Voxeljet VX2000

Maximum flexibility and performance for impressively large and complex parts – all in a single pass.

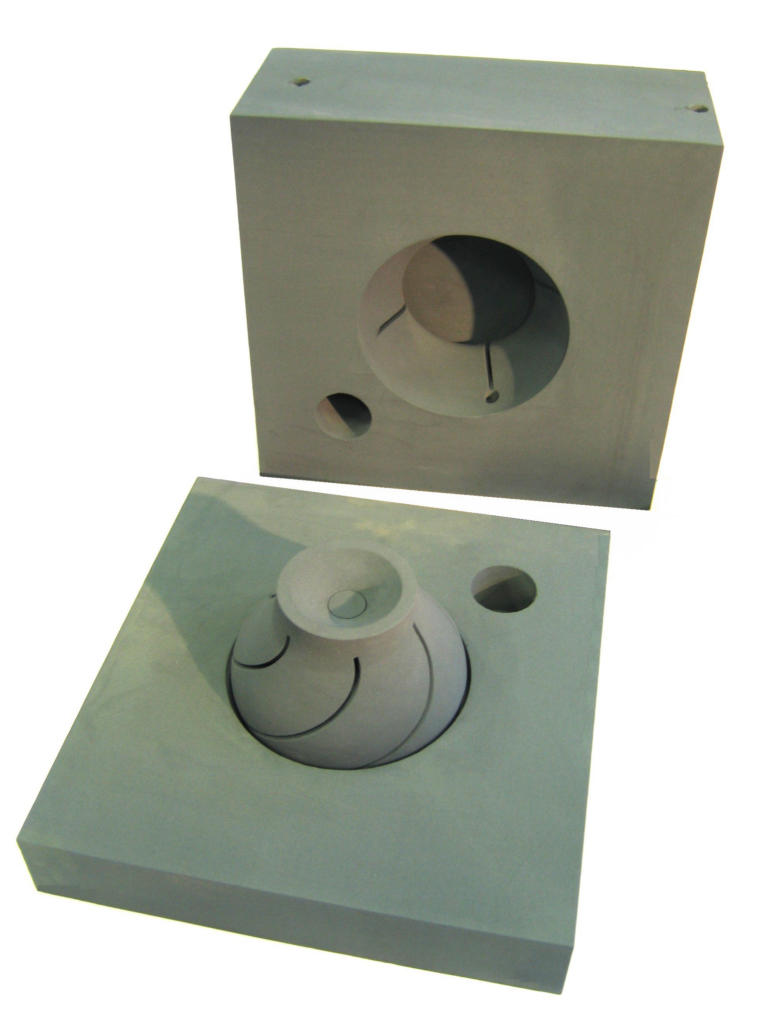

The VX2000 is an industrial 3D printer that makes it possible to produce large and complex parts in a single operation.

The new industrial printer is designed for the use of all particle materials currently offered by voxeljet and combines outstanding performance with a very large installation space for maximum flexibility.

- 3D printers for large formats

- Productivity with flexibility and material diversity

- Use of furan and phenolic resin binders

3D printers for large formats

The VX2000 3D printer is an extremely powerful and proven 3D printing system for industrial applications.

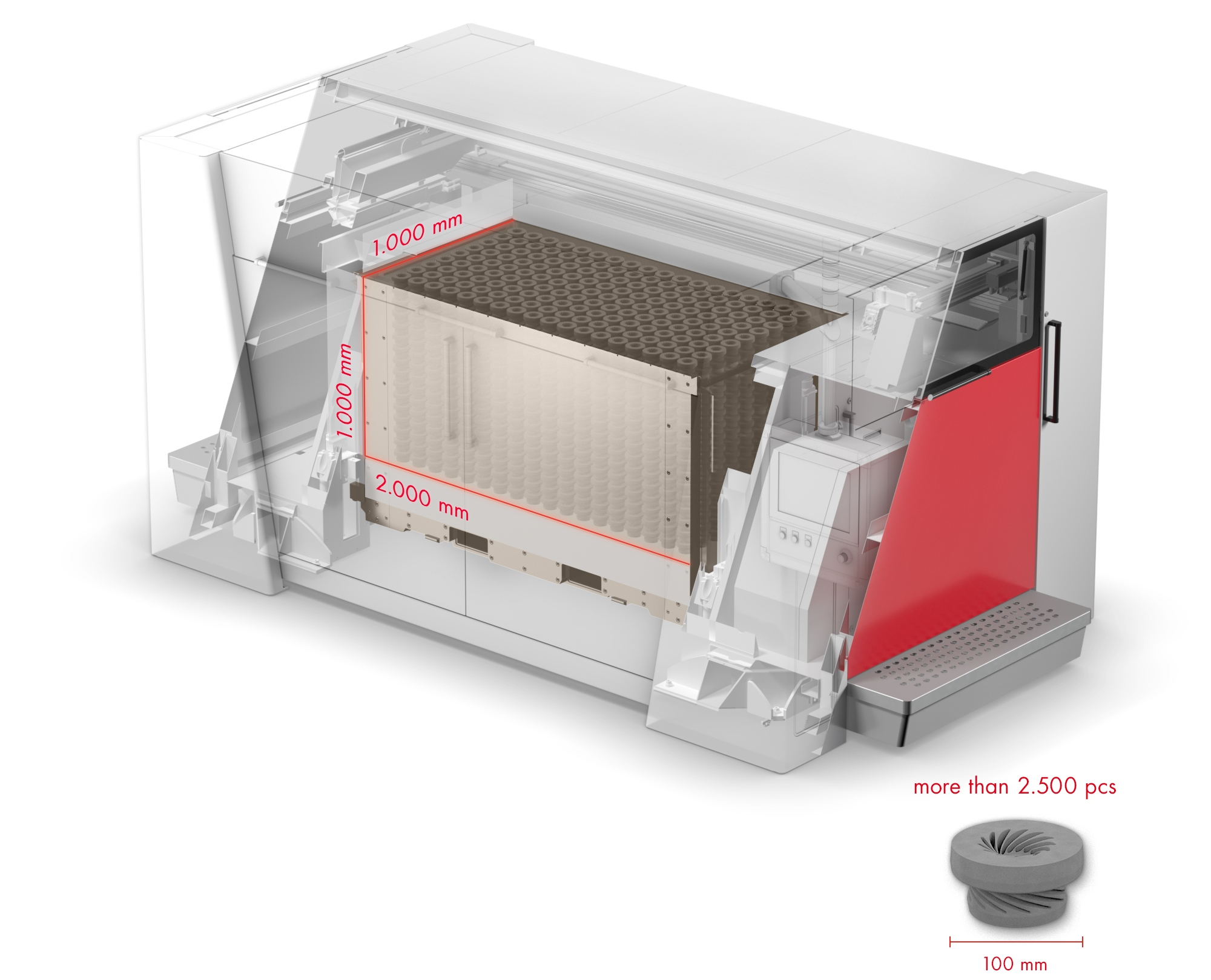

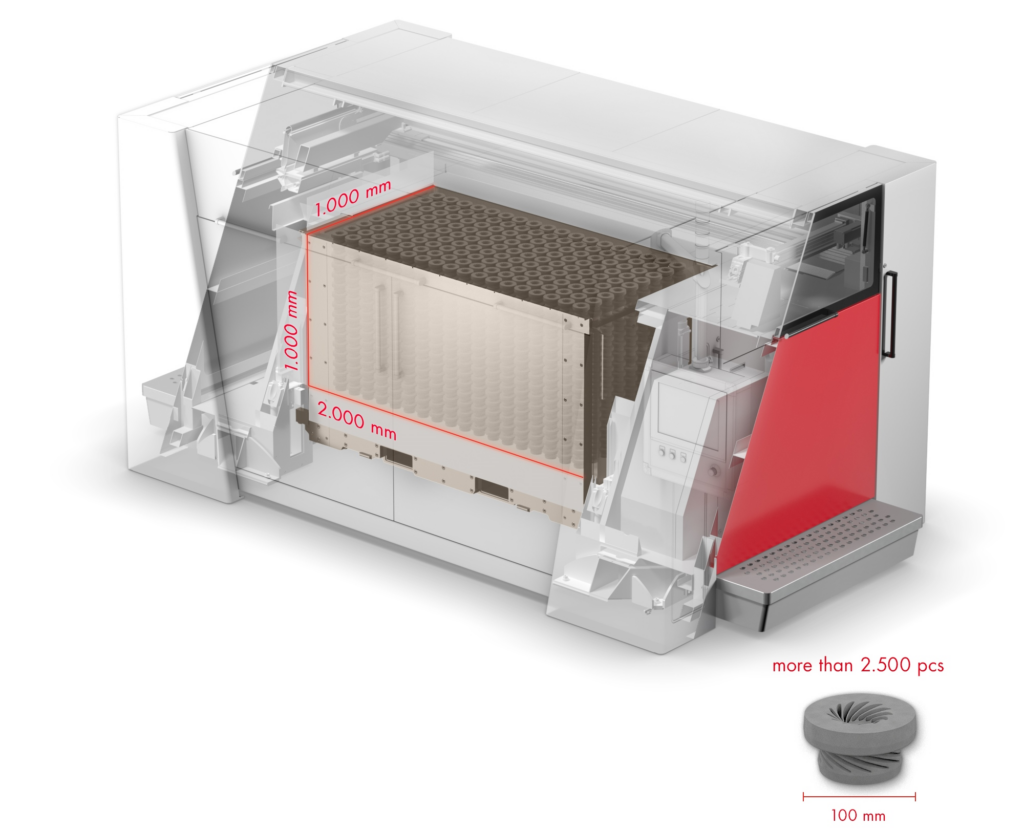

With a build volume of 2000 liters, it is one of the most productive 3D printing systems in the world. It is suitable for both large collection jobs and the production of components with an edge length of up to 2 meters.

Productivity with flexibility and material diversity

The piezoelectric print head modules of the VX2000 guarantee micrometer precision even at high workloads.

With its construction volume of 2000 x 1000 x 1000 mm, the VX2000 is ideally designed to produce small to medium quantities quickly and economically.

Use of furan and phenolic resin binders

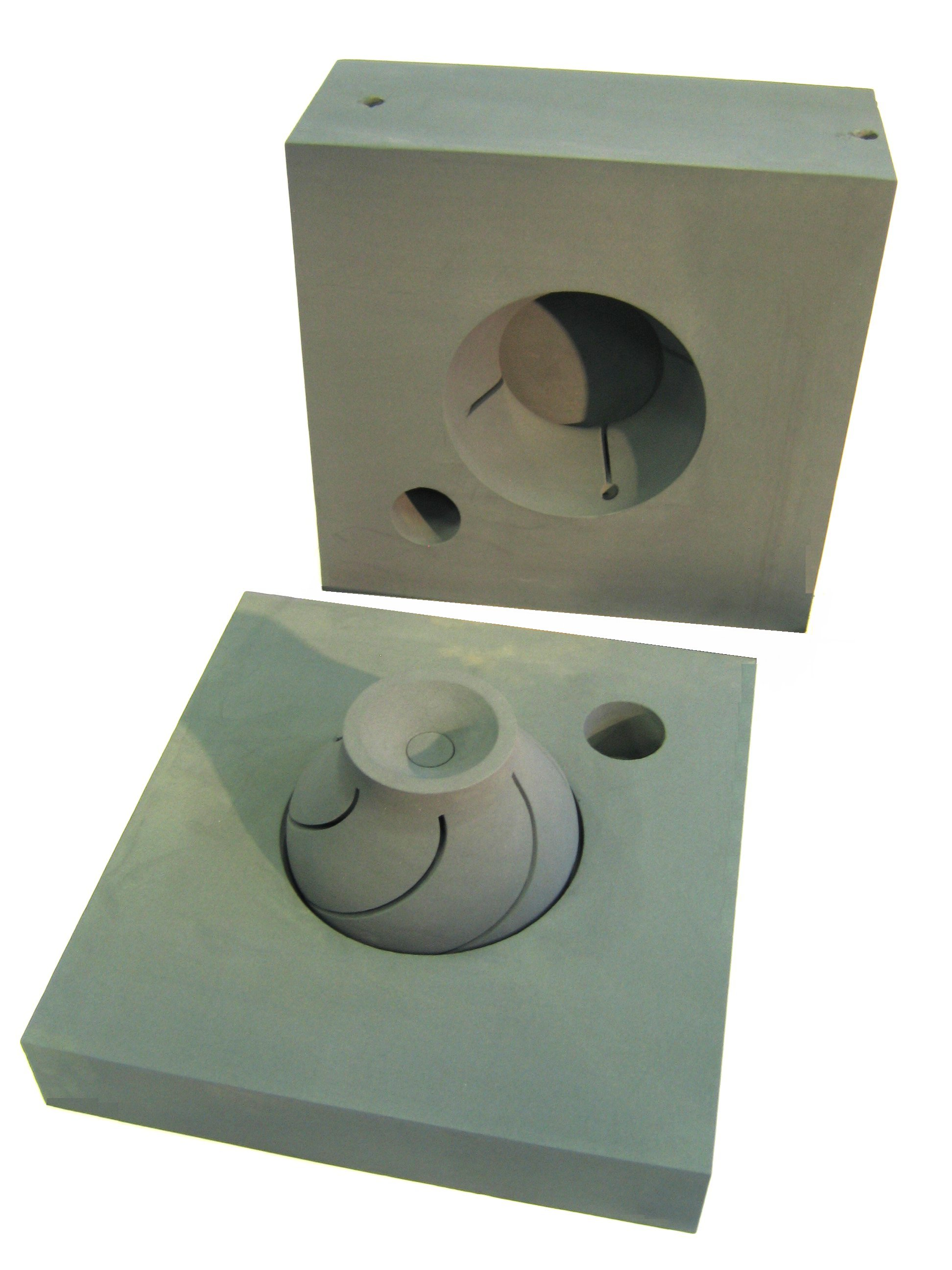

The 3D printer is compatible with a wide range of sand types for the production of sand casting or casting molds, including standard quartz sand as well as special sand types such as cerabeads or chromite.

This makes the VX2000 the perfect addition to your core and mold shop. It makes it possible to produce special components quickly and economically and accelerates product development through flexible prototype production.

Frequently asked questions (FAQs)

What types of materials can I use with Voxeljet VX2000 and how does this affect the application possibilities?

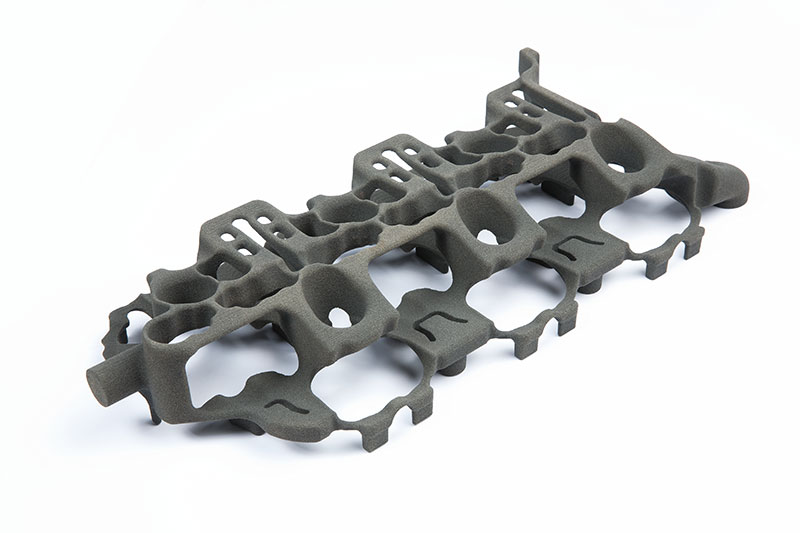

The VX2000 is designed for a wide range of particle materials. These include plastics and sand, which can be used for different applications. This flexibility allows you to produce a variety of products. The choice of material influences the properties of the finished parts, such as strength and detail. With the ability to print both large and intricate parts in a single pass, the VX2000 opens up a wide range of applications for you in series production and the manufacture of customized components.

What advantages does the large installation space offer for my production?

The large installation space minimizes the need for time-consuming post-processing or multiple printing processes, as complex geometries can be produced in one piece without interruptions. This not only reduces assembly and production times, but also overall costs and increases flexibility in the design of your parts.