Metal – Laser | Colibrium

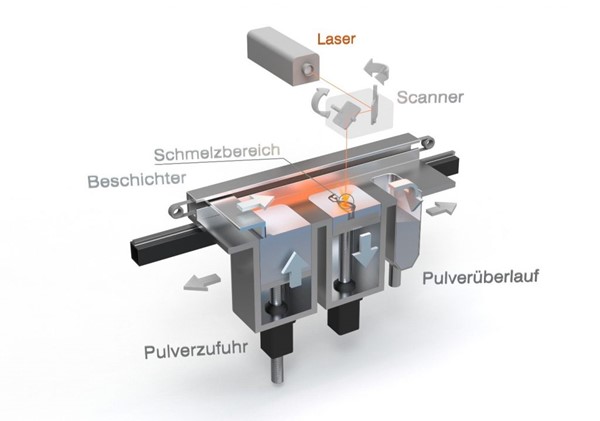

In the powder bed-based metal laser melting process, commercially available series materials are melted locally in powder form using a high-energy fiber laser. For example, powder materials made of stainless steel and hot-working steels, aluminum and titanium alloys or precious metals are used.

During the laser process, the single-component metal powder is completely melted. After solidification, the material solidifies. This gives the finished additively manufactured component almost ideal material properties.

The component contour is created by deflecting the laser beam using a mirror deflection unit (scanner). The component is built up layer by layer by lowering the base of the installation space, reapplying powder and re-melting.

With its patented LaserCUSING® process, Colibrium is one of the world’s leading suppliers of machine and system technology for 3D printing of metal components. The special feature of Colibrium’s 3D printers is the stochastic control of the slice segments (also known as “islands”), which are successively processed. This specially developed process ensures a significant reduction in stresses during the production of very large components.

The process offers the following advantages:

- Freedom of geometry: Complex or conventionally unmanufacturable component geometries can be produced without tools using the laser melting process. There are no limits to the production of components with internal hollow or grid structures with this technology!

- Green Technology: The LaserCUSING® process is a virtually waste-free production process. Metal powder that has not been melted can be completely reused for further processes without any loss of material. Thanks to the high efficiency of the laser systems used at Colibrium, the energy input is efficiently converted into work output.

- Near Net Shape: The production of components with near net shape or ready-to-install geometry shortens the production time and saves costs

The LaserCUSING® layering process can be used to produce tool inserts with conformal cooling as well as direct components for the jewelry, medical, dental, automotive and aerospace industries. This applies to prototypes and series parts. In addition to the 3D printers themselves, you can also purchase high-quality metal powder from Colibrium from us.

Mechatronics & Robotics

Mechatronics & Robotics