hyperMILL 5-axis Milling

hyperMILL 5-axis milling: Maximum flexibility and precision – simply programmed

Discover the outstanding versatility and accuracy of hyperMILL 5-axis Milling. Our advanced CAM software is specifically designed to meet the most demanding requirements of modern 5-axis machining.

With hyperMILL, anyone can machine even the most complex geometries with maximum efficiency and precision in the shortest possible time.

- Perfect results thanks to 5-axis simultaneous machining

- Strategies for every requirement

- Ideal for complex geometries

Perfect results thanks to 5-axis simultaneous machining

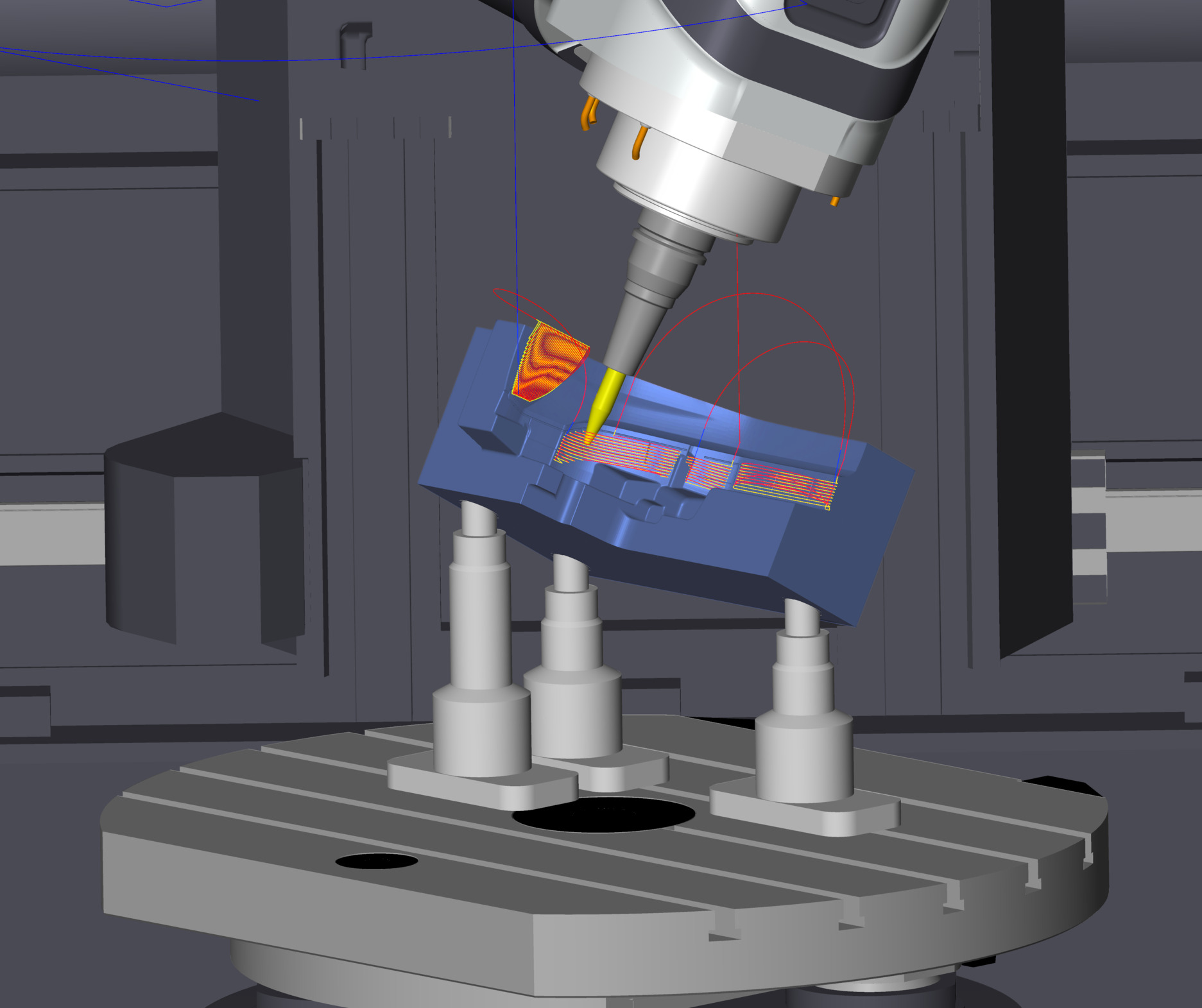

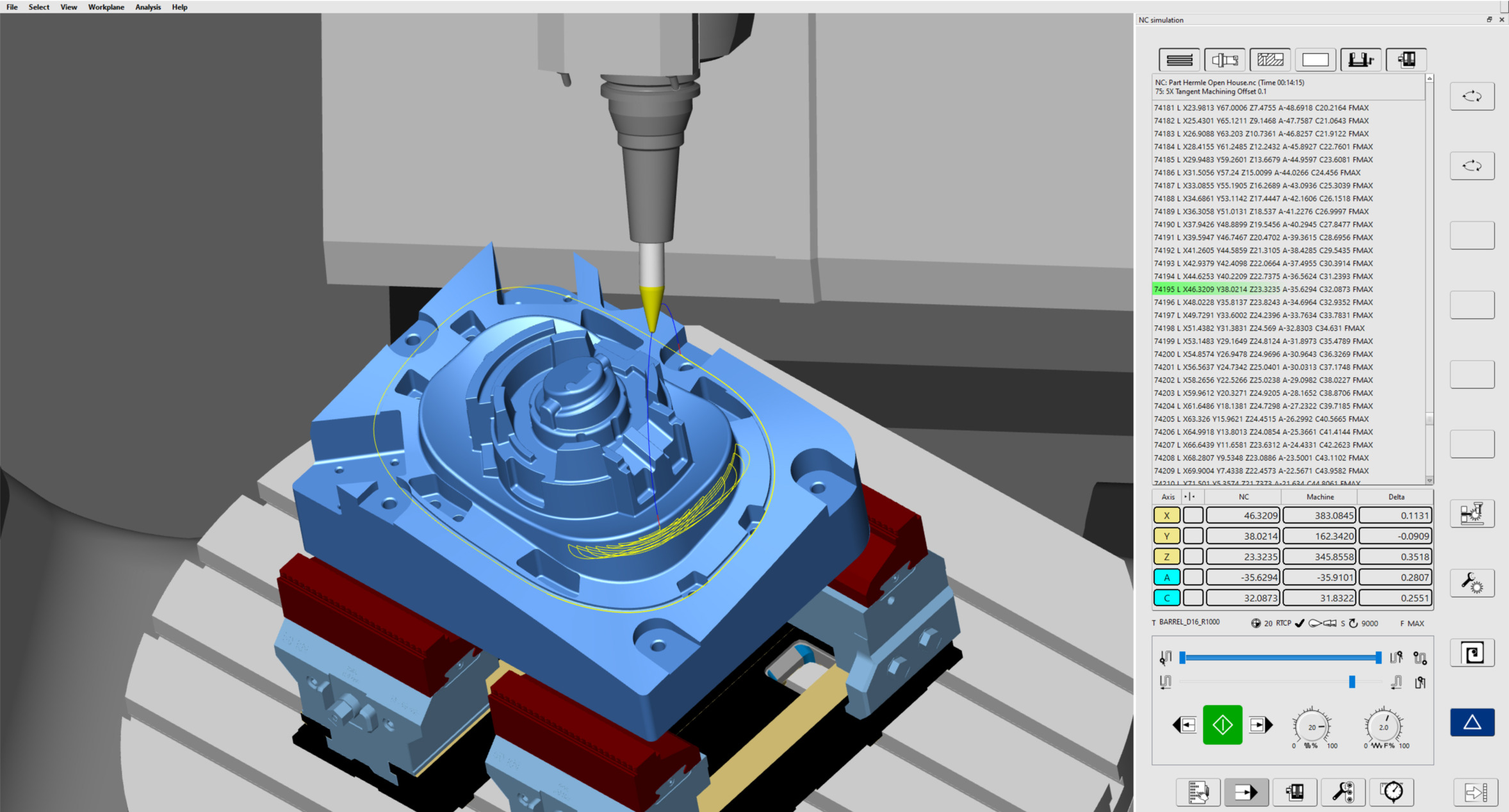

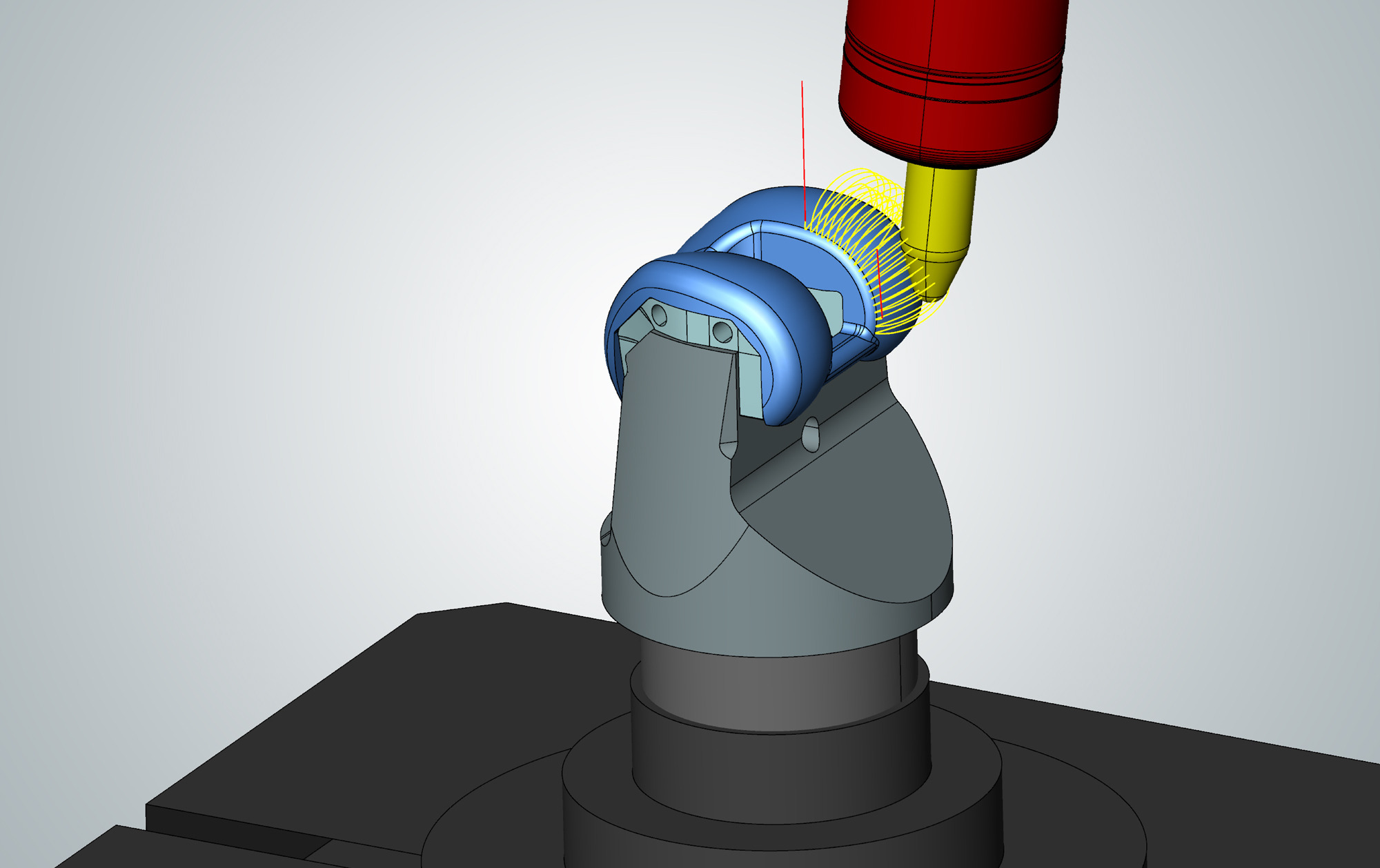

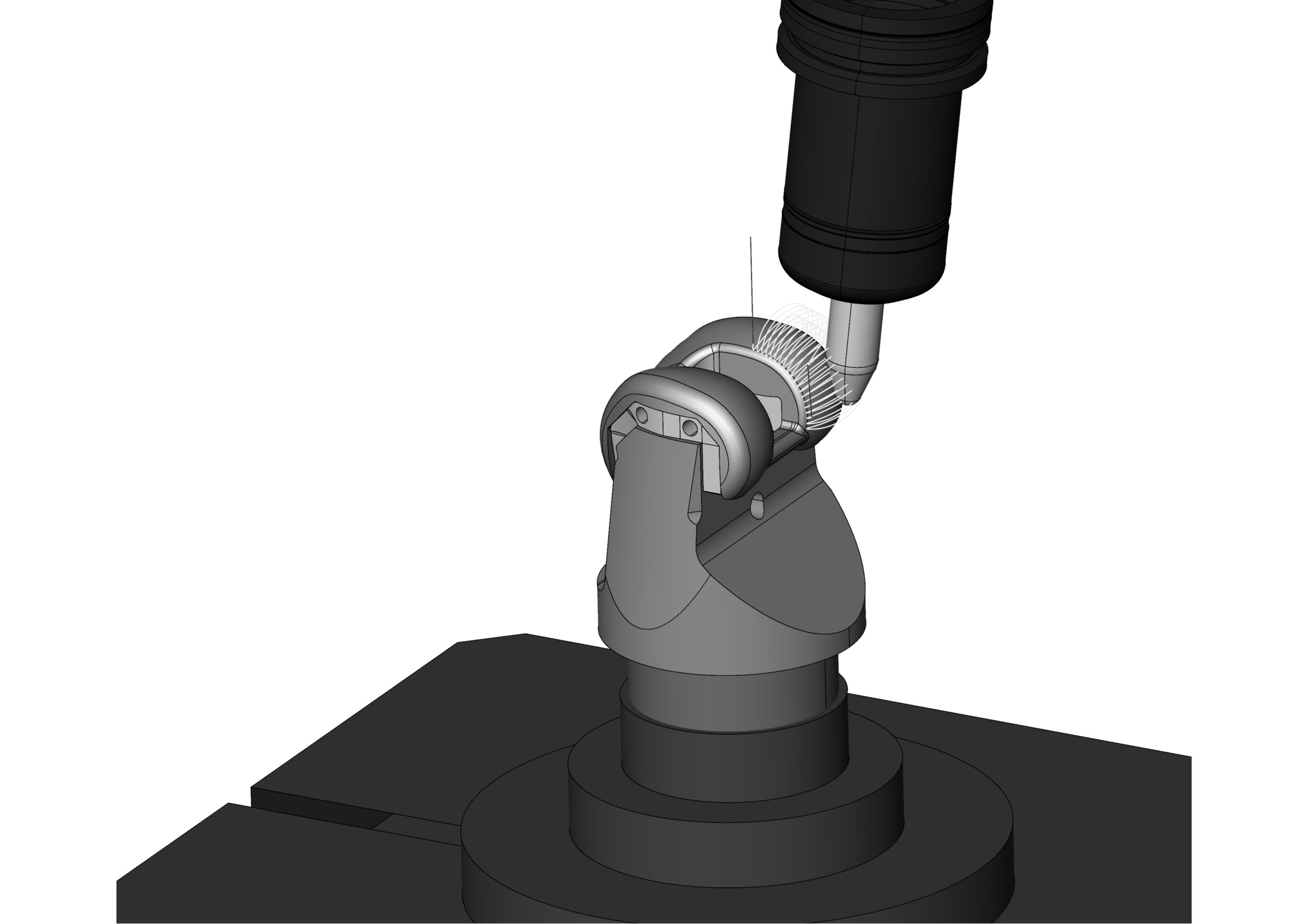

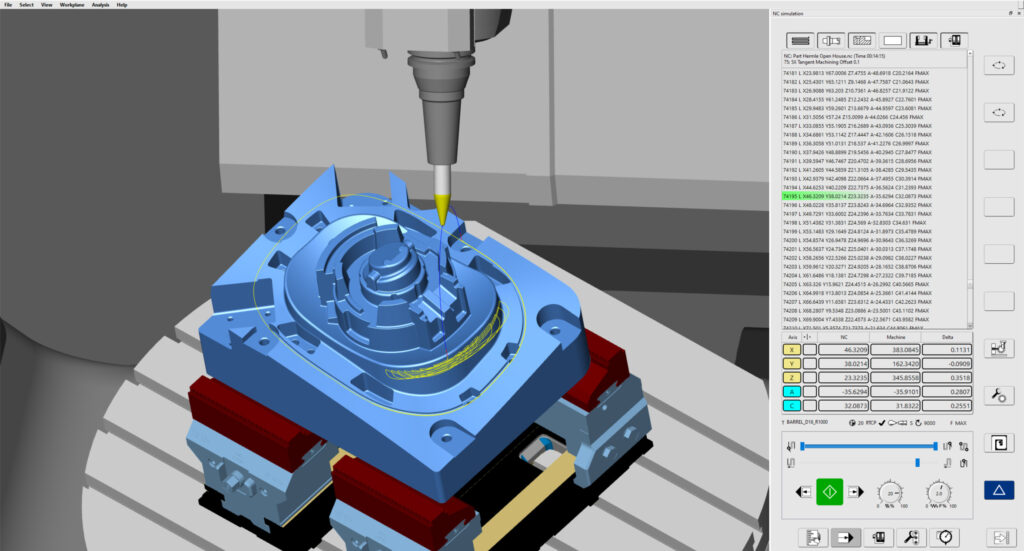

hyperMILL 5-axis machining gives you complete control over all five axes, allowing you to machine workpieces from multiple sides in a single set-up. This reduces set-up times and increases the accuracy of the finished parts.

hyperMILL supports the CAM user by calculating the ideal positions and simultaneous movements. This means that anyone can get started with 5-axis programming very easily and quickly – even without years of experience!

Strategies for every requirement

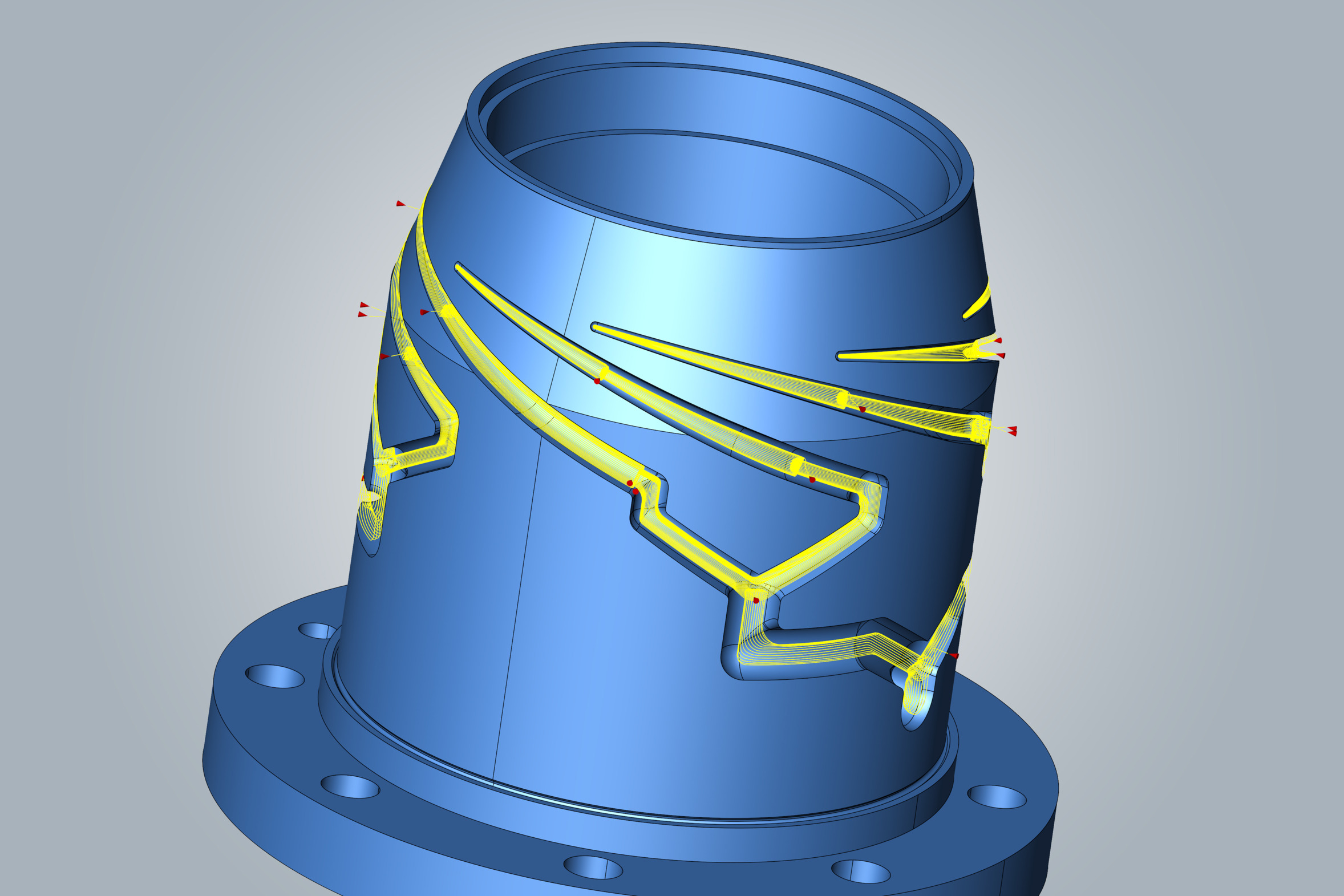

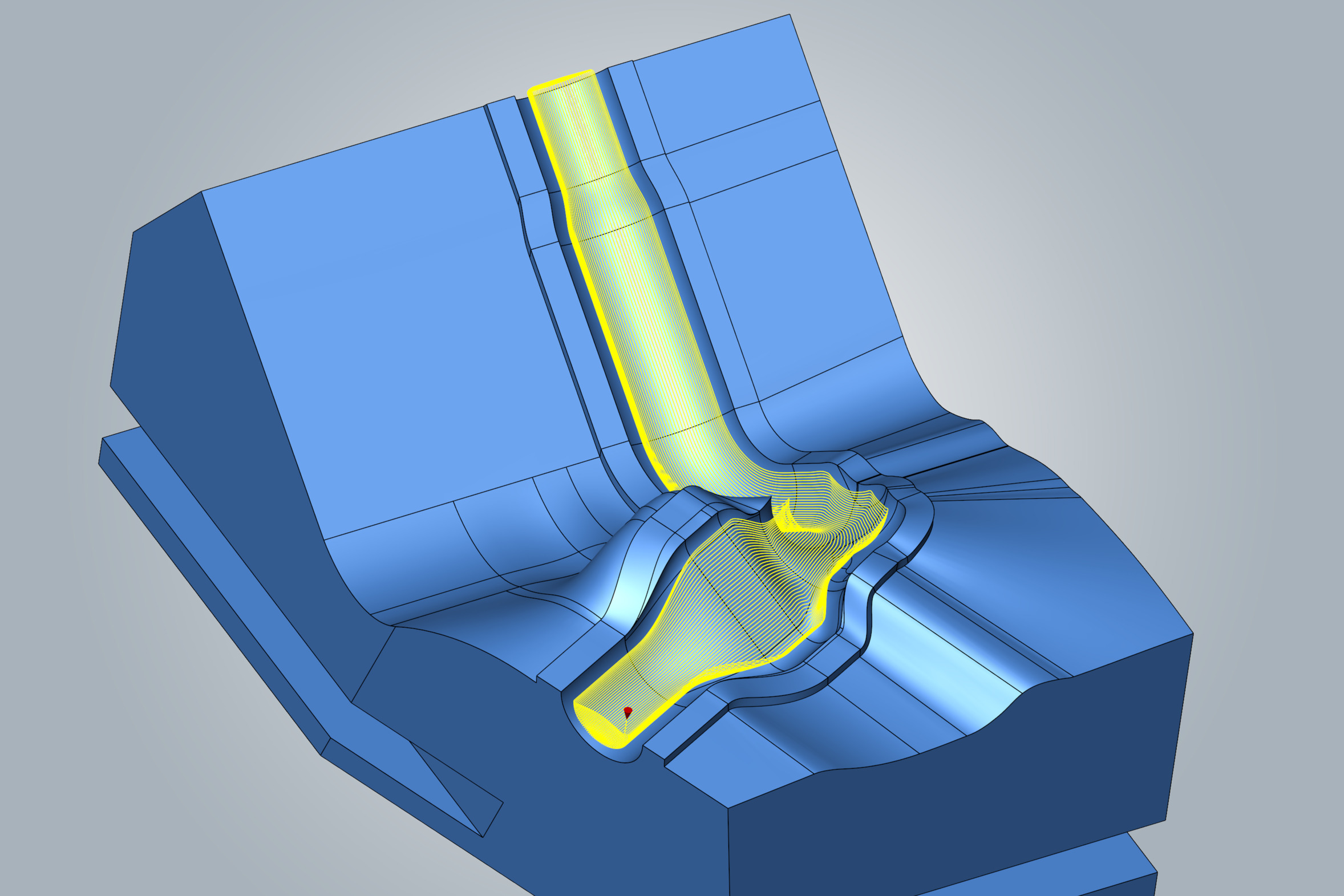

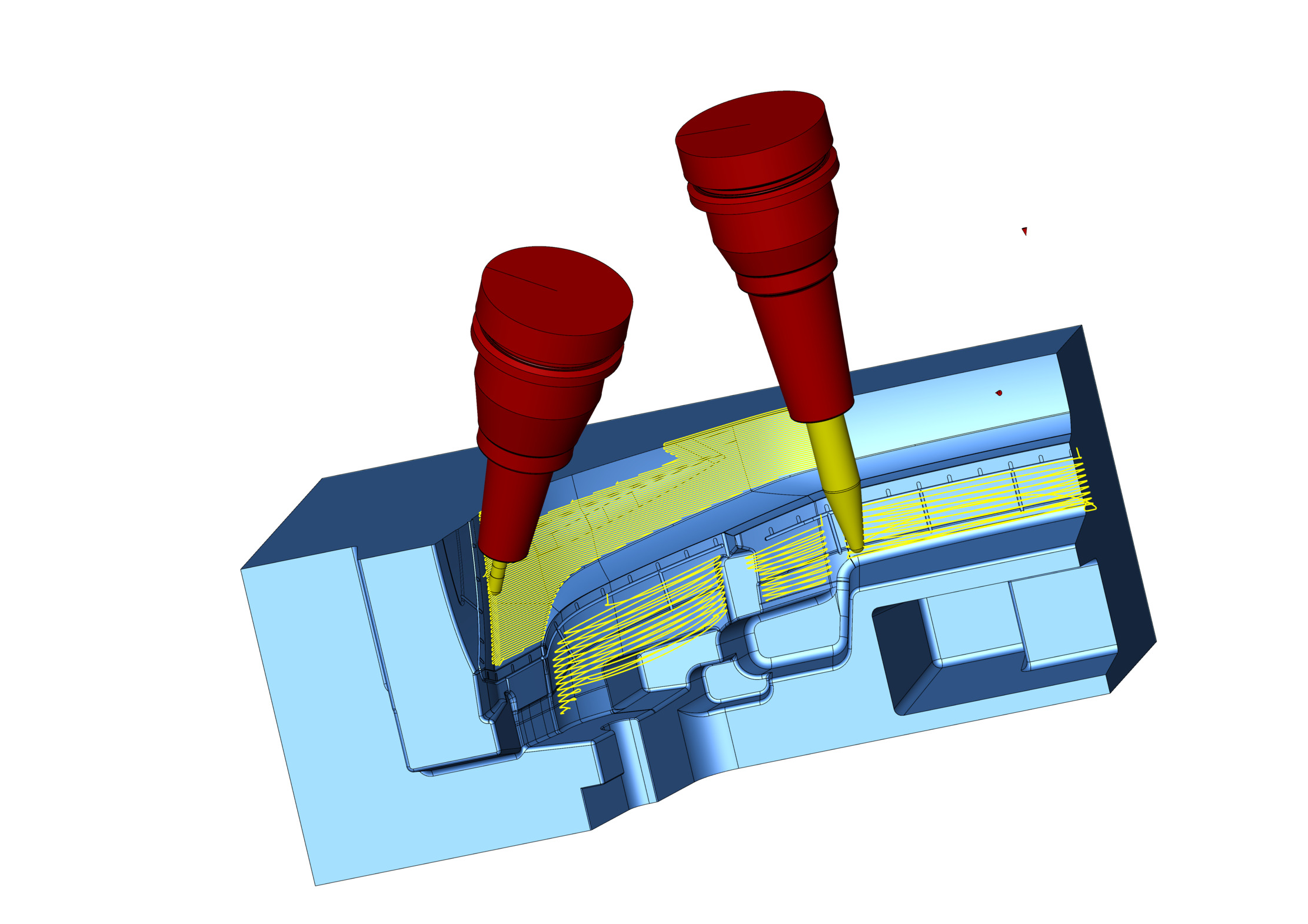

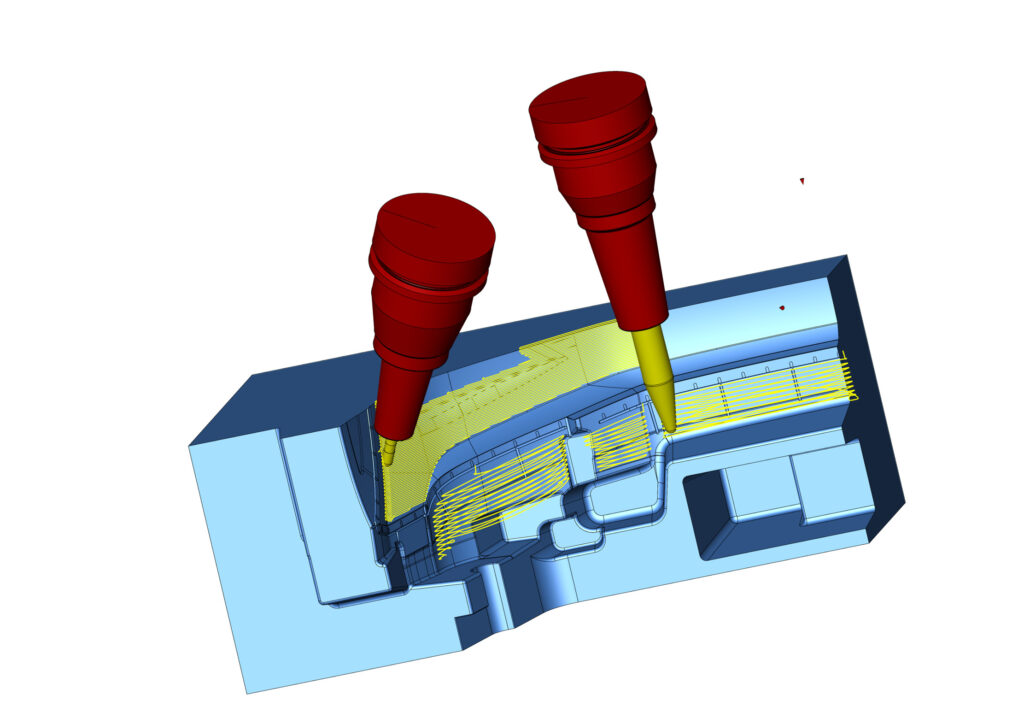

hyperMILL offers a wide range of different machining strategies. A distinction is essentially made between surface and cavity cycles. The cycles are identical to the 3D cycles in terms of operation, but with the addition of automatic positioning strategies.

Thanks to the many targeted strategies, there is a suitable cycle for every requirement!

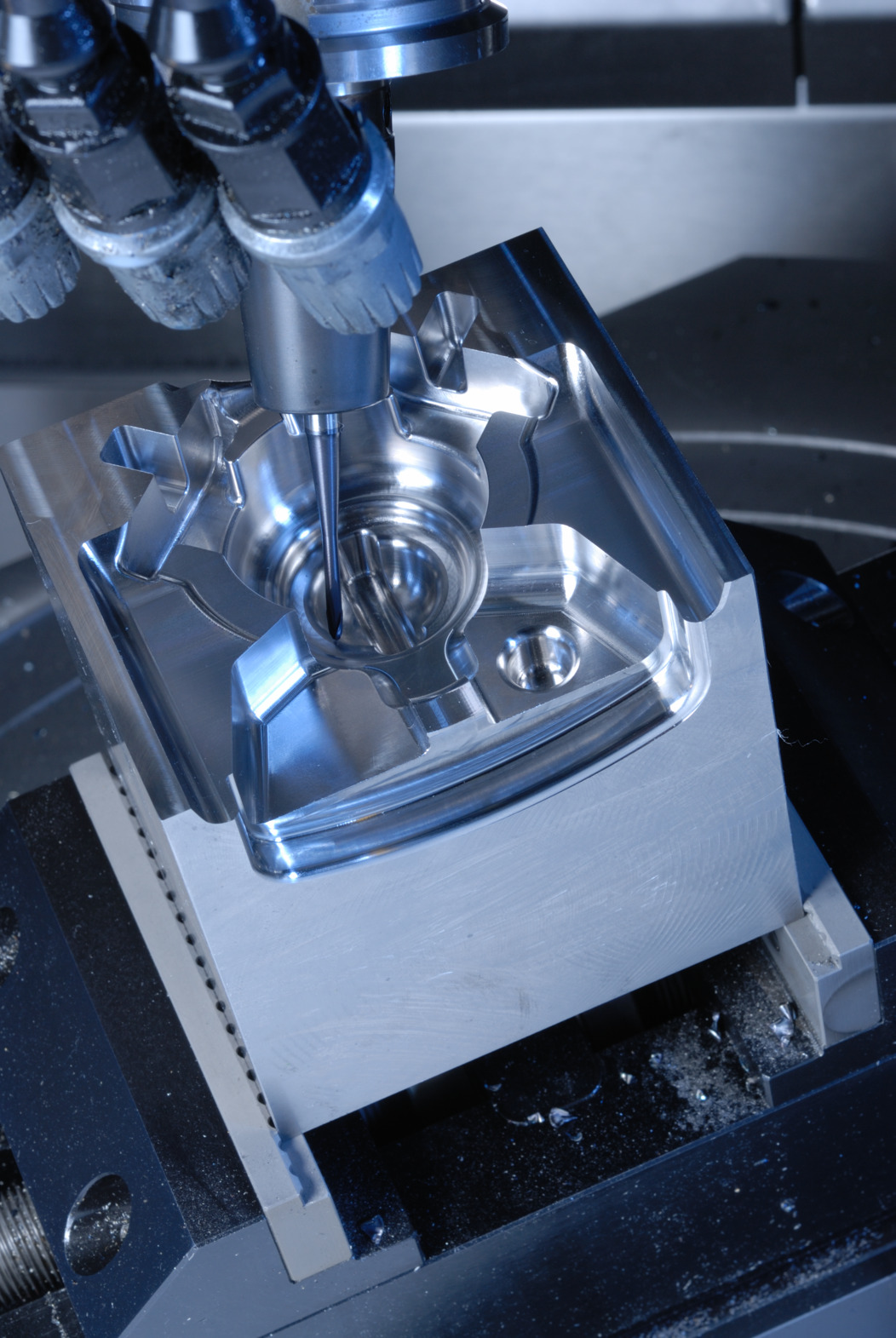

Ideal for complex geometries

hyperMILL 5-axis Milling is the ideal solution for industries that require the highest precision and quality, such as the automotive industry, aerospace and tool and mold making.

The flexible handling of cycles, simple operation and integrated collision control and avoidance allow you to optimize your programming and thus reduce throughput times.

Various strategies are available to you with hyperMILL

Simple programming, as the 5-axis machining is based on the set milling process

Process reliability thanks to proven fully automatic collision control and avoidance

Several setting strategies are available: 3+2, automatic indexing and 5-axis simultaneous machining

Wide range of machining strategies for surface, cavity and special machining

All 5-axis strategies are available in the hyperMILL interface

Frequently asked questions (FAQs)

Was ist 5-Achs Fräsen?

5-axis milling refers to the milling of components on machines with 5 axes. Up to 5 axes are moved simultaneously.

With hyperMILL 5-axis Milling, you can rely on a future-oriented solution for your production requirements. Contact us today to arrange a presentation or a loan and experience the benefits of our advanced CAM software in your production.