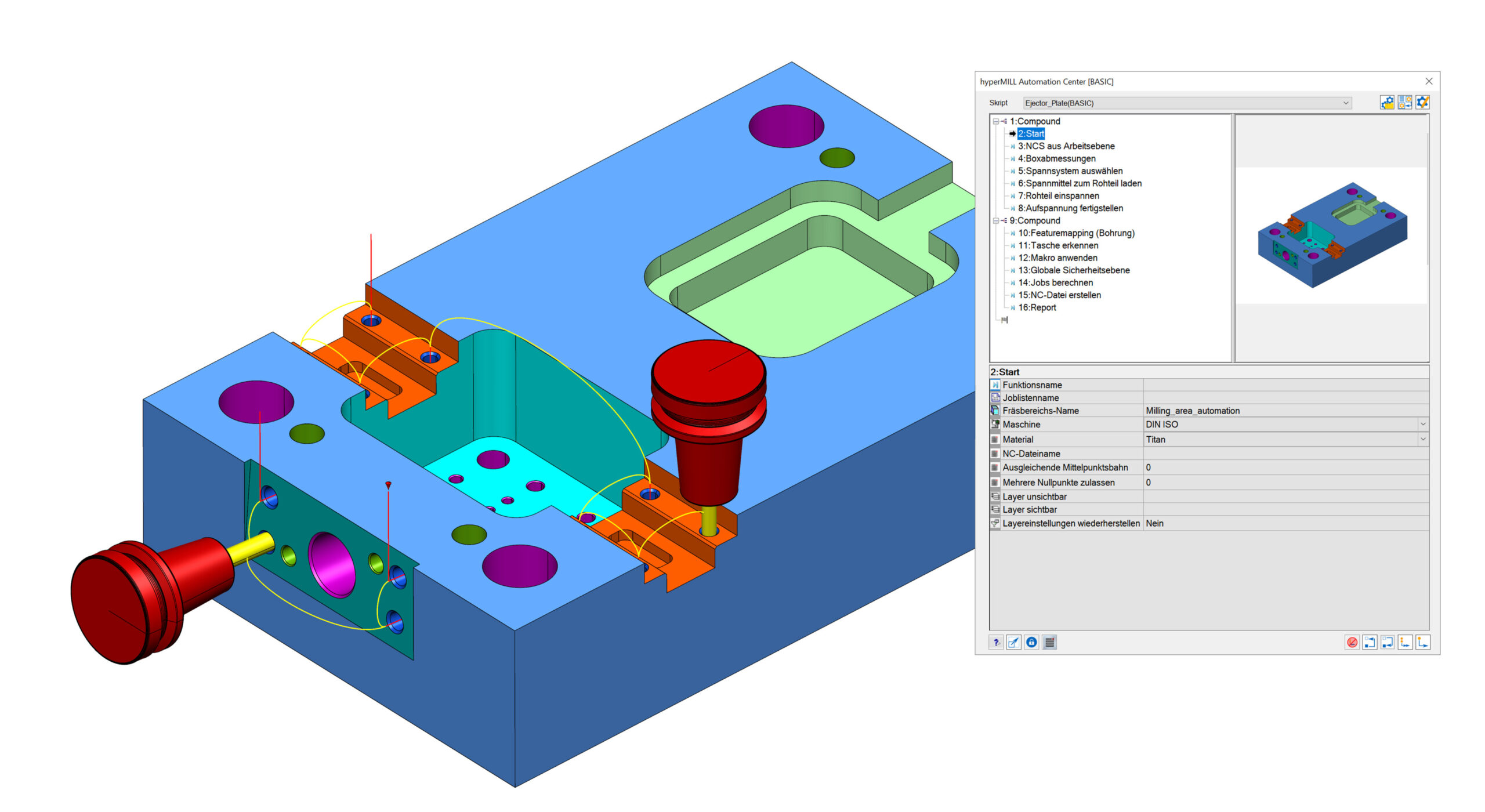

The hyperMILL Automation Center Advanced offers the

possibility to automate complex manufacturing processes efficiently and reliably at

.

The possibilities with the hyperMILL Automation Center go far beyond the automation of simple geometry features and allow you to standardize the entire workflow (import, CAD preparation, CAM programming, NC code simulation and output) and apply it to future parts.

- Clear and standardized production processes

- Automated CAD functions

- End-to-end automation

- Extensive functions and templates

Clear and standardized production processes

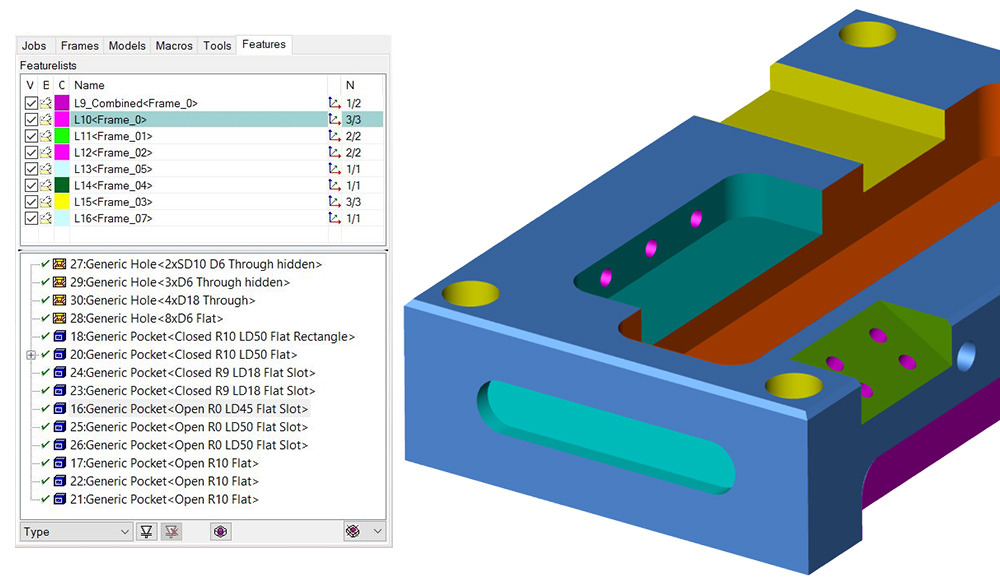

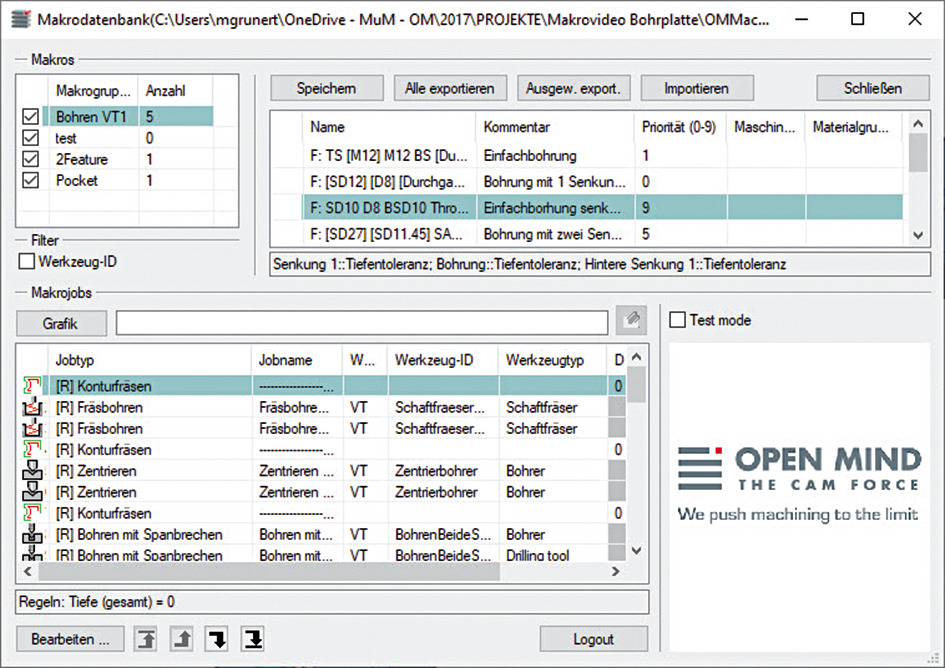

With hyperMILL Automation Center Advanced, you can map and standardize the entire manufacturing process, from data preparation of the CAD model to the creation of the finished NC program. This means that you can define proven processes once and then use them again and again, which significantly shortens programming times and minimizes the error rate.

This not only reduces your programming throughput time – it also enables you to make the knowledge of your production and programming professionals available to less experienced users!

Automated CAD functions

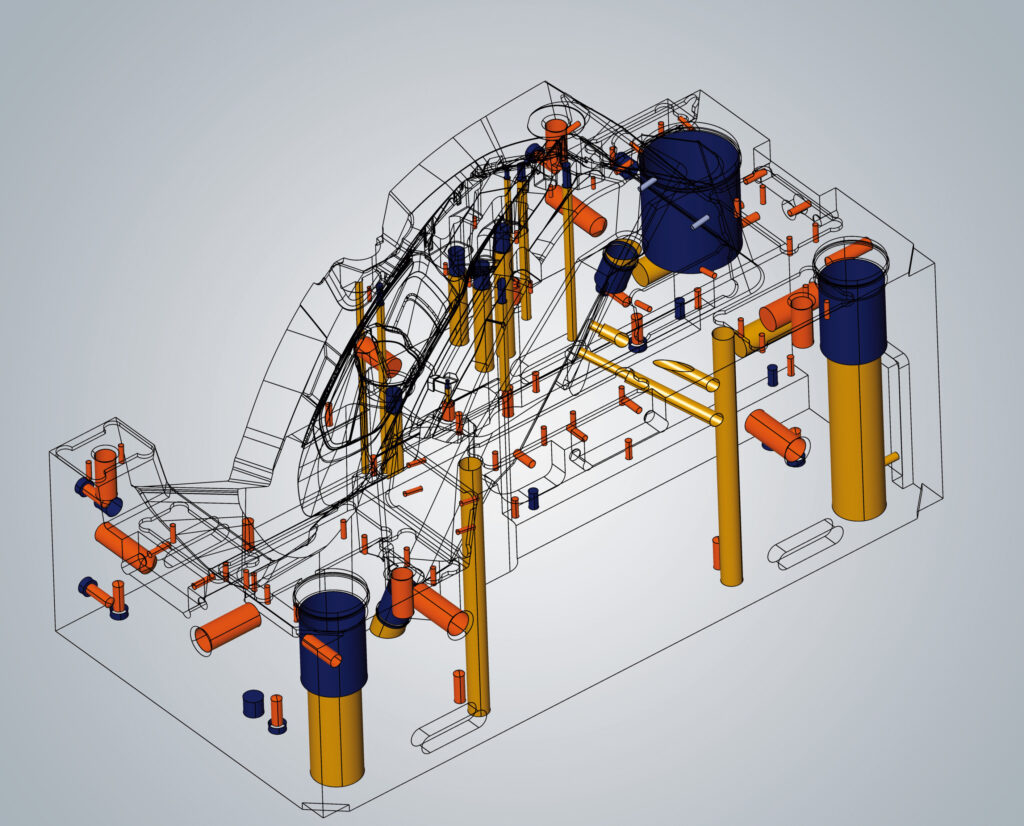

hyperMILL Automation Center Advanced can fully integrate the hyperMILL CAD functionalities into the automation process.

Model data can be automatically prepared in hyperMILL before the actual programming.

This includes closing holes, generating boundary curves and moving coordinate systems. The user can define these steps according to their standards and thus ensure that all model data is optimally prepared for NC programming.

End-to-end automation

Every step, from data preparation and programming to simulation and NC program creation, can be automated and standardized with hyperMILL.

This end-to-end automation makes it possible to apply processes to new components, significantly increasing efficiency. The hyperMILL Automation Center Advanced guides the user interactively through the automation process.

Extensive functions and templates

The hyperMILL Automation Center Advanced offers access to over 500 template functions.

These functions are then put together like a “construction kit” to create an automation sequence.

In addition, hyperMILL Automation Center Advanced can also be used to fully automate documentation.

Your advantages with Automation Center Advanced

Enables the standardization and reproducibility of manufacturing processes.

Complete automation from the CAD model to the finished NC program.

Access to over 500 template functions for maximum flexibility and efficiency.

User-friendly and safe process control through the automation sequence.

Frequently asked questions (FAQs)

Was ist das hyperMILL Automation Center Advanced?

An advanced automation platform that makes it possible to standardize and automate the entire manufacturing process, from data preparation to NC program creation.

Add missing pictures if possible