CAM/CNC integration

Anyone who works with hyperMILL knows the power of our CAD/CAM software. But what happens immediately after programming?

Without a directly connected MES system, NC data is often still transferred manually in many companies – via USB sticks, network paths or local storage locations.

This can lead to errors, search times and production delays. What’s more, it is difficult to maintain an overview when job priorities change!

Humminbird ensures a digital, continuous process chain here and sends NC programs directly from hyperMILL to the CNC machine.

In addition, the Hummingbird MES system offers a powerful platform that can be seamlessly integrated into your existing IT infrastructure. Thanks to its open architecture, Hummingbird MES supports a wide range of interfaces and protocols to ensure smooth communication and data transfer between different systems.

With Hummingbird and hyperMILL we offer you a seamless, digital process chain from programming to CNC machining. More and more companies are optimizing this process with Hummingbird MES.

Let’s optimize your CAM and CNC processes together!

- Consistent workflow in your system environment

- Directly integrated into hyperMILL and other CAM systems

- Connection to various PDM, PLM and ERP systems

- Modern API for future connections

Digital process control – from the CAM to the CNC machine

Hummingbird digitally maps the entire workflow: from programming in hyperMILL to the control of the CNC machine. CAM projects, NC programs and tool data are managed centrally and sent to the right machine.

This reduces misunderstandings, duplicate data and other errors and ensures transparent production with traceable processes. This leaves more time for actual machining instead of searching for data.

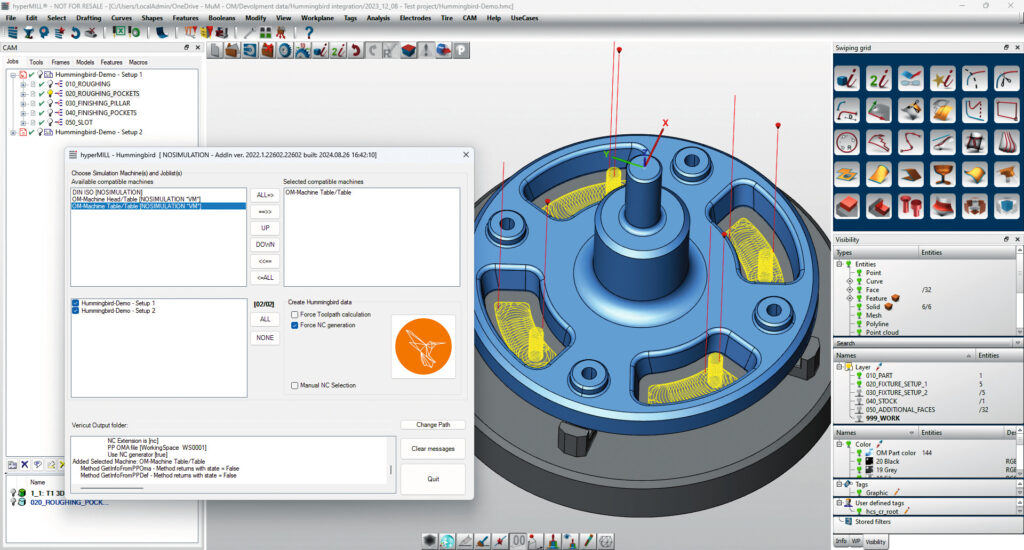

Perfectly matched to hyperMILL

Hummingbird is optimally integrated into hyperMILL (but also in other CAM systems) and supports in-depth integration.

companies can gradually expand hyperMILL and gradually expand Hummingbird into a powerful, centralized production management system.

Advanced integration for Connected Manufacturing

The Hummingbird MES system can of course also be connected to various ERP systems.

The integration enables the direct transfer of orders and associated data.

Information such as stocks, production orders and material availability is synchronized in real time to ensure optimum production planning. By connecting to PDM and PLM systems, Hummingbird ensures that all product data and life cycle information flows into the manufacturing process.