3D printing | Challenge accepted. Produce 6 spare parts in 1 hour

The challenge

More than 6 months delivery time! Cable holders in small quantities? Injection molding or printing?

The solution

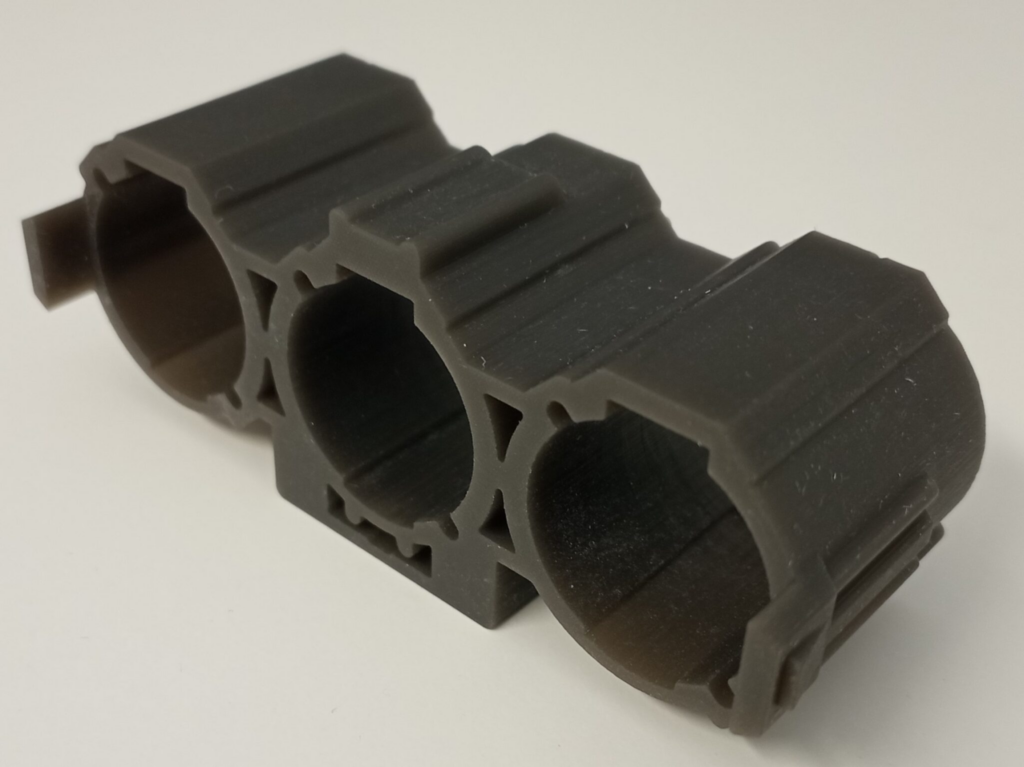

Instead of waiting, take action yourself! Ask WESTCAM! Why invest in prohibitively expensive injection molding tools when you can simply and cheaply 3D print small quantities (approx. 2,000 – 5,000 units)? For example, to hold cables in a precise position so that they do not interfere with moving components, you need two things: the ETEC Envision One or the WESTCAM 3D printing service.

The 3D printer

CABLE HOLDER

Component:

- Cost: € 31,- (for production 6 pcs.)

- Dimensions: 79 x 31 x 30 mm

Additive manufacturing:

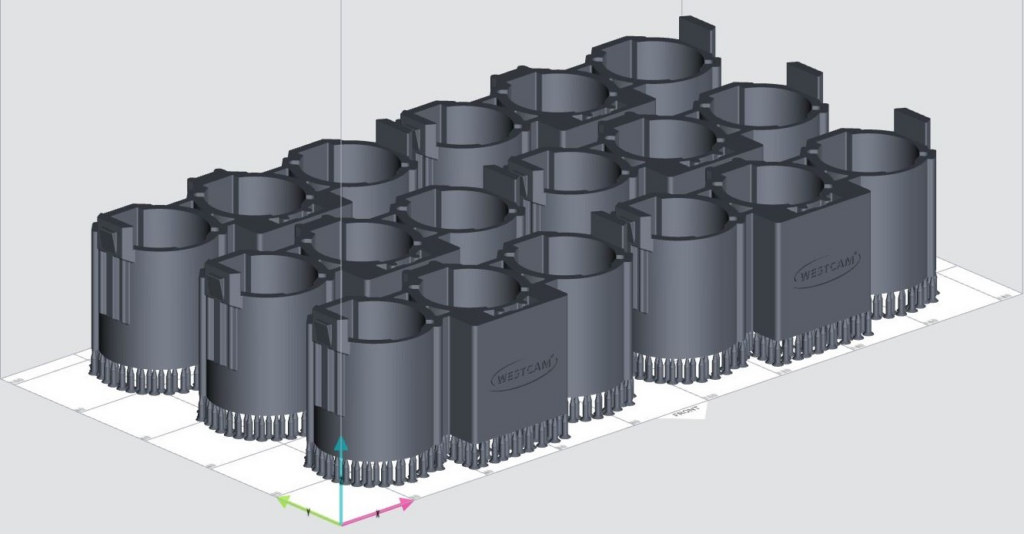

- 3D printer: ETEC Envision One

- Printing time per part: 10 min. (1 h: 6 pcs.)

- Quantity per print: 6 pieces

- Material quantity per piece: 19 ml

- Layer resolution: 100 µm

ETEC Envison One

Multiple exceptional

Whether speed, print resolution, surface finish or part properties – Continuous Digital Light Manufacturing technology (CLDM) enables continuous printing in an exceptional way in every respect.

Look closely

Inaccuracies? Eliminated! With the patented “domeless” printing technology, simply nothing can affect the print result. Count on fine features and smooth surfaces.

Best time?

With pleasure. ETEC Envision One produces your functional components at high speed using continuous printing.

Best in class!

Strong, stable, durable. The ETEC Envision One impresses with best-in-class parts performance, because the isotropic parts can withstand even the most demanding conditions.

Diverse areas of application in 3D printing

From small series to large-scale production

However, 3D printing is not only used for repairs and maintenance. Entire product series can now also be manufactured quickly and cost-effectively using additive processes. Even complex designs are easy to implement – from small series to large-scale production.

Concept models and functional prototypes

Speed plays a decisive role not only in repairs and maintenance. Models or prototypes should also be produced as quickly as possible in order to react flexibly to the market.

With the help of 3D printing, you can quickly obtain a concept model of your product or already functional prototypes that can be put through their paces.

Component optimization

3D printing is also used to optimize components. To avoid production downtime due to repairs, components can be improved using a combination of simulation and 3D printing.

Thanks to the design optimization, the components are more resilient and the service life is increased. The weight of many components can also be optimized.