Wear and spare parts from the 3D printer

Precisely fitting, sustainable, crisis-proof

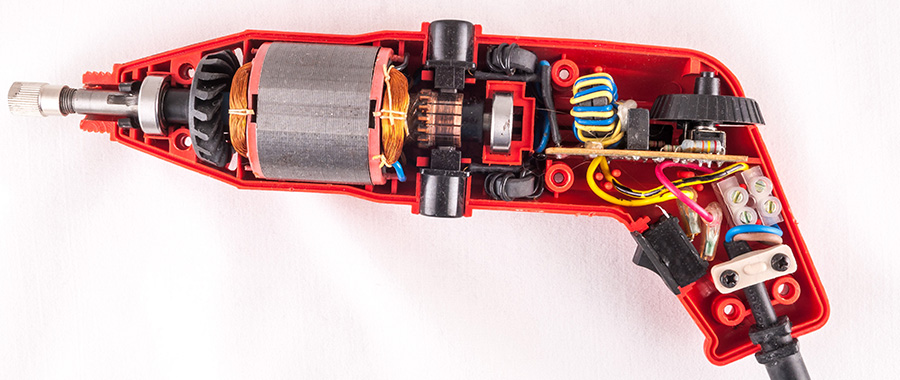

A small component in the production machine breaks and stops the entire production process. The procurement of the replacement part is often associated with long waiting times and high costs. Sometimes some components are no longer produced at all. Not only in industry, but also at home, some spare parts stop vacuum cleaners, microwaves, etc. 3D printing comes into play here, both in industrial production and for repairs in the home. Discover the many possibilities for maintenance, repair & co.

Advantages of 3D printing

Availability without delivery problems

A key advantage of 3D printing is its rapid availability. Once the digital model has been created, printing can begin immediately.

Long lead times for the preparation of production or the delivery of various raw materials are eliminated. This reduces the supply chain, shortens transportation routes and speeds up the entire production process

Sustainable and crisis-proof thanks to regional production

It is not only the shorter delivery routes that make additive manufacturing a climate-friendly production process. With 3D printing, only as much material is used as is actually needed. By avoiding waste, the method is particularly sustainable.

In addition, a lean and regional supply chain also means that dependence on global events and supra-regional producers is reduced. This makes it a very crisis-proof process.

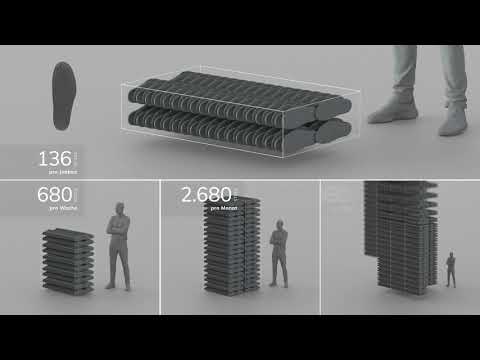

Cost savings due to lower storage costs and avoidance of downtimes

Thanks to the rapid production of components from the 3D printer, you no longer need a huge stock of spare parts. This saves storage costs.

You also save time and therefore money in the event of unforeseen repairs. Spare parts from the 3D printer are produced quickly and reduce any downtime.

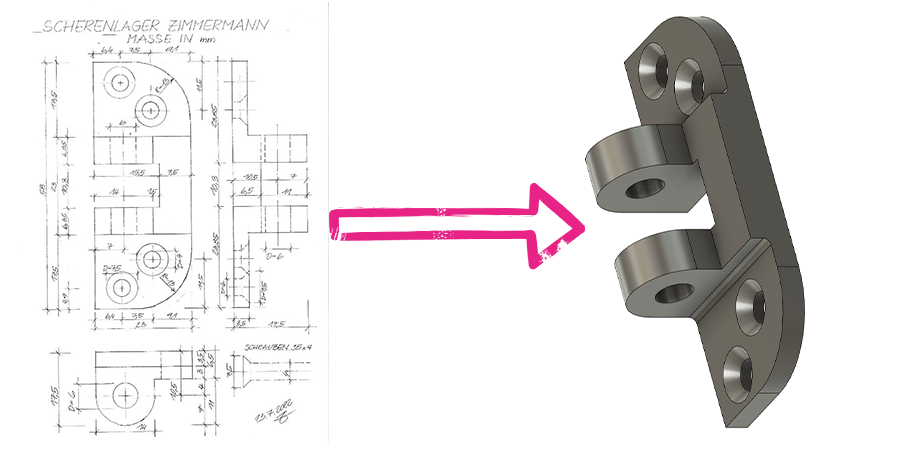

Precisely fitting and made to measure

Components, wear parts, spare parts – with all these modules, every millimeter counts when it comes to production.

No matter how big or small, from a mini spare part for a vacuum cleaner at home to a major repair for a turbine, the 3D printer manufactures the products precisely to size. An exact 3D model is created in advance, which is then printed 1:1.

- Advice on processes and materials

- 3D scan of defective original components

- CAD design of digital 3D models

- 3D printing of spare parts, wear parts, prototypes, etc.

- Fast and professional order processing

- Personal contact from design to the finished product

WESTCAM 3D printing service

Additive manufacturing, which includes 3D printing, has a wide range of applications. In particular, 3D printing of spare and wear parts is becoming increasingly important.

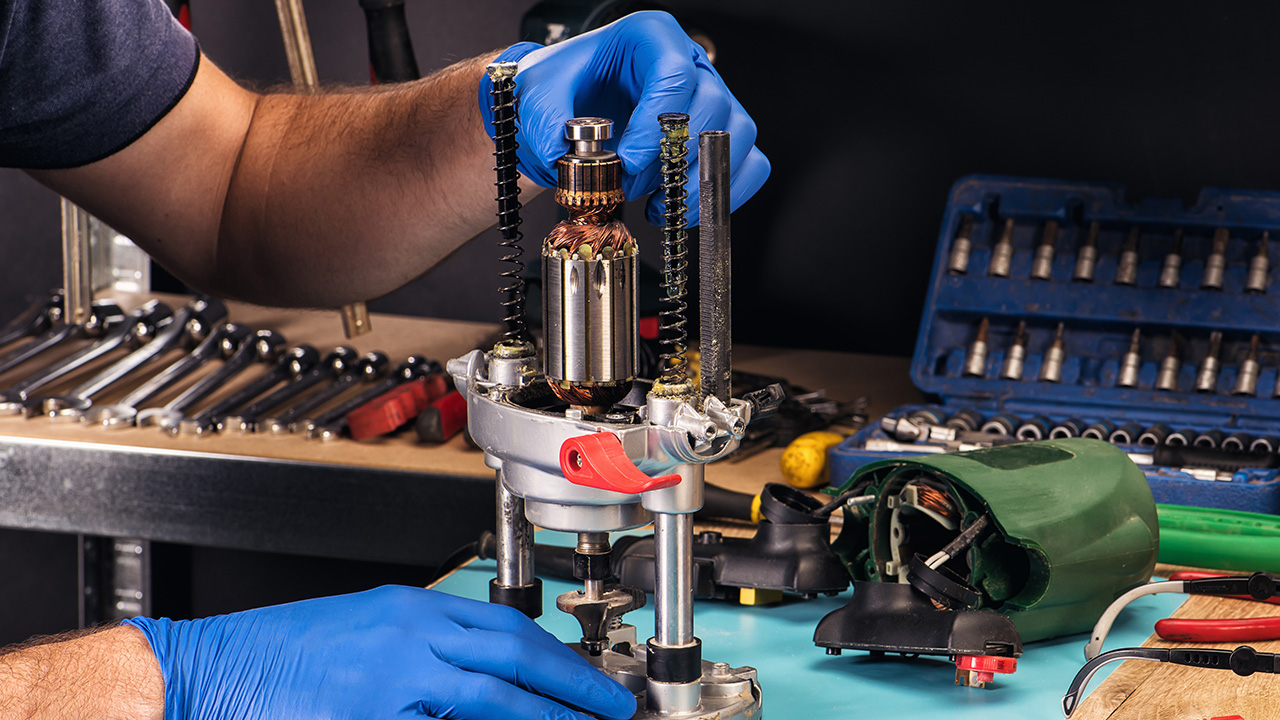

Especially with older machines or complex components, spare parts are (no longer) available. This is where 3D printing comes into play. First of all, if no 3D data is already available, a digital 3D model of the component in question is created. For this purpose, either existing parts are measured with millimeter precision(WESTCAM 3D scan) or our experts construct a 3D model of your spare part that fits exactly.

This digital model now serves as the basis for printing. Different materials can be used depending on the area of application. The most important 3D printing processes are metal printing, plastic printing and sand casting with 3D printed molds.

Diverse areas of application in 3D printing

From small series to large-scale production

However, 3D printing is not only used for repairs and maintenance. Entire product series can now also be manufactured quickly and cost-effectively using additive processes. Even complex designs are easy to implement – from small series to large-scale production.

Concept models and functional prototypes

Speed plays a decisive role not only in repairs and maintenance. Models or prototypes should also be produced as quickly as possible in order to react flexibly to the market.

With the help of 3D printing, you can quickly obtain a concept model of your product or already functional prototypes that can be put through their paces.

Component optimization

3D printing is also used to optimize components. To avoid production downtime due to repairs, components can be improved using a combination of simulation and 3D printing.

Thanks to the design optimization, the components are more resilient and the service life is increased. The weight of many components can also be optimized.

3D printing from the experts

WESTCAM combines specific know-how and years of experience in the field of 3D printing. In addition to selling 3D printers and consumables, we are also happy to model and print your components in-house. Our experts will be happy to advise you on the selection of the right process for your application or support you with further training and product training in the field of 3D design and 3D printing. Experience the unique WESTCAM service – from design to the finished product.