3D printing | Challenge accepted. Increased safety during rescue operations on the rope

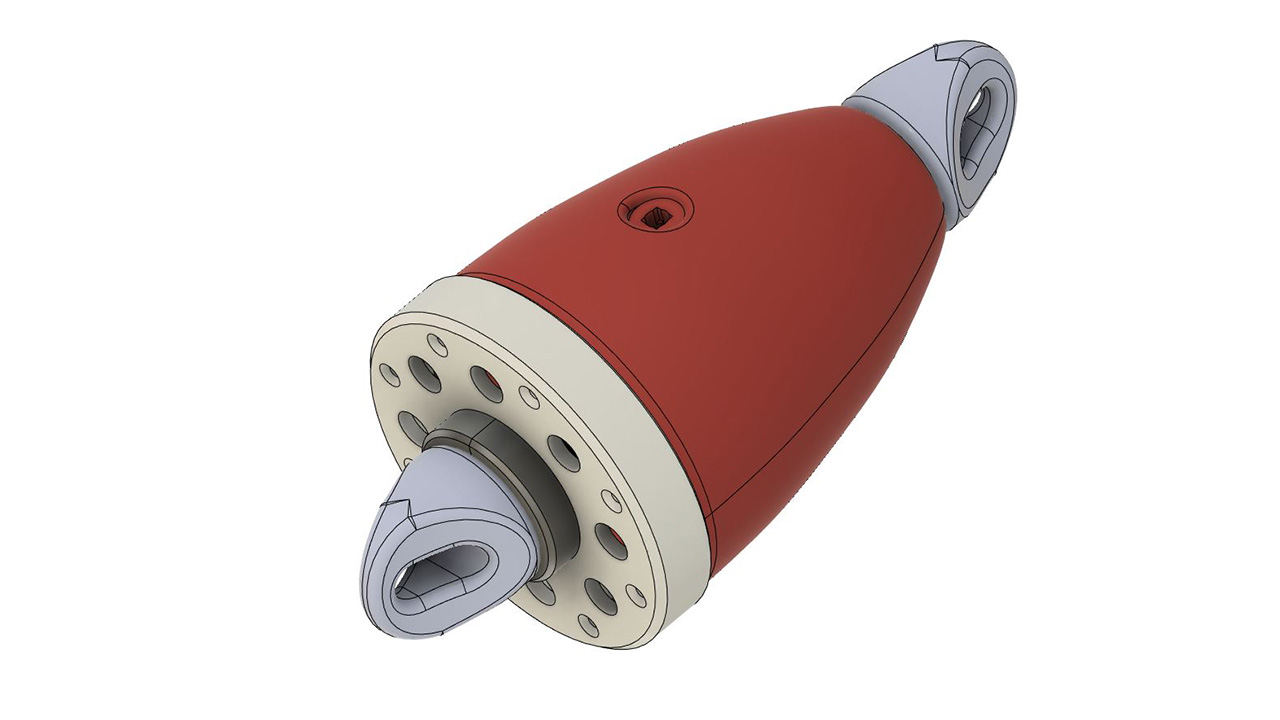

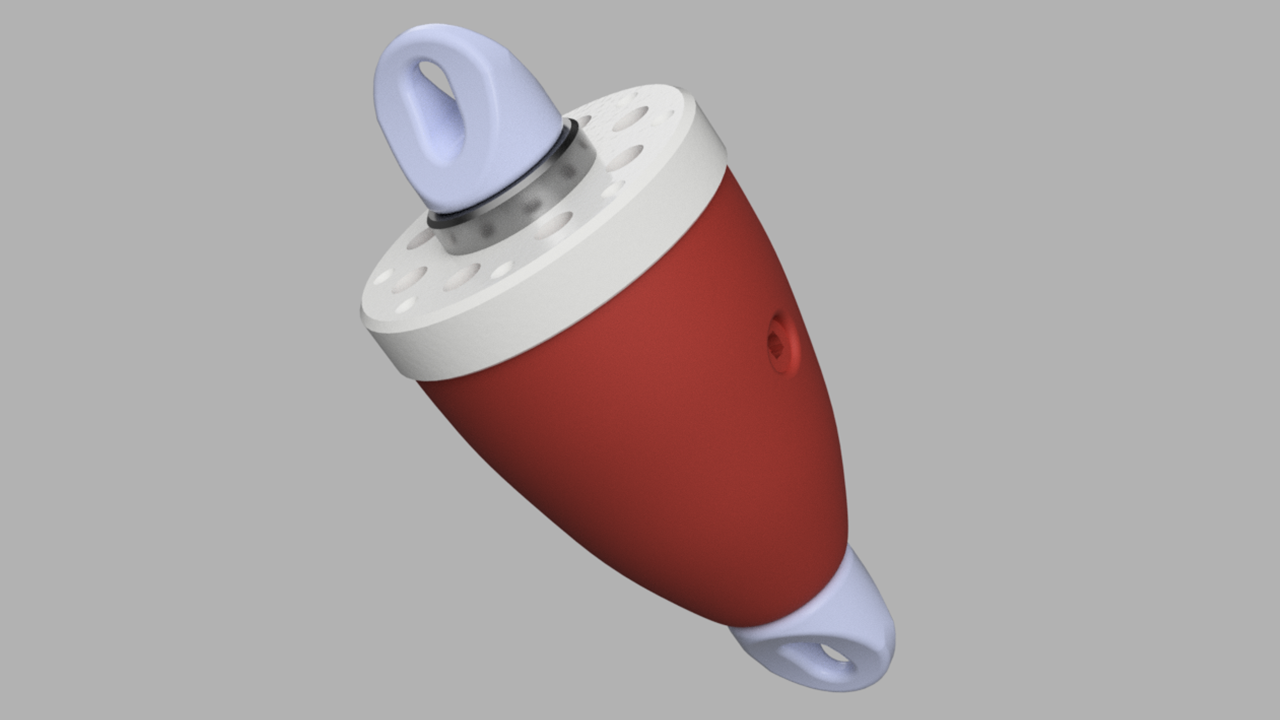

Illuminated STRAP LIGHTING ELEMENT (SLE) on the lower load hook of the rope enables the pilot to better assess his position during a rescue flight

The challenge

The renowned Austrian helicopter flight service WUCHER was looking for a solution: How can the pilot of a rescue helicopter recognize the distance between the load attached to the rope and the ground more precisely in unfavorable visibility conditions or at night?

An employee of WUCHER Helicopter GmbH (Vorarlberg) developed a requirement profile for a special line load element in collaboration with WESTCAM (Tyrol) and HÖRMANN KMT (Salzburg). The following criteria were to be met in the realization of this project:

- Robustness against mechanical (impacts, shocks, friction) and thermal (particularly low temperatures) loads

- Visibility through suitable color selection and special lighting

- Watertightness to protect the electronics inside the line load element (SLE)

The solution

Thanks to WESTCAM’s specialist expertise and 3D plastic printer , a product was developed and produced that meets all requirements. In order to withstand the loads, the wall of the SLE was reinforced and attention was paid to the use of temperature-resistant material. Visibility was ensured by appropriately coloring the 3D print and attaching the LED ring. To prevent water ingress, a seal was glued into a printed groove. Eight screw-in threaded bushes in the 3D print allow the cover to be mounted easily and securely.

Voxeljet VX 1000HSS

Cost-effective

Voxeljet VX 1000HSS is an industrial 3D printer that can be used to produce medium-sized models from plastic and sand cores quickly and cost-effectively. It produces complex parts that are difficult to manufacture using conventional production methods.

Flexible

The large installation space enables maximum flexibility and impresses with its outstanding performance. Whether it’s a medium-sized individual mold or a small series, this 3D printer can handle both.

Are you also “Ready to take off”?

We offer sound 3D printing advice free of charge:

Whether high in the air or on safe ground – 3D printing makes things possible that you may not even have thought of yet. Do you have a component that is pushing you to your limits? We will be happy to advise you and show you the best way to solve your challenge, free of charge and without obligation.

Diverse areas of application in 3D printing

From small series to large-scale production

However, 3D printing is not only used for repairs and maintenance. Entire product series can now also be manufactured quickly and cost-effectively using additive processes. Even complex designs are easy to implement – from small series to large-scale production.

Concept models and functional prototypes

Speed plays a decisive role not only in repairs and maintenance. Models or prototypes should also be produced as quickly as possible in order to react flexibly to the market.

With the help of 3D printing, you can quickly obtain a concept model of your product or already functional prototypes that can be put through their paces.

Component optimization

3D printing is also used to optimize components. To avoid production downtime due to repairs, components can be improved using a combination of simulation and 3D printing.

Thanks to the design optimization, the components are more resilient and the service life is increased. The weight of many components can also be optimized.