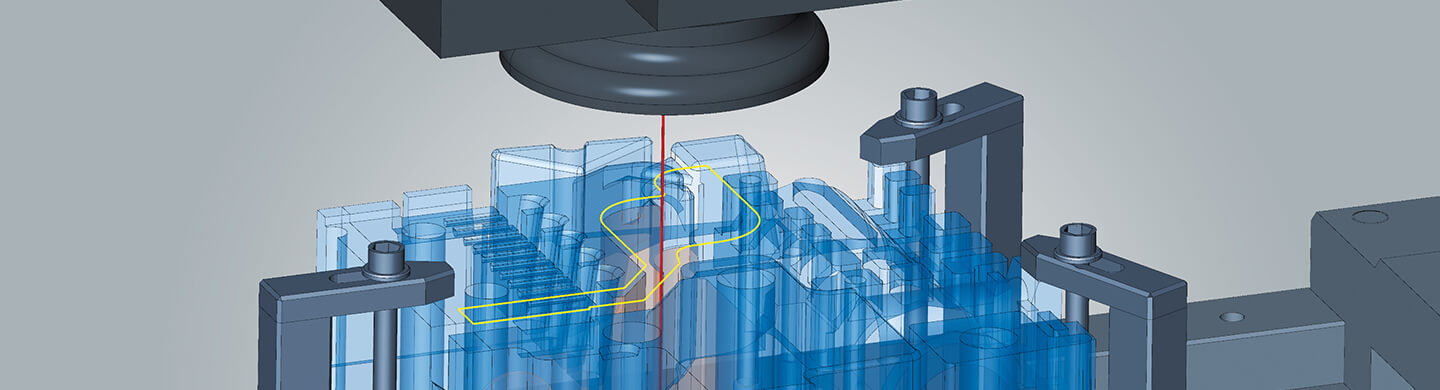

Integration for efficient production

Toolmaker LOACKER, the Vorarlberg expert in injection mold construction, has trusted WESTCAM for over 20 years. The sophisticated combination of hyperMILL & OPTICAM is a key component of the company’s success.

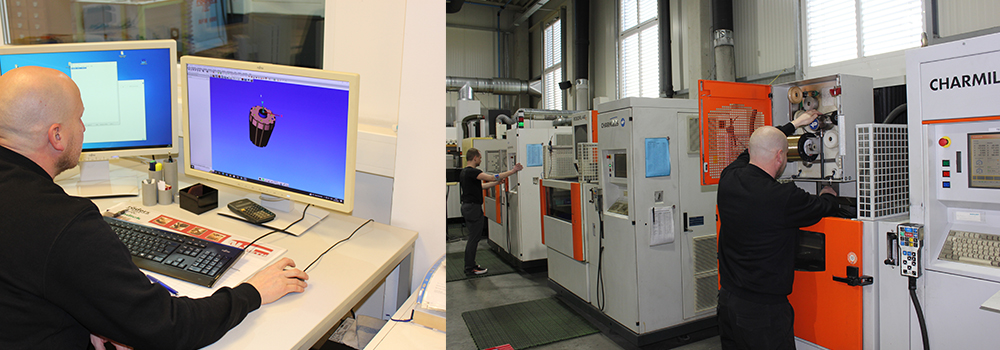

Complete CAM solution with WESTCAM service

The Vorarlberg flagship company Werkzeugbau Loacker has stood for the highest quality for almost half a century. Its core competencies are injection mold making and the production of forming and punching tools. Loacker has also made a name for itself as a contract manufacturer and reliable partner for repairs. No compromises are made when choosing CAM software solutions – WESTCAM has been trusted for over 20 years. The supportand regional assistance provided by the team in Götzis is particularly appreciated.

WESTCAM ist quasi unser Susi-Sorglos-Paket, wenn es um CAM-Software geht. Mit der Kombi OPTICAM & hyperMILL decken wir unser gesamtes Fertigungsspektrum ab. Zwei Markführer aus einer Hand gibt uns ein gutes Gefühl und sorgt für entsprechend gute Ergebnisse.

One user interface for all programming tasks with OPTICAM

Loacker covers almost all manufacturing technologies from 2.5D, 3D, 5X, HSC/HPC/HFC milling, grinding, wire and die-sinking EDM. With OPTICAM and hyperMILL the company has one user interface for all programming tasks.

Unser Kunde LOACKER setzt mit der Kombi OPTICAM & hyperMILL auf die führenden Branchenlösungen. Diese CAM-Komplettlösung für unterschiedliche Fertigungsverfahren zeigt im Alltag seine Stärken. So lassen sich die hohen Qualitätsstandards im kompetitiven Werkzeug- & Formenbau effizient erzielen.

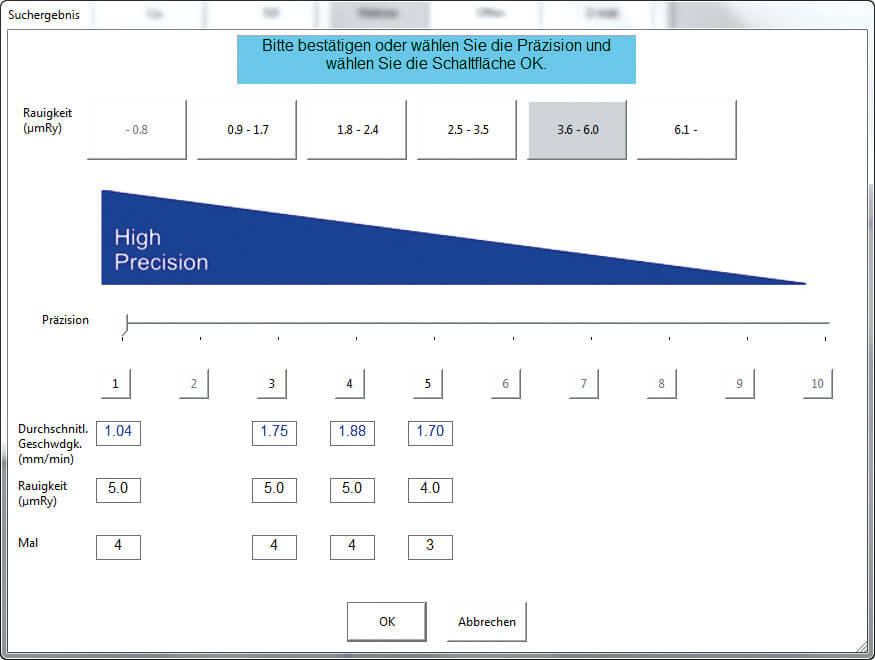

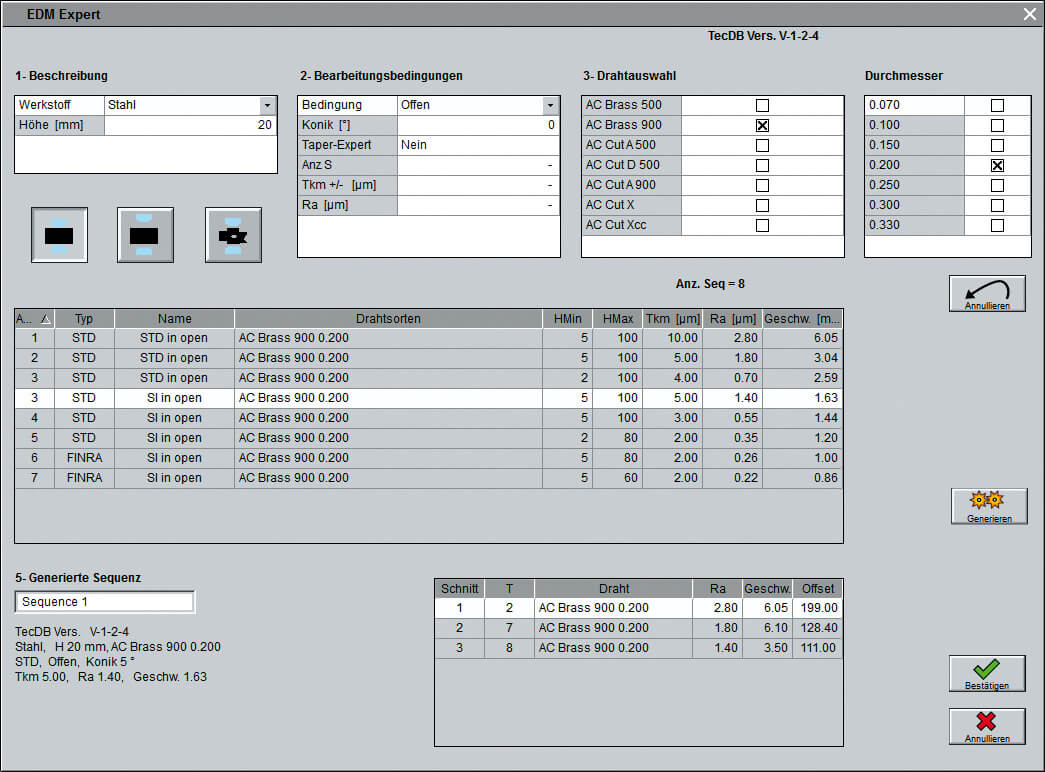

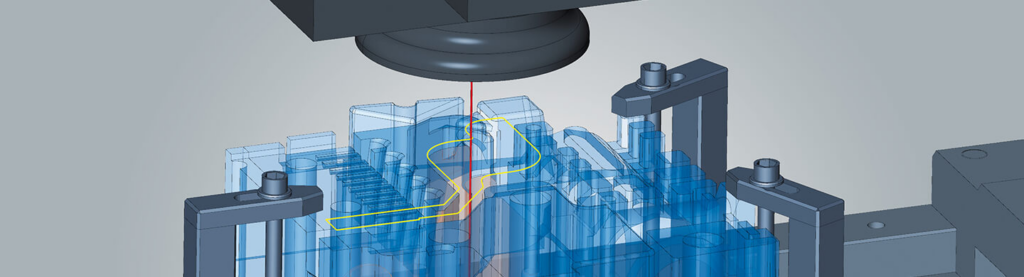

OPTICAM – Wire EDM optimally integrated

As a fully integrated solution for wire EDM in hyperMILL, SOLIDWORKS, SolidCut CAD, GibbsCAM and Siemens NX, OPTICAM reduces programming times to a minimum. More about the plug-in solution

Da wir bereits seit vielen Jahren hyperMILL von WESTCAM im Haus haben, war die Implementierung von OPTICAM in hyperMILL naheliegend. Von der Elektrodenkonstruktion bis zur CAM-Programmierung der 5-Achs-Fräsmaschine oder Drahterodiermaschine erfolgt alles in einer Programmierumgebung.

OPTICAM – Wire EDM optimally integrated

As a fully integrated solution for wire EDM in hyperMILL, SOLIDWORKS, SolidCut CAD, GibbsCAM and Siemens NX, OPTICAM reduces programming times to a minimum. More about the plug-in solution

Mechatronics & Robotics

Mechatronics & Robotics