“Even closer to the original!”

Historic racing car recreated with the help of 3D scanning

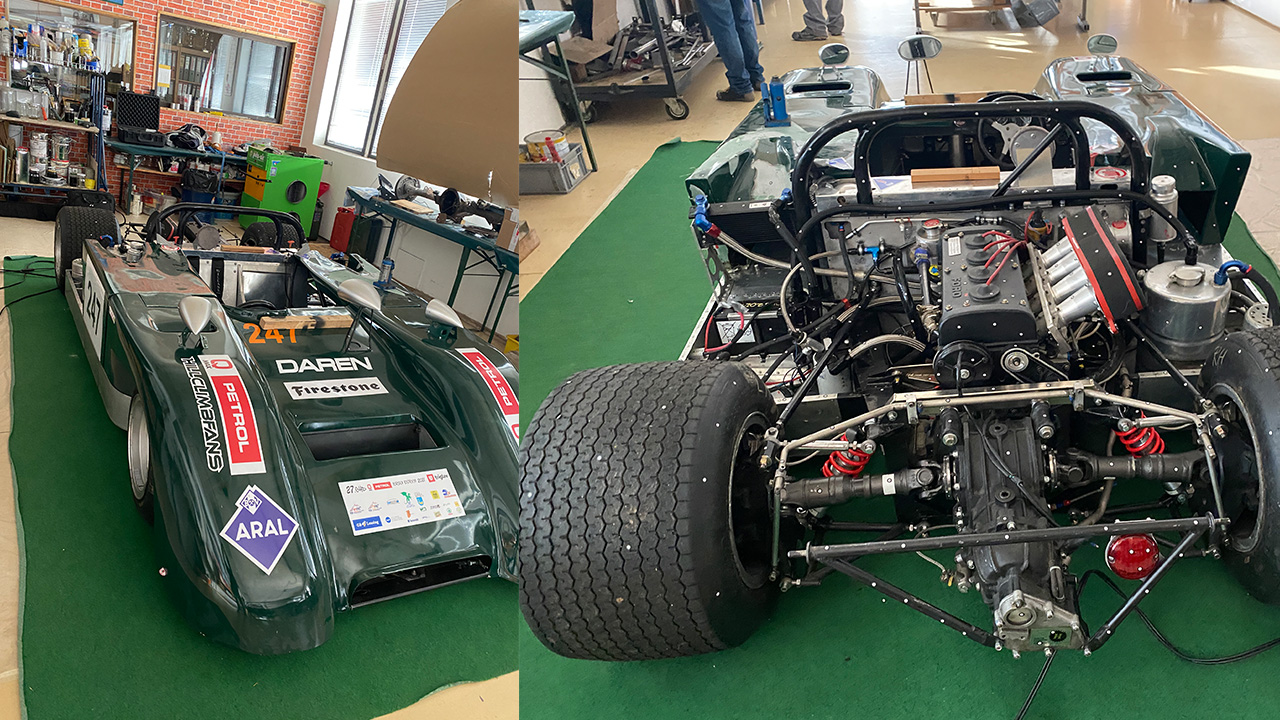

Everyone in the historic racing car community knows him, even if he doesn’t like to push himself to the fore. He is the man to go to when it comes to turning old into new: We are talking about Mr. Friedrich Burgstaller, Managing Director of FB Prototypen GmbH. He has been pursuing his absolute passion for more than 30 years: Rebuilding historic racing and sports cars.

When you enter Mr. Burgstaller’s workshop, you feel more like you’ve landed in a British living room than a car repair shop. It’s clear at first glance that the work here is done with passion and a lot of love.

As old as the car bodies are that end up in his workshop, the technologies he uses to repair and maintain them are just as modern: he recently approached our 3DMetrology experts about 3D scanning.

Historic racing car meets 3DMetrology

Mr. Burgstaller is working on something extraordinary

The reproduction of historic cars. How did you get into it?

All the racing car manufacturers were in England back then, so they were very far away. There were still borders and no internet. If you wanted to replicate something in Austria, it was very difficult: you had to rely on word of mouth. And there was no money either, so you had to do it yourself!

My father once said to me: “Watch out: All beautiful technical things are built with two hands. You have two hands too! You just have to take care of it”. He had a garage himself and built vehicles, albeit municipal vehicles. I was more interested in English sports cars.

So I traveled to England a few times to learn from the masters in the workshops there. And I stuck with it over the years. I’ve been doing this full-time for some time now.

What tasks and challenges do you face in your day-to-day work?

Mr. Burgstaller: In historic racing, which is faster today than ever before, you can no longer drive with 50-year-old parts. They crumble due to oxygen, ageing and vibrations. The old parts can no longer be repaired, which means you have to produce new ones. That’s why probably 80% or more of the cars in historic racing are partially or completely rebuilt.

When rebuilding historical vehicles, the question is always: How did they really build and work in the past? There are hardly any records or plans. Documentation and archives did not yet exist in the 1960s, or they were not of the quality we imagine today. Vehicle plans were often only traced in the archives 20 years later.

That’s why my task is to find out: How did the master craftsmen actually work on the workbench back then? And a 3D scanner is of course a perfect tool for this. It really allows you to see exactly what they did.

That’s why you approached WESTCAM. What exactly was your challenge and how could we help you?

Mr. Burgstaller: I had a customer’s car in front of me, of which only three were produced in total. There were no documents or molds, nothing. Just the car.

The customer is a 10-time European champion in historic racing. Unfortunately, most of the car was destroyed in a crash.

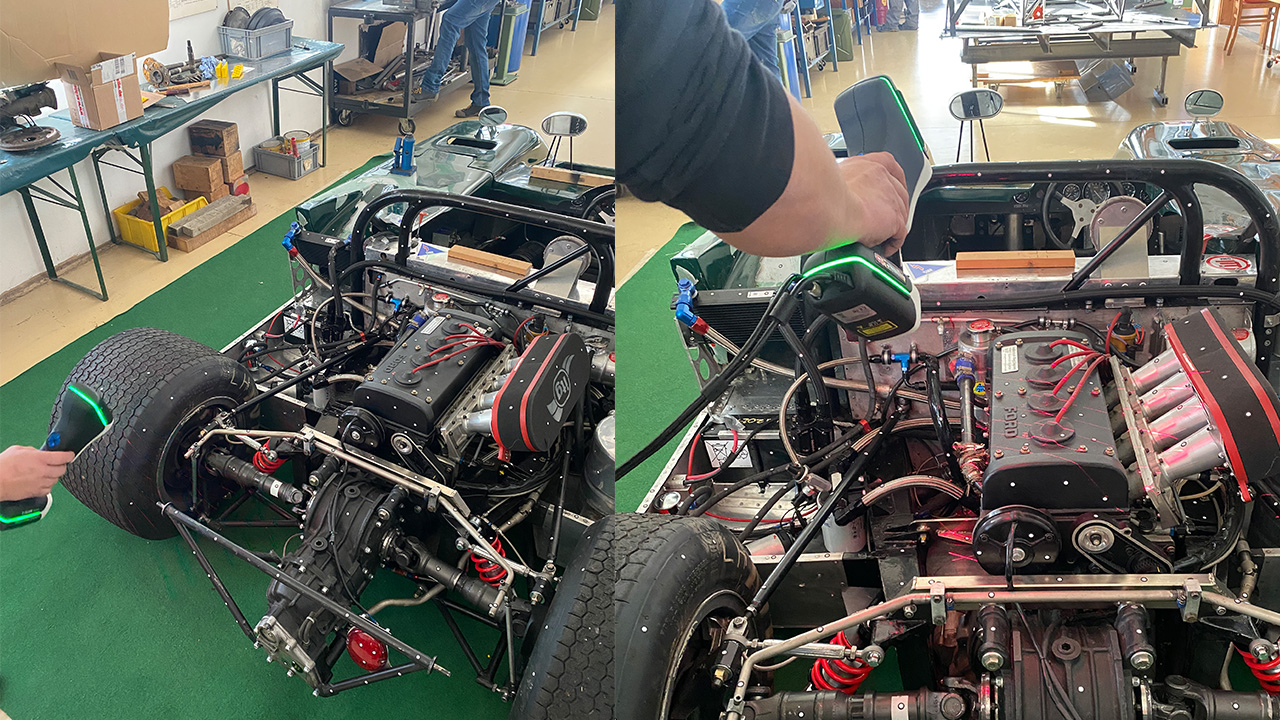

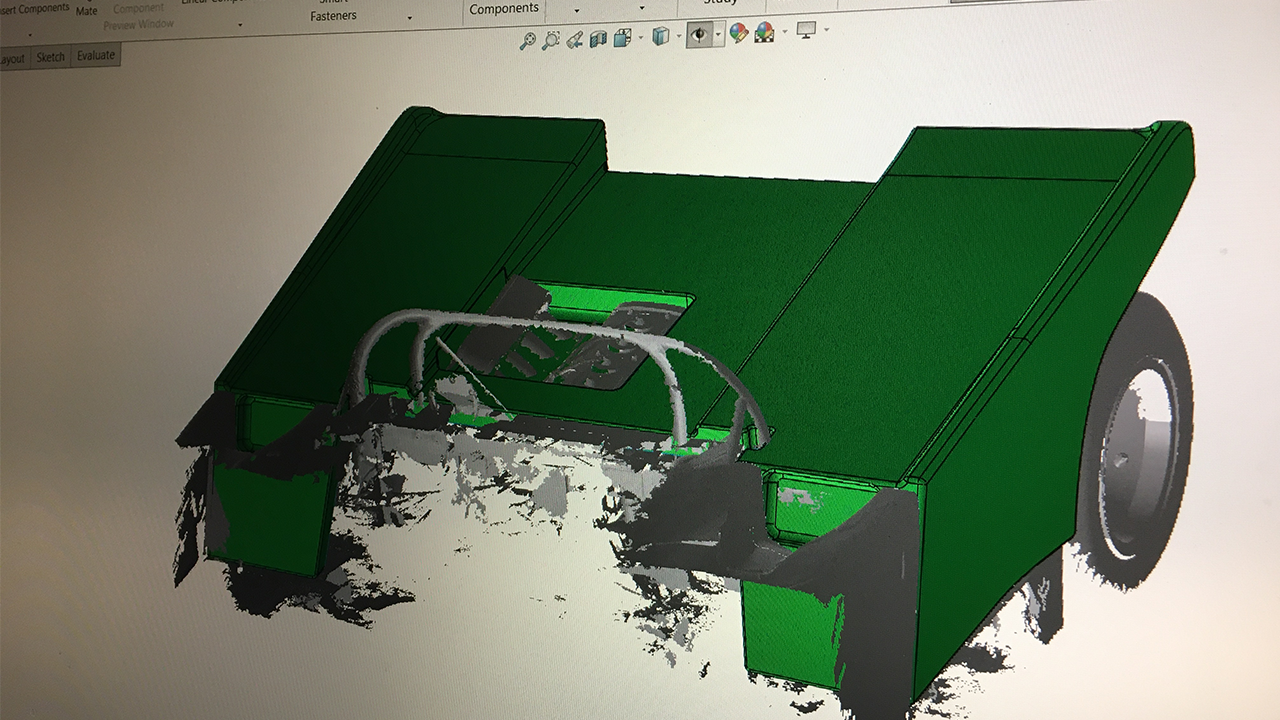

I wanted to use a 3D scanner to scan the remaining side of the car and transfer the scan to the damaged side so that I could restore the vehicle.

How exactly was the task implemented? What was the approach?

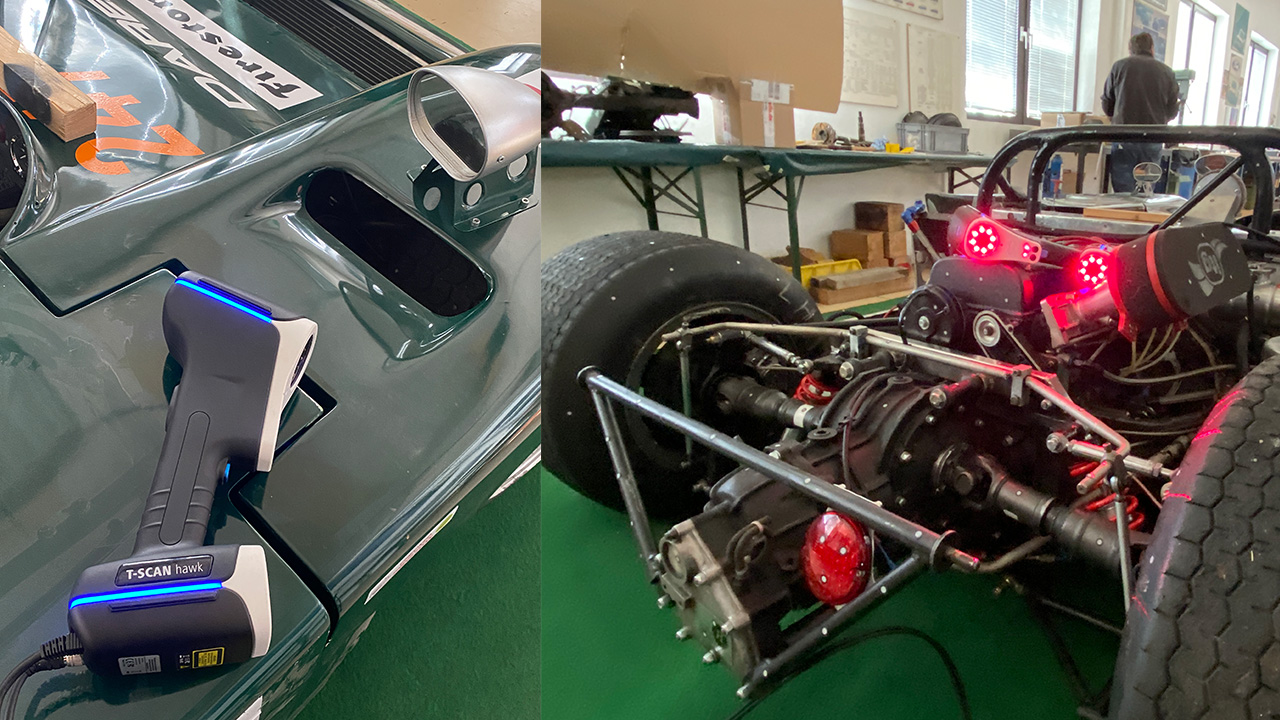

Thomas List, WESTCAM 3D-Metrology expert: ” Based on photos of the broken vehicle, we assessed which system could be used to solve the problem. We came up with the T-SCAN hawk relatively quickly because it is compact, mobile and easy to use, from data acquisition to delivery.

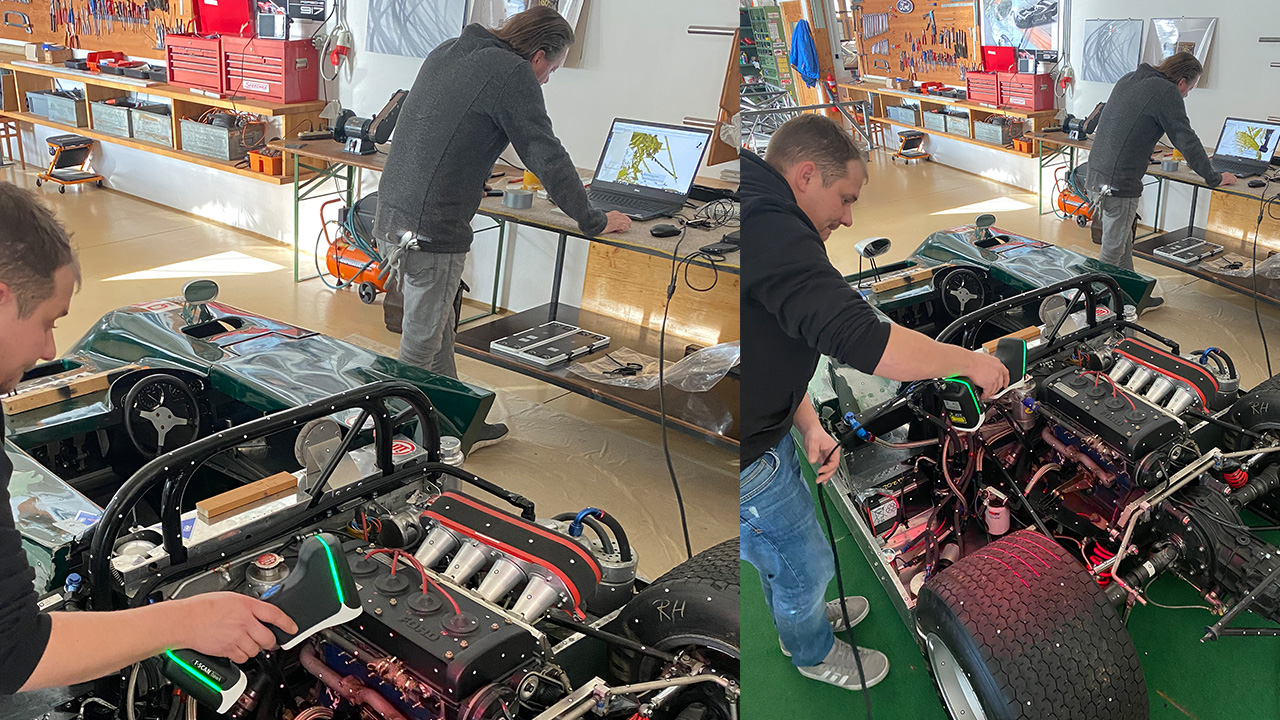

We proceeded as follows for the scan itself: We applied a reference point backdrop to the car. Then we measured it photogrammetrically with the integrated photogrammetry of T-SCAN hawk. This gave us a point cloud. This point cloud gives you immediate orientation in 3D space and maximum accuracy on large surfaces. Based on this point cloud, we scanned the rear of the vehicle.

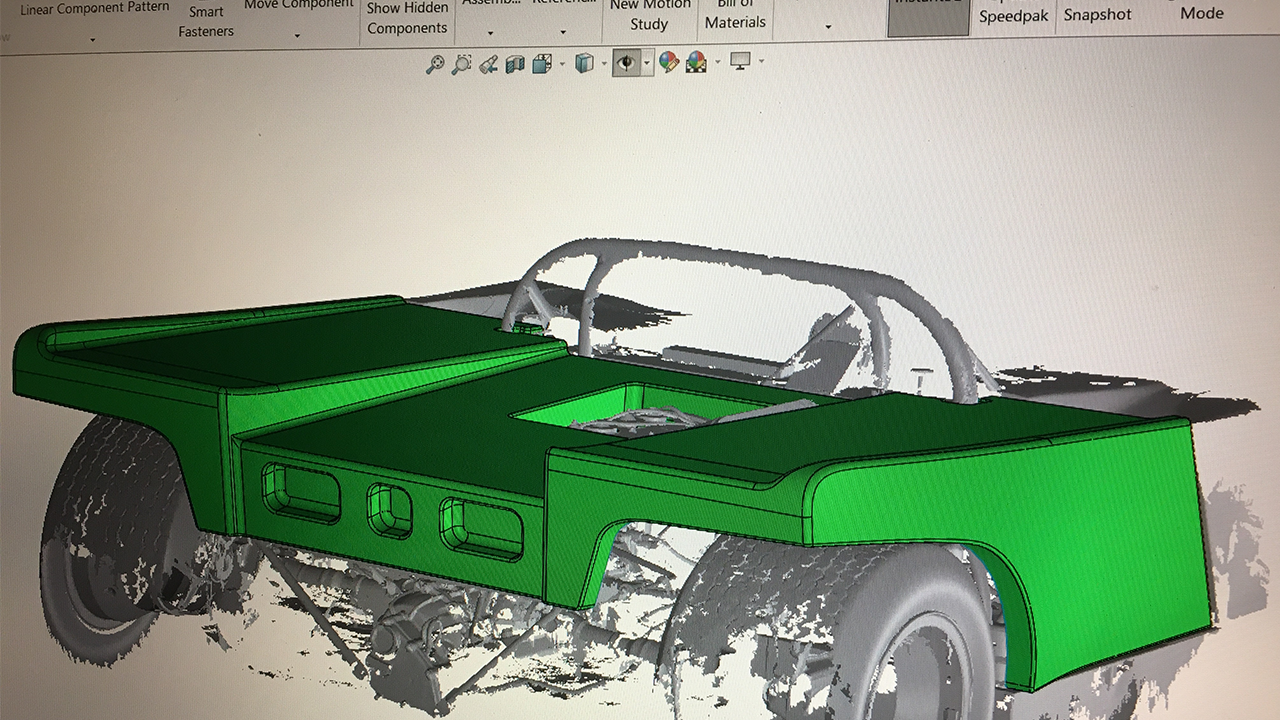

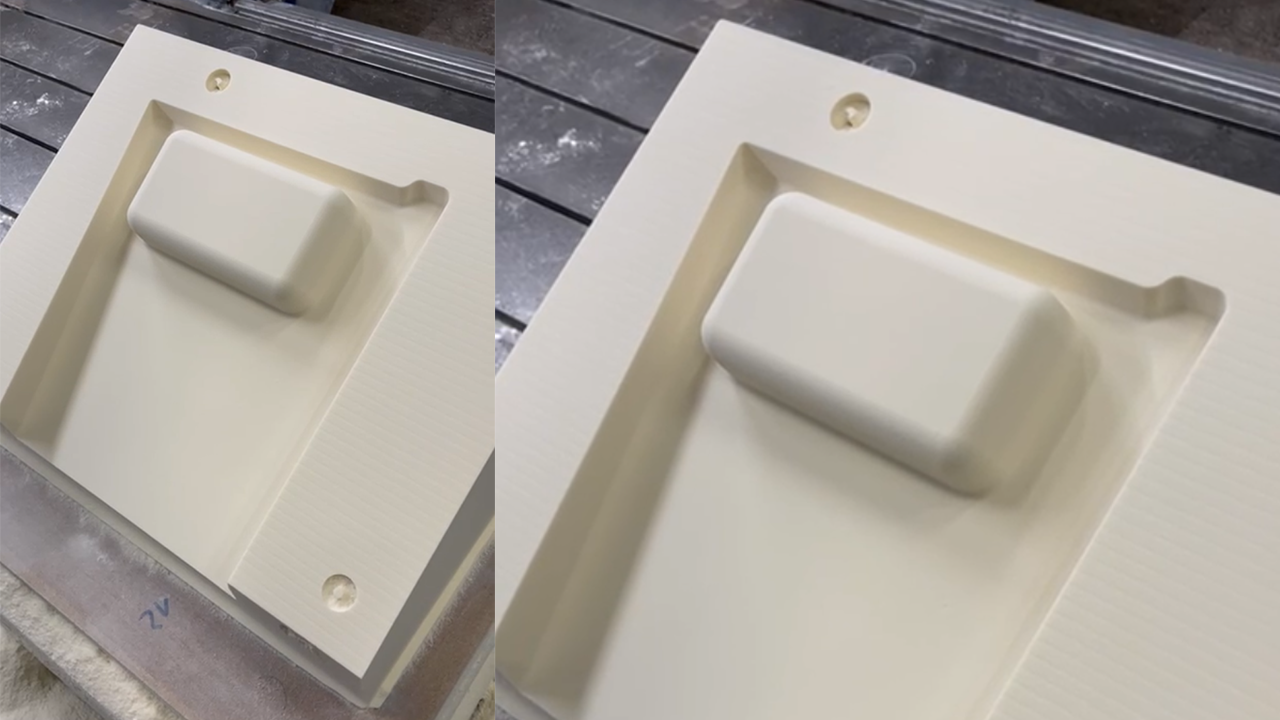

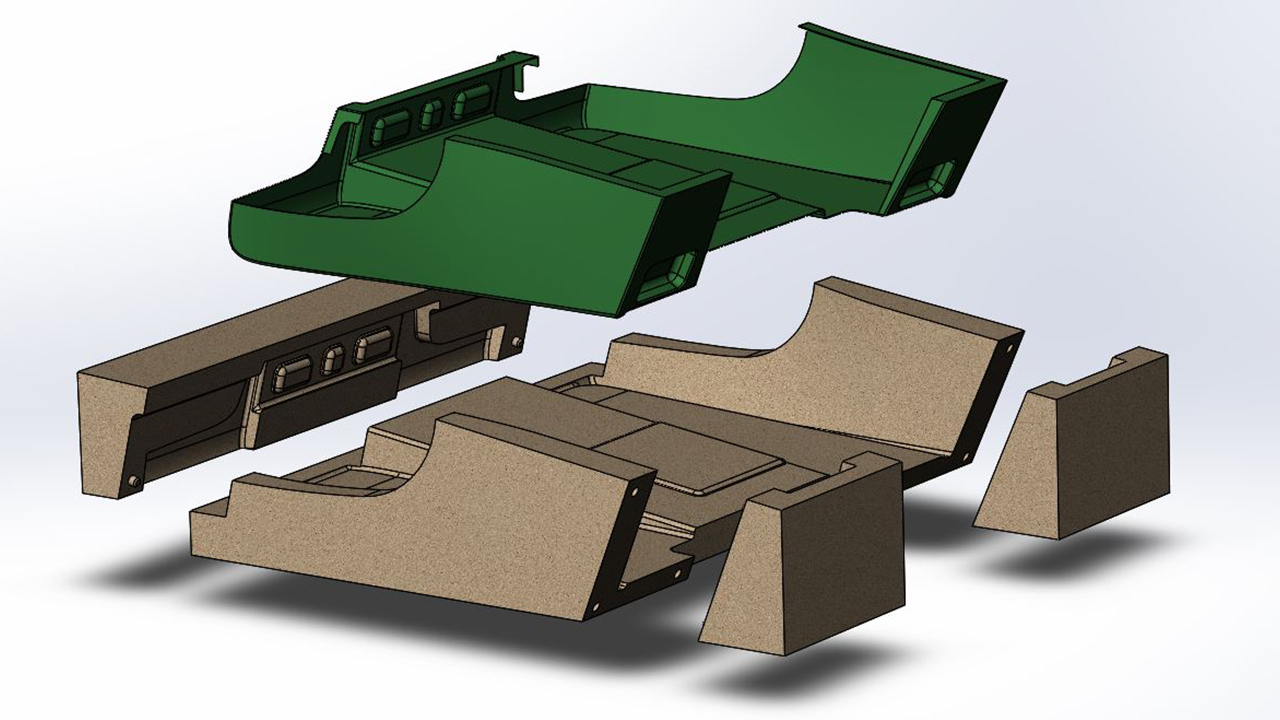

The scan was then aligned in 3D space according to Mr. Burgstaller’s wishes and filleted into individual sections to obtain the 2D lines. The STL data was then provided to Mr. Burgstaller.

And the result? Were you satisfied with the work of our “WESTCAMers”?

Mr. Burgstaller (laughs): I was very pleased, of course. The data is great.

I already had a bit of experience: In the early years, when the scanning thing started, I had already tried a 3D scan from another service provider.

I wasn’t satisfied at the time because I couldn’t process the data. But the data now from WESTCAM, the way it was handed over and aligned, was perfect. Makes me want more 😉

What comes next?

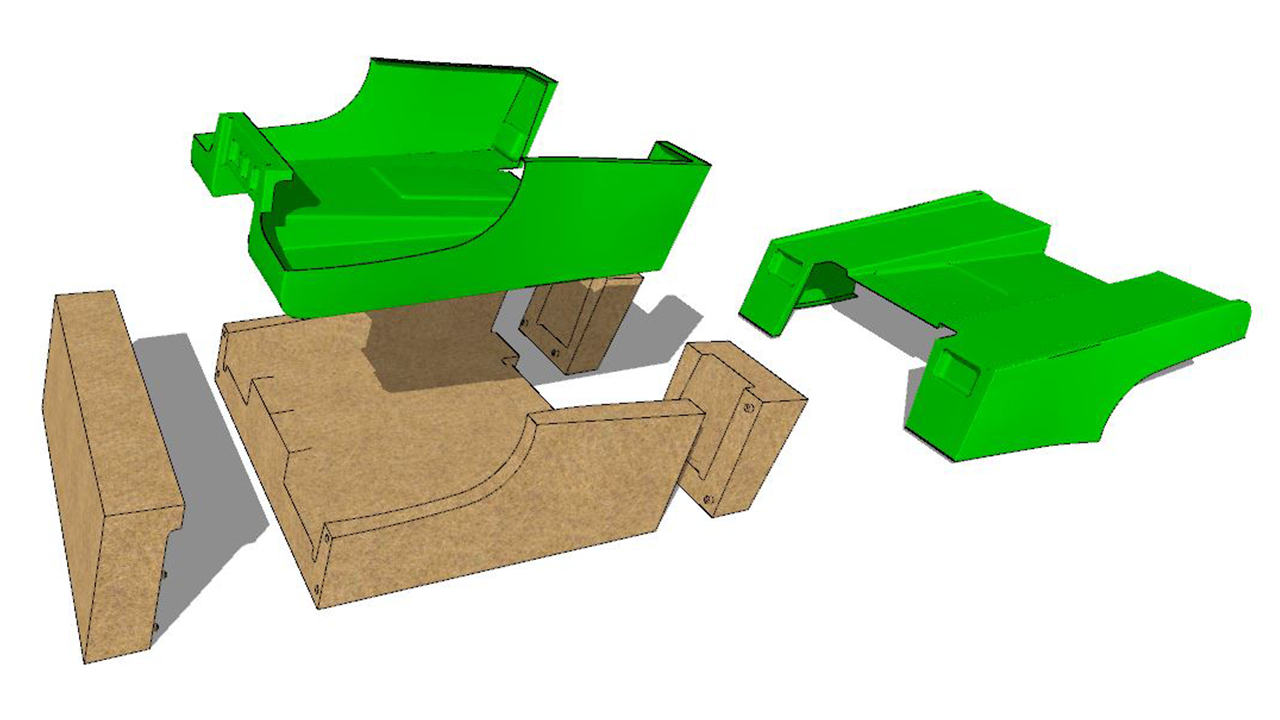

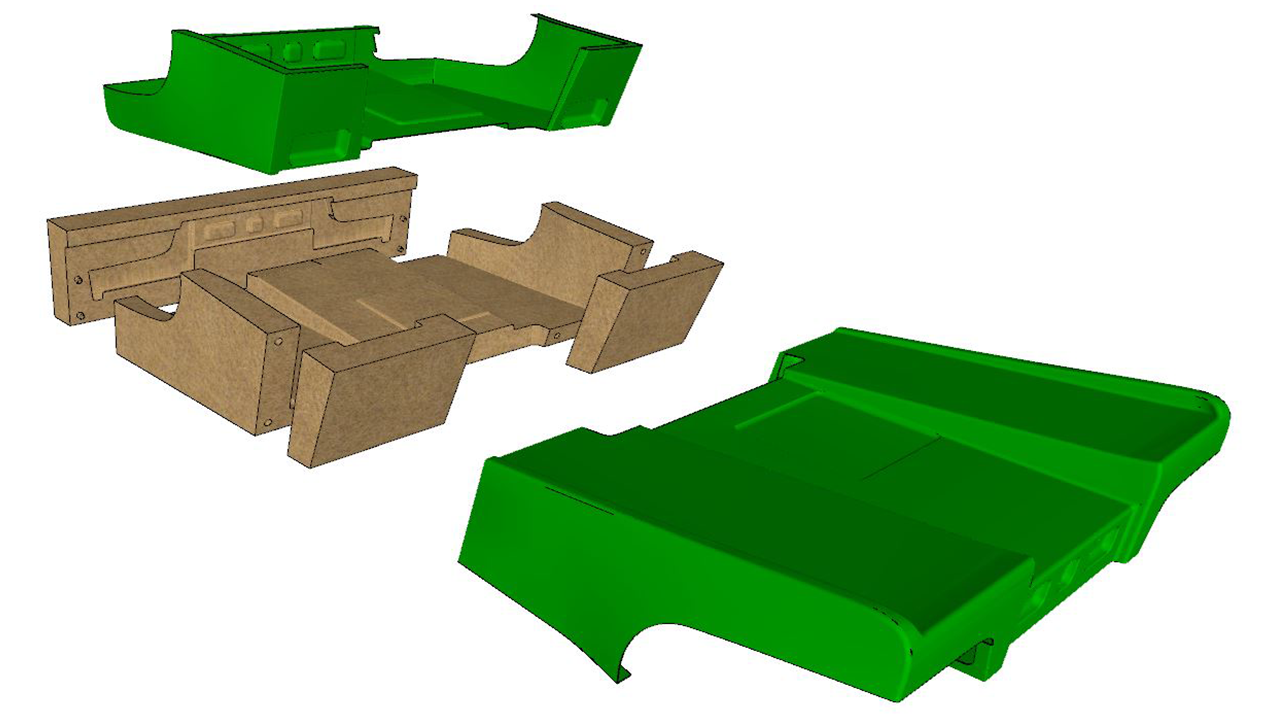

Mr. Burgstaller: I hope very soon! We are hard at work: We have already redesigned the destroyed exhaust system using virtual assembly analysis, also known as digital mock-up, and adapted it to the available space. The multi-part laminating mold was also milled. Nothing now stands in the way of the production of the fiberglass chassis. As you can see: We are working at full throttle and will soon be “ready to race” again! (laughs).