hyperMILL Additive Manufacturing

Additive manufacturing – only truly perfect with CAD/CAM

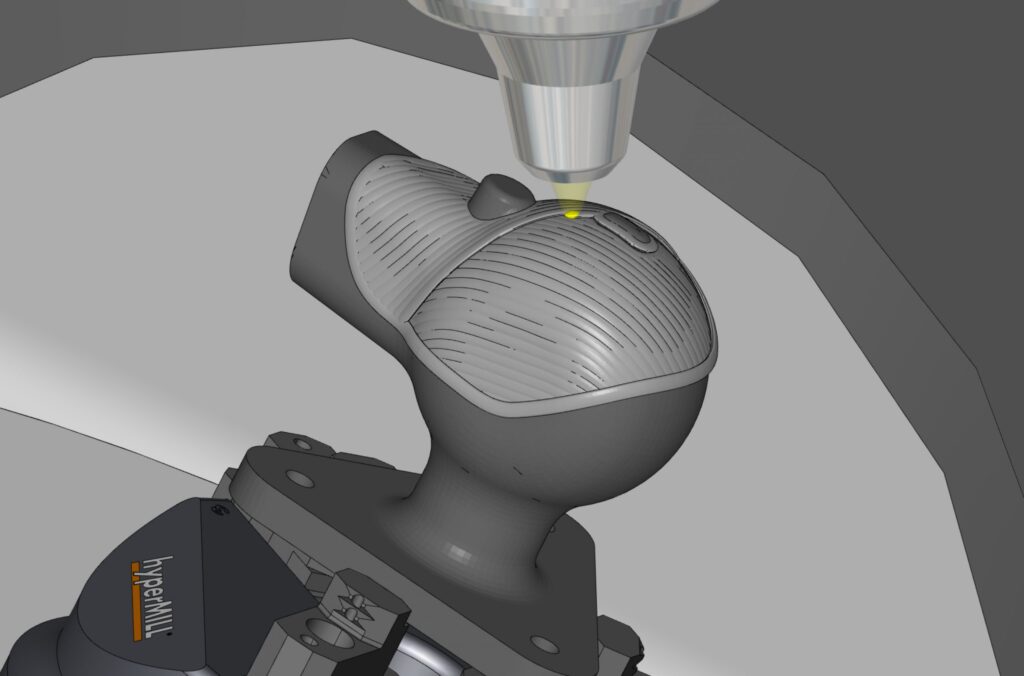

hyperMILL Additive Manufacturing combines the additive world with the subtractive world – the only way to achieve perfect results efficiently.

- Hybrid processing

- Perfect area of application: repair of components

- Different materials

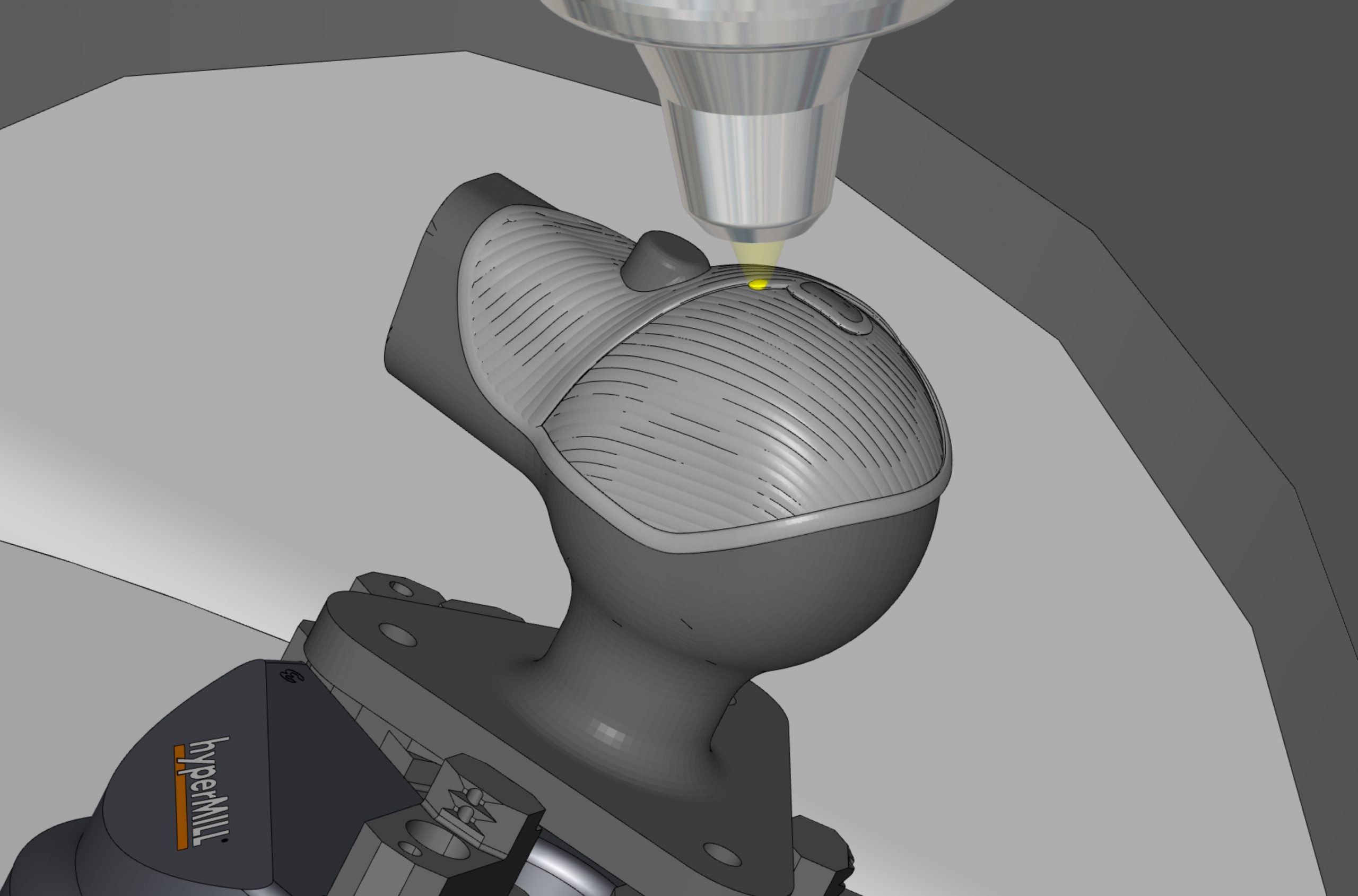

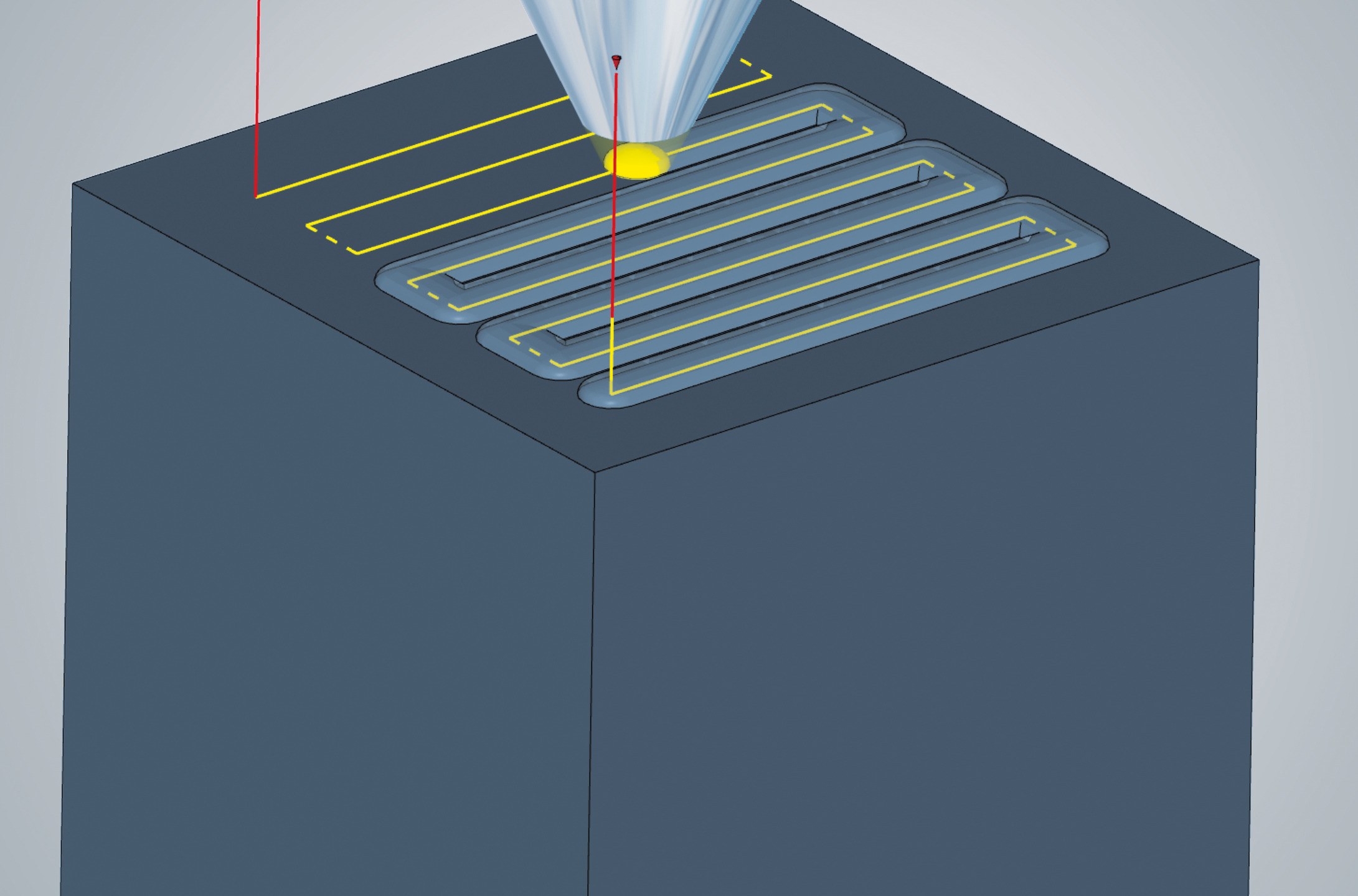

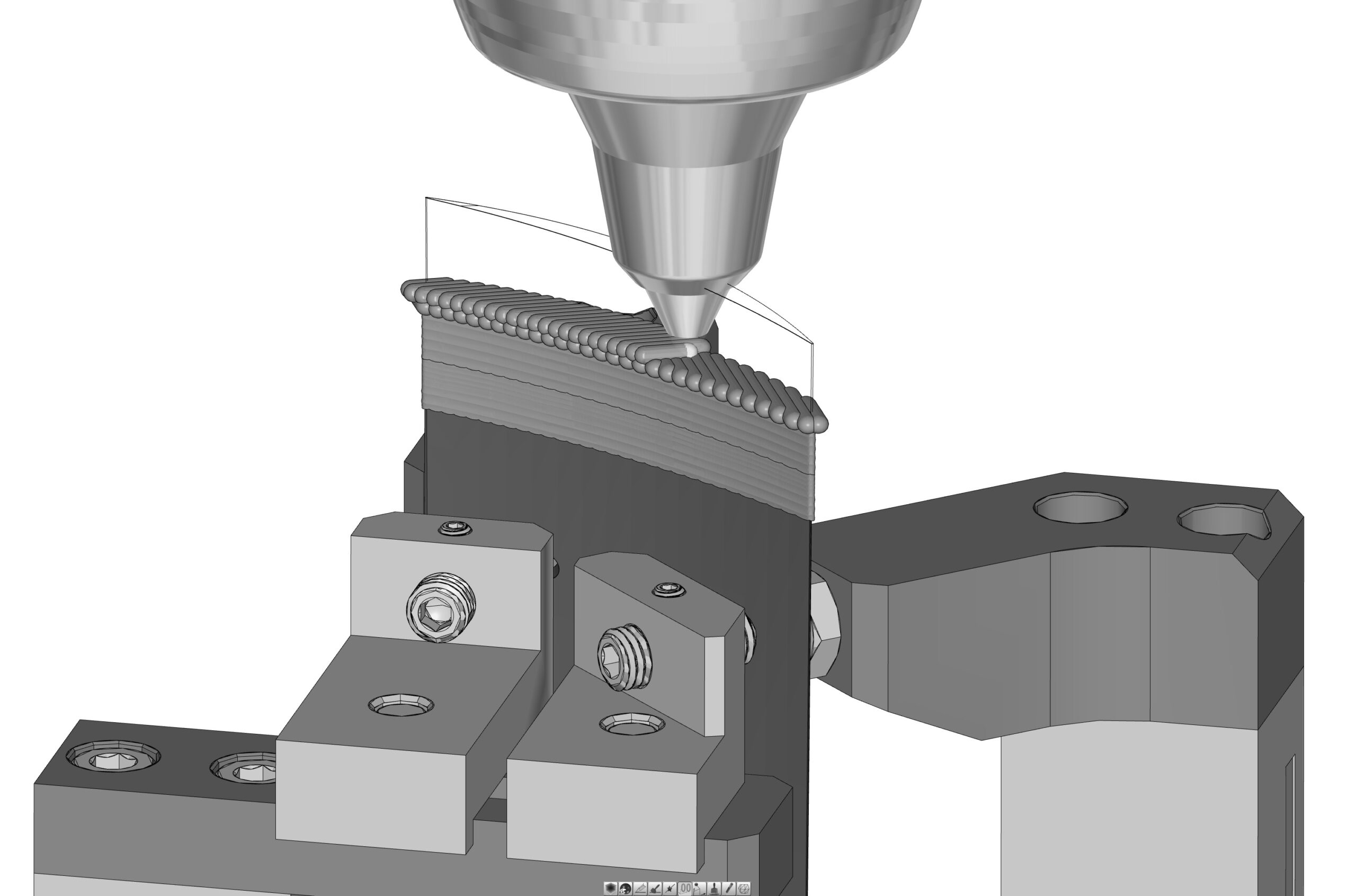

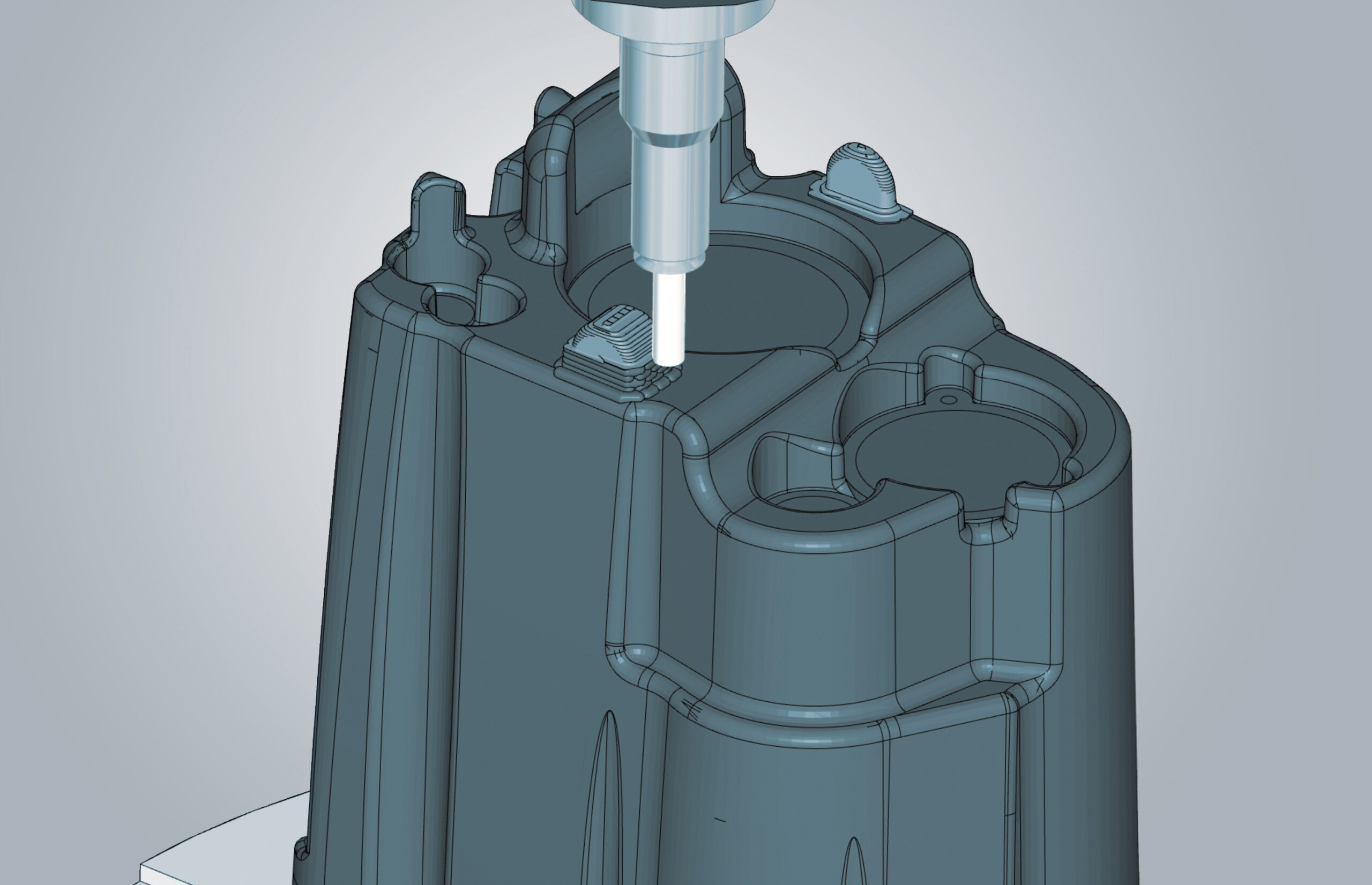

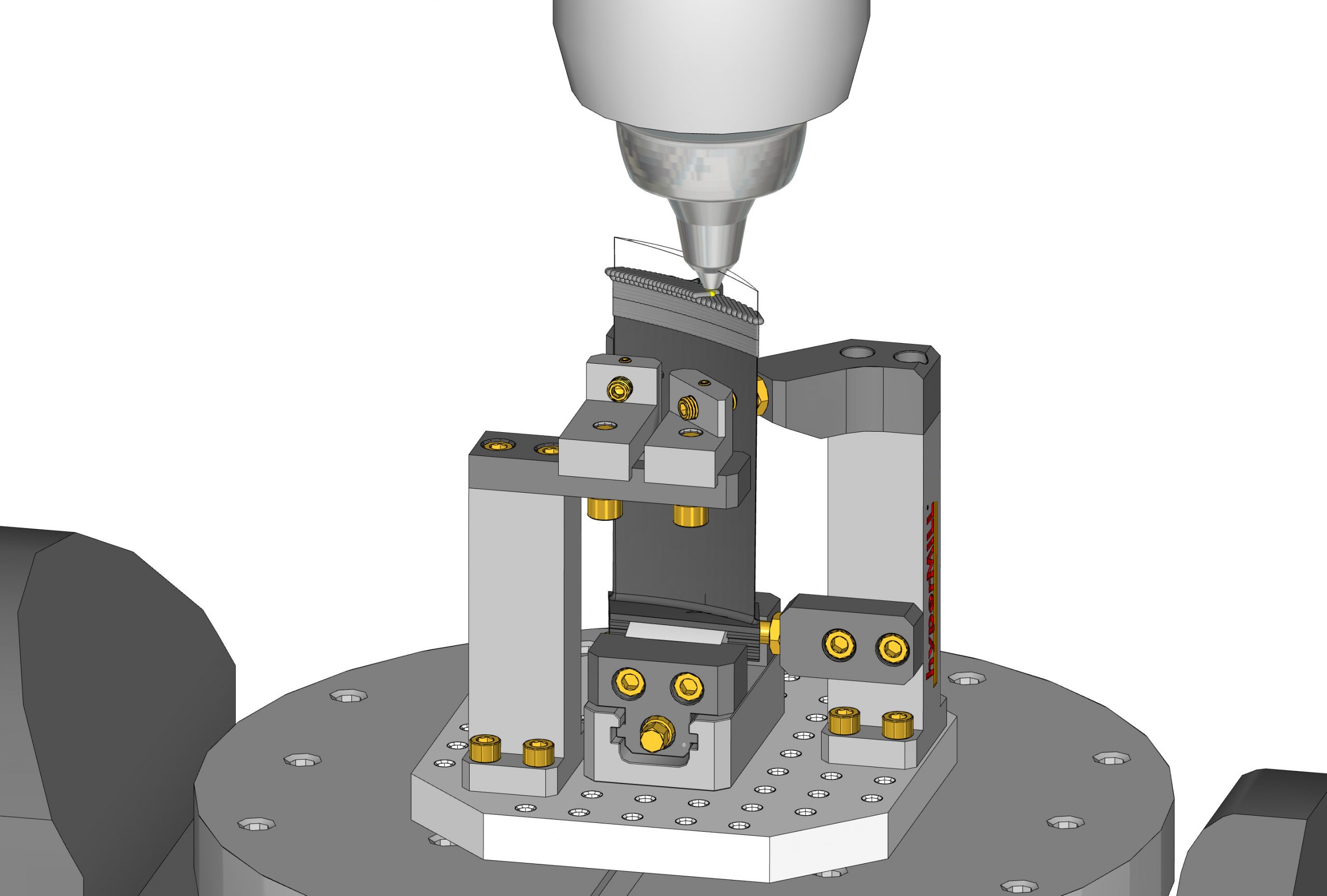

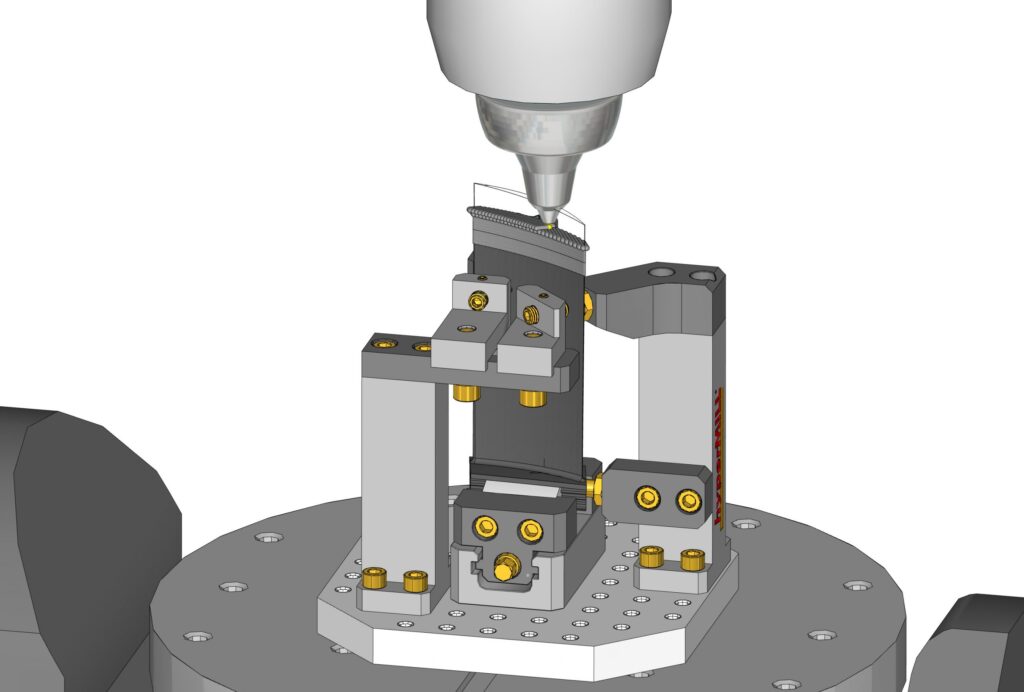

Hybrid processing

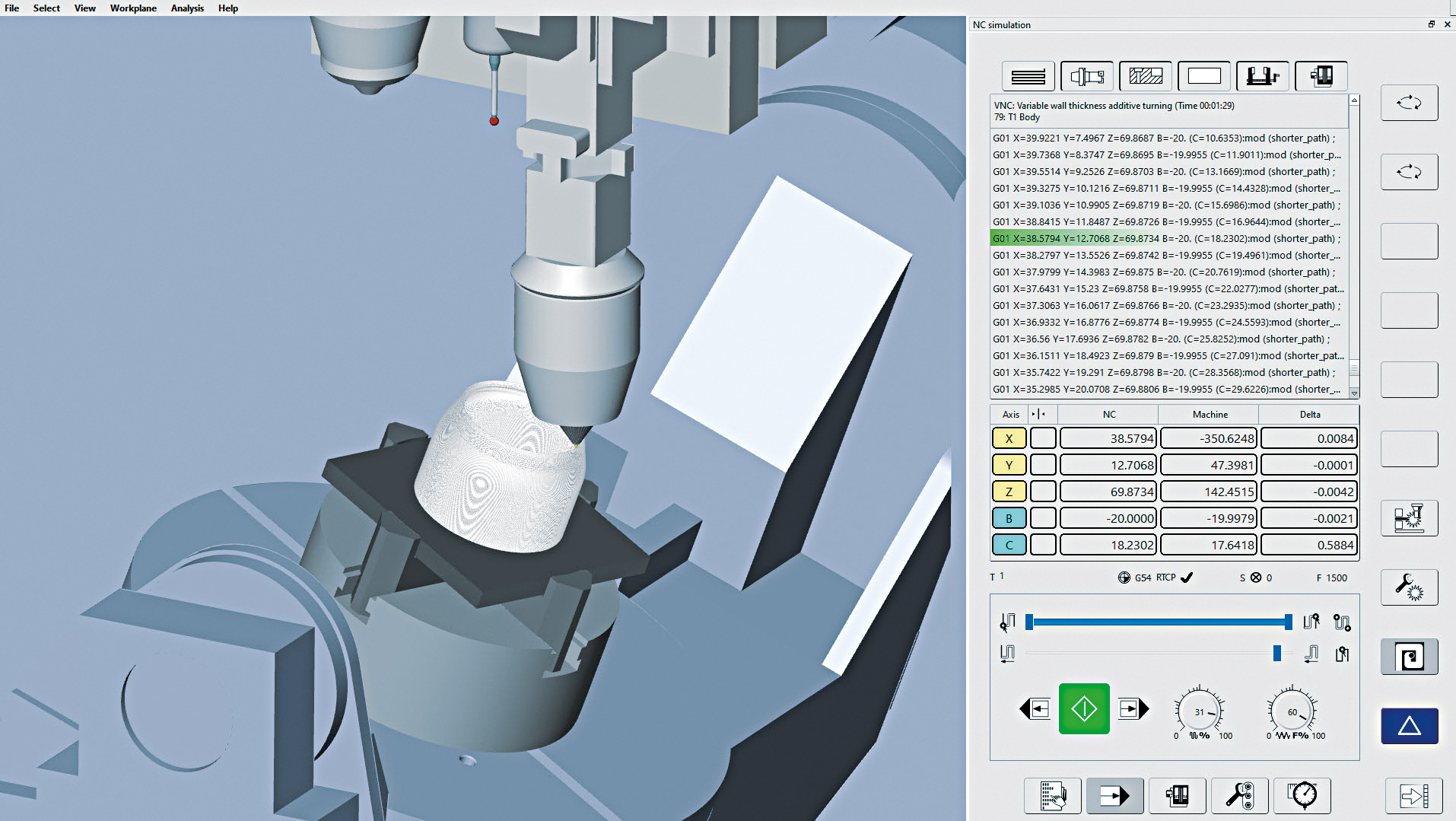

A hybrid manufacturing process is when both additive and ablative, subtractive manufacturing are combined in one processing machine.

Here, hyperMILL offers coverage of “both worlds”, i.e. the programmer is able to program both deposition welding and milling in one interface.

The result is ONE NC file that contains all production steps.

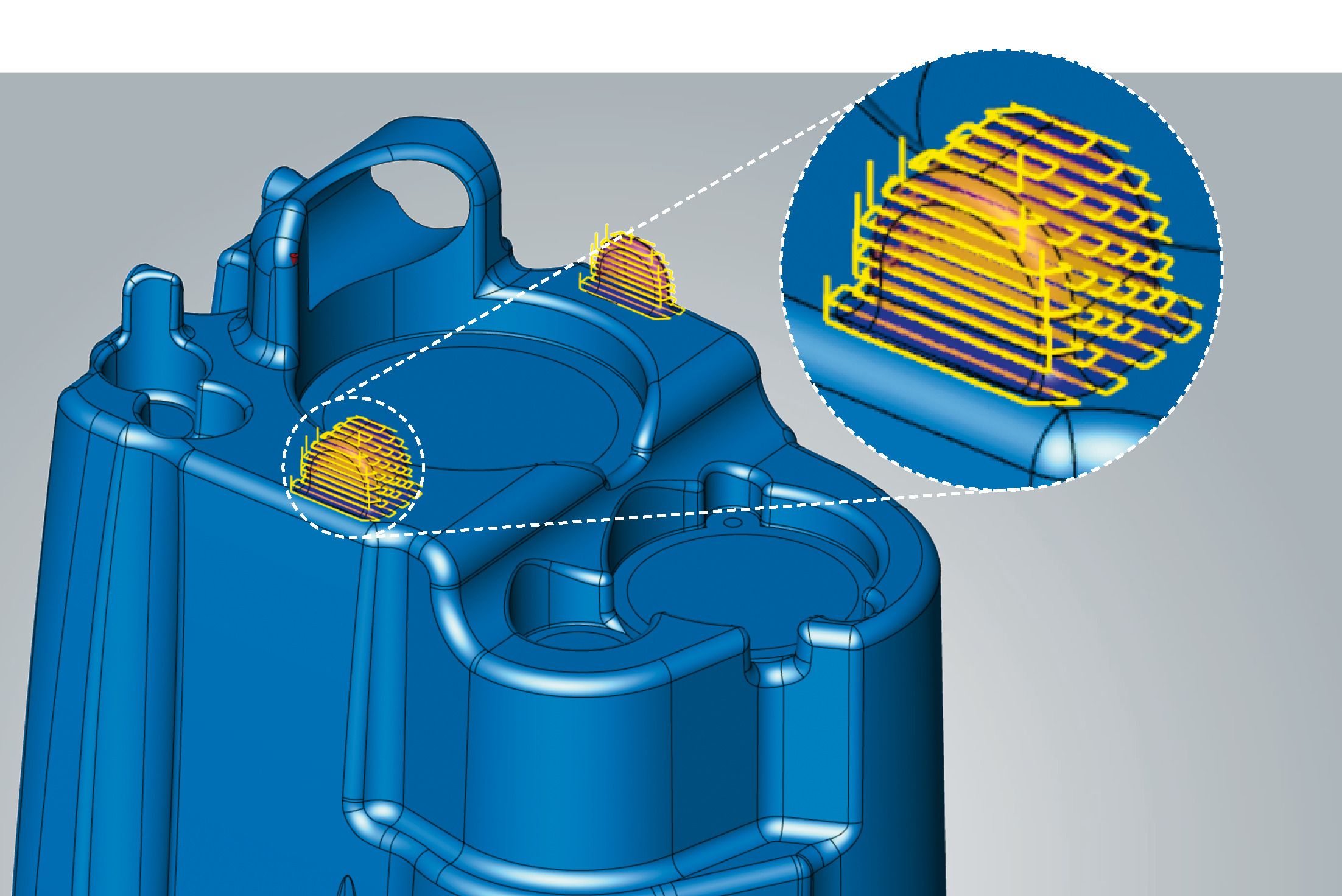

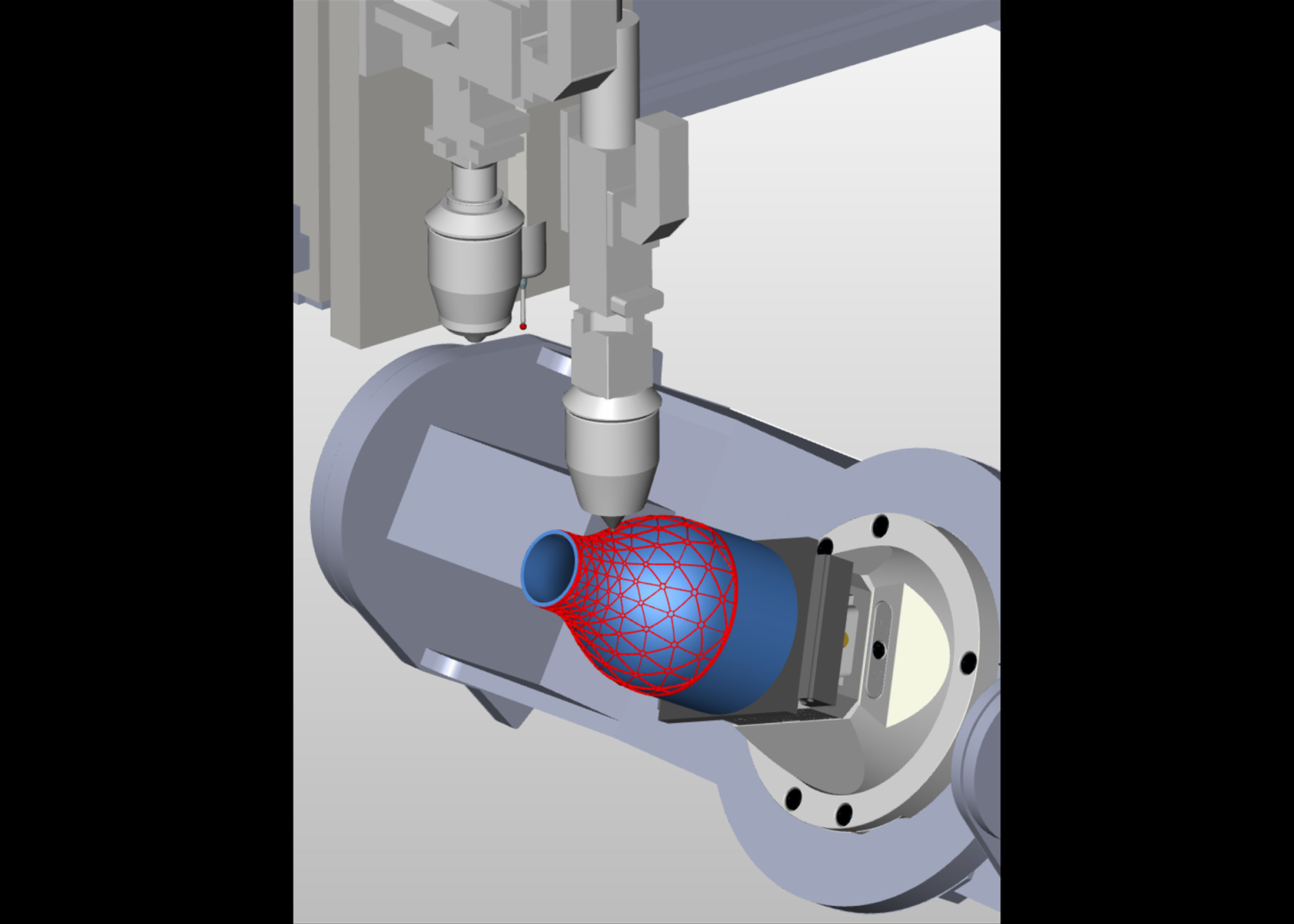

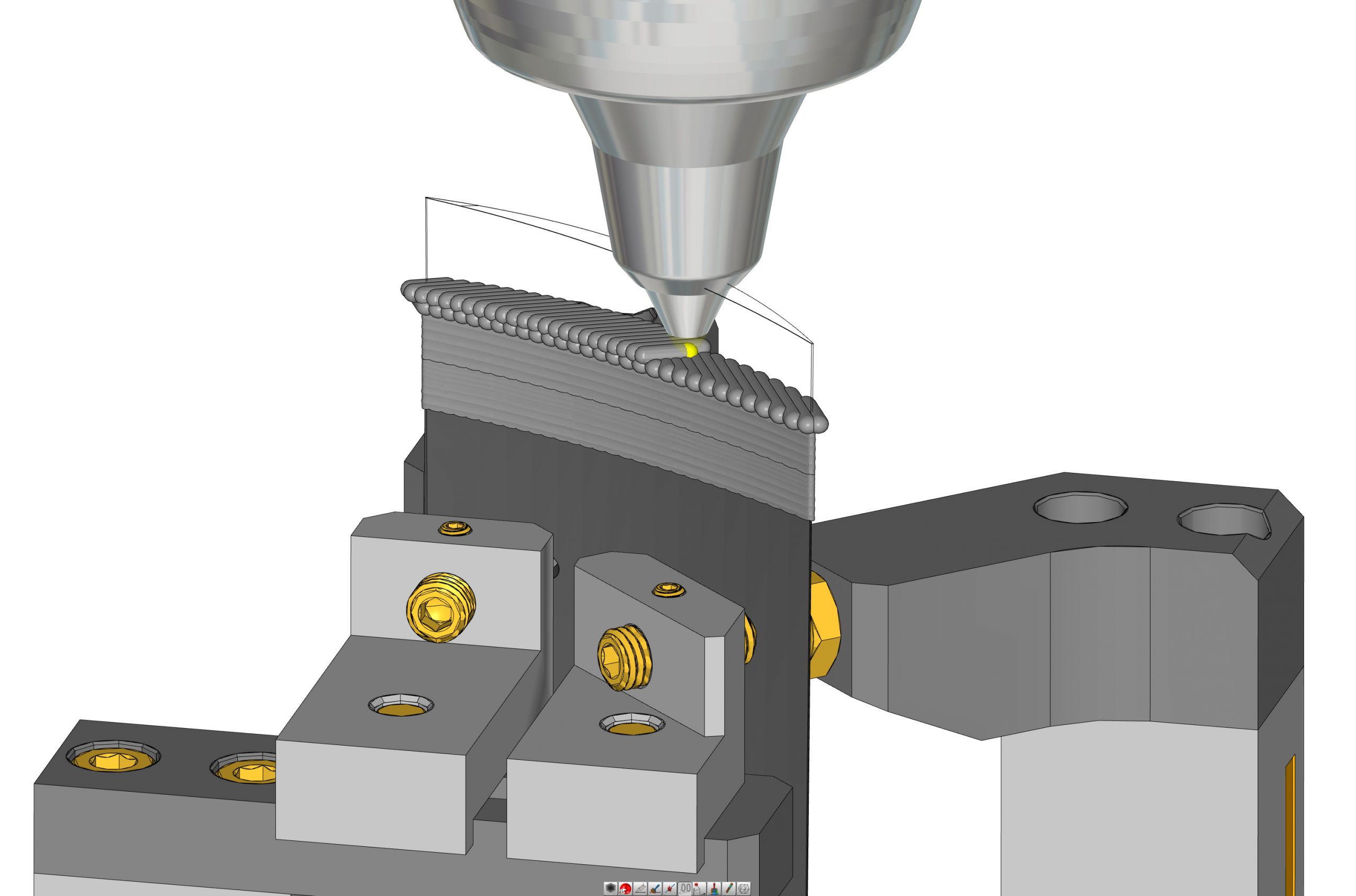

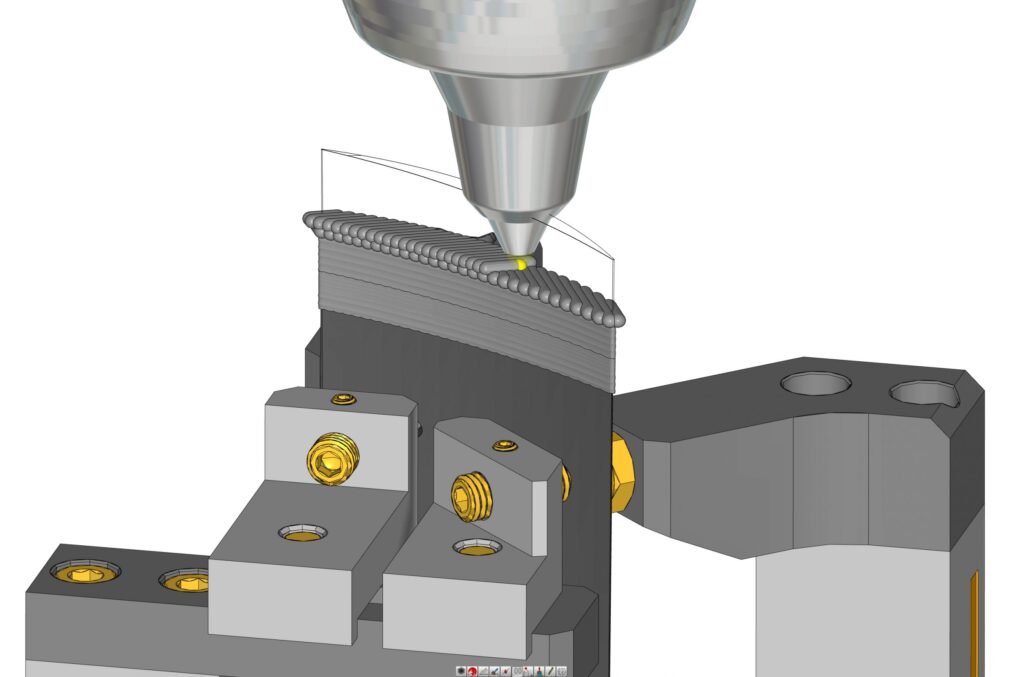

Perfect area of application: repair of components

By covering both the additive process and the subtractive process, completely new areas of application are possible. This combined process is ideal for component repairs.

An example of this would be the repair of a damaged turbine blade. Here, material is applied and then removed until the component geometry is completely restored.

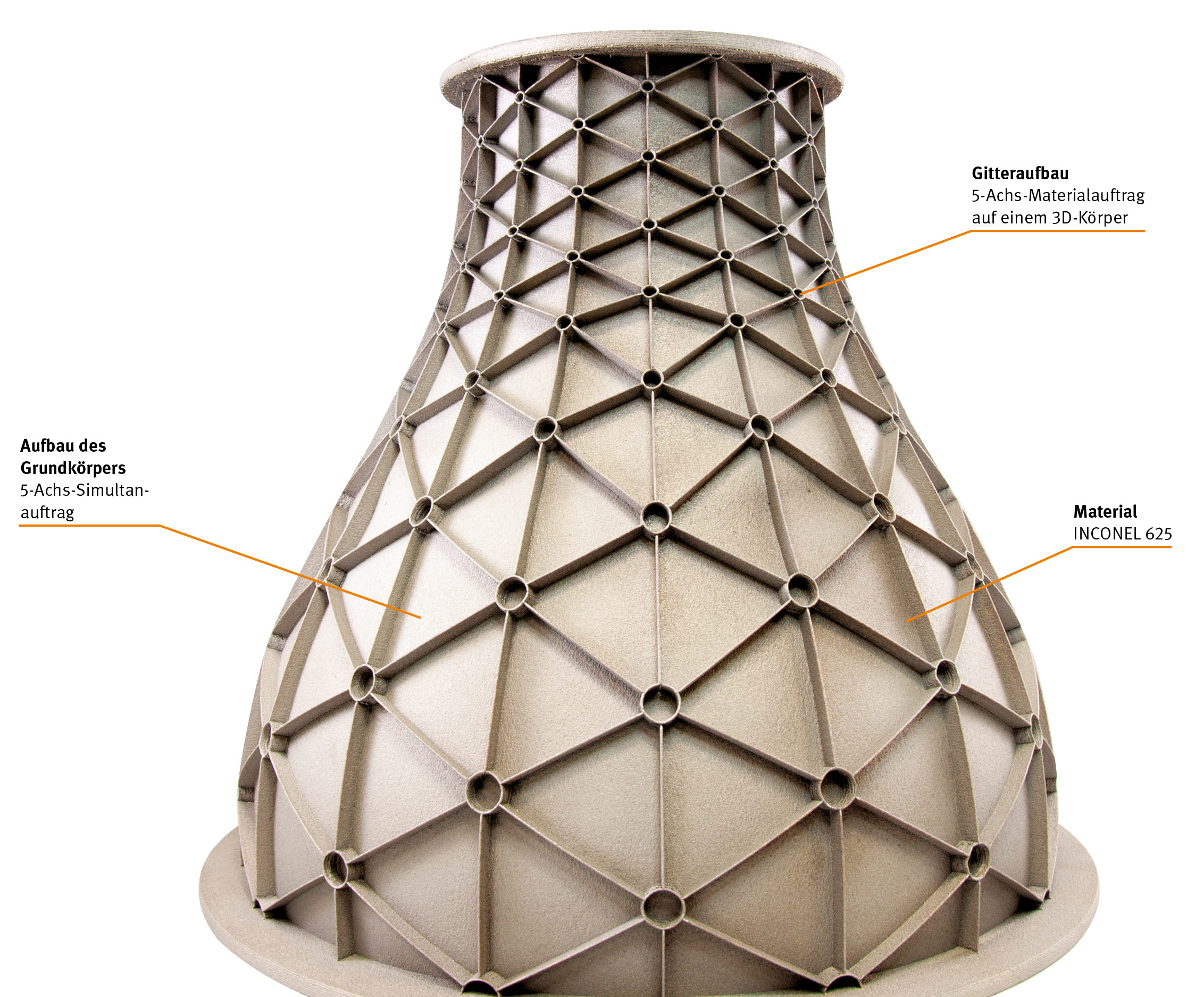

Different materials

Another highly interesting possibility of additive manufacturing is the use of different materials, which allows the component properties to be changed in a targeted manner.