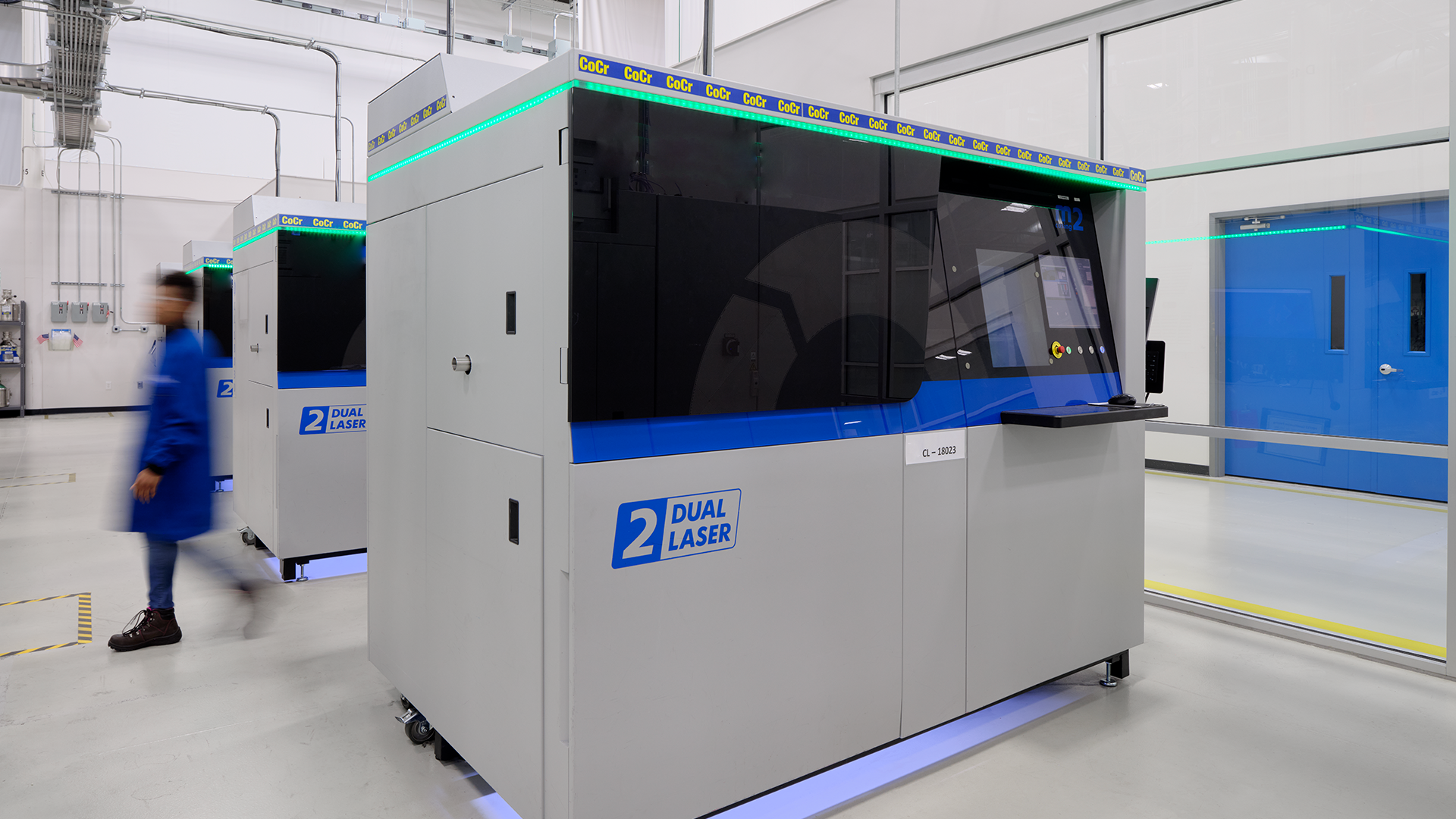

M2 Series 5

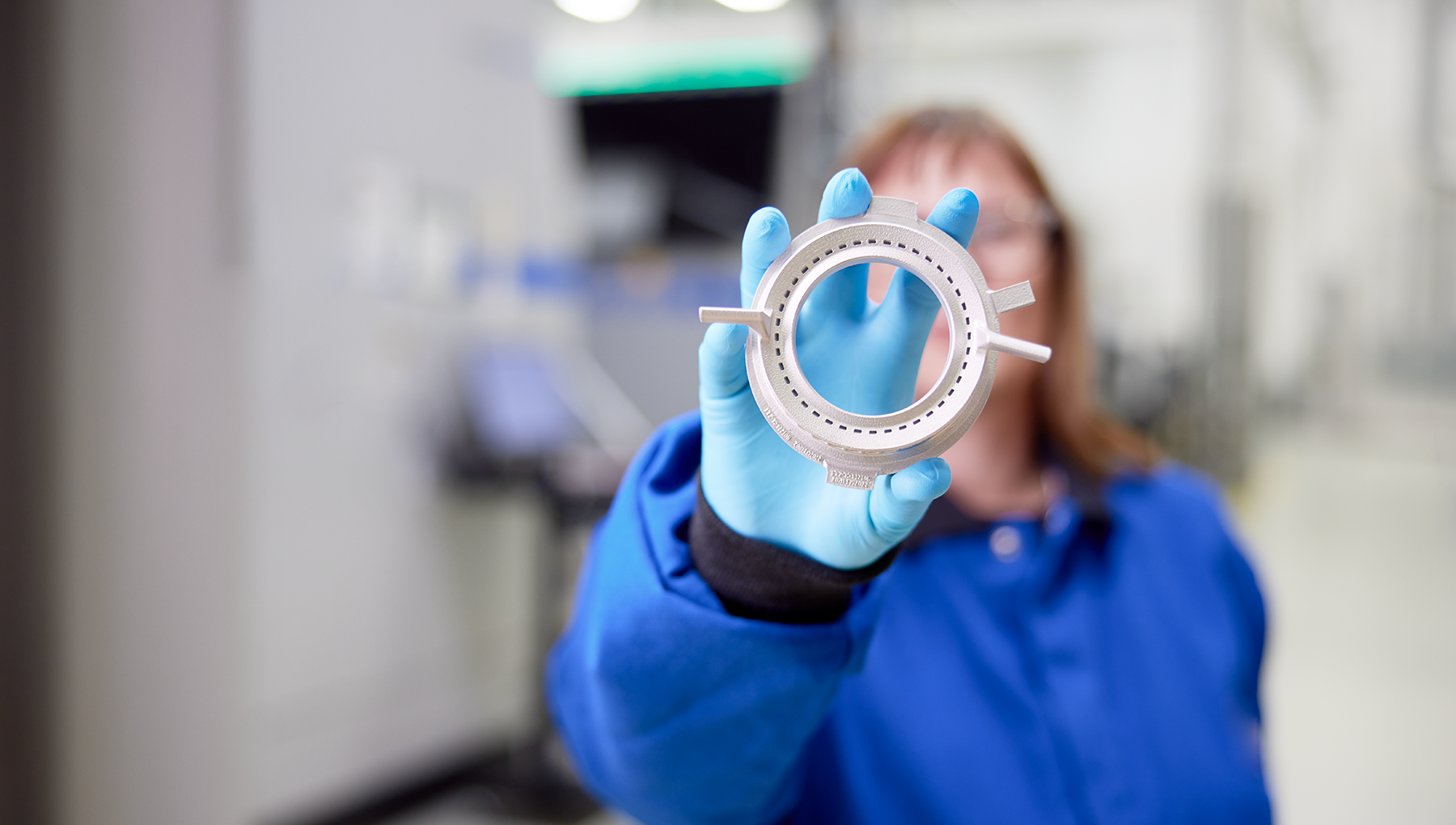

The system for safe processing of reactive and non-reactive metals

The M2 Series 5 is designed in accordance with ATEX guidelines and therefore enables safe processing of all powder materials. Like all machine solutions from Colibrium Additive, the M2 has a spatial separation of the process chamber and handling area for reasons of user-friendliness and safety.

The system is robust and suitable for 3-shift operation. In addition, the laser source and filter technology are integrated into the system, resulting in a small overall footprint. The large filter area of 20 square meters significantly reduces the filter change intervals, thus increasing system availability.

- Multilaser technology

- High variety of materials

- Advanced building chamber technology

Multilaser technology

The Concept Laser M2 Series 5 uses multiple laser sources simultaneously to increase printing speed and improve efficiency in the production of complex parts.

This multi-laser technology enables faster production and greater precision.

High variety of materials

The printer supports a wide range of metal alloys, including stainless steels, aluminum and specialized high-performance materials.

This versatility makes the M2 Series 5 ideal for various applications, from prototypes to functional components.

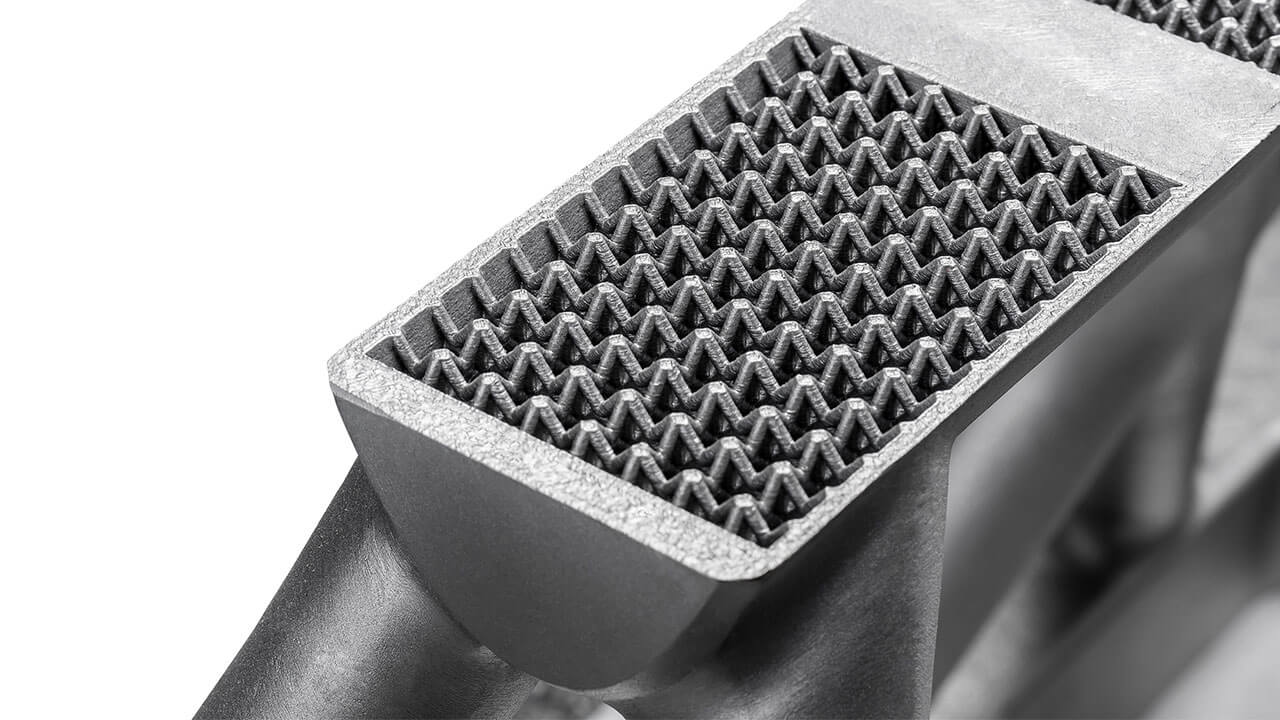

Advanced building chamber technology

The M2 Series 5 is equipped with a state-of-the-art build chamber that enables precise control of the pressure conditions.

This includes precise temperature and atmosphere control to ensure optimum print quality and material processing.

The specially optimized gas flow guarantees the highest component quality and material properties.

“The hybrid design offers the opportunity to implement optimized cooling strategies for cutting tools and thus enormously improve the service life of the tools.”

Frequently asked questions (FAQs)

Welche Materialien kann ich mit M2 Series 5 drucken?

The M2 Series 5 supports a wide range of materials, including various metal alloys such as stainless steel, aluminum, titanium and special high-performance materials. The machine is flexible and can be adapted to different material requirements to achieve optimal results for your specific printing applications.

The machine can also build hybrid on a conventionally prefabricated geometry. This enables an efficient combination of subtractive and additive manufacturing. The machine combines the best of both worlds.

Wie kann ich die Druckqualität steigern und gewährleisten?

The print quality can be increased by precisely controlling the laser power and optimizing the build parameters. Regular maintenance and calibration of the machine are also important to ensure consistently high print quality. Also use the appropriate printing parameters and materials for your specific applications.

Welche Vorteile bietet ein Multilaser System im Vergleich zu Single Laser Systemen?

The use of multiple lasers increases printing speed and efficiency, as several areas can be processed simultaneously. This enables faster production times and more efficient processing of complex geometries. In addition, multi-laser operation improves surface quality and reduces the overall processing time for your projects.