Mlab family

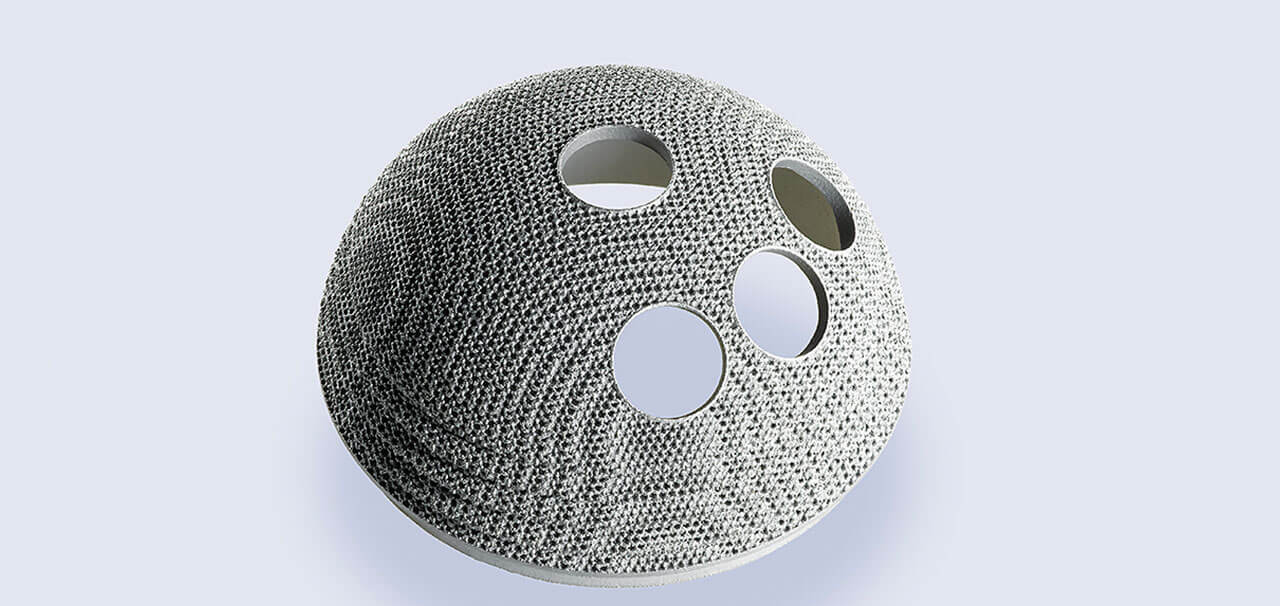

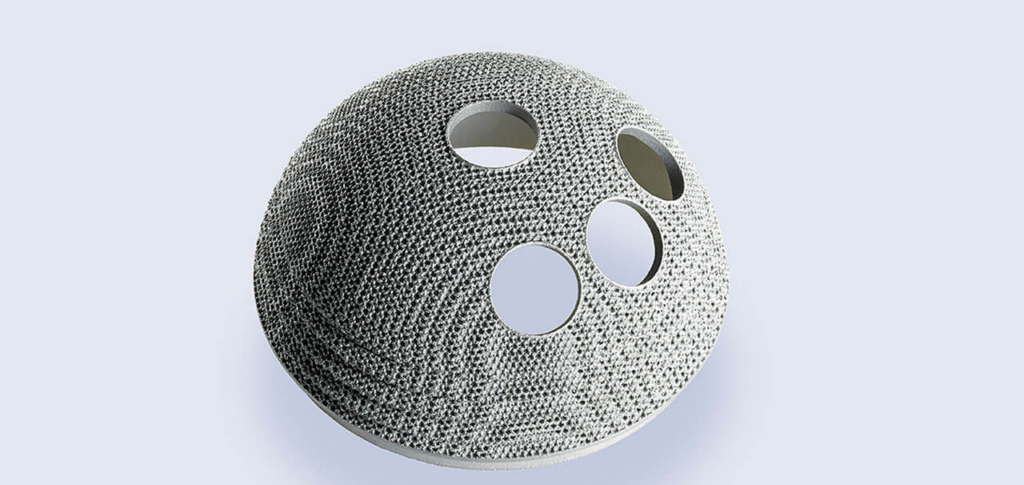

Perfect when high surface quality and the finest component structures are required.

The Mlab family (formerly Mlab cusing), provides modern solutions for manufacturing filigree components from various materials, including reactive materials such as titanium.

The Mlab Family is ideal for demanding applications thanks to its high surface quality and extremely fine component structures.

- Patented drawer system

- Processing of steels to reactive materials

- Increased construction volume for the Mlab 200R

Patented drawer system

The user-friendly drawer system of the Mlab Family comprises the construction chamber, the dosing chamber and the storage container.

This system ensures uncomplicated handling and maximum safety by enabling a quick change of material without the risk of contamination.

Processing titanium

The machines in the Mlab Family, especially the Mlab R variants, are capable of processing a wide range of materials, including titanium and titanium alloys.

All process steps are carried out under inert gas, which increases the safety and quality of production.

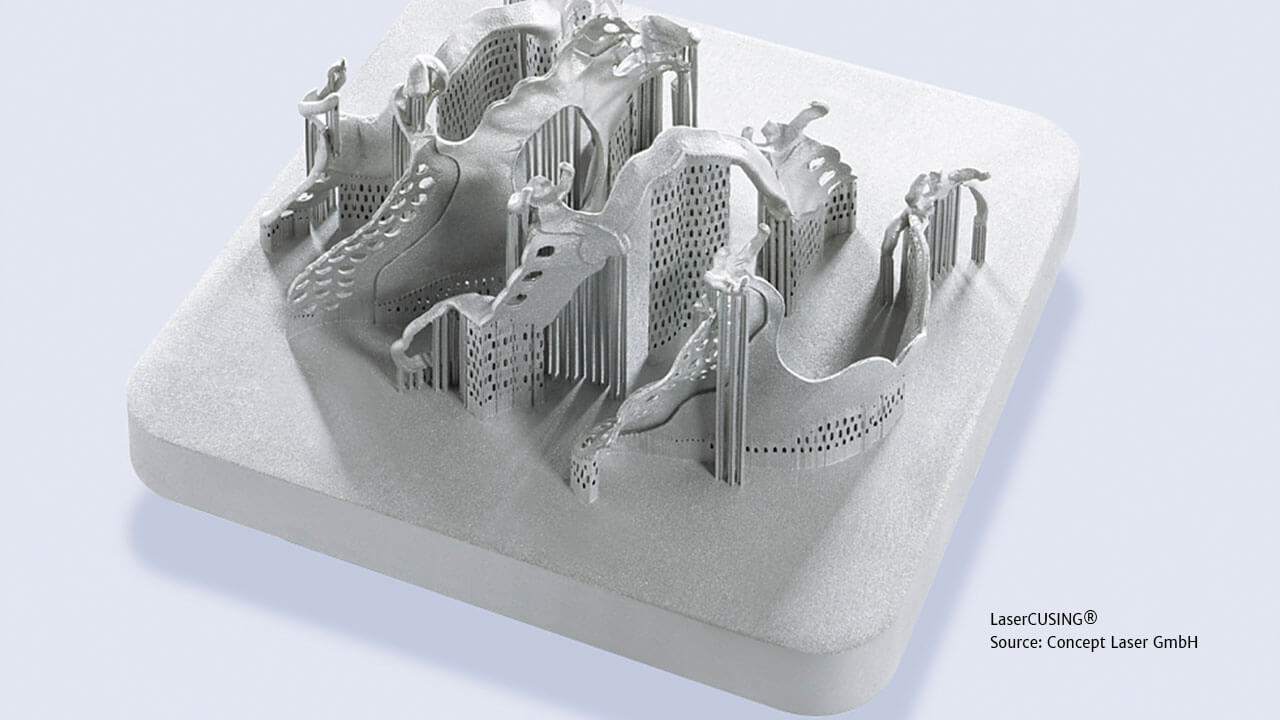

Increased building volume

The Mlab Family offers a 54% larger build volume and twice the laser power of 200 watts compared to previous models.

These improvements enable the production of larger components with increased productivity without compromising the compact design of the machine.

Frequently asked questions (FAQs)

Welche Vorteile bietet das patentierte Schubladensystem der Mlab family?

The patented Mlab family drawer system has several important advantages. It consists of a storage container, a build chamber and a dosing chamber, all integrated into a pull-out system. This makes it possible not only to handle and maintain the machine easily, but also to change materials quickly and without contamination. The user-friendliness of the system makes it much easier to operate, while at the same time complying with the highest safety standards. Furthermore, the drawer system is available in different sizes in order to meet the various construction volume requirements.

Welche Stoffe sind für die Mlab family geeignet, und warum ist sie besonders gut geeignet für reaktive Materialien wie Titan?

The Mlab family can process a wide range of materials, including reactive materials such as titanium and titanium alloys. The machine has been developed in strict accordance with ATEX guidelines which ensure that the components produced are not only of high quality, but also guarantee the safety of the operator and the service life of the machine.

Welches sind die Besonderheiten der Mlab 200R und welche Vorzüge hat sie im Vergleich zu früheren Modellen?

The flagship model of the Mlab family is the Mlab 200R, which has a number of significant innovations compared to its predecessors. On the one hand, it has a higher construction volume which makes it possible to produce larger components without changing the compactness of the machine. By increasing the laser power to 200 watts, efficiency is increased and faster build rates are possible. The Mlab 200R also has a new, user-oriented design that enables improved maintenance and operation. This makes it a perfect option for applications that require a high-quality surface and the finest component structures.