PRS – Parts recognition system

Error-free recognition and allocation of individually produced parts/components.

We help you to reassign individually generated components, which are produced in a production batch, e.g. milled, 3D printed, laser sintered, to the correct orders.

The system consists of a PLS – Part Learning System for teaching the parts and the PRS – Part Recognition System for recognizing and assigning the parts to the production orders.

It compares your CAD data with the physical component within fractions of a second. The components are recognized and assigned to the right customer in the shortest possible time.

No more guesswork, just precise allocation.

Test the PRS parts recognition system:

Send us your parts and we will show you the performance in terms of correct identification and allocation.

- Confusion-free identification

- Process optimization through elimination of manual activities

- Increased throughput due to larger placement

- Error-free order allocation

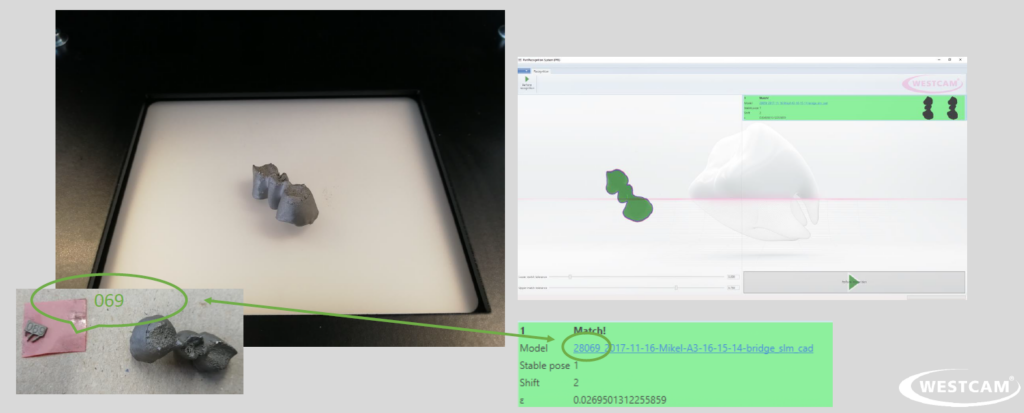

Reference example: Dental

The PRS part recognition system is already being used in the dental industry for products such as bridges and crowns.

Powerful automation

The assignment is fully automatic using optical image recording and image recognition software.

Your CAD/CAM process is thus sustainably supplemented by a powerful automation solution.

The advantages of the PRS system

Automating the identification of your products after production

Process optimization by simplifying manual tasks in the preparation, inspection and packaging of your components

Increased throughput thanks to increased utilization of upstream systems (e.g. sintering furnaces, 3D printers, processing stations, shipping)

Increased efficiency through time savings and reduced inspection costs – thanks to autonomous monitoring

Direct system connection to your ERP or PPS, correct customer delivery thanks to mix-up-free identification of components

Frequently asked questions (FAQs)

Wann brauche ich ein PRS Teileerkennungssystem?

Items and parts that are difficult to distinguish can easily be mixed up. Our PRS part recognition system prevents mix-ups. Speed and precision in the process remain constant. This increases your efficiency.

Ist das PRS Teileerkennungssystem auch in anderen Bereichen einsetzbar?

Yes, with our PRS parts recognition system, we help you to correctly recognize and assign individually manufactured products or components of “any type”.