Voxeljet VX200

Voxeljet VX200: Compact size, high performance – your cost-effective entry into high-quality 3D sand printing

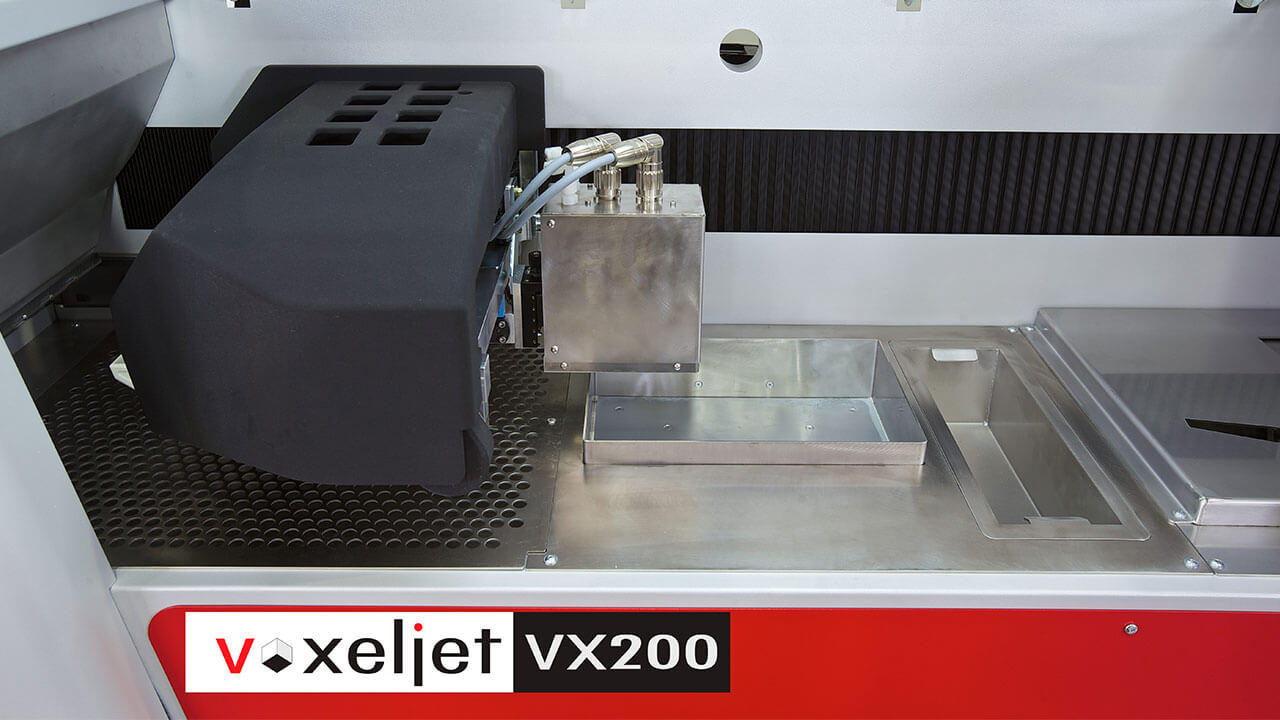

The VX200 is the smallest 3D printer in the Voxeljet range. The machine is very compact, easy to operate and allows a cost-effective entry into 3D sand printing.

Even the smallest 3D printer scores with the well-known advantages of the large machines. The VX200 is characterized by a robust machine design and is also suitable for continuous use thanks to the use of high-quality components.

- Maximum precision and speed

- High resolution

- Compact machine concept

Maximum precision and speed

In addition to research and development, the VX200 also demonstrates its strengths in mold production for aluminum and steel casting.

Thanks to the high-resolution piezoelectric print head modules, it offers outstanding performance stability and achieves a resolution of up to 600 dpi, depending on the material.

This enables the VX200 3D printer to produce even the most complex component geometries quickly and with impressive precision. The result is shorter delivery and development times

High resolution

With a resolution of up to 254 dpi, depending on the material configuration, the VX200 prints even the finest components with impressive precision.

Binder jetting: Fast, flexible and innovative

In all areas where speed and adaptability are required, this technology provides significant competitive advantages. Additive manufacturing also opens up new perspectives for design and functionality in construction.

Frequently asked questions (FAQs)

Welche Materialien kann ich mit dem Voxeljet VX200 verwenden?

The open system of the VX200 allows a wide range of materials to be qualified and used. Its simple and compact design makes it the ideal system for material parameter development. The choice of material directly influences the properties of your printed models, such as strength, surface finish and level of detail. In the foundry, the VX200 can be used with a wide variety of foundry sands. Our 3D printing specialists will be happy to advise you!

Wie kann ich die Druckparameter des Voxeljet VX200 anpassen, um die beste Druckqualität zu erzielen?

To achieve the best print quality with the Voxeljet VX200, you should carefully adjust the print parameters. These include, above all, the layer thickness and printing speed as well as the binder application. The layer thickness influences the level of detail and the surface quality of your models. A finer layer thickness leads to more detailed prints, but requires more time. The printing speed and binder application should be adapted to the complexity of the model and the material used.

Welche Wartungsarbeiten muss ich regelmäßig durchführen, um die Leistungsfähigkeit meines Voxeljet VX200 zu erhalten?

To maintain the performance of your Voxeljet VX200, you should carry out regular maintenance work. This includes cleaning the print chamber and print heads to remove material residue and prevent clogging. Check and calibrate the mechanical components regularly to ensure they are working properly and allow precise movements. It is also important to keep the filters and ventilation systems clean to ensure optimal cooling and ventilation. Regular software updates ensure that your printer is always equipped with the latest features and improvements. These maintenance measures will keep your printer in optimal condition and deliver consistently high print quality.