“From taster course to heavy user” – AUSTRIALPIN wants to hyperMILL

Woe betide anyone who sniffs. ABA Hörtnagl GmbH, better known under its sales name AUSTRIALPIN, has smelled success. It is completely convinced by the CAM suite hyperMILL and recently became a new WESTCAM customer.

Put through its paces

For Michael Hörtnagl and Dominik Sterzinger from AUSTRIALPIN, the hyperMILLtaster course was an excellent investment. Thanks to the in-depth basic training, they were able to operate the system well during the two-month system trial.

All training content was vividly conveyed using striking practical examples. A particular highlight was the on-site configuration of the post-processor. Would you recommend the taster course to others? Absolutely.

In addition to series production, our CAM evaluation focused primarily on tool and mold making. For this industry, hyperMILL is known as the top dog and proves this time and time again. The great thing about the evaluation is that hyperMILL is suitable for all production areas and integrates perfectly into our existing IT landscape.

Visit to WESTCAM in the test phase

Together with WESTCAM area manager Samuel Bader, they took the opportunity to discuss the resulting advantages, make them usable for AUSTRIALPIN and determine the expansion stage tailored to the specific requirements. At the end of the testing phase, a two-day power workshop was held to fine-tune and get the most out of hyperMILL.

The test proves it:

Faster with hyperCAD-S

The in-house design is based on SOLIDWORKS. With hyperCAD-S, the native SOLIDWORKS data can now be opened directly from the PDM system. The model quality is now top notch and there is also no need for a work step to export the component as a STEP or IGES file. The geometry information such as planes, coordinate systems, PMIs, bookmarks, thread or fit information is available for CAM programming.

Half the programming effort

The fact that hyperMILLis more sophisticated than its predecessor has delighted users. More setting options, higher quality toolpaths, a logical algorithm for the cycles, greater user-friendliness, feature mapping, better work organization thanks to very

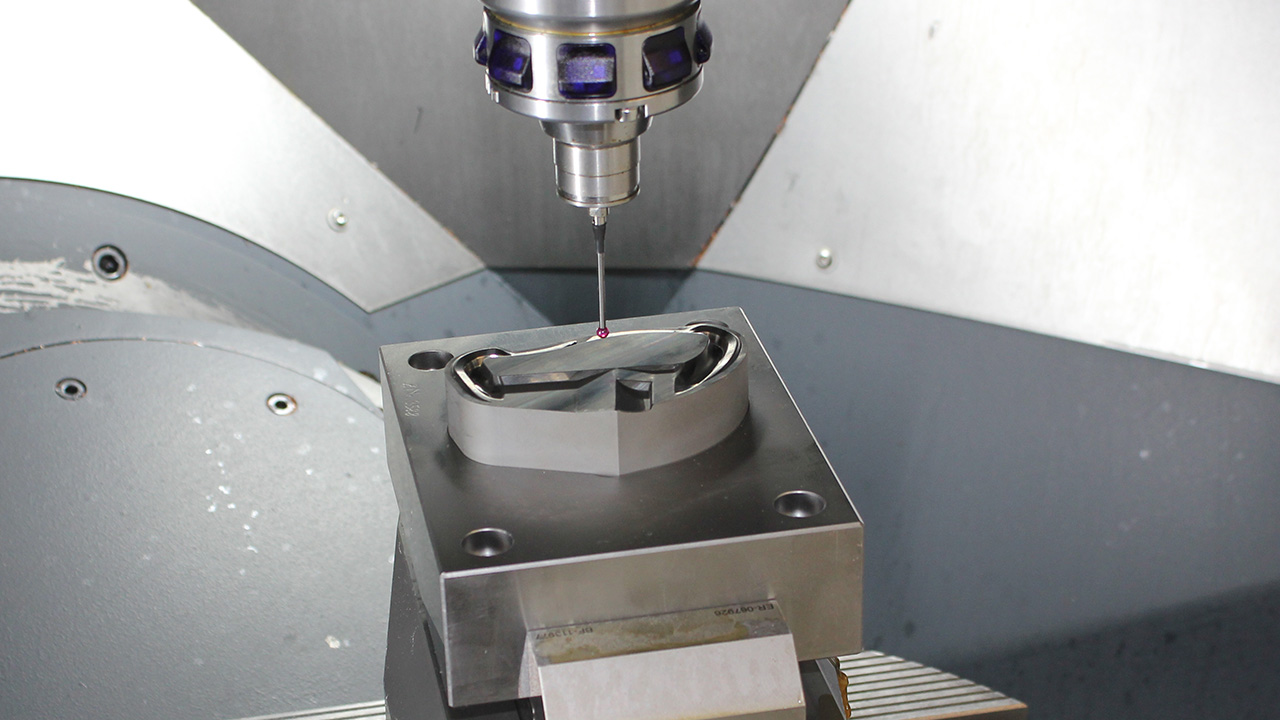

COBRA® Quick Release

A buckle that meets the highest safety requirements for its users, as the buckle can only be opened by pressing both clips simultaneously. It allows effortless engagement of the thrust and main sections.

The COBRA® Quick Release, the most innovative and safest buckle in the world, has made AUSTRIALPIN the world market leader.

Support around the corner

In addition to cutting, punching and bending tools, injection molding tools are also manufactured and repaired in the in-house tool and fixture construction department. According to AUSTRIALPIN, hyperMill increases efficiency, especially for complex components.

AUSTRIALPIN recognizes the local availability of WESTCAM as a clear plus. As we have already experienced, support is not an empty promise, but a special concern of WESTCAM. And you can rely on this in the future too.

Anchored on Tyrolean soil

The traditional Tyrolean company AUSTRIALPIN has been manufacturing high-quality metal mountain sports & safety equipment since 1996, which they develop and produce themselves with decades of metalworking experience and expertise, all at one location in Fulpmes in the Stubai Valley.

The demands on component quality are constantly increasing, while at the same time cost-effective production is more important than ever. In order to reconcile these requirements, a high-end product and good service are needed. With hyper MILL you can see the many years of market presence and customer-oriented development. The product is fully developed, which is reflected in the quality of the tool paths and the user-friendliness.

We advise you personally!

Gladly there for you