Integration for efficient production

Toolmaker LOACKER, the Vorarlberg expert in injection mold construction, has trusted WESTCAM for over 20 years. The sophisticated combination of hyperMILL & OPTICAM is a key component of the company’s success.

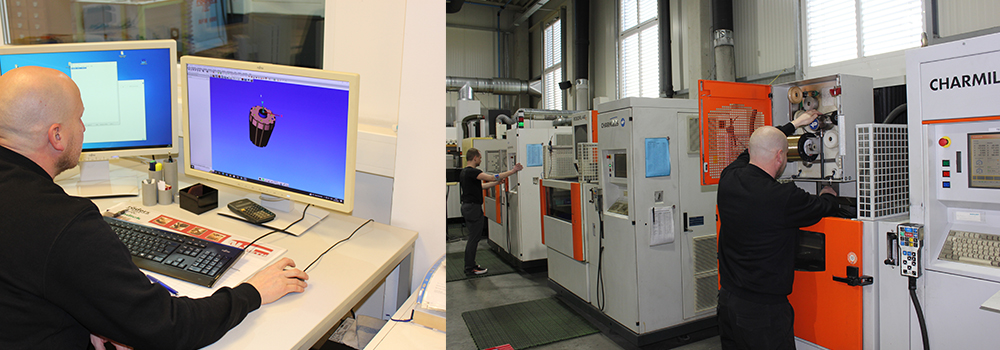

Complete CAM solution with WESTCAM service

The Vorarlberg flagship company Werkzeugbau Loacker has stood for the highest quality for almost half a century. Its core competencies are injection mold making and the production of forming and punching tools. Loacker has also made a name for itself as a contract manufacturer and reliable partner for repairs. No compromises are made when choosing CAM software solutions – WESTCAM has been trusted for over 20 years. The supportand regional assistance provided by the team in Götzis is particularly appreciated.

When it comes to CAM software, WESTCAM is virtually our carefree package. With the combination of OPTICAM & hyperMILL, we cover our entire production spectrum. Two market leaders from a single source gives us a good feeling and ensures correspondingly good results.

One user interface for all programming tasks with OPTICAM

Loacker covers almost all manufacturing technologies from 2.5D, 3D, 5X, HSC/HPC/HFC milling, grinding, wire and die-sinking EDM. With OPTICAM and hyperMILL the company has one user interface for all programming tasks.

With the combination of OPTICAM & hyperMILL, our customer LOACKER relies on the leading industry solutions. This complete CAM solution for different manufacturing processes demonstrates its strengths in everyday use. It enables high quality standards to be achieved efficiently in competitive tool and mold making.

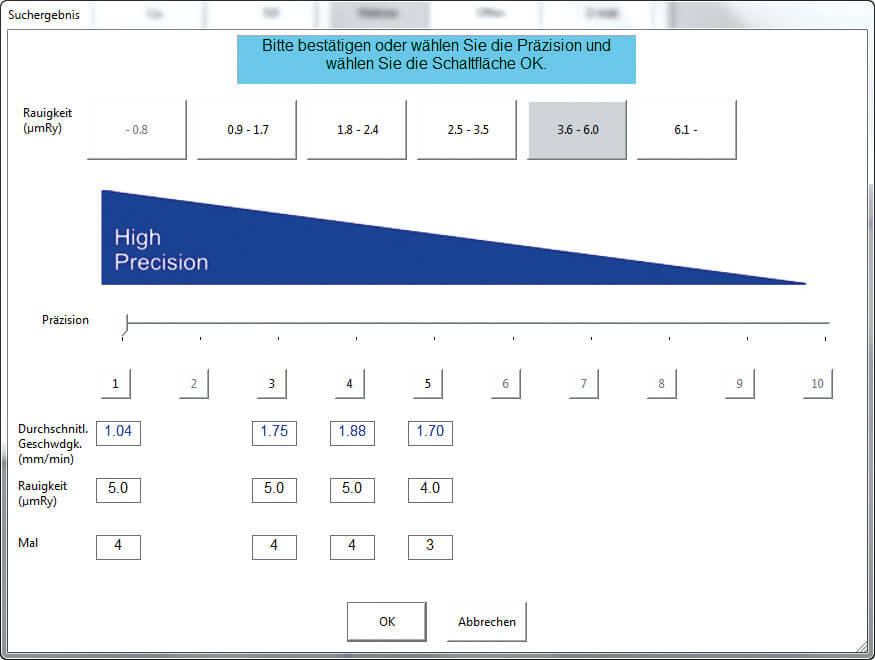

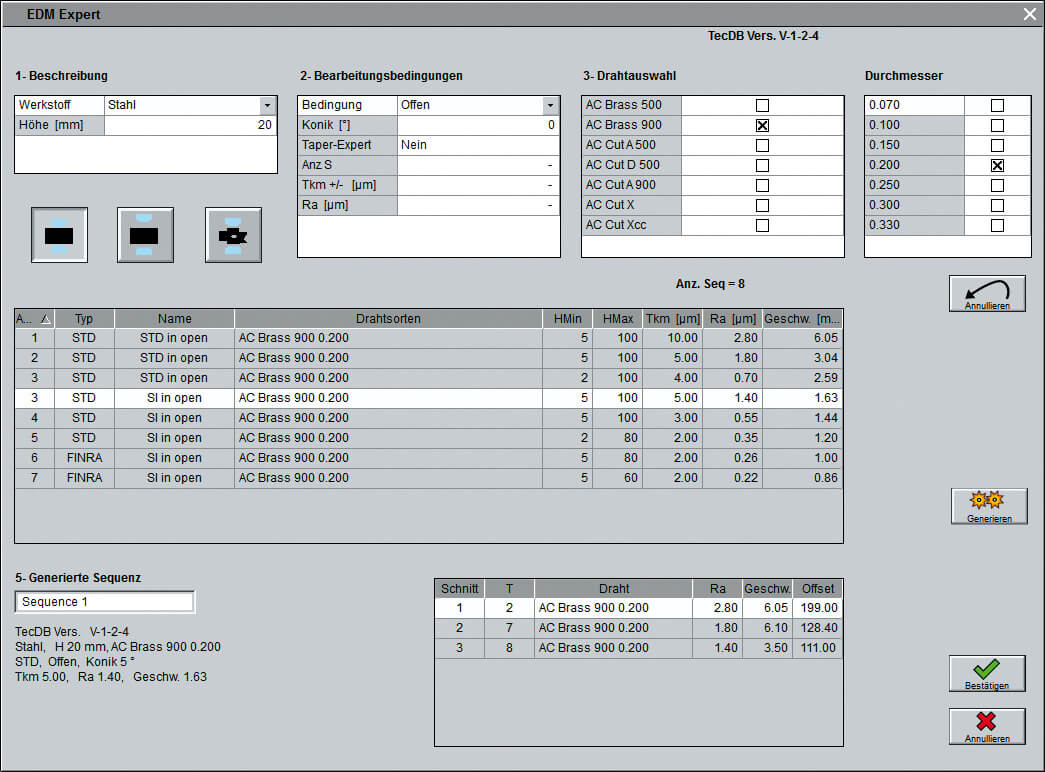

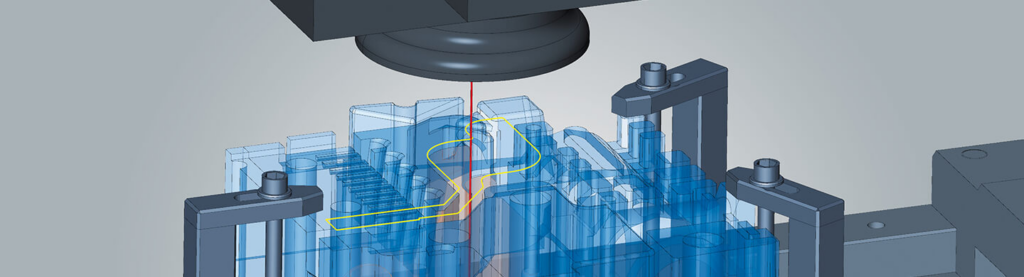

OPTICAM – Wire EDM optimally integrated

As a fully integrated solution for wire EDM in hyperMILL, SOLIDWORKS, SolidCut CAD, GibbsCAM and Siemens NX, OPTICAM reduces programming times to a minimum. More about the plug-in solution

As we have had hyperMILL from WESTCAM in-house for many years, the implementation of OPTICAM in hyperMILL was an obvious choice. From electrode design to CAM programming of the 5-axis milling machine or wire EDM machine, everything is done in one programming environment.

OPTICAM – Wire EDM optimally integrated

As a fully integrated solution for wire EDM in hyperMILL, SOLIDWORKS, SolidCut CAD, GibbsCAM and Siemens NX, OPTICAM reduces programming times to a minimum. More about the plug-in solution