hyperMILL Electrode

hyperMILL CAD/CAM is the integrated CAD software for hyperMILL usersthat has been specially developed to meet the needs of CAM programmers.

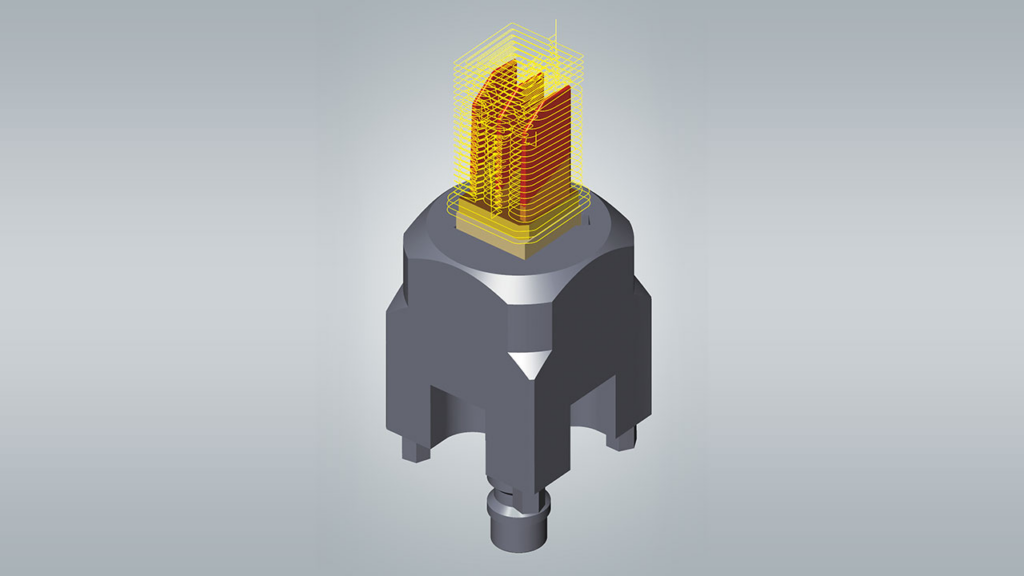

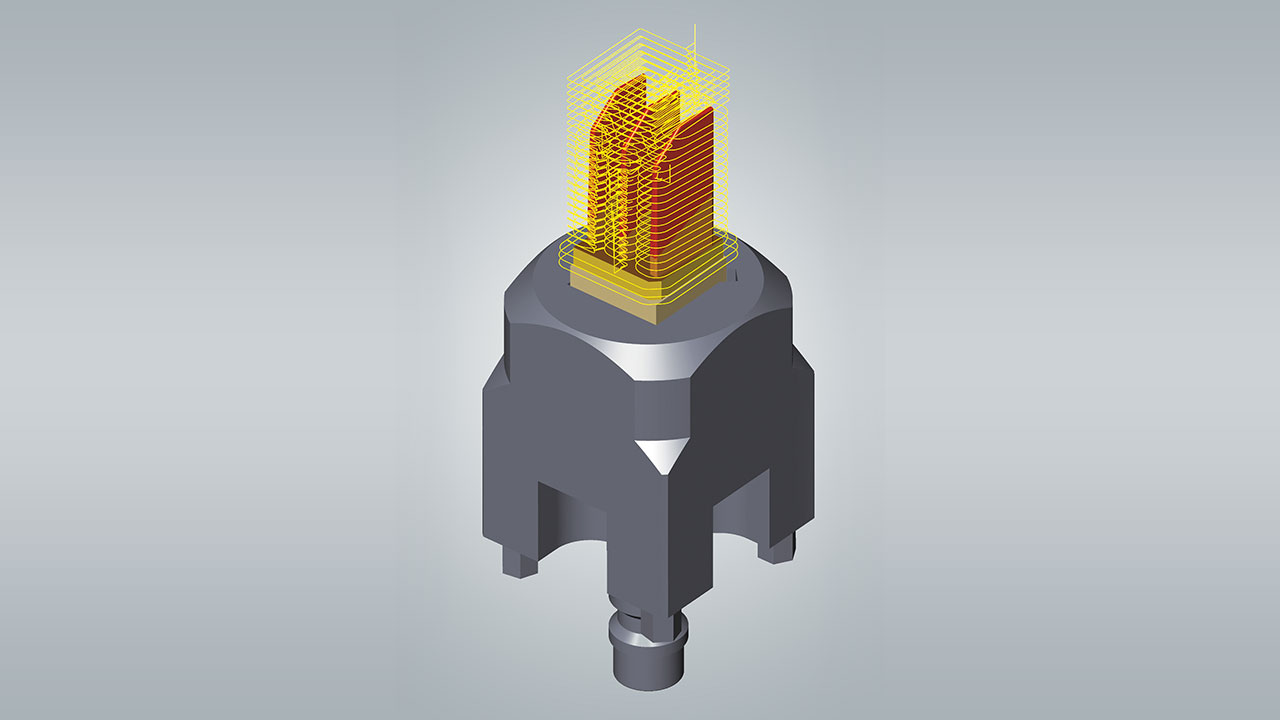

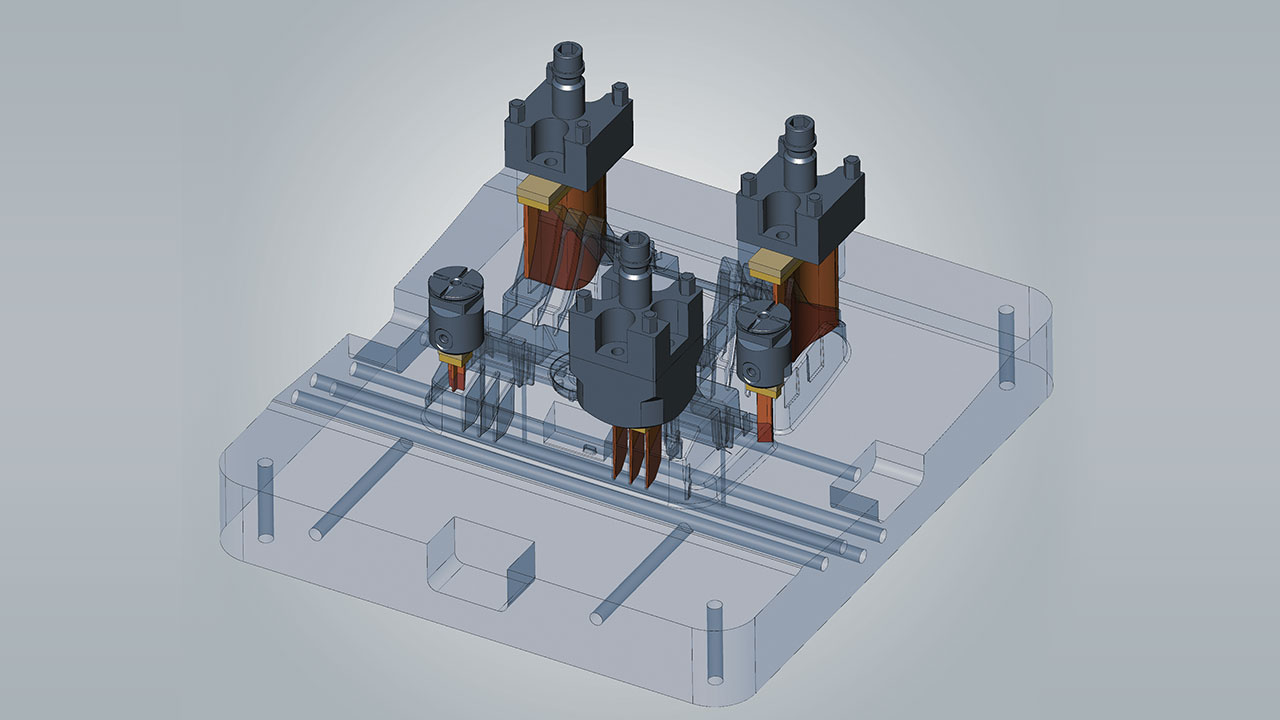

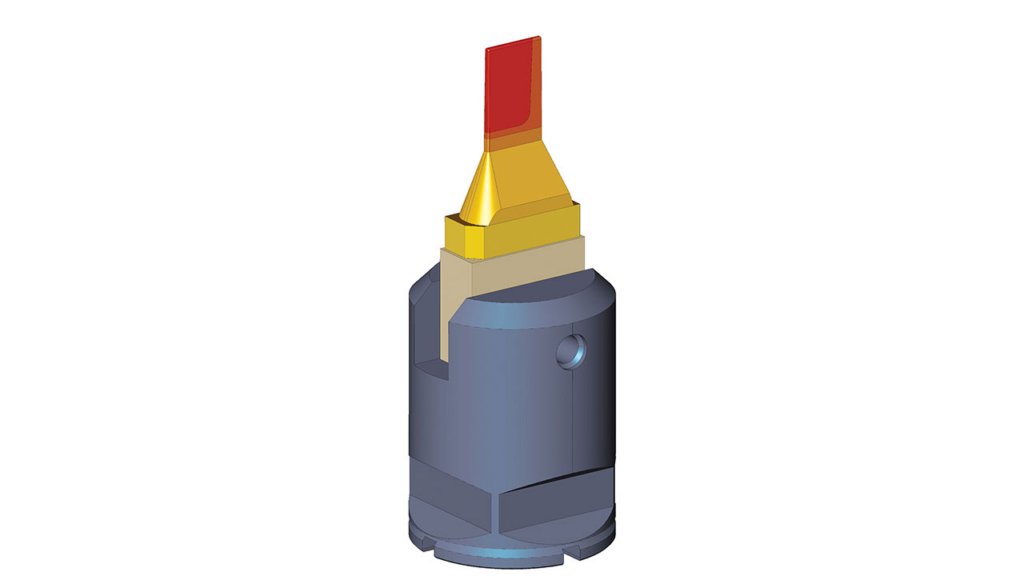

The outstanding innovation is the module for the rapid design of die-sinking electrodes. Thanks to a convenient and automated process, the electrodes can be easily derived from the surface to be eroded in the component geometry without specialist knowledge.

- Based on the target geometry

- Direct transfer to the CAM system

- Individual advice

Based on the target geometry

The surfaces to be eroded from the component geometry are the starting point. The NC programmer selects them and, if necessary, the CAD software automatically extends the electrode surfaces and derives the blank and the holder.

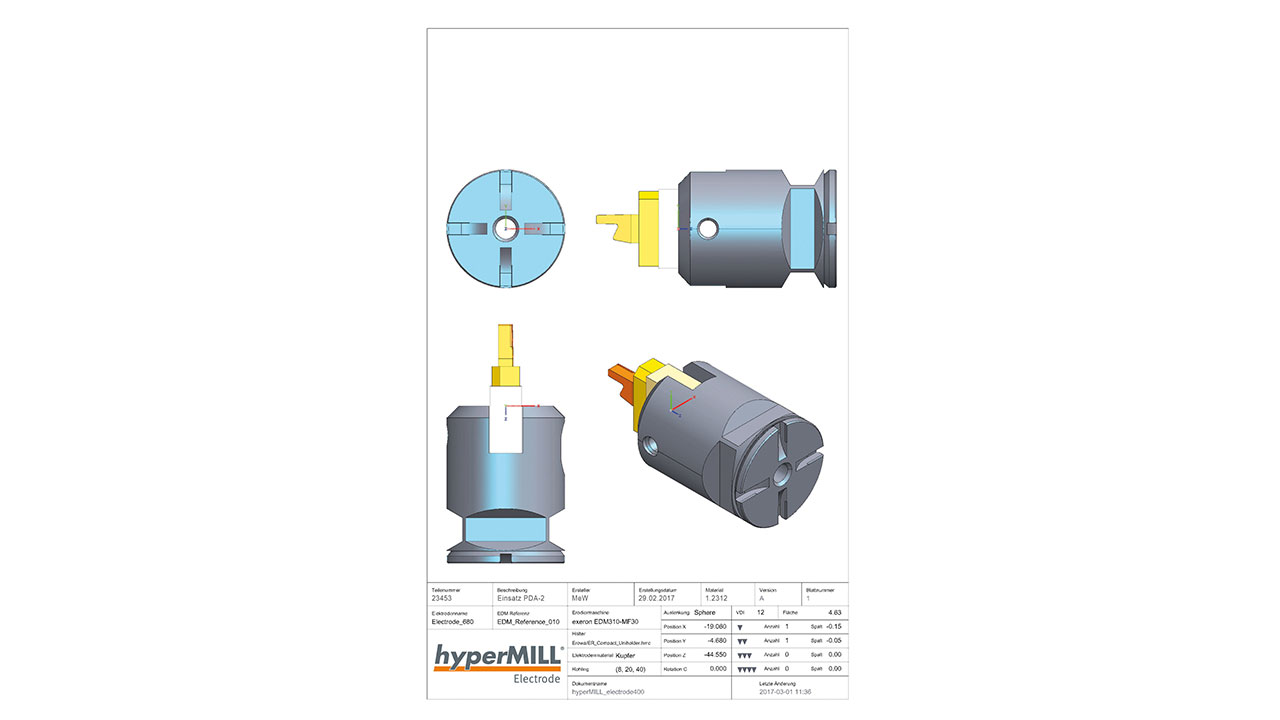

The module works with solid and surface models and the geometry can be selected using surfaces and contours. Openings in the geometry are closed automatically and hyperMILL CAD/CAM also calculates the minimum rib distance, blank protrusion and C-angle. All technology data such as undersize, blank size, position reference and color ranges are automatically transferred to hyperMILL.

Direct transfer to the CAM system

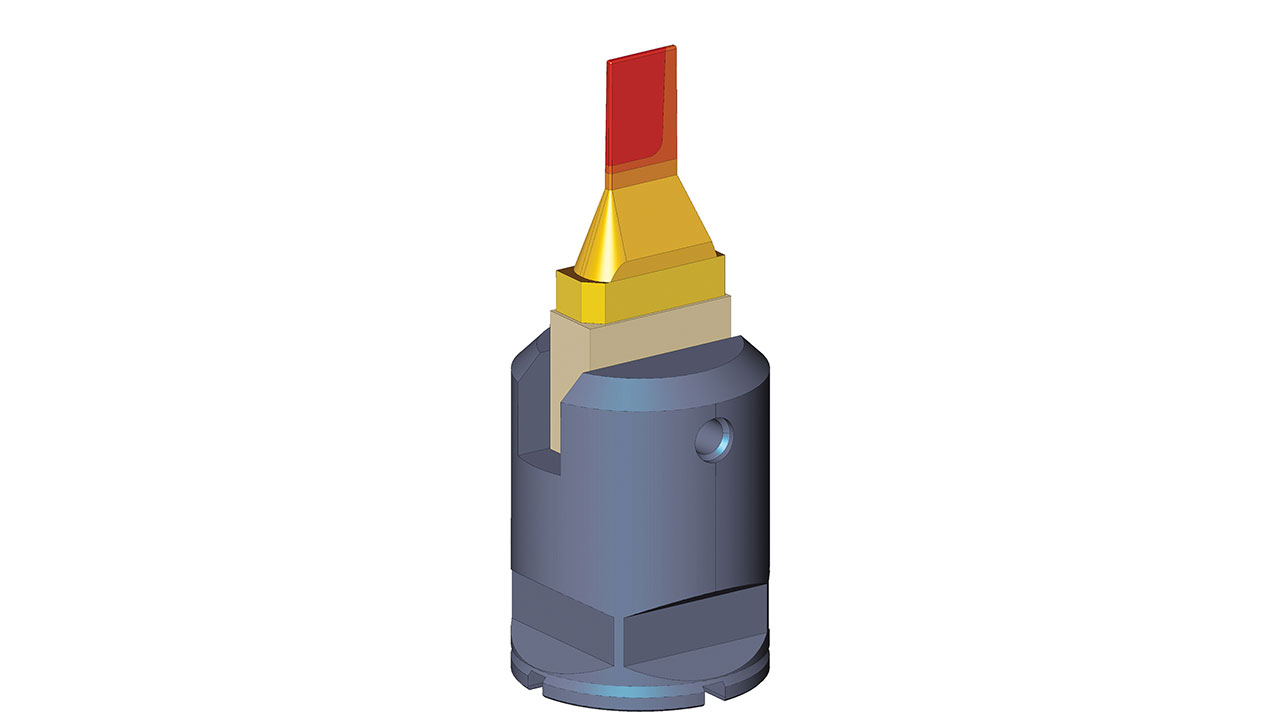

The electrodes designed in hyperMILL CAD/CAM are processed directly in the CAM system. The user simply selects the appropriate electrode and starts programming.

A separate dialog box is available for this purpose, in which the milling operation for the electrode is specified with just a few clicks. hyperMILL then automatically generates the job list with all the relevant parameters.