Ifw mold tec via hyperMILL: “Finally completely satisfied”

The ifw mold tec GmbH recently switched to the CAD/CAM solution hyperMILL. WESTCAM was able to provide the company with professional support as a partner. The world’s leading specialist in the production of high-quality injection molds now reveals its reasons for the switch, how it experienced the changeover and why it is completely satisfied with the new, powerful CAM system.

The company and its requirements

ifw mold tec GmbH is based in Upper Austria/Micheldorf. Since it was founded by Manfred Otte in 1969, the company has developed into one of the world’s leading specialists and full-service providers in the product development and manufacture of high-quality injection molds for the shortest setup and production cycles.

An important corporate goal of ifw mold tec GmbH is the economical production of components. The challenge: increasingly sophisticated parts have to be produced faster and in even better quality. In addition to state-of-the-art machinery, this requires a high-performance CAM system. Because the software also makes a decisive contribution to the rapid amortization of high investments in machine tools!

Even more reasons for a new CAM system

CAM systems offer considerable potential for continuous optimization: With innovative milling strategies in particular, the NC programming of machine tools can be continually accelerated and simplified. More effective tool paths can be created, more components can be produced in the same amount of time and machine running times can be reduced. The service life of tools is also increased. Overall, this saves costs and significantly improves efficiency.

As ifw mould tec GmbH is well aware of the considerable potential of an optimal CAM system, it turned to WESTCAM, the innovation leader among CAM providers, for support in the search for the ideal software solution.

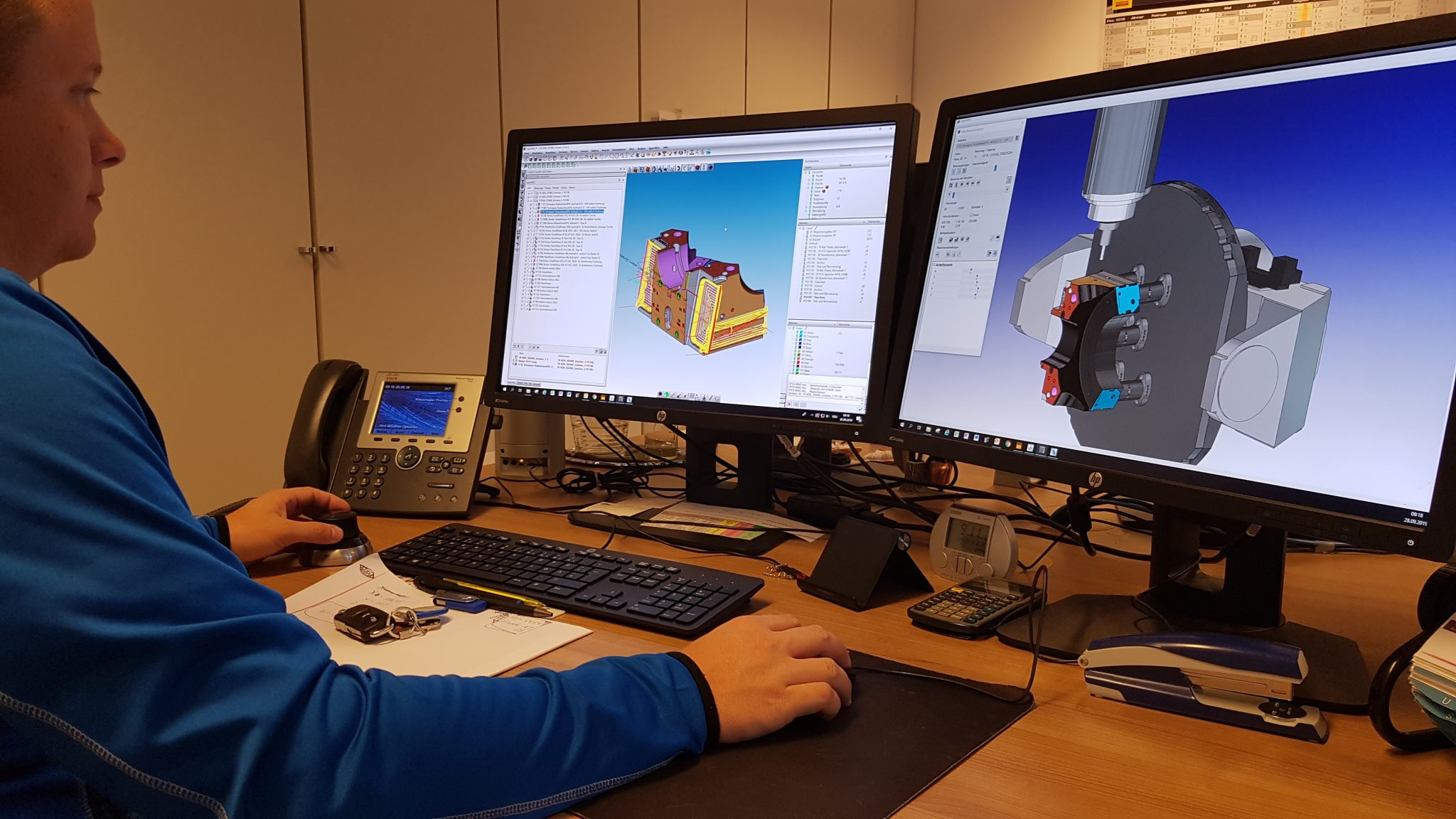

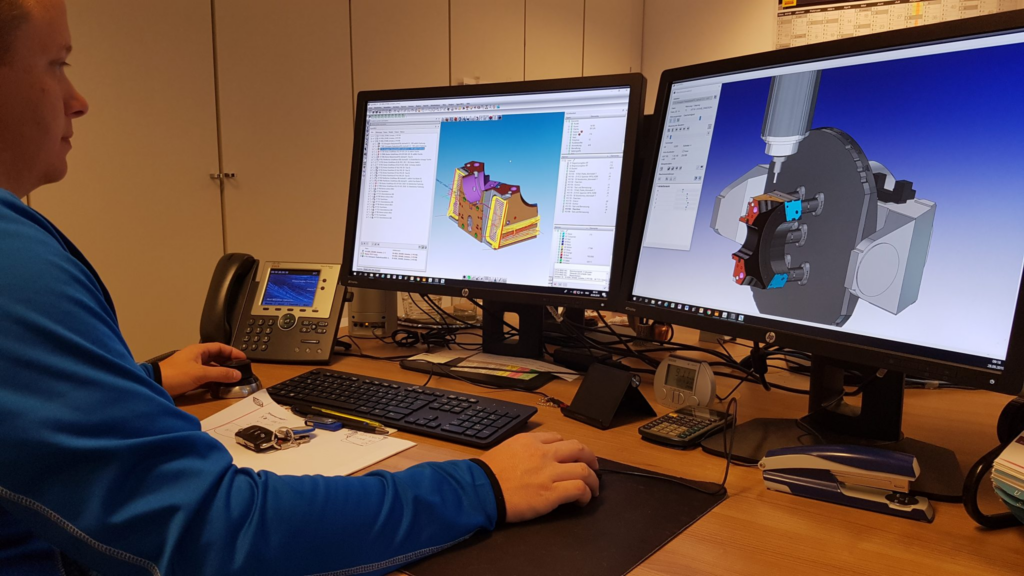

hyperMILL– simply unbeatable

After familiarizing themselves with the company’s requirements, the WESTCAM professionals recommended hyperMILLas a high-end CAM solution. One of the software’s strengths is its wide range of CAM modules. The most efficient machining can be found effortlessly at any time – from 2.5D and 3D strategies to HPC solutions, 5-axis machining and mill turning. The software ensures maximum performance, is user-friendly and easy to learn. Users are able to create NC programs for machine tools quickly and easily.

Dreams of the future: thinking about tomorrow today

When manufacturing companies decide on a particular CAM system, they usually have their current range of parts in mind. However, WESTCAM advises companies to think about tomorrow when making their decision: “Future-proof CAM software must also be able to meet market trends. For example, the complete machining of complex components with milling-turning centers will continue to gain in importance. CAM software must be able to provide the necessary milling-turning strategies to fully exploit the functional scope of these machine tools. Other trends include the growing proportion of 5-axis machining and the increasing importance of automated CAM programming.”, explains Klaus Baumgartner, WESTCAM Sales Manager, St. Florian branch. hyperMILL already takes tomorrow’s technology into account today and is therefore the optimum software solution.

ifw mold tec praises WESTCAM and hyperMILL

Ifw mold tec is completely satisfied with its new CAM system hyperMILL:

“We were all aware of the effort involved in a CAD/CAM changeover. However, together with WESTCAM, it was planned perfectly! Practical knowledge was imparted quickly and effectively, and WESTCAM organized the training and product launch in such a way that there were no losses in production. This makes it very easy for us to report a positive result to our management. But that was to be expected with hyperMILL and WESTCAM…”praises Markus Kothgassner (Head of CAM) from ifw mold tec.

Mechatronics & Robotics

Mechatronics & Robotics