“Easier manufacturing” – with the hyperMILLcomplete CAM solution

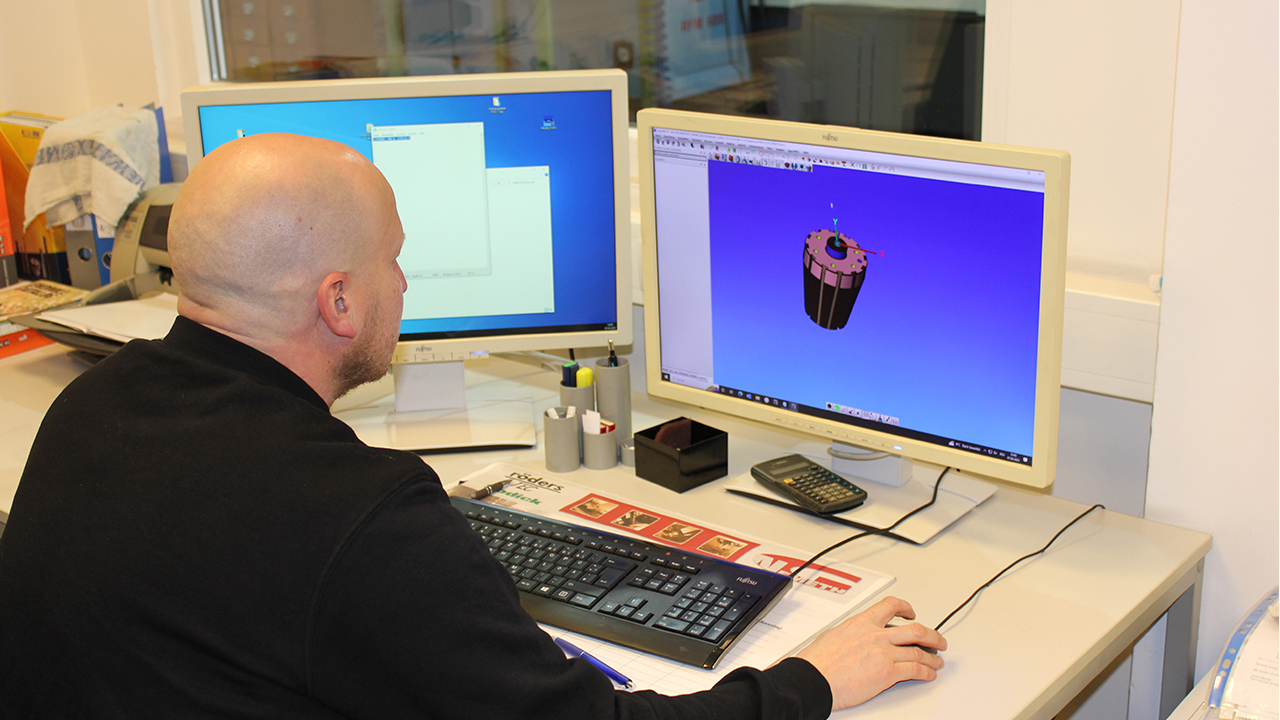

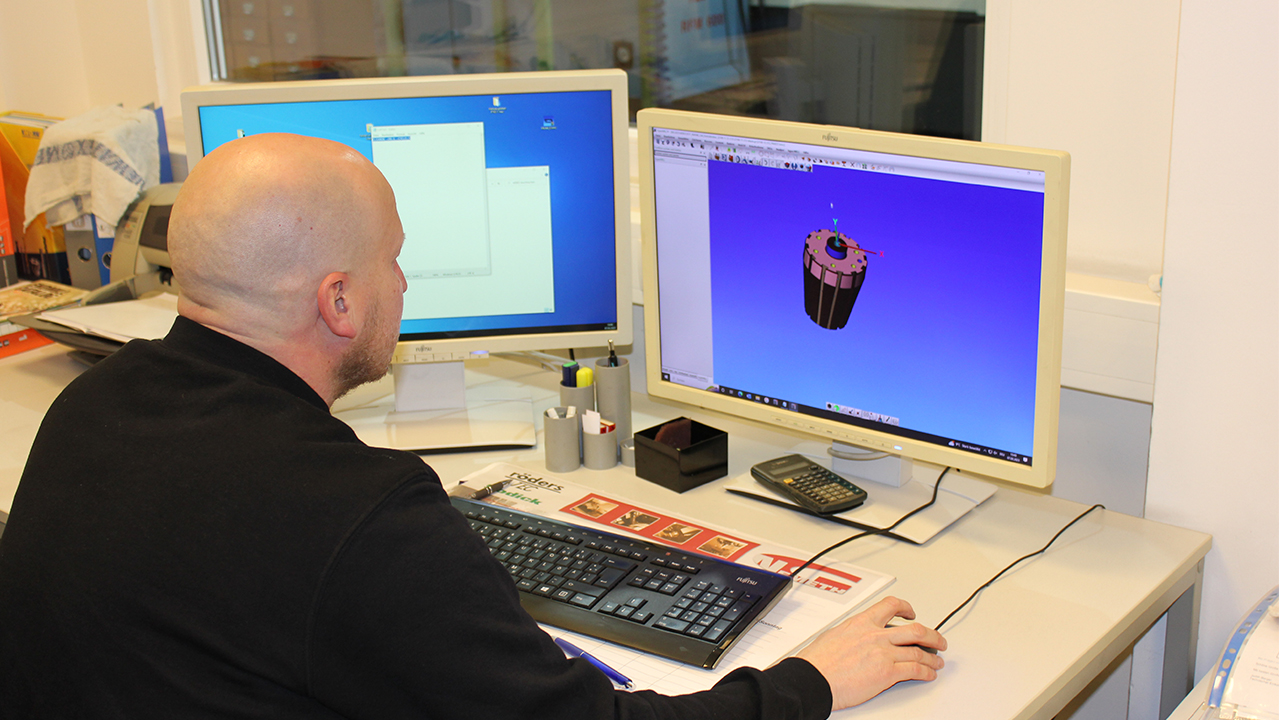

A strong duo in Vorarlberg: The expert in injection mold construction & its software service partner. Werkzeugbau LOACKER & WESTCAM have been working together successfully for over 20 years. The basis of their success: hyperMILL – the end-to-end CAM solution for tool & mold making.

High performance with high-end service

For over 45 years, Werkzeugbau Loacker, based in Weiler/Vorarlberg, has stood for the highest quality in injection mold construction. Thanks to its many years of industry expertise, the company went one step further and also made a name for itself in toolmaking. Forming tools and punching tools are also manufactured in Weiler. The company is also a strong performer when it comes to contract manufacturing and repairs.

For over 20 years now, the flagship company has been a partner of WESTCAM, which has been offering exactly what Managing Director Bernd Loacker swears by for his own customers at the Götzis site for 28 years: support and regional care. No ifs and buts. Spontaneous, uncomplicated and solution-oriented.

The central CAD/CAM software for all manufacturing process steps

Other quality suppliers have already discovered the advantages of precision manufacturing. From the aerospace and medical technology sectors to the automotive industry, these are being used to increase quality and efficiency. With the right CAM software, it is possible to exploit the full potential of state-of-the-art CNC machine tools. In the case of Loacker, they rely on hyperMILL. And they have been delighted with it – for over two decades! Loacker covers almost all manufacturing technologies from 2.5D, 3D, 5X, HSC/HPC/HFC milling, grinding, wire and die-sinking EDM. hyperMILL is the central complete solution for all process steps along the entire value chain.

With WESTCAM, we have a strong partner who supports us in the challenge of production digitization. We appreciate the regional support. If we have any questions, someone will come to our premises or we can simply meet at the branch in Götzis. We feel we are in good hands at WESTCAM and appreciate the constructive discussions that help us move forward together.

In recent years, the Tyrolean company has grown to around 45 employees and eight permanent designers work with the programs. “We realized that it was time to switch to Vault Professional. Our requirements have outgrown the capabilities of Vault Basic and we are being held back at one point or another by the lack of options, which we now want to change,” says Egger.

Tool & mold making is at a very high technological level. In order to meet the high quality requirements and competitive pressure, a complete high-end CAM solution is required for a wide range of manufacturing technologies.

Where is the journey going? Ready for MES?

With Hummingbird-MES, hyperMILL‘s sister product, production can seamlessly dock onto existing hyperMILL datathat has been built up over decades. MES stands for Manufacturing Execution Systemand enables the most efficient production control possible (> Learn more). WESTCAM will also be at Loacker Werkzeugbau’s side as a regional contact for this future topic.

As a team of 7, we are very agile in our project work. For me as an entrepreneur and businessman, a dashboard for digital production planning and control is becoming increasingly important. Especially in tool and mold making, we are talking about batch sizes of 1 piece. In order to maintain our agility, transparency and agile control are also very important for us. A clever MES can certainly help us with this – we are currently looking into it.

We advise you personally!

Gladly there for you