3D printing | Challenge accepted. Printing mini components with maximum precision

5,000 custom-made mini gears printed “on the side”

The challenge

Print 5,000 tiny components, which are extremely difficult to produce using conventional methods, down to the last detail. Is that possible?

The solution

You can! If you take action yourself and simply ask WESTCAM.

Practical example: ETEC D4K prints mini gears with maximum precision

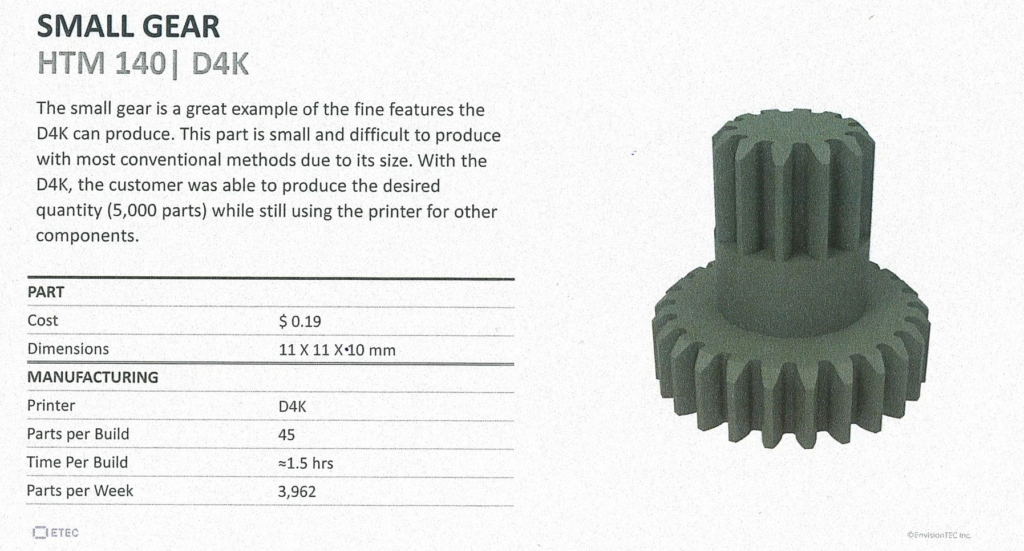

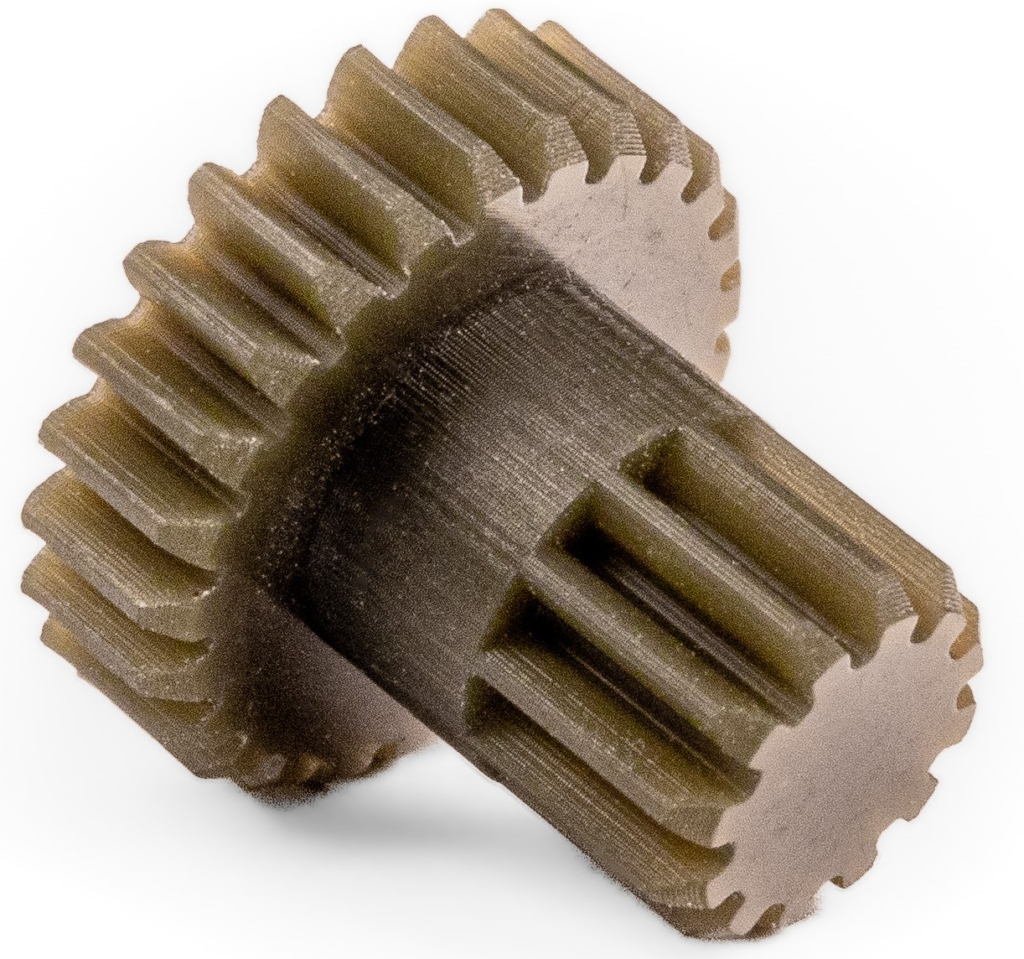

The tiny mini component, the HTM 40 gear wheel, is a great example of how precisely the WESTCAM ETEC D4K masters the challenge down to the last detail. With the ETEC D4K, the customer not only managed to print the desired number of 5,000 pieces, but also to produce other components with the same desktop 3D printer.

The printer

Reference example

SMALL GEAR | HTM 140 | D4K

Component:

- Cost: approx. € 0.18 per piece

- Dimensions: 11 x 11 x 10 mm

Additive manufacturing:

Parts per week: 3,962 pieces

3D printer: ETEC D4K

Parts per printing process: 45 pieces

Time per printing process: approx. 1.5 hours