Huge sculptures at 2,500 m – the world’s largest 3D prints in quartz sand to date

The challenge

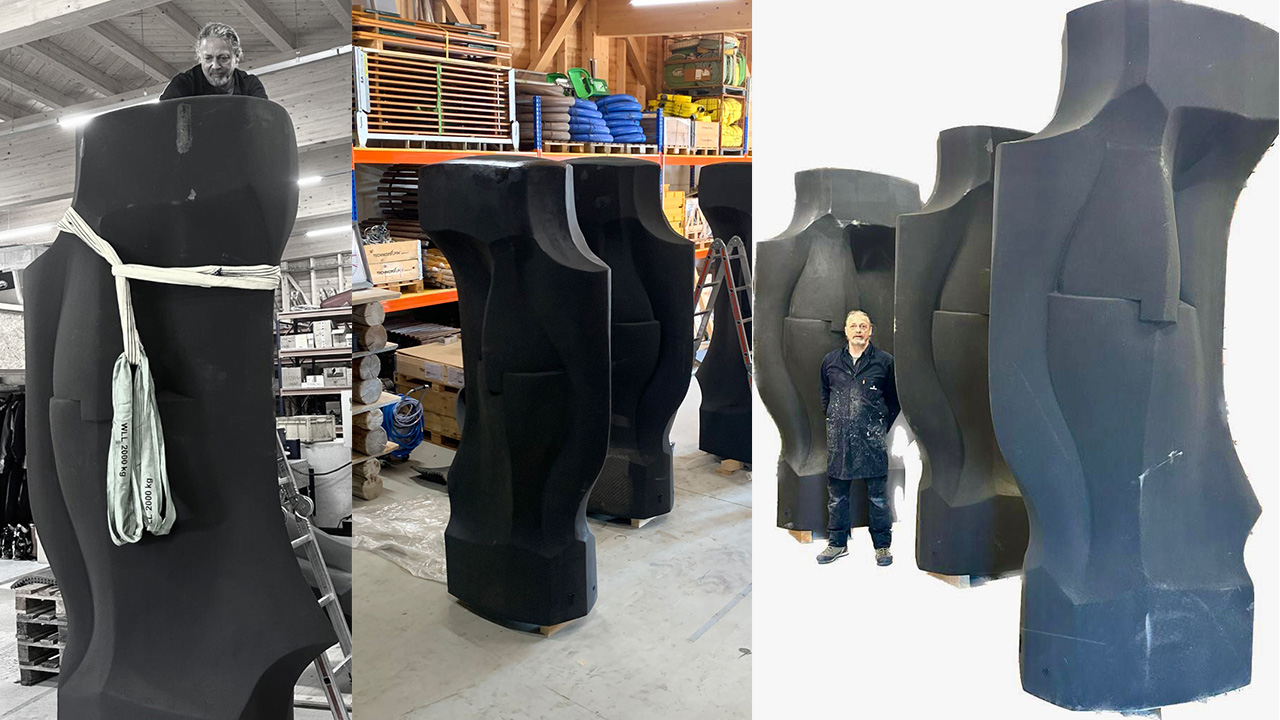

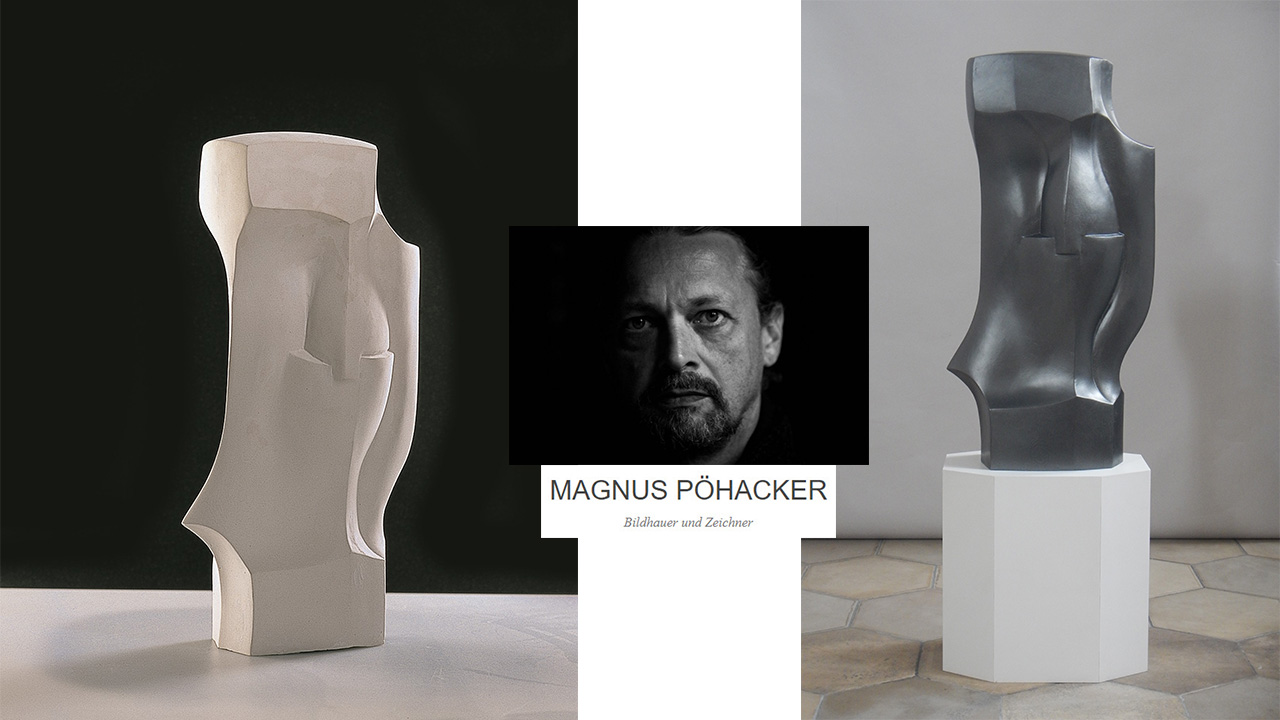

Presenting the true artistic craft of a small plaster sculpture larger than life on a Tyrolean summit? Three replicas with a height of 2.80 m. The idea came from the renowned Tyrolean sculptor and draughtsman

It has always been my dream to present small art exhibits made in the studio on a grand scale in the majestic mountain world. What most people thought was impossible finally became reality thanks to WESTCAM.

The solution

3D scan & 3D print from WESTCAM:

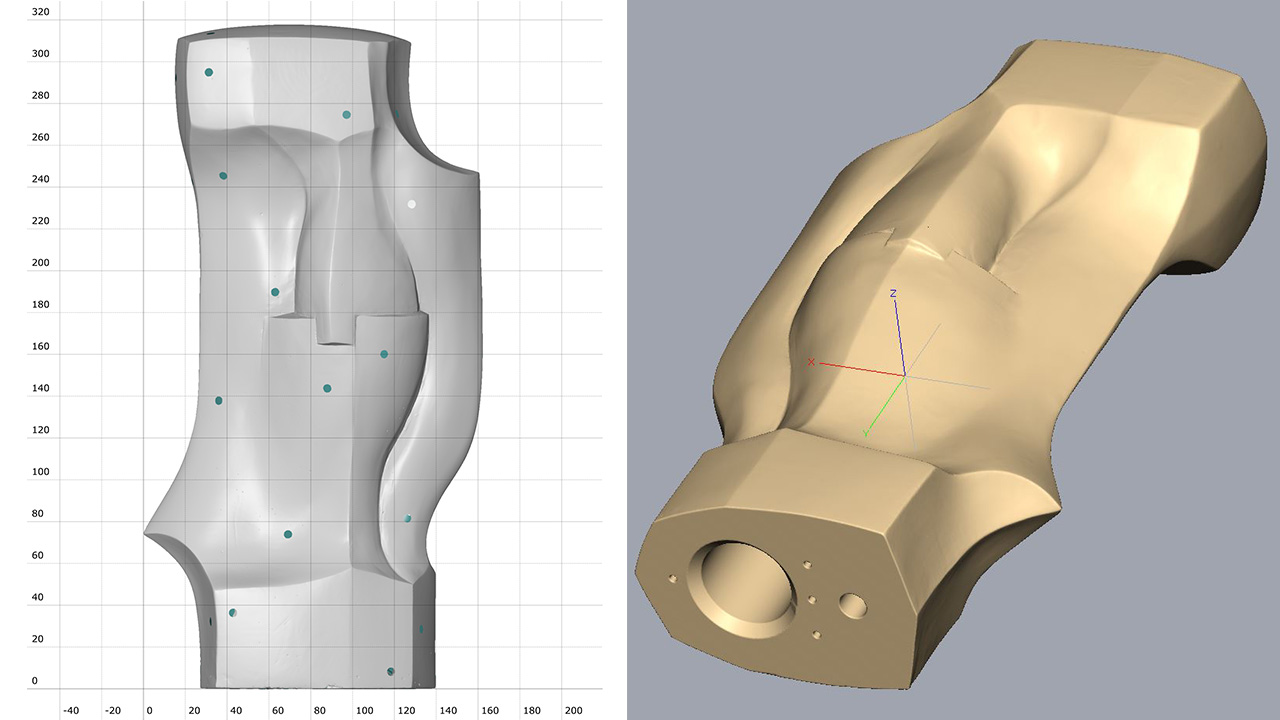

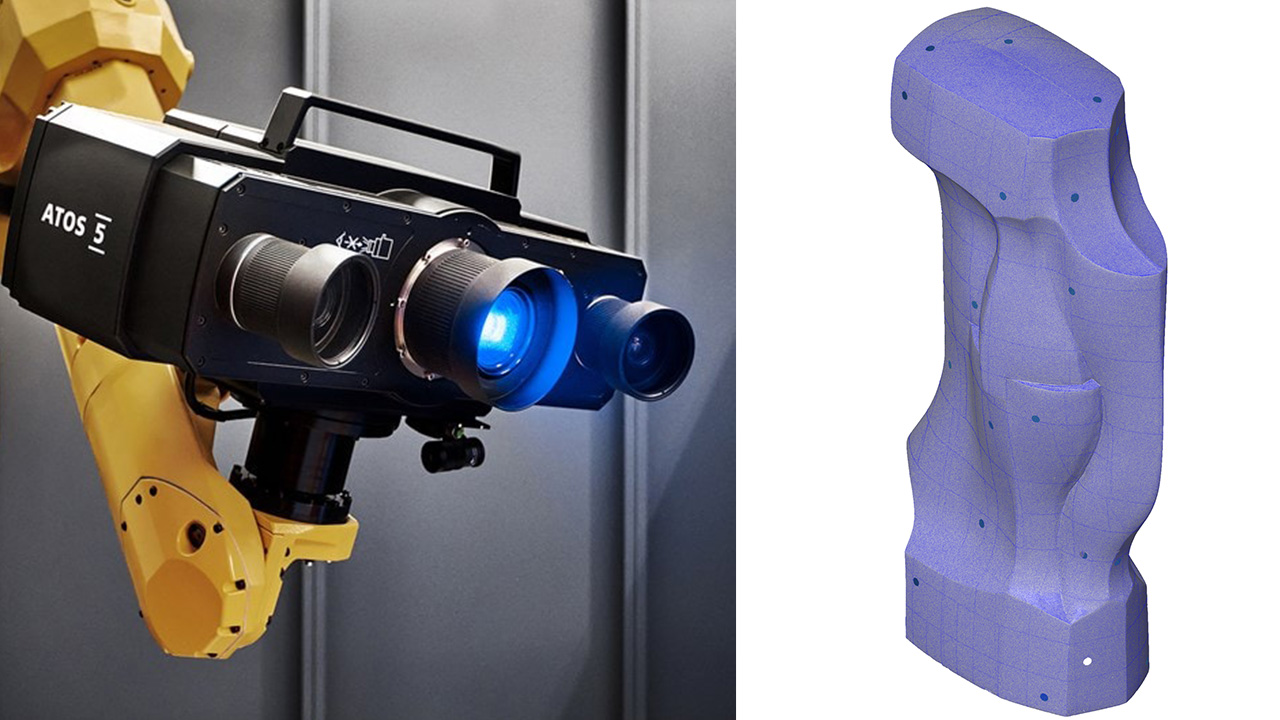

- Step 1: 3D scan of the hand-created plaster sculpture (approx. 40 cm)

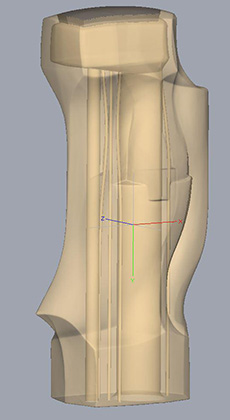

- Step 2: Construction of production model

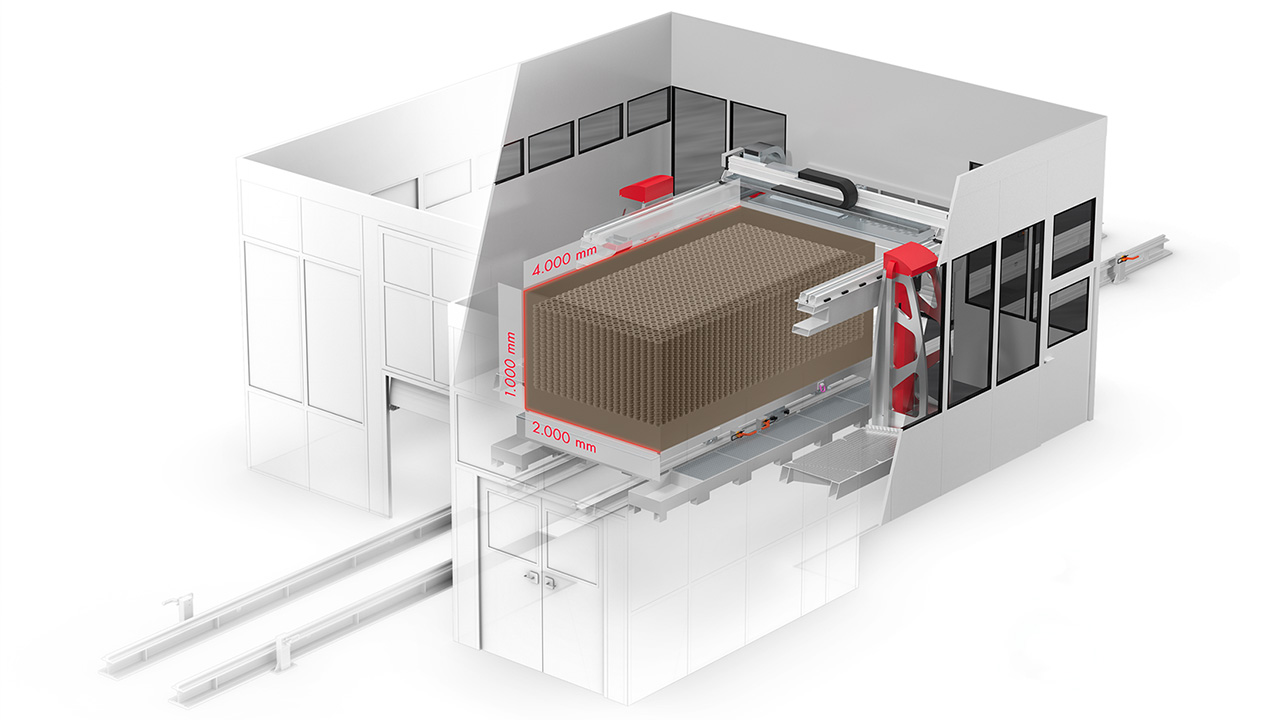

- Step 3: 3D printing using the binder jetting process by WESTCAM partner voxeljet

- Step 4: Finishing with elegant special alloy in metallic silver

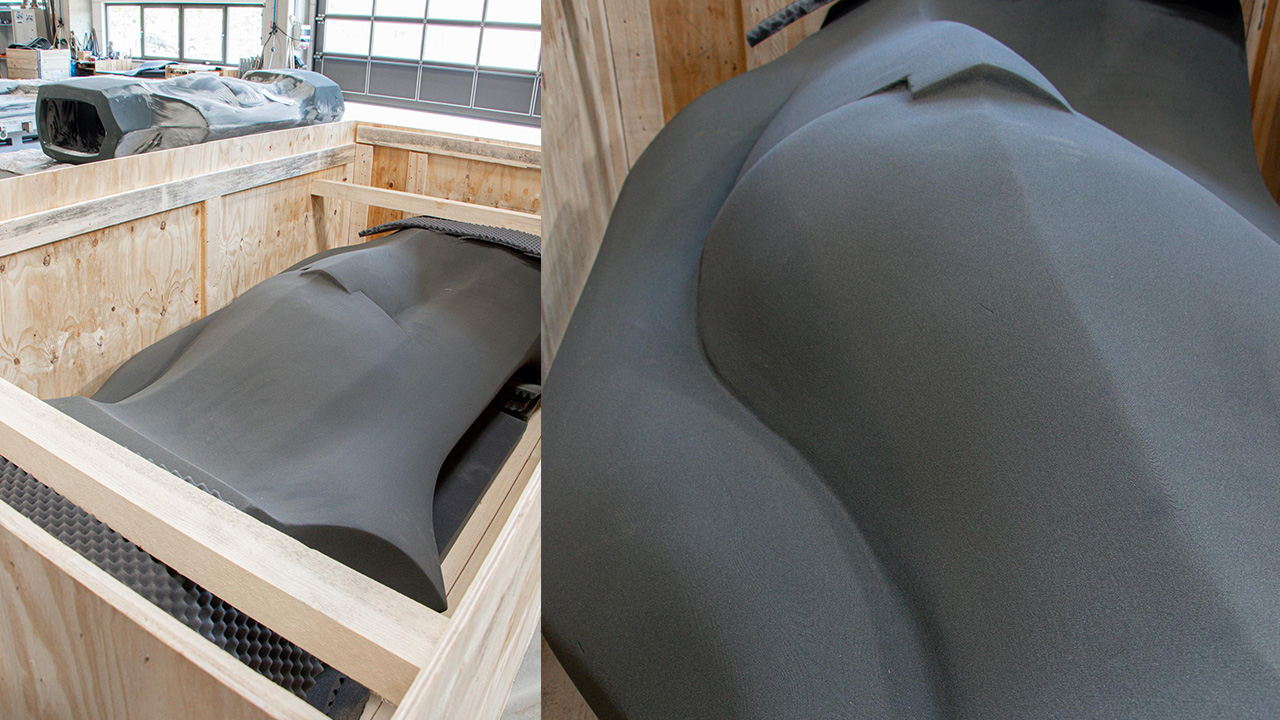

- Step 5: Transport & on-site assembly of the oversized sculptures at 2,500 m above sea level

The statically calculated reinforcement was incorporated directly into the finished model. Positioning and fastening were carried out using an integrated steel frame and threaded bushes.

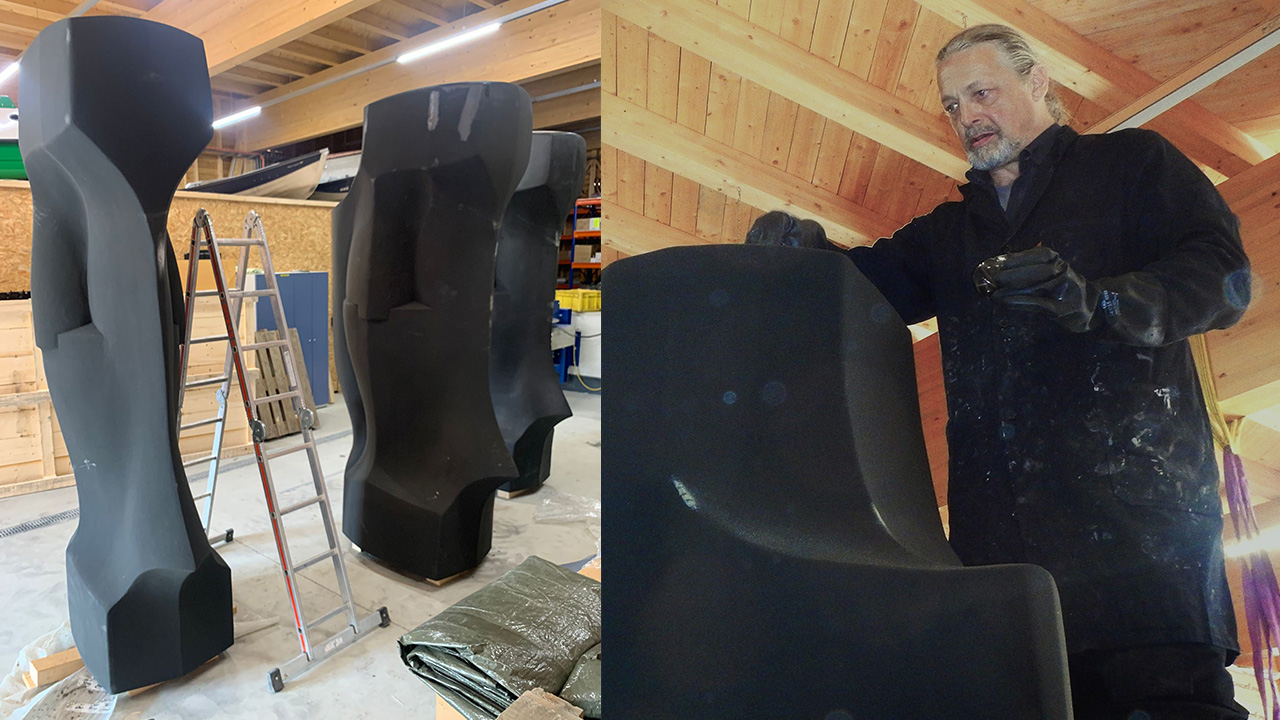

The weather-resistant surface coating by artist Magnus gives the statues their noble metallic sheen.

WESTCAM as your extended workbench

Our 3D printing service is ideal for pilot projects or individual productions. You can test your options flexibly and without risk:

3D printing at voxeljet

The three larger-than-life sculptures were produced by WESTCAM partner voxeljet in Germany.

WESTCAM scanned the statue as a small plaster model and scaled it to 2.8 meters. With the input of the artist, structural engineer and steel constructor, we then created the model for production using 3D sand printing. It took just 3 months from commissioning to installation on the mountain!

The enormous sculptures, standing above things, seem to look in three directions, at our existence and the peaks and valleys of our nature. They give the viewer their own special perspective and room for interpretation in this fast-moving world.

It fills us with pride that we were able to realize this unique project, a synthesis of art, high-tech and tourism at an impressive altitude of over 2,500 meters, in close cooperation with our partners. This project was both inspiring and a challenge, which was only made possible by the use of innovative and advanced technologies from WESTCAM. We are overwhelmed by the positive response and attraction that this attraction has had on our guests since its opening.

Ready for the next feat?

What is your challenge? We will be happy to advise you:

3D printing makes things possible that you may not even have thought of yet. Do you have an object where you are reaching your limits? We will show you free of charge and without obligation whether and how 3D printing can help.

Mechatronics & Robotics

Mechatronics & Robotics