EnvisionTEC Bioplotter

The world market leader in biofabrication

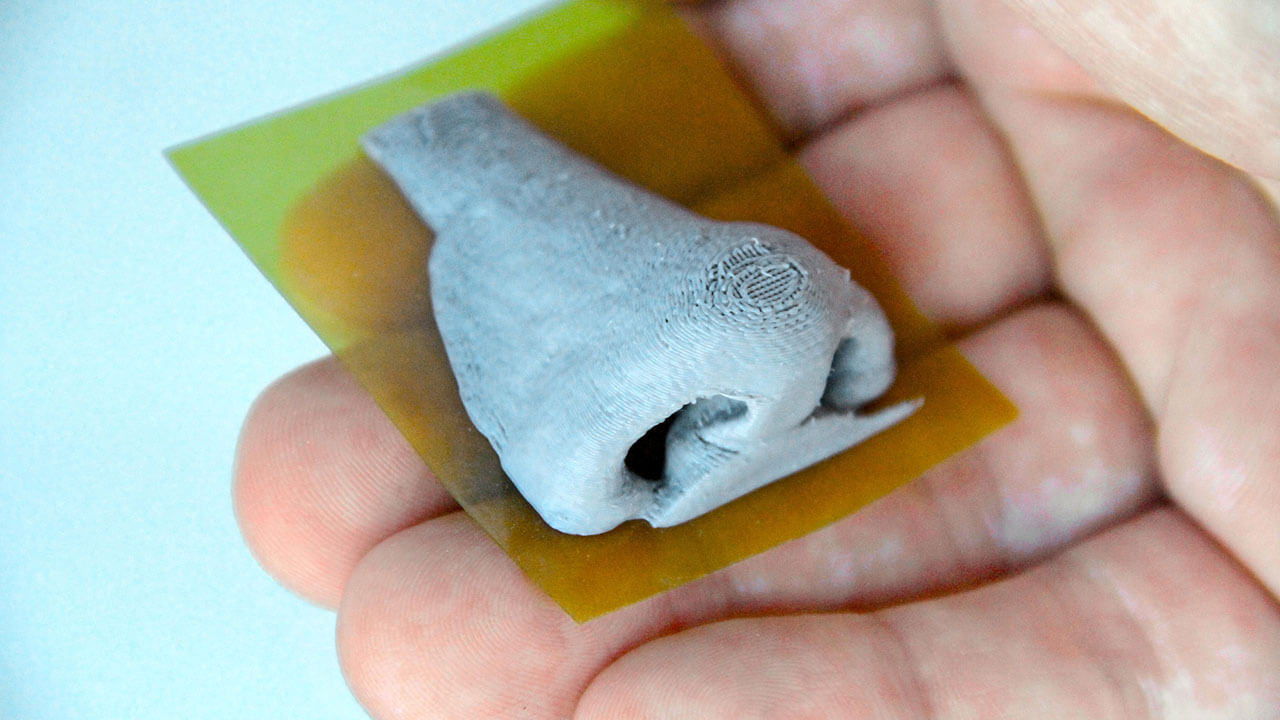

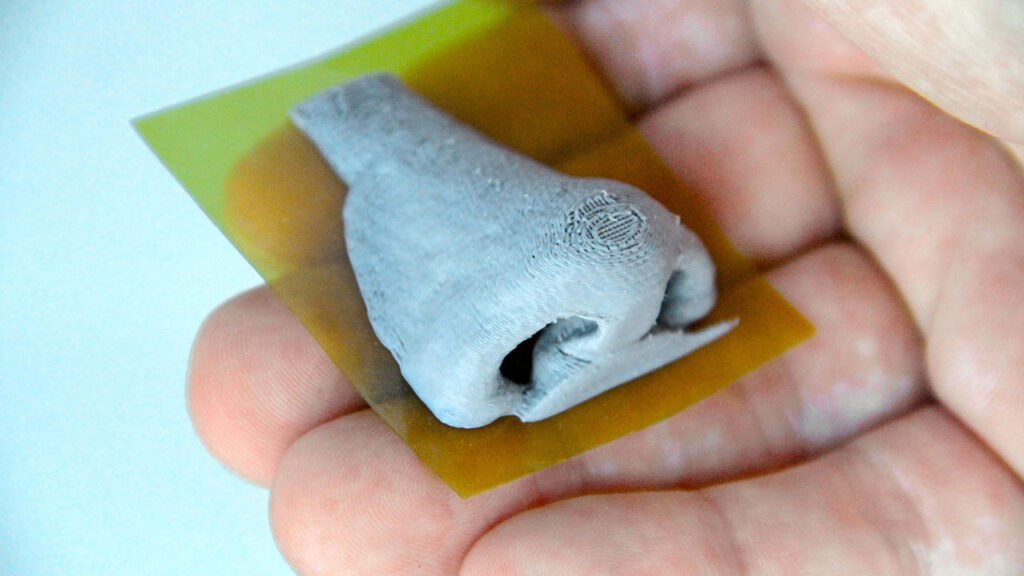

The EnvisionTEC Bioplotter is also used for the production of hyperelastic bone, ovarian implants or for a placenta model and is used in bone regeneration research.

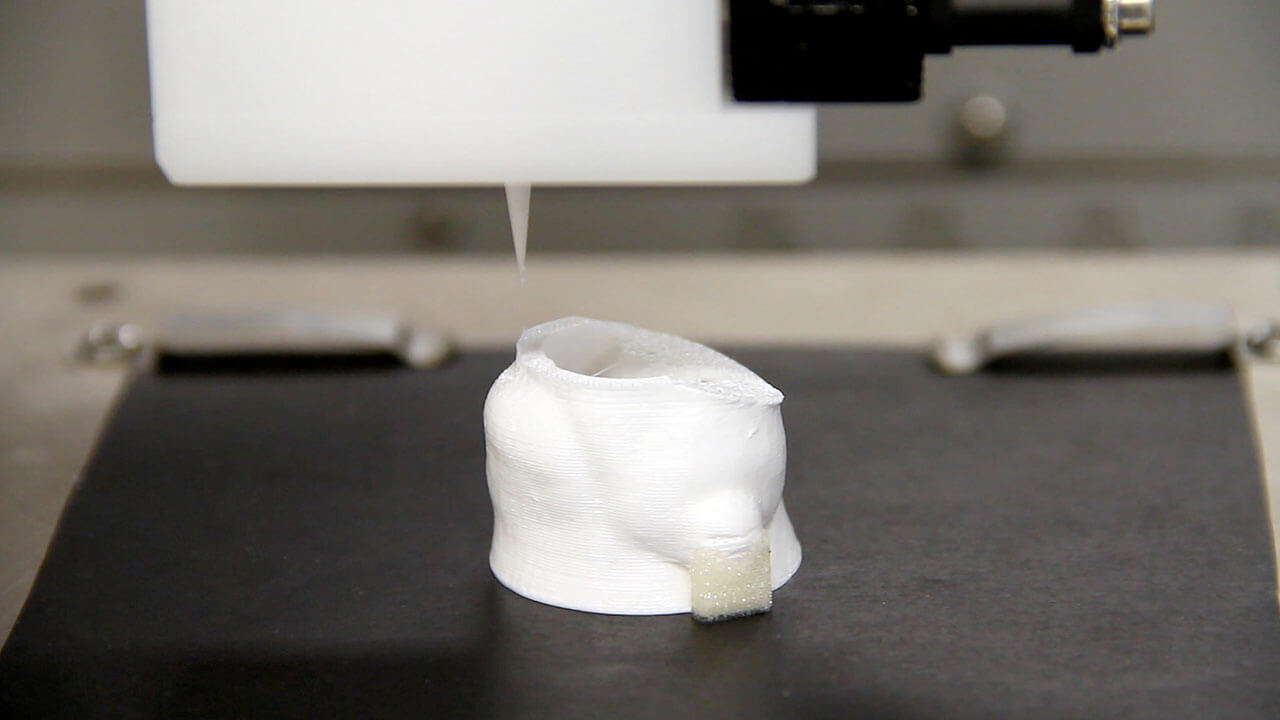

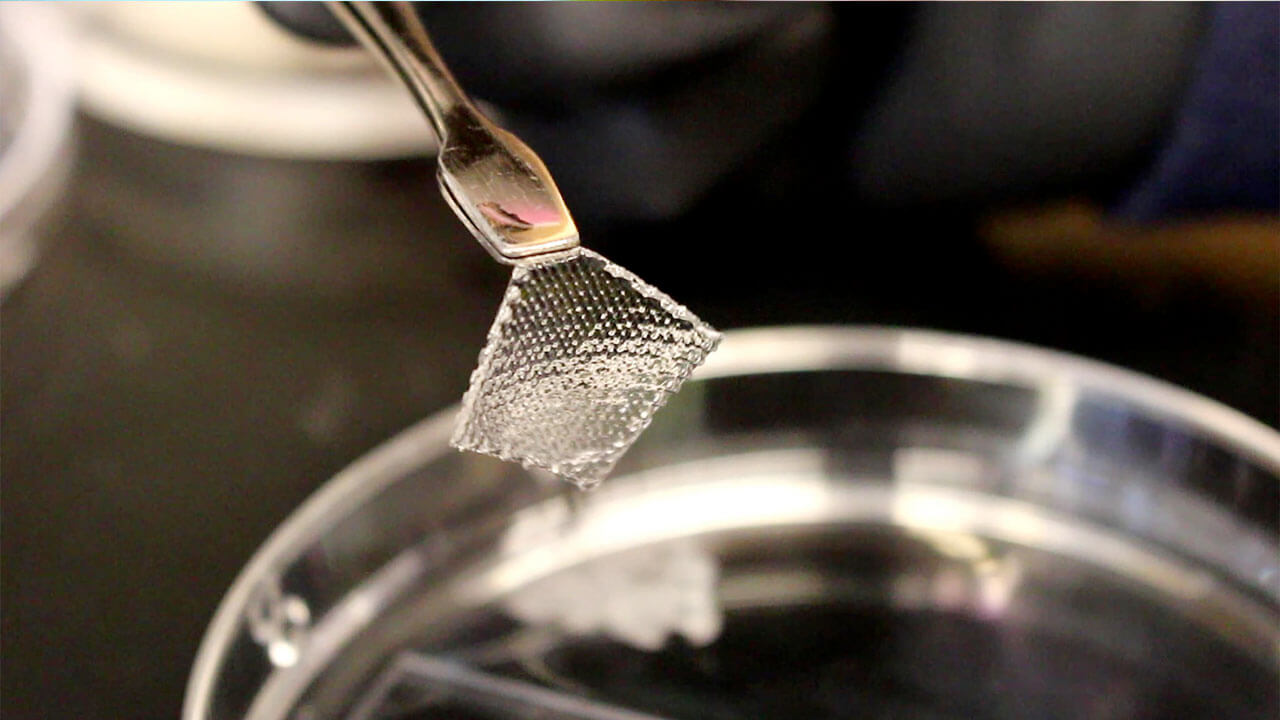

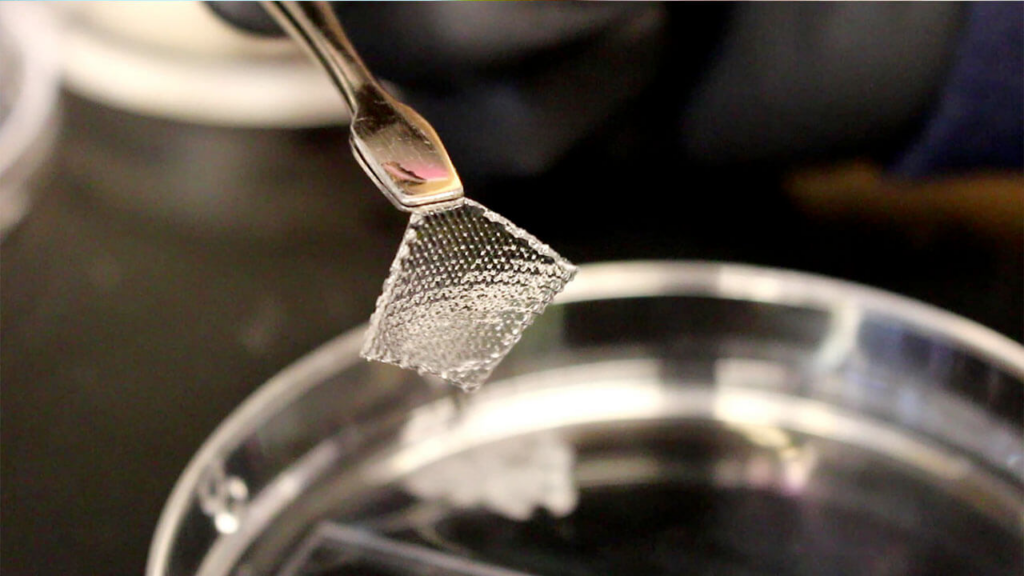

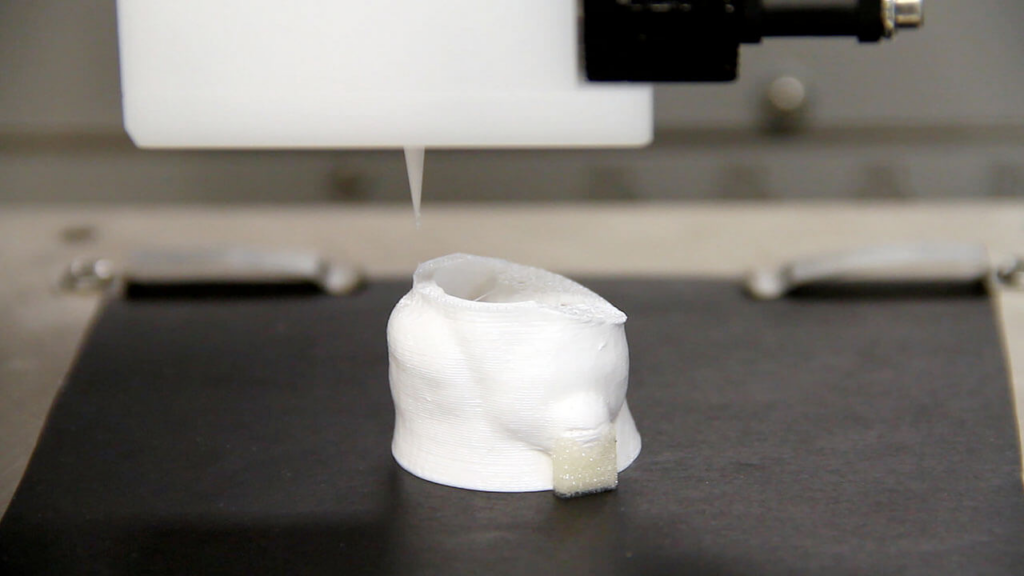

Available in two versions – Developer and Manufacturer – this bioprinter family processes open-source biomaterials. Using air or mechanical pressure, the scaffolds can be produced to create tissues, organs and more.

- Modular components for precise biofabrication

- Optimized for cell and tissue pressure

- Reliable and fast

Modular components for precise biofabrication

The 3D Bioplotter is a versatile rapid prototyping tool for processing a wide range of biomaterials for Computer-Aided Tissue Engineering (CATE), from 3D CAD models and patient CT data to a physical 3D scaffold with a designed and defined outer shape and an open inner structure.

- The built-in camera is used to improve needle calibration and ensure consistent prints

- Temperature-controlled build platform and various sensors enable a greater variety of materials and finely tuned environments for low-tolerance frameworks.

- Five cartridge slots for more materials in a single print.

Optimized for cell and tissue pressure

Up to 5 print heads and a heated platform with sterile filter enable optimal 3D printing of individual cells or organic tissue.

Reliable and fast

High-quality components guarantee reliable and fast printing. This leaves more time for research and development.

Frequently asked questions (FAQs)

Wie flexibel ist der ETEC Bioplotter in Bezug auf die verwendbaren Materialien?

The ETEC Bioplotter offers exceptional flexibility in terms of the materials that can be used. It is an open system that allows you to use a variety of biomaterials, including hydrogels, polymers, ceramics and other specialized materials.

Welche Wartungsmaßnahmen sind erforderlich, um die optimale Leistung des ETEC Bioplotters aufrechtzuerhalten, insbesondere bei kontinuierlichem Einsatz?

To maintain the optimum performance of the ETEC bioplotter during continuous use, you should carry out regular maintenance measures. This includes regular cleaning and disinfection of the print heads and print chambers to remove contamination and material residues. You should also regularly calibrate the print heads and check the material feed systems to ensure that all components are working properly. It is also important to keep the bioplotter software up to date and install any updates promptly.