Believe or know: Can 3D printing technology go big?

3D-printed tunnel paves the way for the energy transition

In order to store more water for the generation of green energy, the dam wall at the Kaprun power plant is to be raised by 8 meters. The critical factors here? The overflow and the existing ventilation. Verbund commissions the University of Innsbruck . And they bring WESTCAM on board for the pilot project.

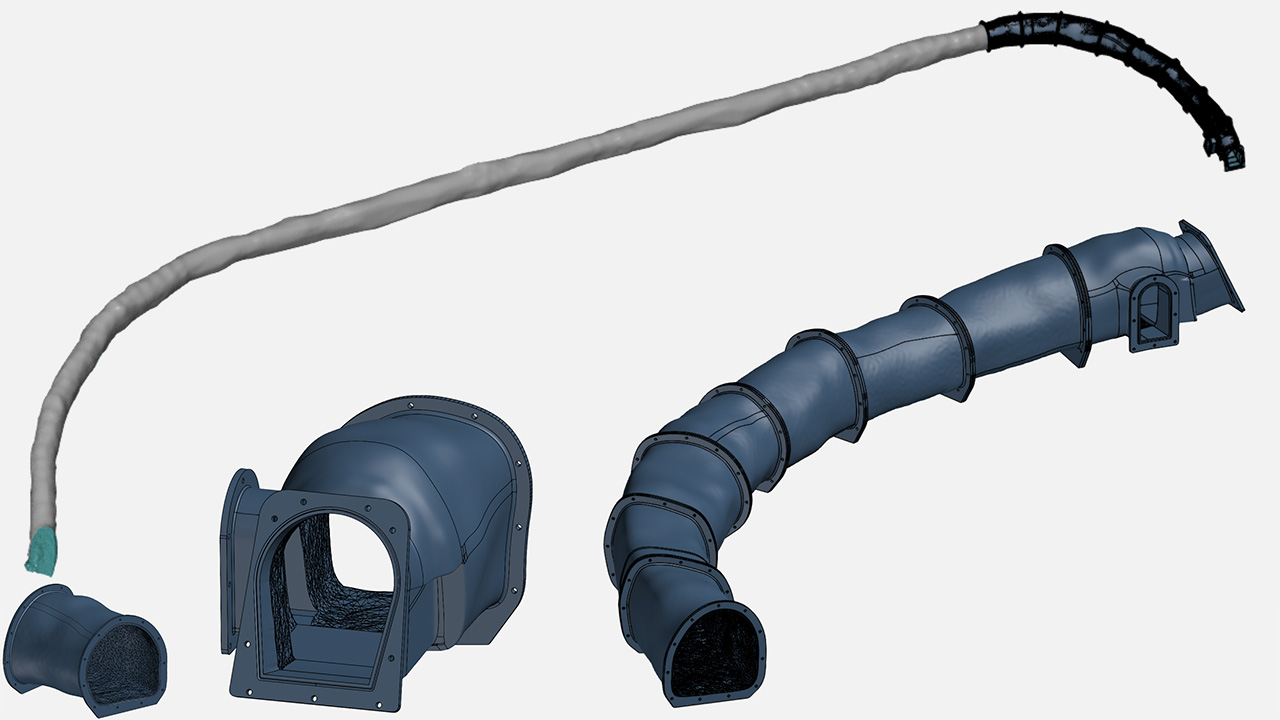

Relief tunnel is 3D scanned

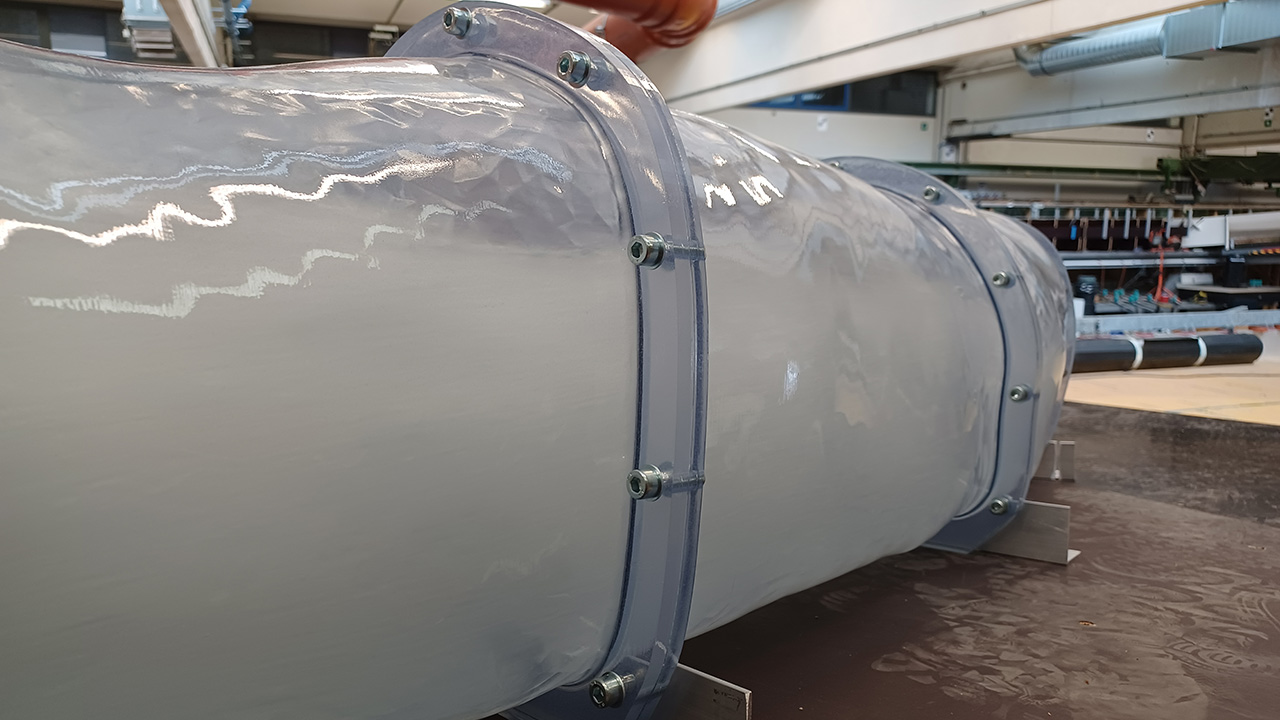

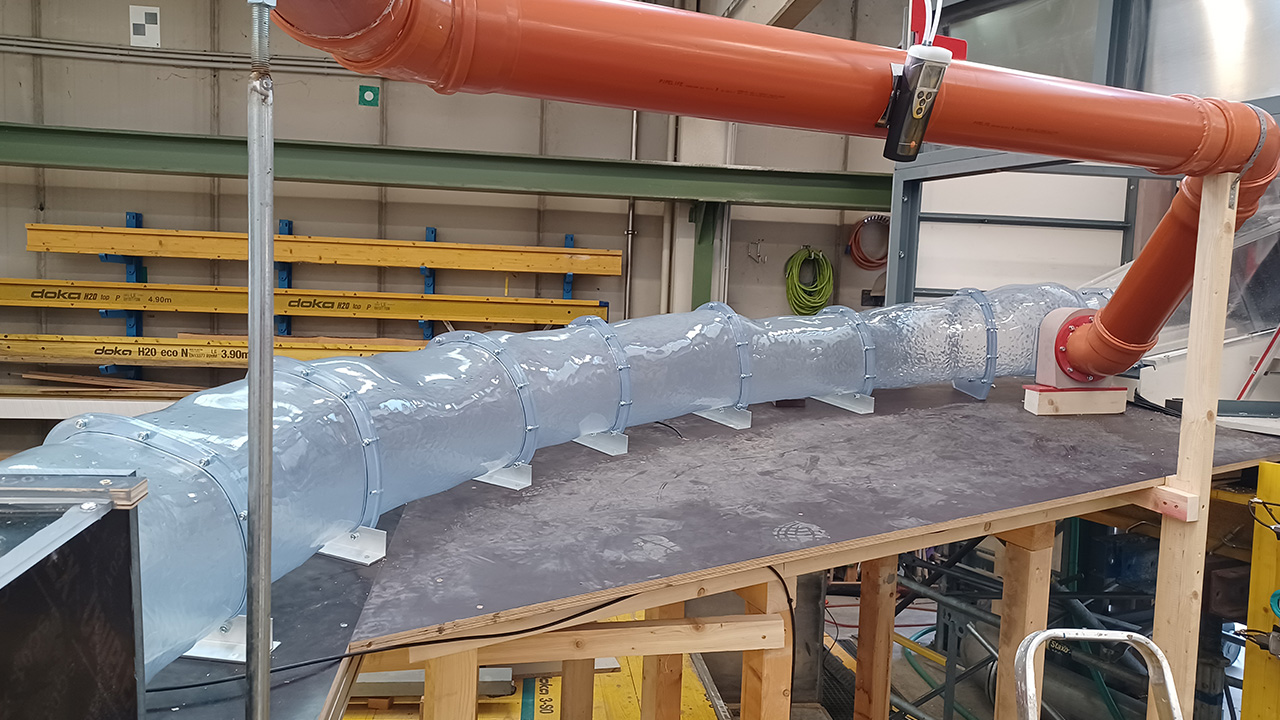

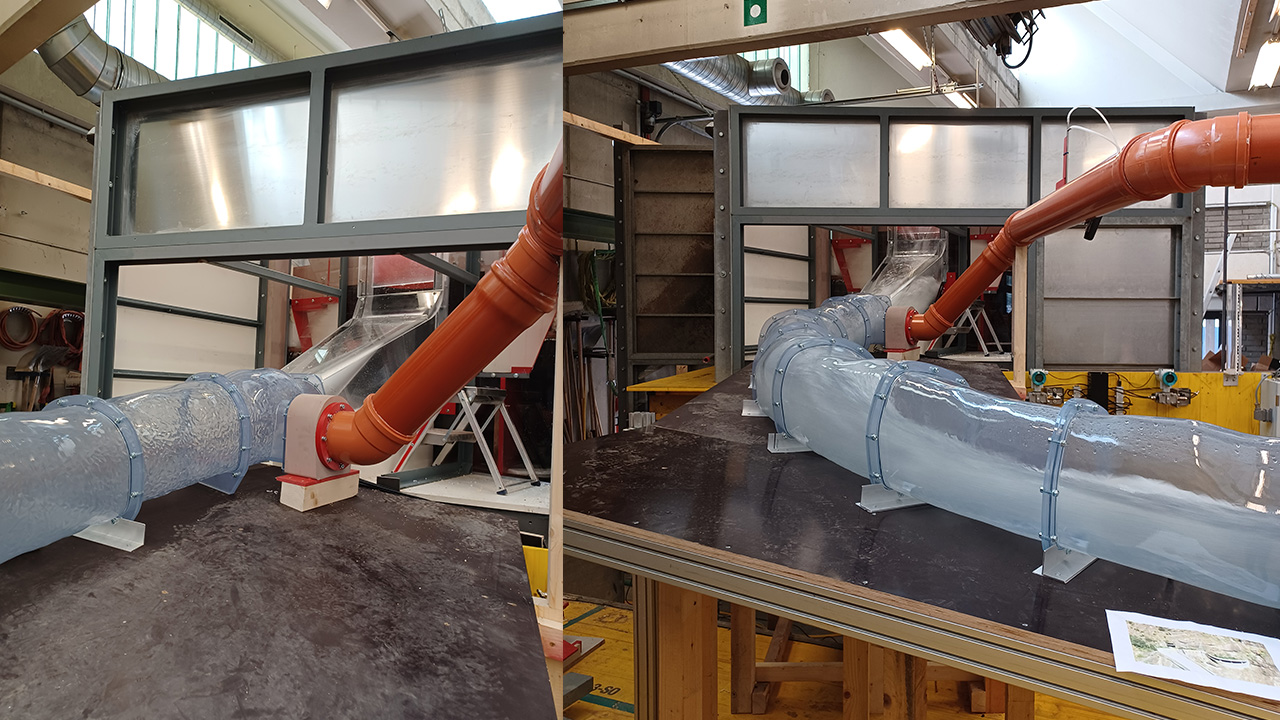

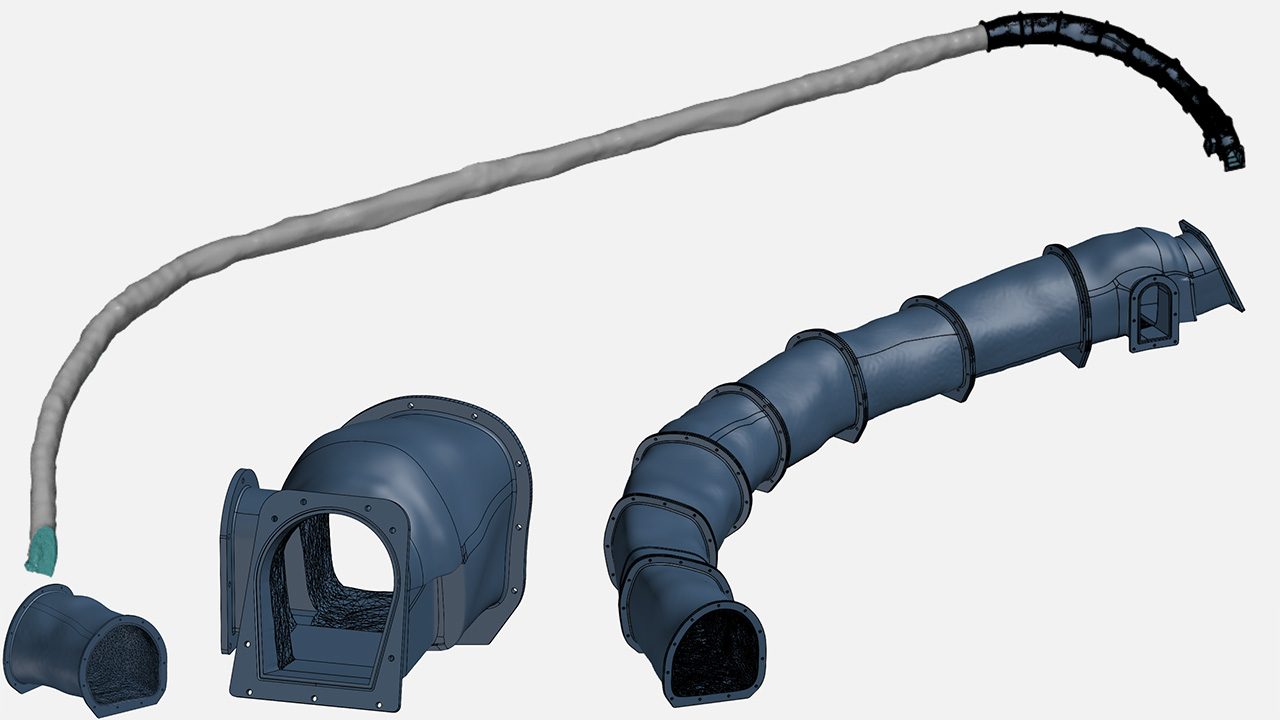

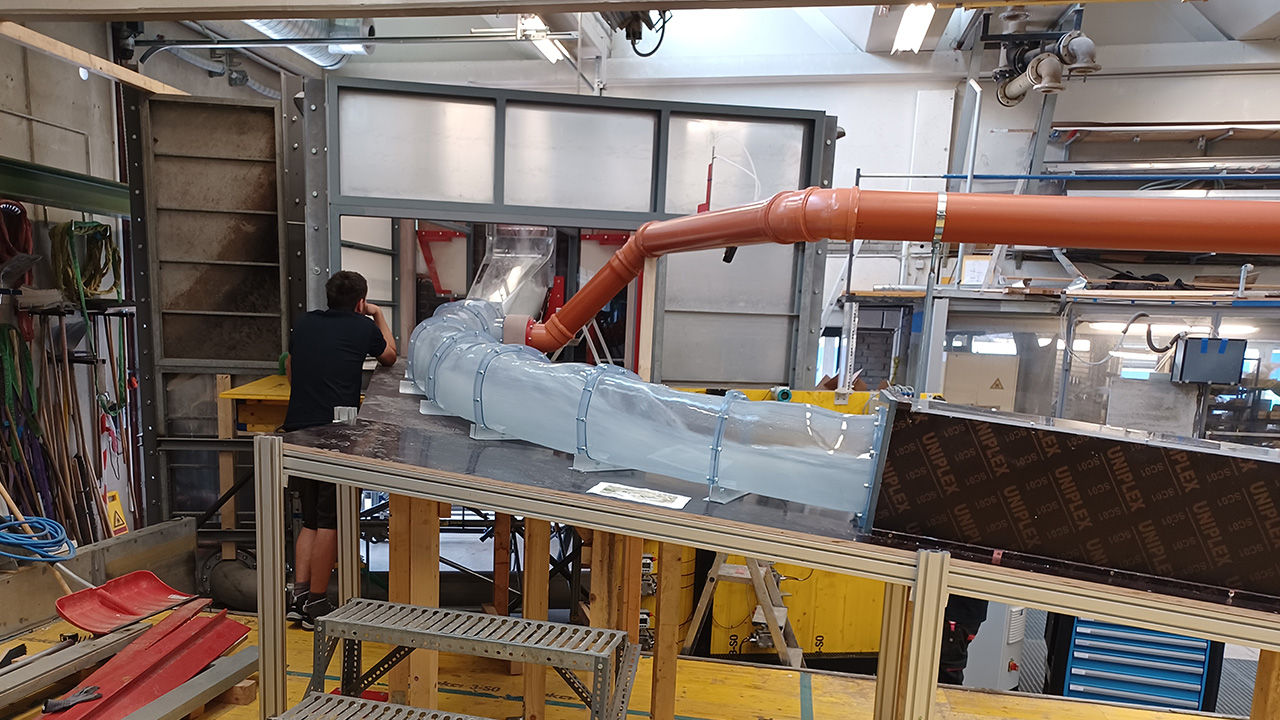

Based on the original data of the tunnel and rock structure, the tunnel was reconstructed true to the original in plastic using the 3D printing process. In reality, the original length of the tunnel is approx. 300 meters. A copy on a scale of approx. 1:15 was used for the model test. In the laboratory at the University of Innsbruck, the rock tunnel was simulated with a plastic tunnel approx. 20 meters long.

Relief tunnel elements manufactured and milled using 3D printing

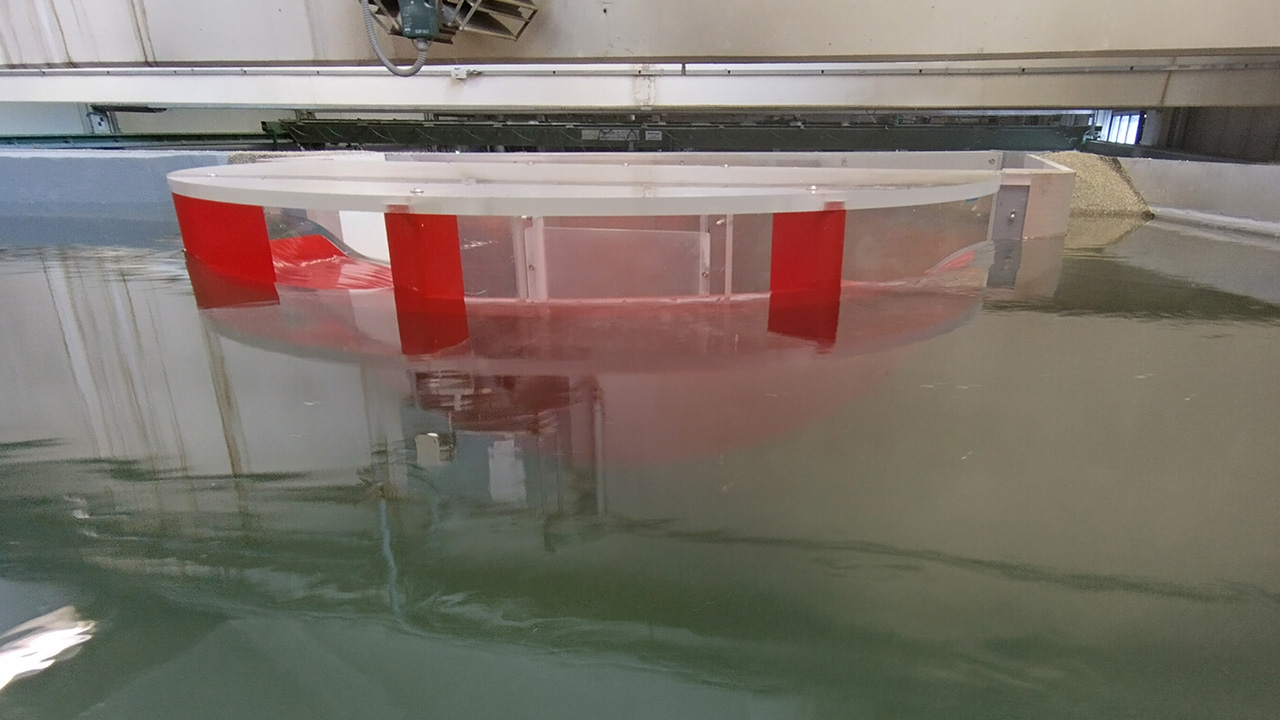

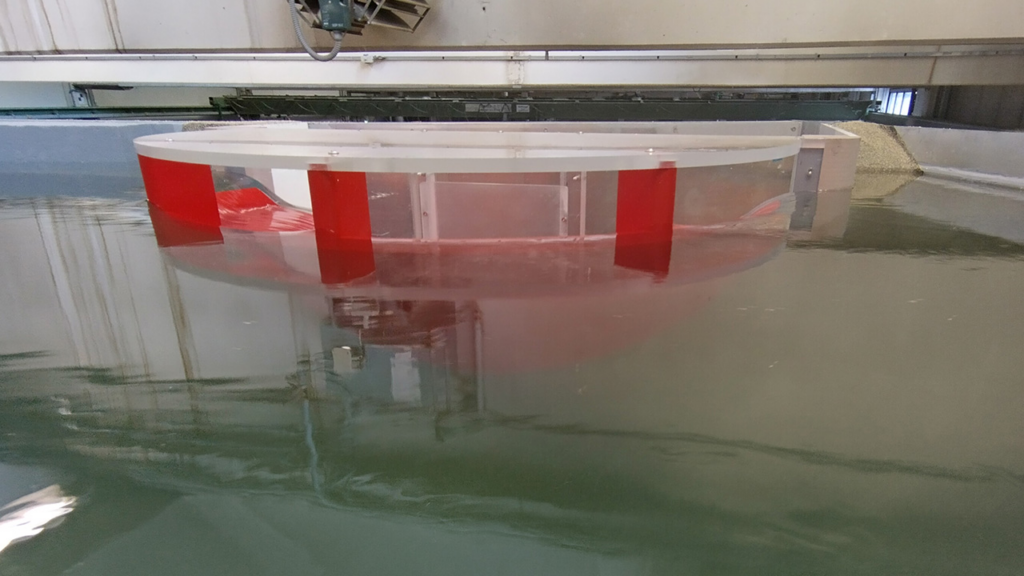

Is the existing overflow including ventilation sufficient for the planned capacity expansion? Does it need to be extended? Can the overflow absorb the additional water masses? The model test answers crucial questions.

To this end, the first crucial 60 meters of the spillway tunnel were commissioned from WESTCAM in a 1:15 scale 3D print. The result: a tunnel around 4 m long from the 3D printer. Positions and brackets for a large number of sensors and measuring devices were taken into account directly in the 3D print and manufactured at the same time. This was followed by further gallery elements, which were milled from Plexiglas and assembled piece by piece.

3D printing technology faithfully simulates the roughness of the tunnel wall

An important insight: the rougher the surface of the tunnel wall, the more friction is generated. This slows down the flow of water, which in turn reduces performance.

Increasing abrasion is also feared to wash out the tunnel. In order to make well-founded statements, reality must be realized as realistically as possible in the model. For better control, the tunnel was made transparent.

Green light for green energy from WESTCAM

The expansion of alternative energy sources poses new challenges for the energy industry, science and technology. Green energy does not just start with generation, but, as this project demonstrates, as early as the planning stage. Thanks to digital technologies, important decisions can be made in the test laboratory before construction begins, without major interference with nature. This protects the environment and the budget. Everyone is pulling in the same direction in the expansion of the Glockner-Kaprun power plant group.

The result: the pilot project was successfully implemented together. The data and analyses of the pilot project are already being scientifically evaluated and professionally assessed.

The direction is clear: we can only achieve the energy transition together.

Mechatronics & Robotics

Mechatronics & Robotics