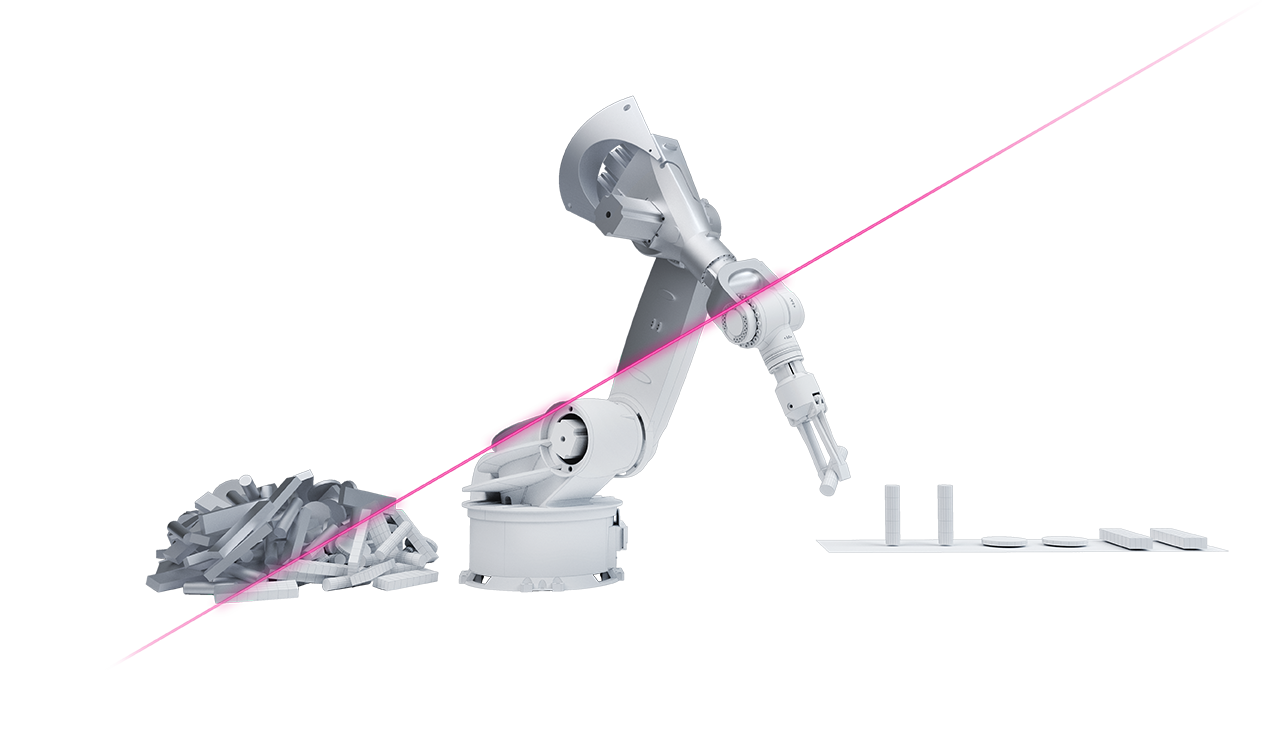

Pick & place positioning system

With “Pick & Place” we realize the so-called “handle in the box” for you.

The WESTCAM“Pick & Place” positioning system is used for fully automatic manipulation. At its heart is the software developed and patented by WESTCAM. This makes it possible to pick and place complex-shaped components.

This might also interest you:

- “Reach into the box” through pick & place applications

- Fully automatic manipulation

- No position or directional orientation necessary

- Specially developed for complex shaped free-form parts

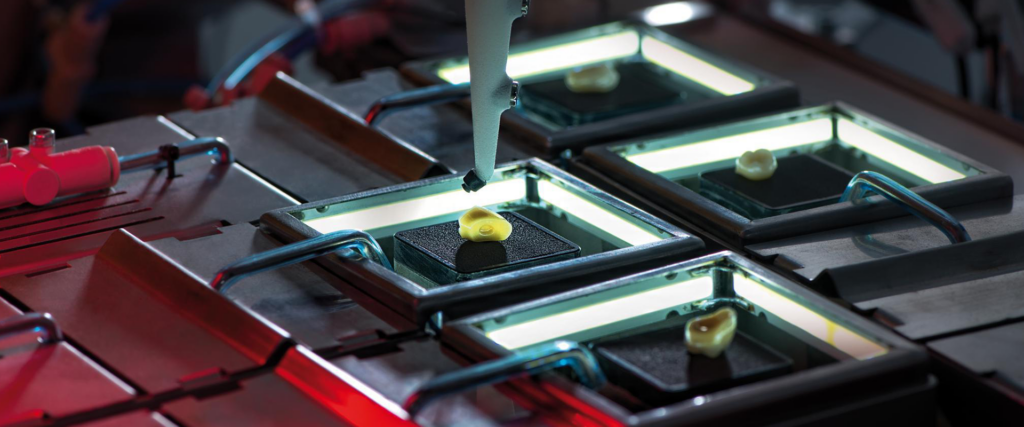

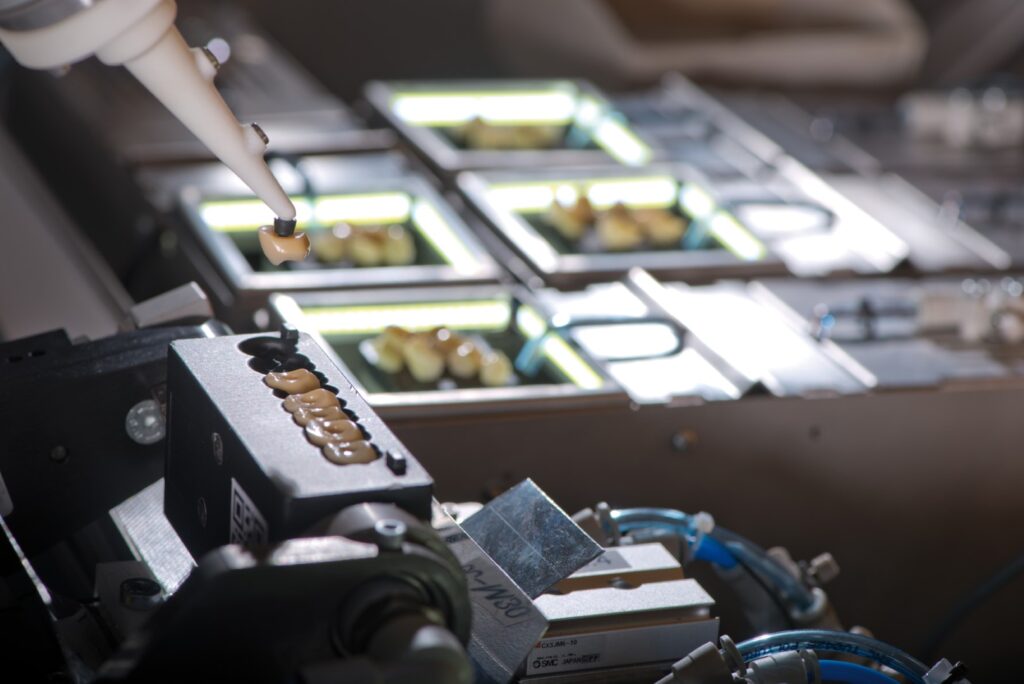

Practical example: Pick & place system for the dental industry. Here, denture teeth are automatically placed on wax strips.

REFERENCE PROJECT

PLUG-IN SYSTEM “TEETH”

Teeth only consist of free-form surfaces and are therefore highly complex“components”. The aim of this system is to press the respective tooth onto the wax strips in the correct position . The tooth wax strips produced in this way are then sold to dental technicians as the final product.

Compared to manual positioning, the system ensures a constant speed and consistently high quality.

Further advantages:

– Low maintenance effort

– Flexible use of the system

– High repeat accuracy

– Precise results

Imaging procedures

Imaging processes are used to determine the current position of the components and control the system precisely. The system supplies production data in real time and can be integrated into your production planning system.

Correct positioning – without preparatory work

The positioning system is part of the fully automated system. No effort is required for prior direction and position orientation. The handling of parts/components is accelerated and simplified.

VARIANTS TO CHOOSE FROM:

The WESTCAM “Pick & Place” positioning system can be operated as a stand-alone system or with a sorting system with an additional storage unit.

This might also interest you:

Frequently asked questions (FAQs)

Sind Pick & Place-Anwendungen bei komplex geformten Teilen/Bauteilen realisierbar?

For our pick & place processes, it doesn’t matter whether your parts have a complex shape or several “stable layers”. With our systems, we offer part recognition and pick & place systems for complex-shaped and freely positioned free-form parts.

„Pick & Place“ – was ist das eigentlich?

Picking up, positioning and placing “parts” – that’s “pick & place” in a nutshell. Our pick & place processes can be used for all tasks in which a part or object is picked up and placed in a different location. A pick & place robot reaches into a “box”, figuratively speaking, picks up a part and places it in the desired location fully automatically. No position or directional orientation is necessary. Our patented software performs this task fully automatically.

Was sind die Vorteile von Pick & Place?

Thanks to automation, pick & place tasks are carried out more precisely, faster and at a consistent speed. The repeat accuracy is impressive. Modern software makes operating the systems simple and customizable. Our patented software enables fully automatic manipulation and no position or directional orientation is necessary. Learning errors are minimized by an automatic process.

Große Teilevarianz? Lose Position der Teile auf ebener Fläche? Ist hier Pick & Place-Automatisierung sinnvoll?

Yes, if there is a very high component variety of complex/organic/free-formed parts in your production, “manual teaching” is often not efficient. We have the right pick & place automation solution for you, with which you can automatically teach-in parts, then sort them and move them with pick & place. The WESTCAMGripplanning© software supports these processes.