EBM – Electron beam for 3D metal printing

Metal – Electron Beam | Colibrium

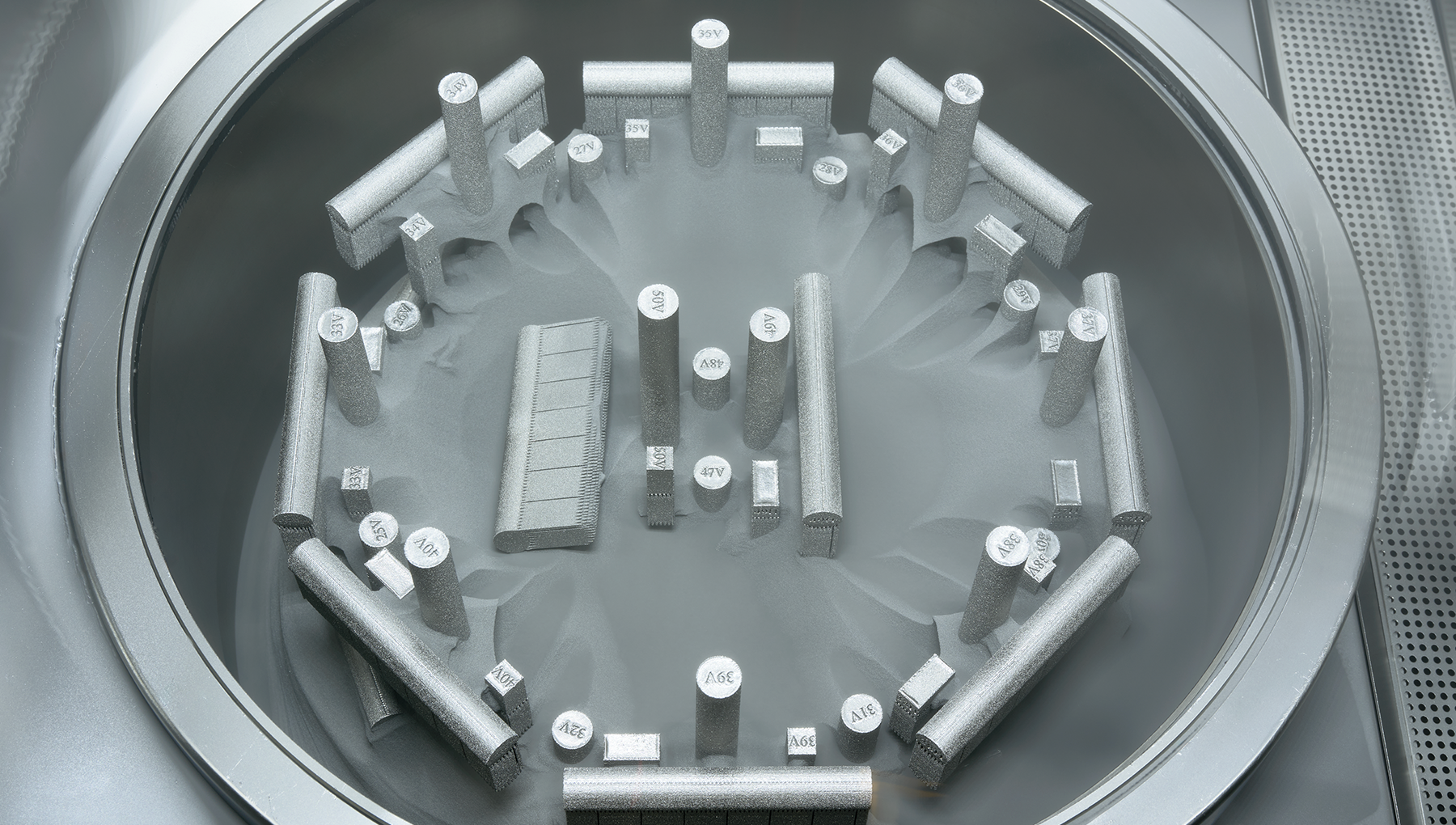

EBM (Electron Beam Melting): Electron beam melting

EBM is often used in the aerospace, medical technology and automotive industries to produce complex metal parts.

How electron beam melting works

- Preparation of the powder: The process begins with a fine metal powder that is evenly applied to a build platform. Typical materials are titanium, cobalt-chrome and nickel-based alloys.

- Electron beam: A powerful electron beam is generated in a vacuum. The beam is controlled by magnetic fields and moved precisely across the building platform.

- Selective melting: The electron beam selectively melts the metal powder in the areas that correspond to the design of the component. This happens layer by layer until the entire component is built up.

- Structure of the component: After a layer has melted and solidified, a new layer of powder is applied and the process is repeated. In this way, the component is created layer by layer.

- Cooling and post-processing: The finished part is cooled slowly after the printing process. Heat treatment as with laser melting is not necessary.