Data management is now. Successful and competitive with Autodesk Vault

Leaning back comfortably and doing everything the way it has always been done – unimaginable for Günter Stöckl. The owner of Metallbau Eckhart – Günter Stöckl GmbH, which he took over eight years ago, is an innovative employer. In the Tyrolean Oberland in Prutz, his 15 employees work on state-of-the-art machines and use the latest technologies for unusual design projects, but also for the day-to-day work involved in metal construction. To ensure that the data flow between 3D measurement, planning and production does not come to a standstill, Günter Stöckl is currently in the process of introducing Autodesk Vault as a data management system. He is being supported by the professionals at WESTCAM Datentechnik GmbH.

Günter Stöckl has been with the metal construction company since it was founded in 1992. Before that, he worked for an automotive supplier, which is where his enthusiasm for new technologies comes from: “A lot of high-tech is used in the automotive sector and I have tried to integrate these highly automated work processes into the metal construction sector here too.

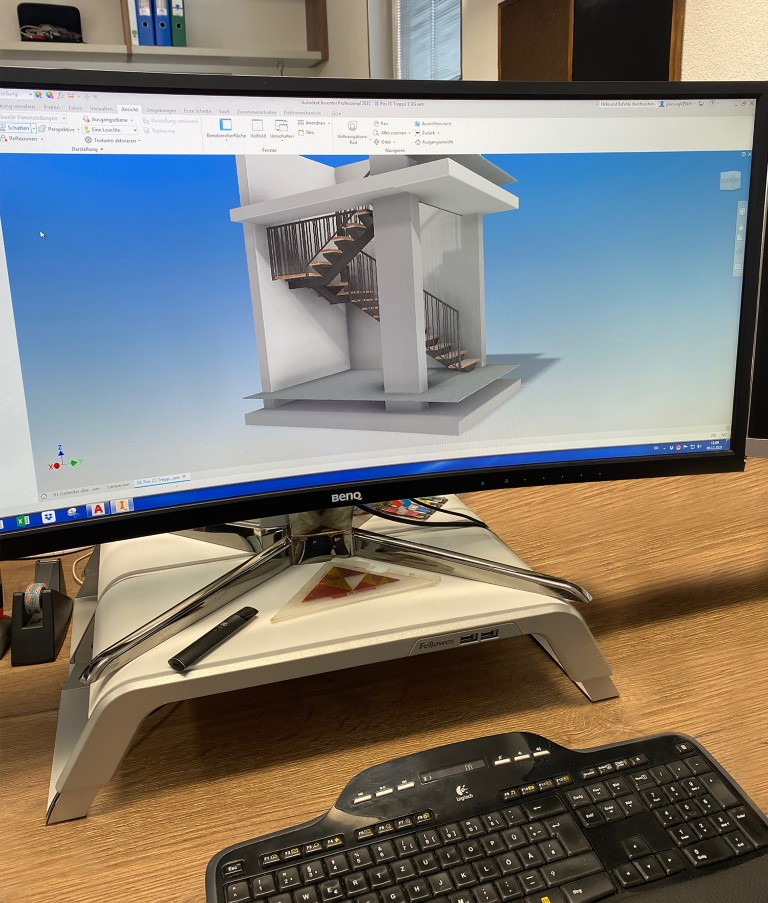

Günter Stöckl and his team have been drawing with Autodesk Inventor since 2015. He acquired the licenses via WESTCAM.

“WESTCAM knows what makes sense for me. They are complete professionals and that makes the collaboration fun.”

For us at WESTCAM, it was particularly important to start by taking a close look at the needs and objectives of the metalworking company. In this way, we created a basis of understanding and trust that continues to grow to this day – one reason why Günter Stöckl is also fully relying on the competent support of WESTCAM for the current introduction of Vault.

Our aim is to help our customers step by step and make them more successful. Vault is one building block in this process. But there are many pieces of the puzzle, from the consulting phase and many discussions through to product introduction, training and telephone support, which create trust and ensure good all-round support

The technicians at Metallbau Eckhart now have four Product Design & Manufacturing Collections (PDM) are now available. Since October 2020, Günter Stöckl and WESTCAM have also been working together on the implementation of the Vault Workgroup including Vault Office.

Advantages of data management with Vault

A data management system like Vault – does it even make sense for small companies like Metallbau Eckhart? Christoph Geiler is convinced that data management makes sense, regardless of the size of the company. Because the benefits of data management are the same for everyone:

Time and therefore cost savings thanks to automated processes such as saving documents in different formats. Configured files can be reused at any time and saved data can be found in seconds.

Data security: By storing the data in Vault, the data is stored securely. The central storage of all relevant data and associated documents ensures efficient file organization. Access rights can be assigned individually and versions are saved.

Error reduction and avoidance through versioning – everyone always has access to the latest version. Several team members can work simultaneously on designs that are stored centrally. This enables secure and simultaneous access to data.

“Data management is not the future, it’s now! It’s a tool that everyone should have these days”says Christoph Geiler. Of course, introducing a data management system like Vault is a complicated process that takes time. The data management system specifies certain processes, which means that the customer has to be prepared to accept changes – even if some workflows have proved successful so far. This is not immediately met with understanding by all customers. But the WESTCAM data management expert knows: “The customer should, must, may give their input, but they must also adapt to the new system. It makes sense for products to have a certain standardized procedure and processes. Excessive customization not only causes high costs, it also often affects functionality and leads to high follow-up costs for the next update. Customers should understand this: You have to allow process changes in order to move forward.”

Continuous data flow and cost savings

Günter Stöckl has a new goal in mind: paperless production. With the help of process optimization and automated procedures, his employees should be able to complete more work in the same amount of time. Although the company is already well-positioned digitally, there is currently still a logjam in the data flow:

“I have already tried to make the manufacturing process from the technician to the machines as seamless as possible. We measure in three dimensions and draw in Inventor based on the point data cloud. My problem is the insane amount of data that can be processed by my technicians, but not in production. A lot of information that is already there is lost again. And I want to optimize this with Vault”,

explains Mr. Stöckl. Once stored in the Vault, data from the design drawings, for example, is automatically sent to the correct production machine in the correct format.

“For me, this means huge time savings – and therefore also a competitive advantage, as we can of course save enormous costs in the production process.”

And he sees yet another advantage for his company: digitizing his work processes eliminates many tedious tasks, such as saving data in different formats. Instead of pressing “Save copy as” to obtain a PDF, DXF, DWG or other format of a drawing, the job processor automatically generates this copy and saves it, including any desired changes. For the technicians, this also means more fun at work.

At the same time, Günter Stöckl offers its employees the opportunity to work in metal construction at the highest technical level. This makes him an attractive employer in the region in times of a shortage of skilled workers. One thing is certain for the metalworker:

“Thanks to WESTCAM’s advice, I can offer fast, cost-effective and labor-intensive production in less time. You need a reliable partner so that you can process very complex components in a short time – for me, that’s WESTCAM and Autodesk with Vault and Inventor.”

Autodesk products used at Metallbau Eckhart:

Do you also want to become even more successful and competitive with data management?

Don’t hesitate – I’m here for you!