ScanBox Series 7 & 8

Precise 3D-Metrology for large and heavy components in car body construction, press shops and try-out toolmaking.

With the ZEISS ScanBox Series 7, you can digitize and inspect large components such as the side panels of cars up to a length of 10 meters. Welded assemblies for transportation, machine and aircraft construction can also be measured. The surface measurement data enables the evaluation of hole patterns, bleed allowances and characterization lines.

With the ATOS ScanBox Series 8, you can digitize complete vehicles from the outside and inside at high speed. The modular 3D measuring machine is the complete solution for OEMs for analysis in master jigs and cubing, for inspecting finished vehicles and for quality assurance in the body shop. Use the powerful ZEISS INSPECT software for linear evaluation of gap and flush.

- 8-axis kinematics

- Modular layout

- Scanning in duplex mode

- Inspection of bodyshells

Series 7

8-axis kinematics

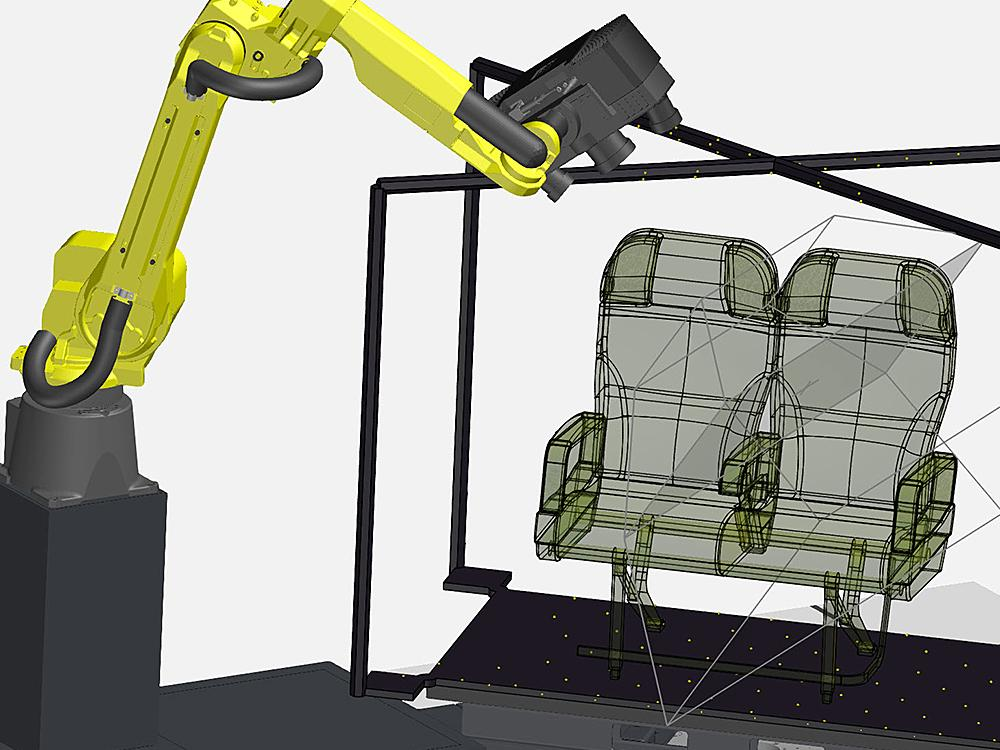

More flexible sensor positioning thanks to eight degrees of freedom. Thanks to the 8-axis kinematics – a combination of horizontal rail, vertical lift and articulated arm robot – the full-surface measurement of large and heavy components is possible without any problems.

Modular layout

You have the option of extending the ZEISS ScanBox 7160 with an additional rotary table work area as required to increase throughput even further.

Due to the same components, an upgrade to the ZEISS ScanBox Series 8 is also possible without any problems.

Series 8

Automated scanning in duplex mode

Two robots are used synchronously in one measuring cell. Thanks to the two 8-axis kinematics, full-surface measurement of particularly large assemblies is possible without any problems. The duplex mode ensures the synchronous, coordinated use of two robots in the measuring cell.

As the dual robot operation takes place in a common coordinate system, a common data set of measurements is generated. Depending on the requirements, the two ZEISS ScanBox Series 8 robots can also be used for independent measurements on two different components.

Accelerated

Inspection of bodyshells

A reference frame for the ZEISS ScanBox Series 8 makes production control during series production even more efficient. The flexible system is ready for use without any preparation time.

You can significantly increase your throughput. Check more than 1000 measurement features such as surface and edge points, holes and bolts. The measurement results can be easily exported to a statistics database.

General

Virual Measuring Room

The virtual measuring room (VMR) is the central control and planning tool for ZEISS ScanBox. Here, the real environment is depicted in a precise virtual simulation.

The VMR contains a robot with sensor, enables the programming of the robot paths and the creation and execution of the measurement plan. Thanks to the VMR, no special robot knowledge is required.

Analysis tool included

WESTCAM offers everything from a single source: scanning, testing and reporting for detailed target/actual comparisons as well as shape and position tolerances.

The easy-to-understand results enable you to implement the necessary corrections directly. Carry out comprehensive analyses, create detailed reports and integrate the measurement results seamlessly into your existing processes.

Frequently asked questions (FAQs)

What is special about the ZEISS ScanBox Series 8 with regard to the digitization of car bodies?

With the ZEISS ScanBox Series 8, it is possible to digitize complete vehicles both from the outside and the inside. Quality assurance in body construction, the inspection of finished vehicles and the analysis of master bucks and cubing are its main areas of application.

Which programming environment does the ZEISS ScanBox Series 8 use to analyze the measurement data and what functions does it have?

The ZEISS ScanBox uses the powerful ZEISS INSPECT software with VMR extension, both for robot and measuring position programming, as well as for the subsequent digitization and inspection of the measured values. The measurement results are automatically stored and used for further process optimization.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics